Energy-saving roasting method in formwork investment casting

A technology of investment casting and mold shell, which is applied in the field of investment casting mold shell roasting and energy saving, and can solve the problems of reduced electrical efficiency and increased equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

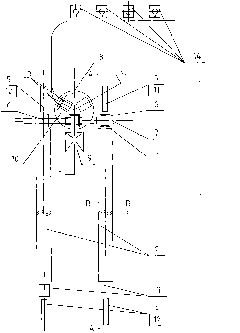

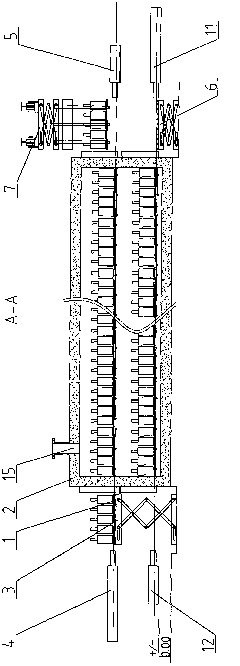

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Using the heat storage of various metal liquid metal casting mold shells with a casting temperature of 1500°C and a specific heat capacity of 0.837 or above, the dewaxed mold shells are dried and roasted to achieve no or less energy consumption.

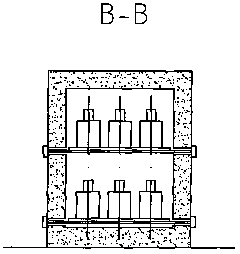

[0021] A continuous formwork heat exchange furnace 2 with good thermal insulation performance, 15 meters in length, and double-layer roller support trays is used. The mold shells to be dried and roasted are placed in the tray 1 of the upper track of the furnace in the state of being cast; the mold shells after casting molten steel are placed in the tray 1 of the lower roller table; Under the conditions of radiation and radiation, sufficient heat exchange is carried out. There is a spare electric heating element at the discharge end of the mold shell, so that it can be used when the new furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com