heat sink

A technology of heat dissipation device and heat source, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of limited heat dissipation effect of heat dissipation device, single cycle failure, poor flow effect, etc., to improve cycle efficiency and heat dissipation efficiency, avoid Thermal vaporization, reducing drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

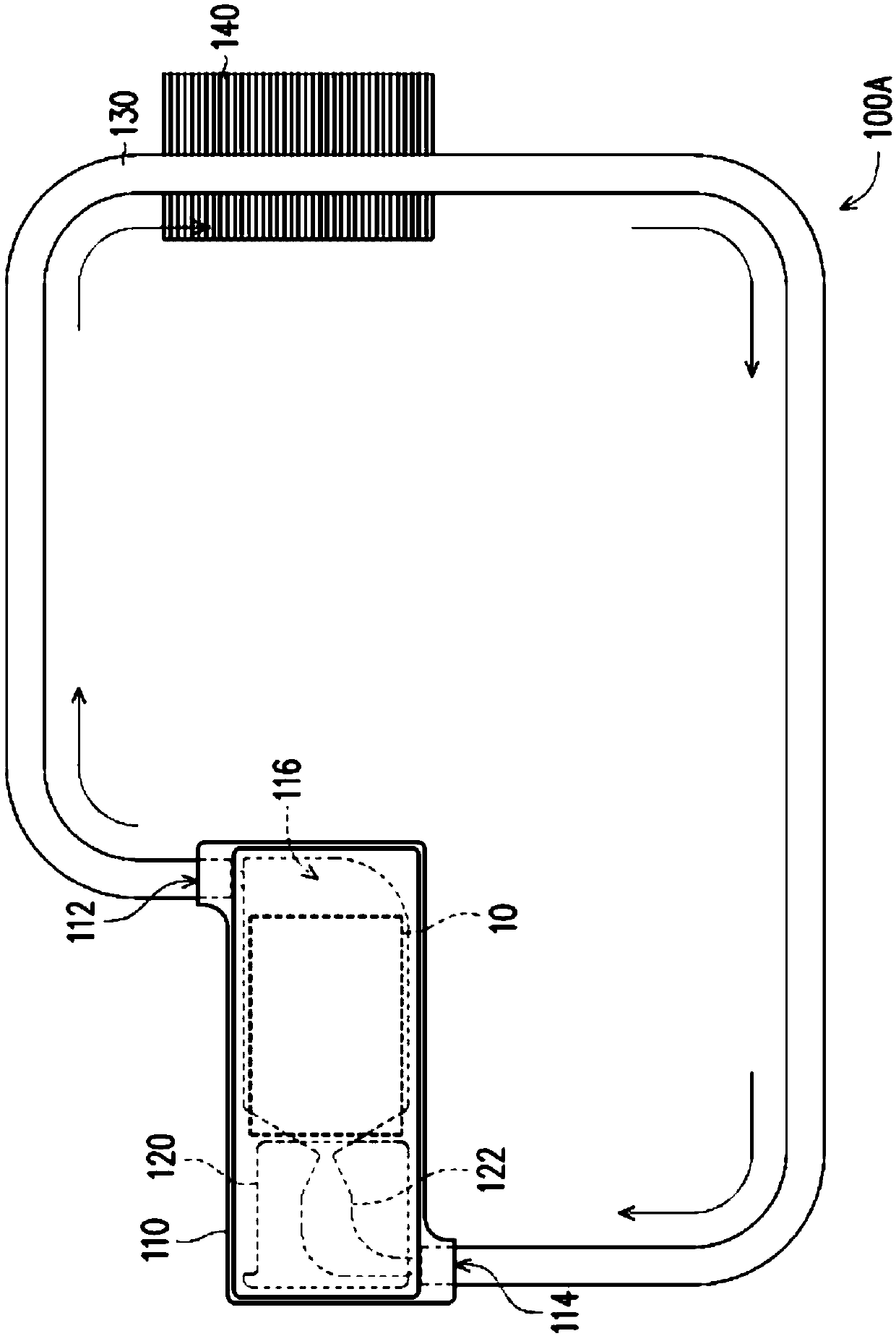

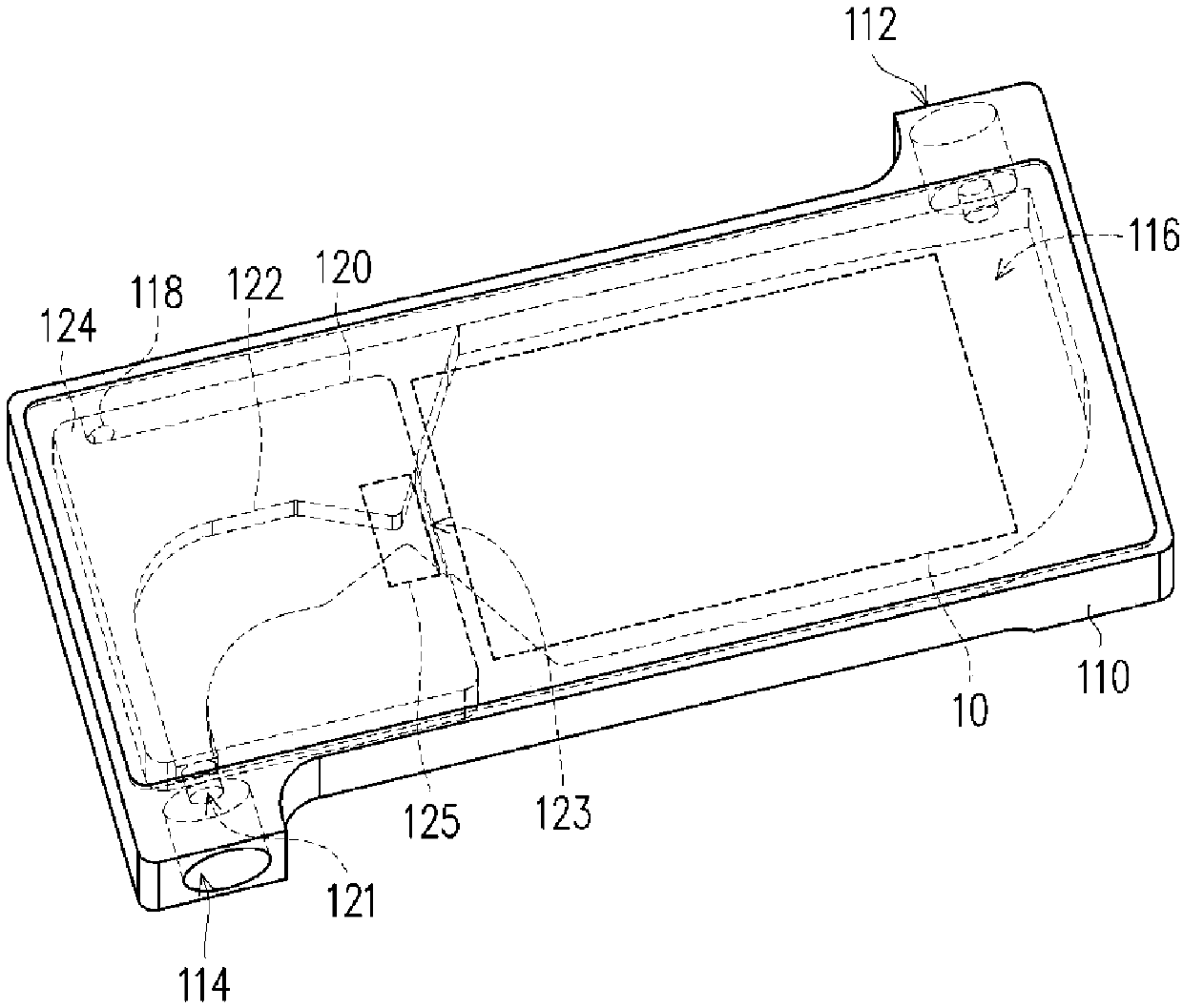

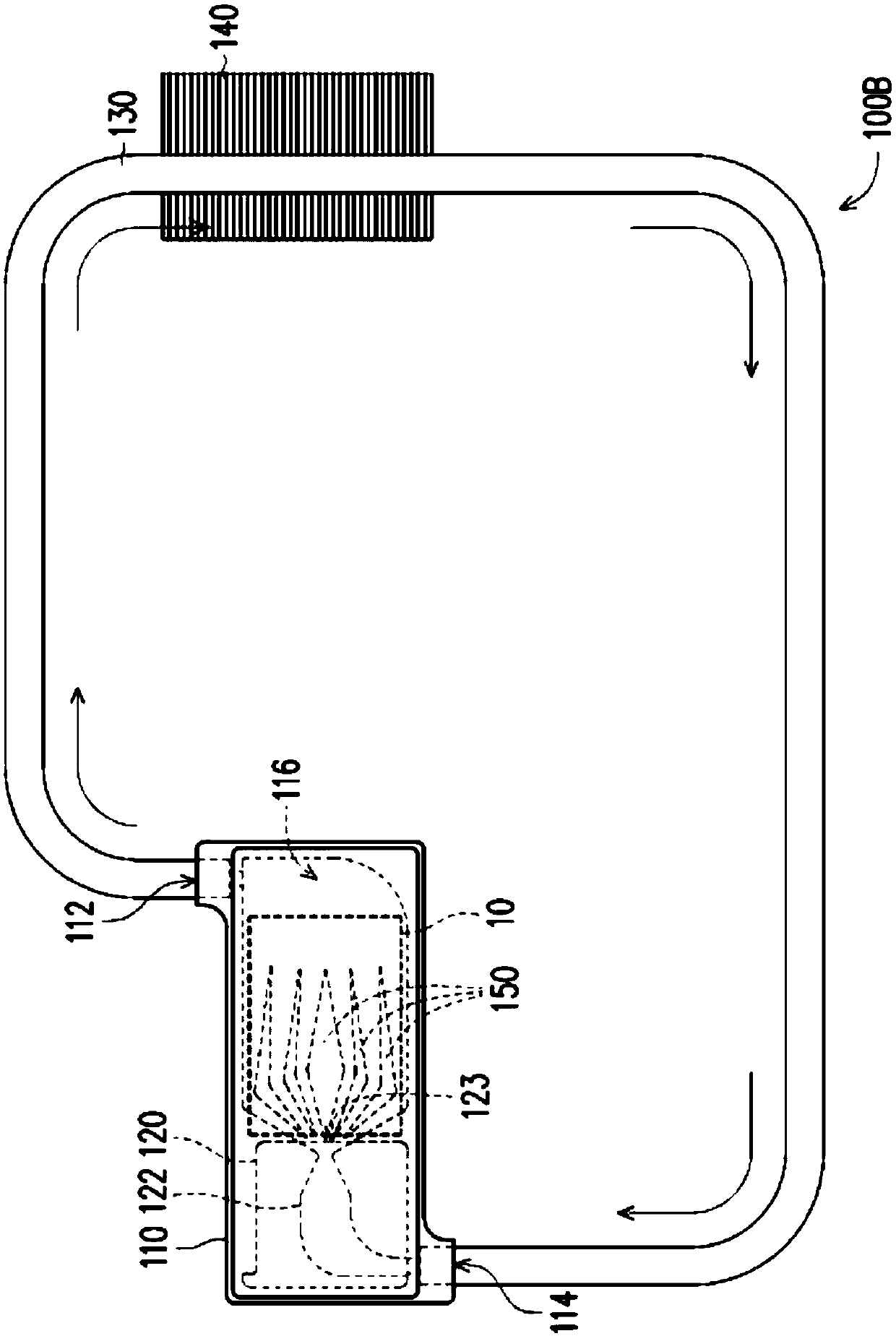

[0038] Figure 1A Shown is a schematic top view of a heat dissipation device according to an embodiment of the present invention. Figure 1B Shown as Figure 1A The three-dimensional schematic diagram of the accommodating slot of the heat dissipation device and the heat insulation unit. Please also refer to Figure 1A versus Figure 1B The heat sink 100A of this embodiment is suitable for dissipating heat from the heat source 10, where the heat source 10 is, for example, a heating element such as a chip or a processor in an electronic device, or a heat pipe, which can absorb heat from other heating elements and transfer heat to the device. Invented heat sink. In other words, the heat dissipation device 100A of this embodiment is suitable for electronic devices, such as portable electronic devices such as laptop computers, and the heat dissipation device 100A can be disposed in the housing of the electronic device, and the electronic device can be made by the thermal contact effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com