Spiral-plate heat exchanger welding machine

A spiral plate heat exchanger technology, applied in the direction of welding rod characteristics, welding equipment, welding equipment, etc., can solve the problems of complex chemical characteristics, low processing efficiency, troublesome processing, etc., to achieve guaranteed efficiency, guaranteed welding speed, and easy flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

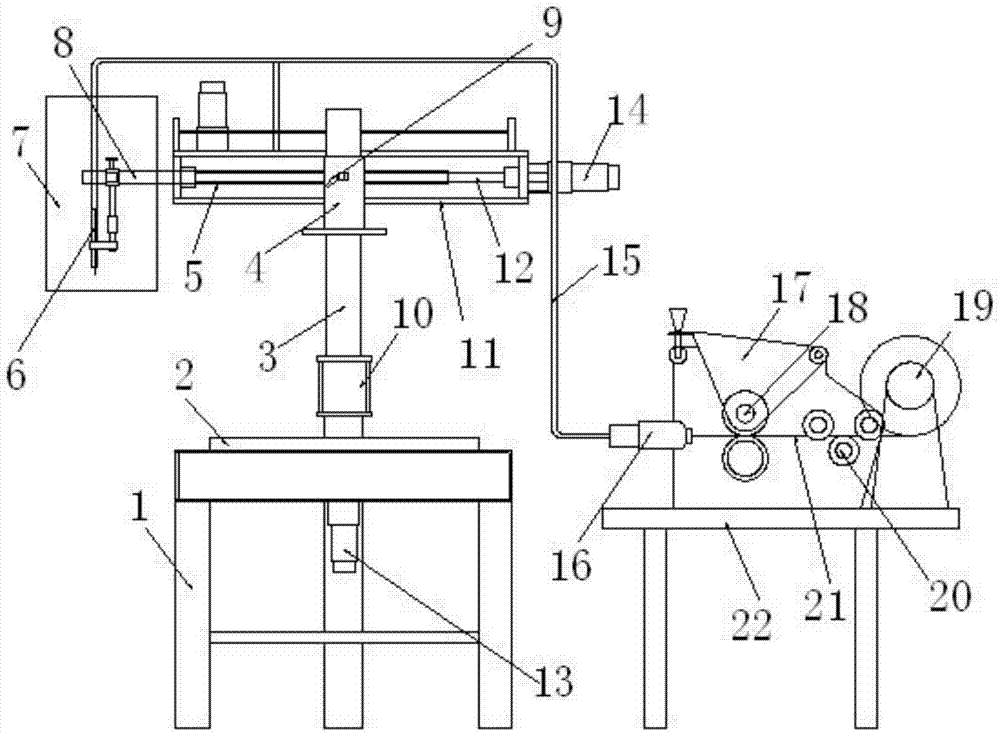

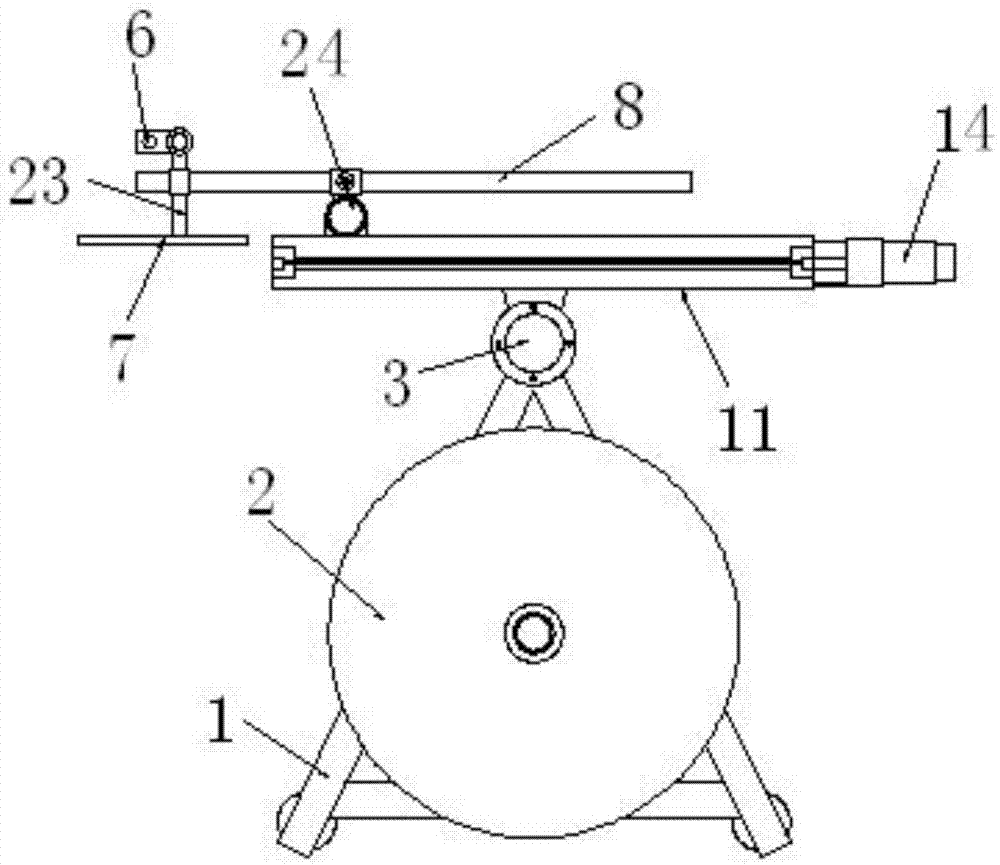

[0019] As shown in the figure, the structure of the spiral plate heat exchanger welding machine of the present invention includes a frame 1, on which a turntable 2 is arranged, and the turntable 2 is connected with a drive motor 13, driven by the drive motor 13, the turntable 2 can be Rotate on frame 1.

[0020] The frame 1 is triangular in shape, and three corners of the frame 1 protrude to the outside of the turntable 2 , and a column 3 is fixed vertically at one corner of the frame 1 . A beam 11 is connected to the column 3, the welding torch 6 is movably coupled to the beam 11 through a clamping mechanism and a pushing mechanism, and the beam 11 is arranged along a horizontal direction. A probe for detecting the position of the heat exchange plate is provided at the position of the welding torch 6, and the probe is connected with the pushing mechanism for controlling the action of the pushing mechanism. During the welding operation, the disc-shaped base plate is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com