Three-dimensional displacement measurement system and method based on laser self-mixing grating interference

A technology of displacement measurement and grating interference, applied in measurement devices, optical devices, instruments, etc., can solve problems such as limited range, and achieve the effect of improving measurement resolution, high resolution, and high modulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

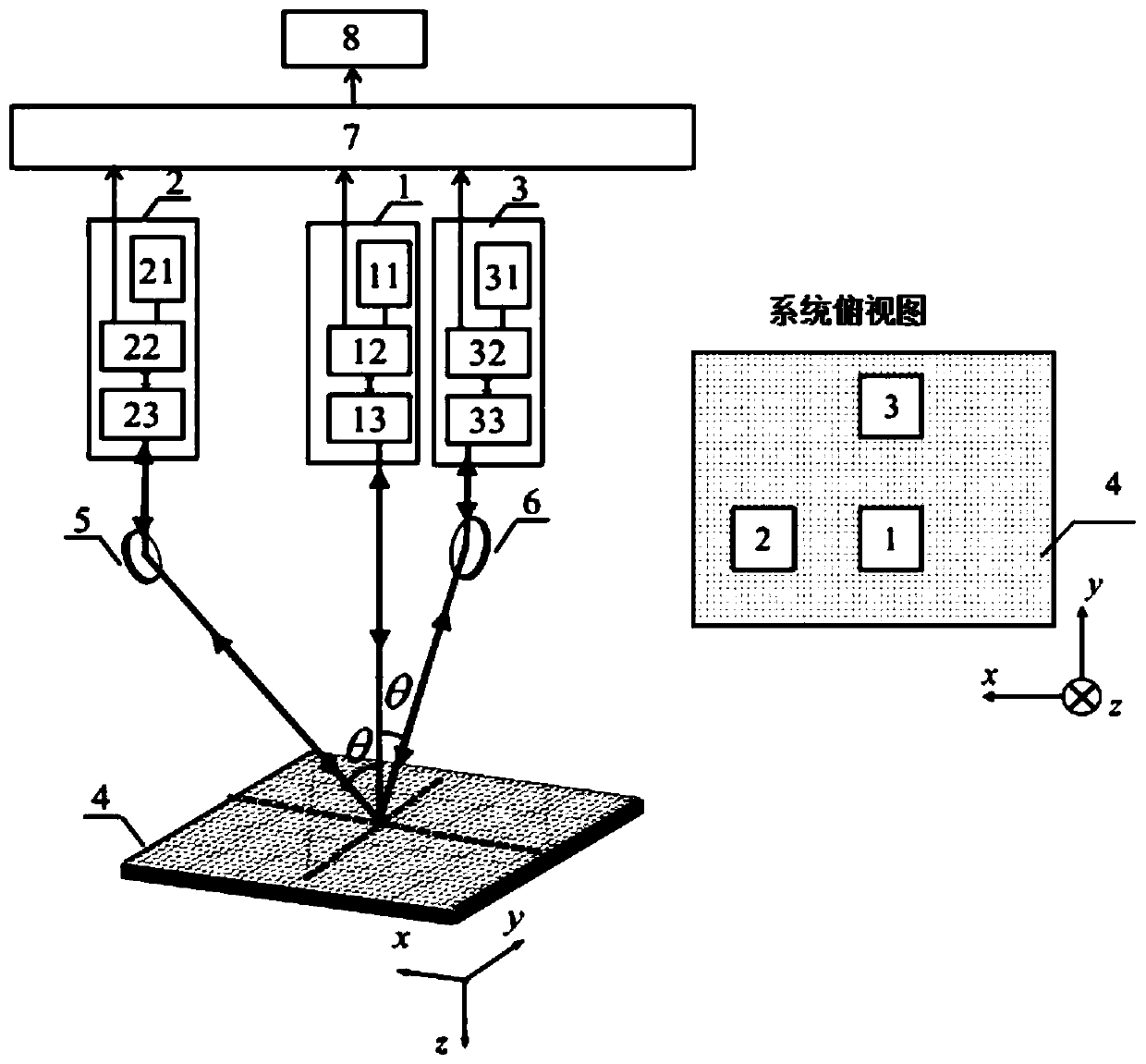

[0030] The measurement system of this embodiment is as figure 1As shown, it includes a first semiconductor laser sensor head 1, a second semiconductor laser sensor head 2, a third semiconductor laser sensor head 3, a reflective two-dimensional plane grating 4, a first plane reflector 5, a second plane reflector Mirror 6, data acquisition card 7 and computer 8. The first semiconductor laser sensor head 1, the second semiconductor laser sensor head 2, and the third semiconductor laser sensor head 3 are perpendicular to the reflective two-dimensional planar grating 4, that is, the directions of their outgoing beams are perpendicular to the reflective two-dimensional planar grating 4 , their projections on the reflective two-dimensional planar grating 4 form an isosceles right triangle, the projection of the first semiconductor laser sensor head 1 is located at the apex of the triangle, the second semiconductor laser sensor head 2, and the third semiconductor laser sensor head 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com