Elastic forming method for panel of curtain wall and curved-surface building curtain wall

An elastic deformation, panel technology, applied in the direction of building, building components, building structure, etc., to achieve the effect of solving the appearance effect and cost, low cost, smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

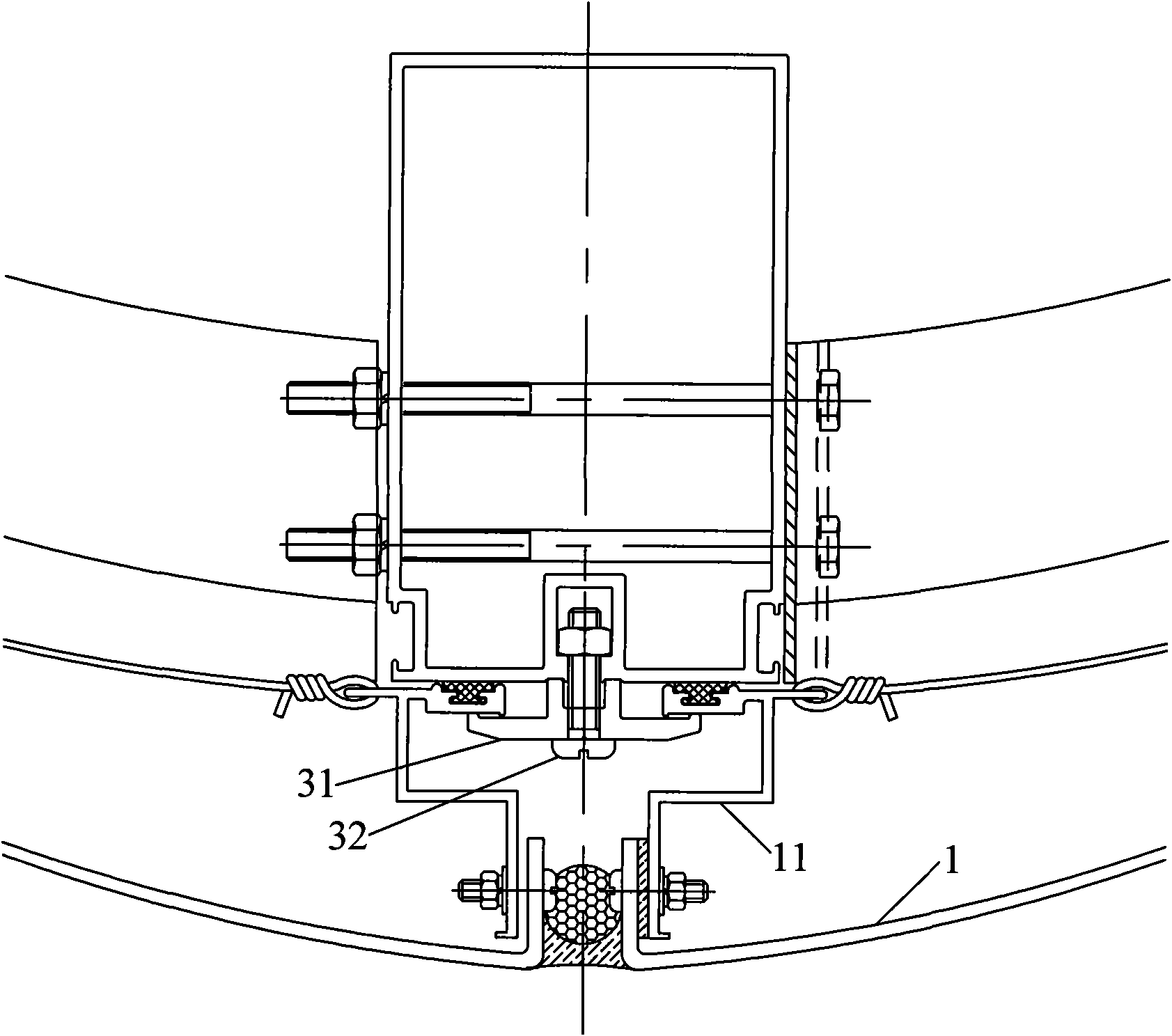

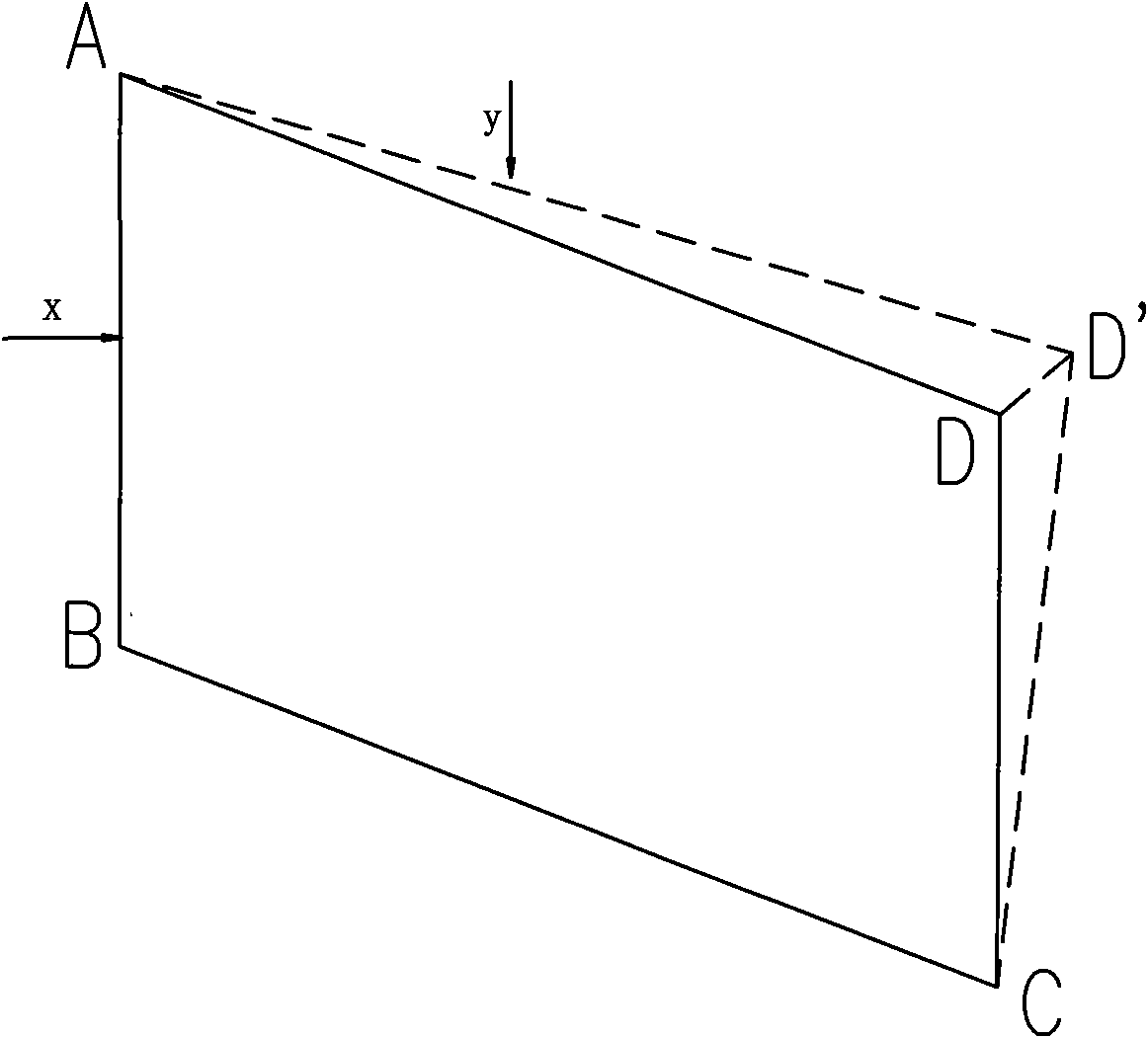

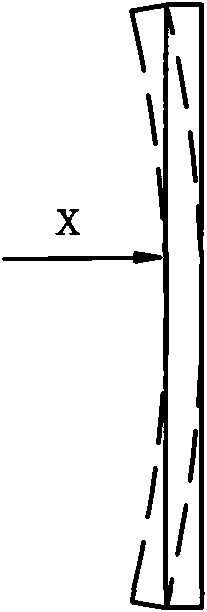

[0038] Such as figure 1 As shown, this embodiment is a method of elastically deforming the panels by using bolts and pressure plates, and the curtain wall adopting this method includes panels and fixing devices, and the fixing devices include several groups of bolts and pressure plates. figure 1 For a partial diagram of this method, several sets of bolts are actually arranged on the panel, and the pressing plate 31 is used to press the sub-frame 11 of the panel 1, and then by adjusting the bolts 32, several points at the end of the curtain wall panel are driven to reach the predetermined position , making use of the flexible and bendable characteristics of the curtain wall panel itself, so that the curtain wall panel can be bent into various shapes such as single curve and double curve. Take the above-mentioned cold bending measures for all the panels to form the entire curved curtain wall.

Embodiment 2

