Transferring method of holographic anti-counterfeiting patterns suitable for gravure positioning overprinting

A technology of holographic anti-counterfeiting and transfer method, which is applied in the field of transfer molding and compounding, can solve the problems of accumulated error deviation, etc., and achieve the effect of saving resources, reducing production costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] The transfer method of the holographic anti-counterfeiting pattern suitable for gravure positioning overprinting of the present invention comprises the following steps:

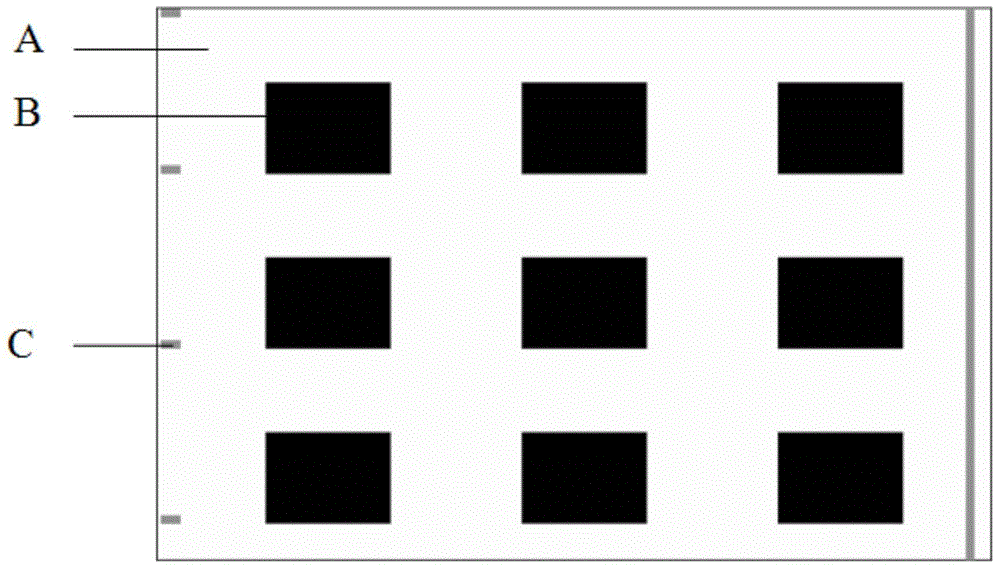

[0023] The first step: using a large-format full-page lithography equipment to make a full-page laser version A with a positioning pattern B (see figure 1 ), the size of the positioning pattern B is designed according to the gravure printing typesetting diagram, the accuracy of the positioning pattern B reaches ±0.01mm, and a holographic positioning mark C is made next to each positioning pattern B;

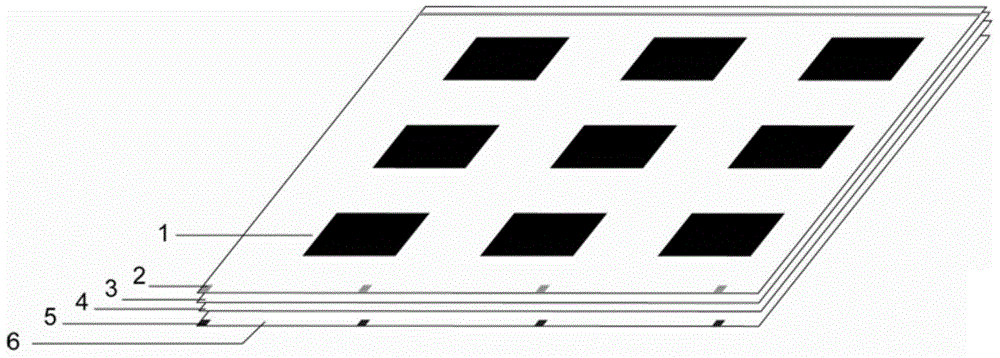

[0024] The second step: use a PET base film with a thickness of 18 μm, and coat a layer of transferable acrylic wax coating with moldability on the base film;

[0025] Step 3: Use molding equipment to emboss the positioning pattern B and holographic positioning mark C on the laser plate A on the acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com