More environment-friendly print transferring method and product thereof

A transfer method and an environmentally friendly technology, which is applied in the direction of printing, printing of special varieties of printed matter, printing technology, etc., can solve the problems of rough products and insufficient printing and production, and achieve improved anti-counterfeiting performance, improved anti-counterfeiting performance, and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

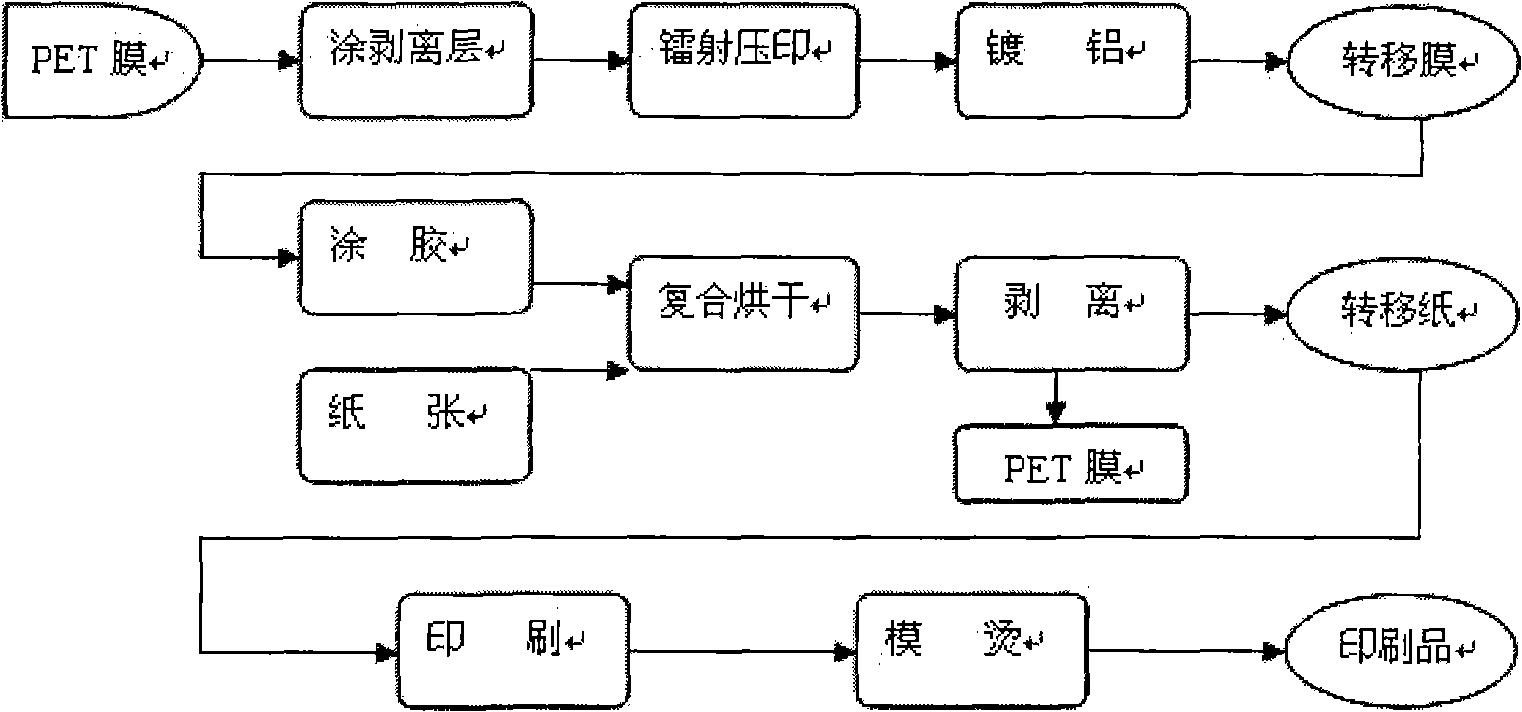

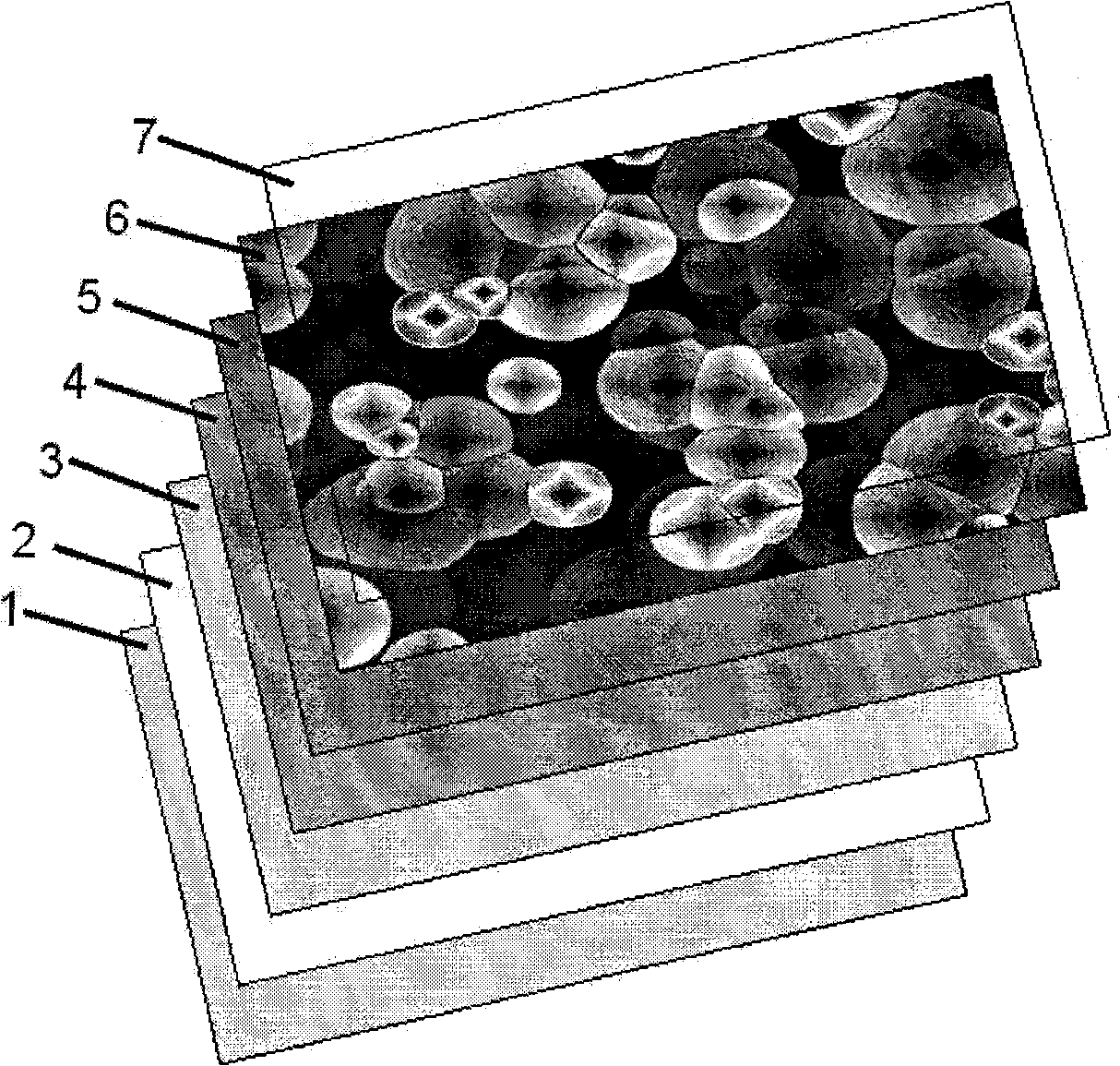

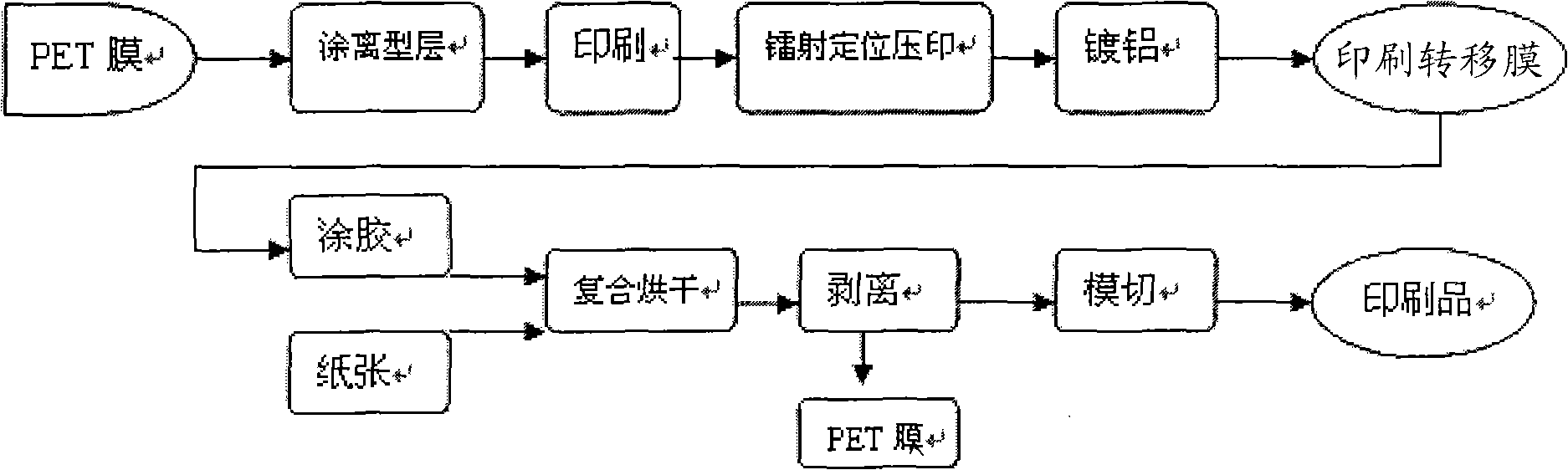

[0026] Such as image 3 refer to Figure 4 As shown, the present invention is a more environmentally friendly and efficient printing transfer method, which comprises the following steps:

[0027] (1) coating, coating release layer 6 on 15-30umPET light film, can be coated with on the special coater also can finish coating in the first color group of multi-color printing machine, the release layer 6 The main function is to complete the peeling (separation) from the PET film during composite transfer. Its main component is oily or water-based polymer resin. When coating, use a metal anilox roller with 100-200 lines / inch, the coating speed is 100-150 m / min, the temperature is 90-120°C, and the drying time is 5-9 seconds;

[0028] (2) Graphics and texts are printed directly on an ordinary film gravure printing machine, and the printing layer 5 is directly printed on the release layer 6, so that the entire printing layer 5 can be completely peeled off, and the printing speed is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com