Solar dyeing machine system with function of gradient use of heat

A technology of solar energy and dyeing machine, which is applied in the field of solar dyeing machine system to achieve the effect of saving heat energy, solving the excess of low temperature heat energy and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

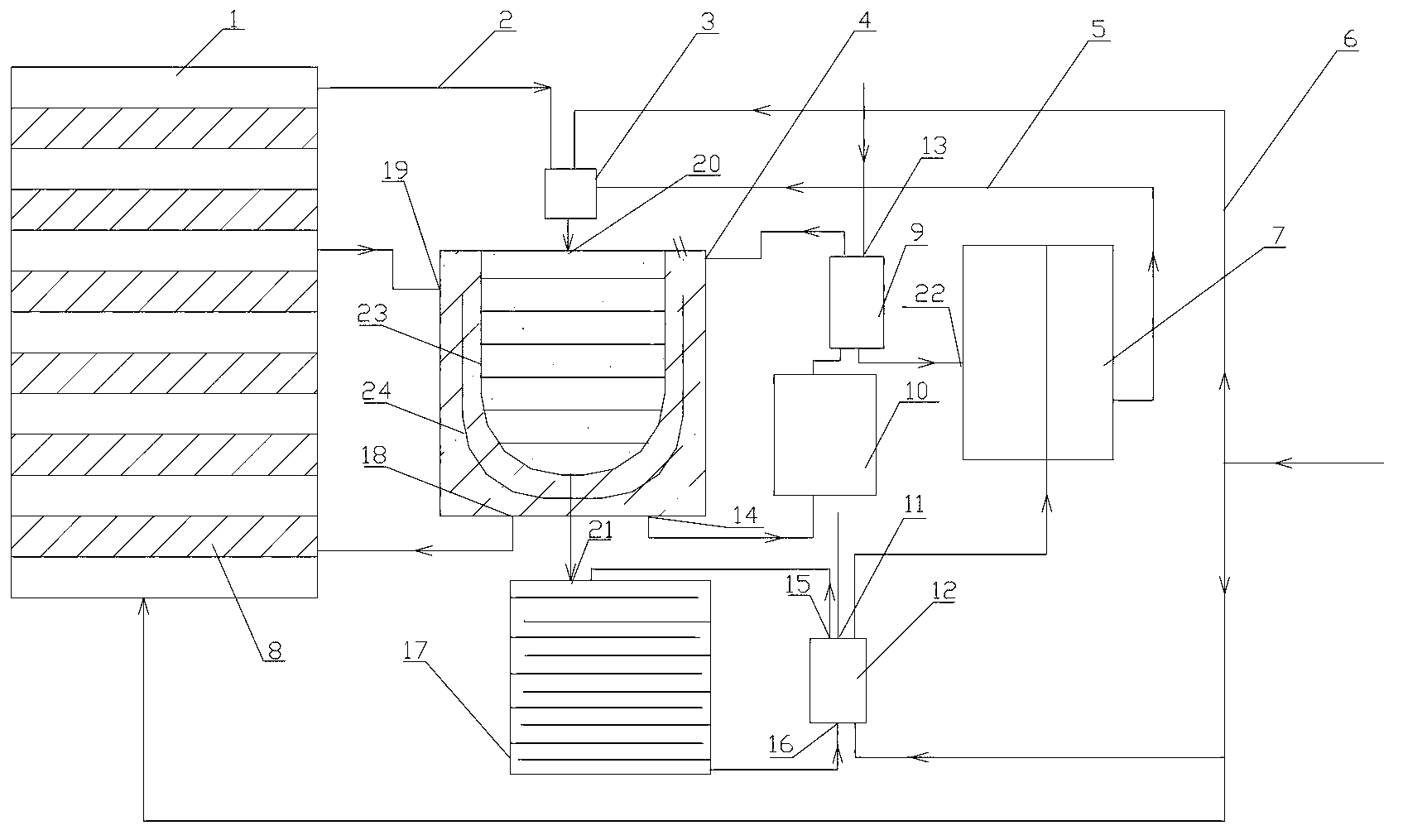

[0024] Such as figure 1 The solar dyeing machine system shown is composed of a solar heating system, a waste heat recovery system, a high temperature heating compensation system, a dyeing machine system and a cooling system.

[0025] The solar heating system forms two circulations, one is a water circulation consisting of several solar vacuum tubes 1 connected in series for water heating, cold water pipes 6 and hot water pipes 2, and the other is a water circulation composed of several series connected solar vacuum tubes 1 for water heating. The oil circulation formed by the solar vacuum tube 8 heated by heat conduction oil and the oil pipeline. The dyeing machine system is composed of intermittent dye vat 23 and a control cabinet for controlling the work of the intermittent dye vat. The high-temperature heat supply compensation system is composed of a steam pipe capable of thermally compensating the water in the intermittent dye vat and an electric heating tube capable of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com