[0042] Such as image 3 As shown, this embodiment is a method of elastically deforming the panel by using a hook, and the fixing device of the curtain wall using this method is a hook. Fig. 2 is a partial view of this method. In practice, several sets of hooks 12 are arranged on the panel 1, and corresponding sets of hooks 41 are fixed on the wall 4. By adjusting the positions and protruding heights of these hooks, After the hook 12 is hooked on the hook, it will drive the panel 1 to undergo elastic deformation along with the position of the hook, so as to reach a predetermined curved surface. Take the above-mentioned cold bending measures for all the panels to form the entire curved curtain wall. In this embodiment, the hook is equivalent to the clamping point, and the hook is equivalent to the support of the clamping point. This type of curtain wall includes at least three elements: the panel, the clamping point and the support, and the panel can be directly fixed on the wa...

Embodiment 3

[0044] Such as Figure 4 As shown, this embodiment is a method of elastically deforming the panel by using glue, and the fixing device of the curtain wall using this method is glue. image 3 In order to adopt a partial diagram of this method, in this method, the skeleton 2 is stretched and bent into a predetermined curved surface in advance, and then the glue 5 is pasted on the skeleton 2, and finally the panel 1 is glued on, and the panel 1 will follow the skeleton 2 in advance. The stretched curved surface is elastically deformed to achieve the predetermined curved surface. Take the above-mentioned cold bending measures for all the panels to form the entire curved curtain wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com