Water circulation evaporation heat exchange cooling type condenser

An evaporative heat exchange and condenser technology, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc., can solve the problem of waste of circulating cooling water, improve the utilization rate of cooling water and stabilize the temperature , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

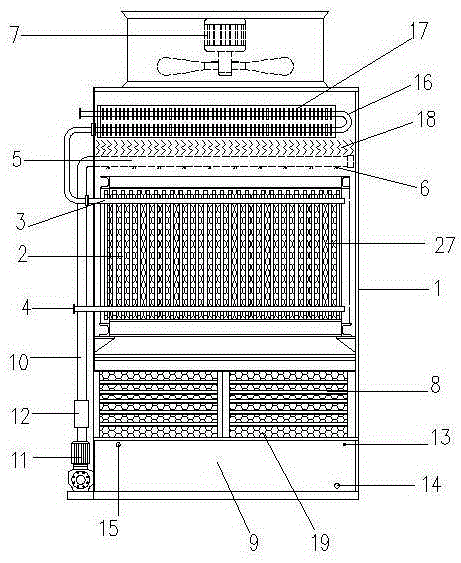

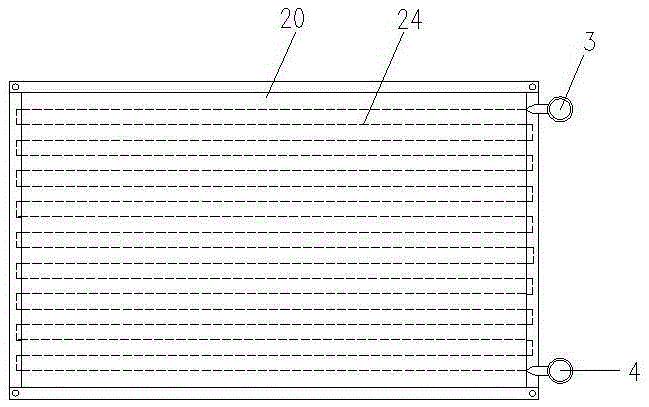

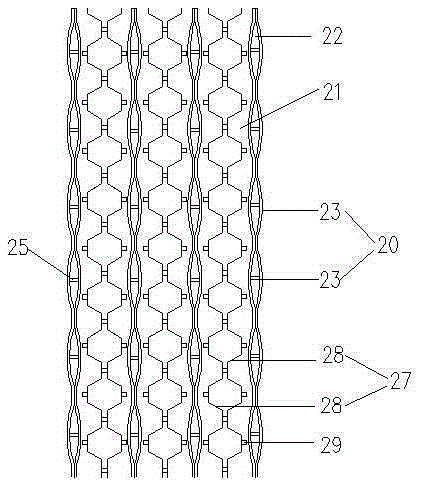

[0023] Such as figure 1 A water circulation evaporative heat exchange cooling condenser shown includes a condenser shell 1, and a heat exchanger 2 is provided in the middle of the condenser shell, and the heat exchanger 2 includes several heat exchange plates distributed vertically and in parallel 20. There are cooling gaps 21 between the heat exchange plates, such as image 3 As shown, the heat exchange plate 20 is provided with several parallel fluid passages 22, the heat exchange plate 20 is made by connecting two corrugated heat conduction plates 23, the convex surfaces of the two corrugated heat conduction plates are bonded and connected, the two corrugated heat conduction plates The concave surfaces are buckled and connected to form the fluid channel 22. The cooling gap 21 is provided with a heat exchange packing plate 27. The heat exchange pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com