Energy-saving and cooling system for communication room with pre-dehumidification and cooling structure

A technology of cooling structure and communication room, applied in air conditioning system, space heating and ventilation details, household appliances, etc., can solve the problems of power consumption discount of power consumption fan, mechanical vibration of fan, and the system can not work normally, so as to achieve the guarantee Heat exchange efficiency, keeping air humidity, cost and energy consumption low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

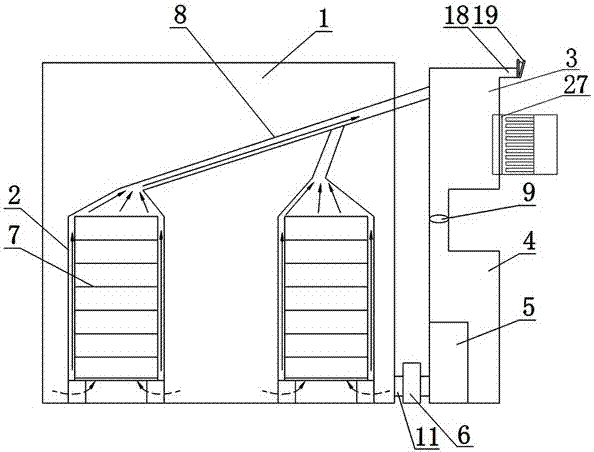

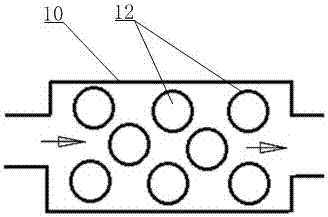

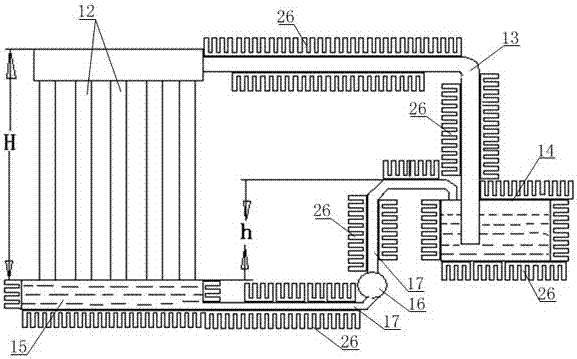

[0028] Such as Figure 1-Figure 3 As shown, the communication machine room energy-saving cooling system with a pre-dehumidification and cooling structure includes a machine room 1, and the bottom of the machine room 1 is provided with an air inlet pipe 11. The system also includes a grid room 2, a return air area 3, and The air inlet room 4, the cooling equipment 5 and the dust removal equipment 6; the air return area 3, the air inlet room 4, the cooling equipment 5 and the dust removal equipment 6 are all arranged outside the machine room 1, and the top of the grid room 2 is connected to the return air duct 8 through the air inlet pipe 8. The wind zone 3 is connected, and the return air zone 3 is connected to the air inlet room 4 through a pipeline, and a fan 9 is arranged on the pipeline; The heat chamber 10, the two ends of the heat exchange chamber 10 are respectively provided with an air inlet and an air outlet, the air inlet is connected to the air inlet room 4, the air ...

Embodiment 2

[0034] Such as figure 1 As shown, this embodiment adds the following structure on the basis of Embodiment 1: the air return area 3 is provided with an air inlet A18, and an air inlet control panel 19 is arranged on the air inlet A18.

[0035] In this embodiment, the external cold air can enter the return air area 3 through the air inlet A18 for supplementation, so as to prevent negative pressure from forming inside the return air area 3 and cause poor air flow and thus increase energy consumption. The air intake control panel 19 can be manually or manually Intelligent control system for switch control.

Embodiment 3

[0037] Such as figure 1 As shown, this embodiment has been further optimized on the basis of embodiment 1 or embodiment 2, specifically: a grid 7 for placing communication equipment is arranged inside the grid room 2, and at the bottom of the grid room 2 Vent holes are also provided.

[0038] In order to enhance the heat dissipation efficiency of communication equipment in this embodiment, a grid 7 for placing communication equipment is arranged inside the grid room 2. Communication equipment can be placed on the grid 7 in an orderly and hierarchical manner, which is convenient for installation and maintenance, and the communication equipment They are separated from each other to facilitate full contact with the cold air and enhance the heat dissipation effect. At the same time, the bottom of the grid room 2 is provided with ventilation holes, and the cold air enters through the ventilation holes and flows upward from the bottom of the grid room 2 and takes away the communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com