Battery module with fluid cooling passage

A battery module and fluid cooling technology, applied in batteries, secondary batteries, battery temperature control, etc., can solve the problems of difficult battery packs, low battery convection heat exchange coefficient, and inability to ensure uniform heat exchange, so as to ensure thermal stability. The effect of exchange efficiency, simple assembly process and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

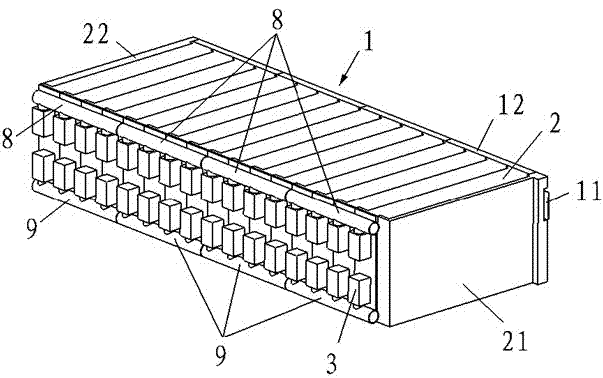

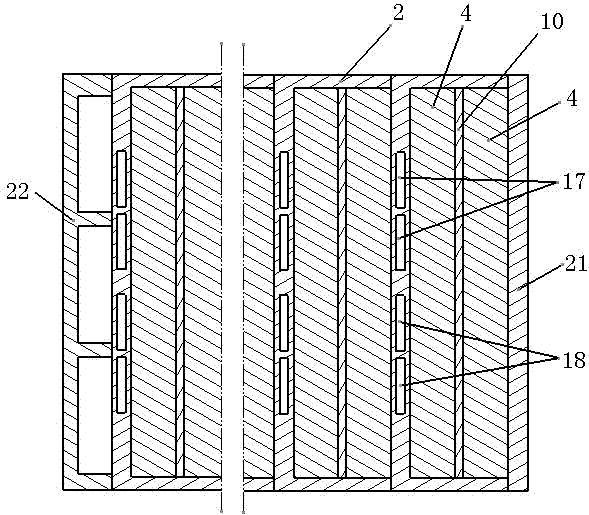

[0024] Such as figure 1 As shown, a battery module with a fluid cooling channel includes several liquid heat exchange management units 1, and each liquid heat exchange management unit is provided with several battery cells 4 side by side in the same liquid heat exchange management unit Two adjacent battery cells 4 are insulated by battery grids 10, such as figure 2 As shown, in this embodiment, each liquid heat exchange management unit 1 is provided with two battery cells 4; several liquid heat exchange management units 1 are connected side by side to form a battery module, and the rear end cover of the entire battery module A tab cover 12 is provided, and a left cover 21 and a right cover 22 are installed on both sides of the battery module. There are 16 total negative pole ears.

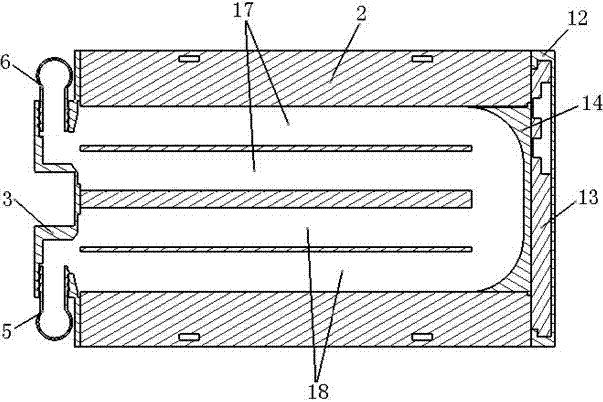

[0025] Such as image 3 , 4 , 5, the present invention can be further described as, the liquid heat exchange management unit includes a water jacket shell 2, and the water jacket shell 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com