Sleeving shell of round block hole type graphite heat exchanger and production process thereof

A graphite heat exchanger and production process technology, applied in the direction of regenerative heat exchanger, indirect heat exchanger, heat exchanger type, etc., can solve the problem of low circulation efficiency of low-temperature medium and difficulty in meeting the heat exchange needs of graphite heat exchangers , low-temperature medium flow rate and other problems, to ensure firmness, easy installation, and improve cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

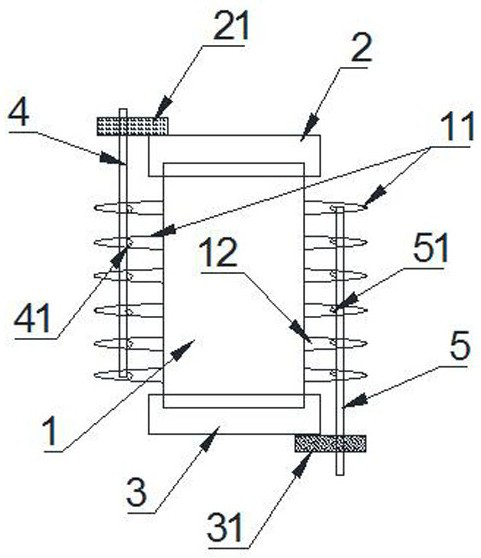

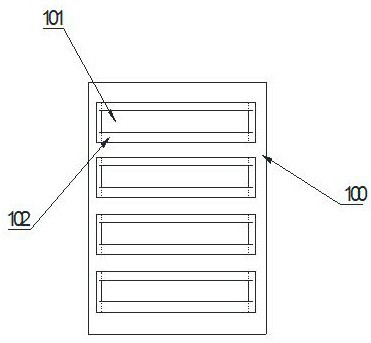

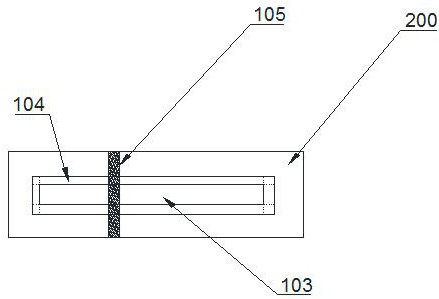

[0029] Such as Figure 1 to Figure 6 It is a specific embodiment of the present invention, and its structure includes an intermediate housing 1, an upper flange cover 2 and a lower flange cover 3 that are screwed to the upper and lower ends of the intermediate housing 1, and its structure also includes a water inlet pipe 4 and an outlet pipe 5. The middle shell 1 is distributed with a number of annular protrusions 11 from top to bottom, and the interior of the annular protrusions 11 is formed with a guide groove 12. The upper flange cover 2 extends outwards with an upper fixing plate 21, and the upper fixing plate 21 is located on the Directly ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com