Electronic speckle pattern interference detection system and lossless detection method for failures of solder balls

A technology of electronic speckle interference and detection method, applied in the field of electronic speckle interference system, can solve the problems of low detection efficiency, poor process integration and high cost, and achieve the effects of good industrial integration, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Electronic speckle interference test system for detecting solder ball failure in board-level assembly ball grid array package

[0045] The system includes: fixing and loading parts, off-plane displacement test optical path part of electronic speckle interference and computer data processing part. Among them, the fixing and loading part is used to provide stable clamping and mechanical loading for the tested board-level assembly ball grid array package device; the off-plane displacement test optical path part is used to form interference fringes after the package is deformed under mechanical load, that is, the surface micro Displacement: The computer data processing part is used to collect fringes, perform phase unpacking and displacement calculation, locate the failure area, and through further calculation and processing, finally determine the failure solder joint and its damage degree.

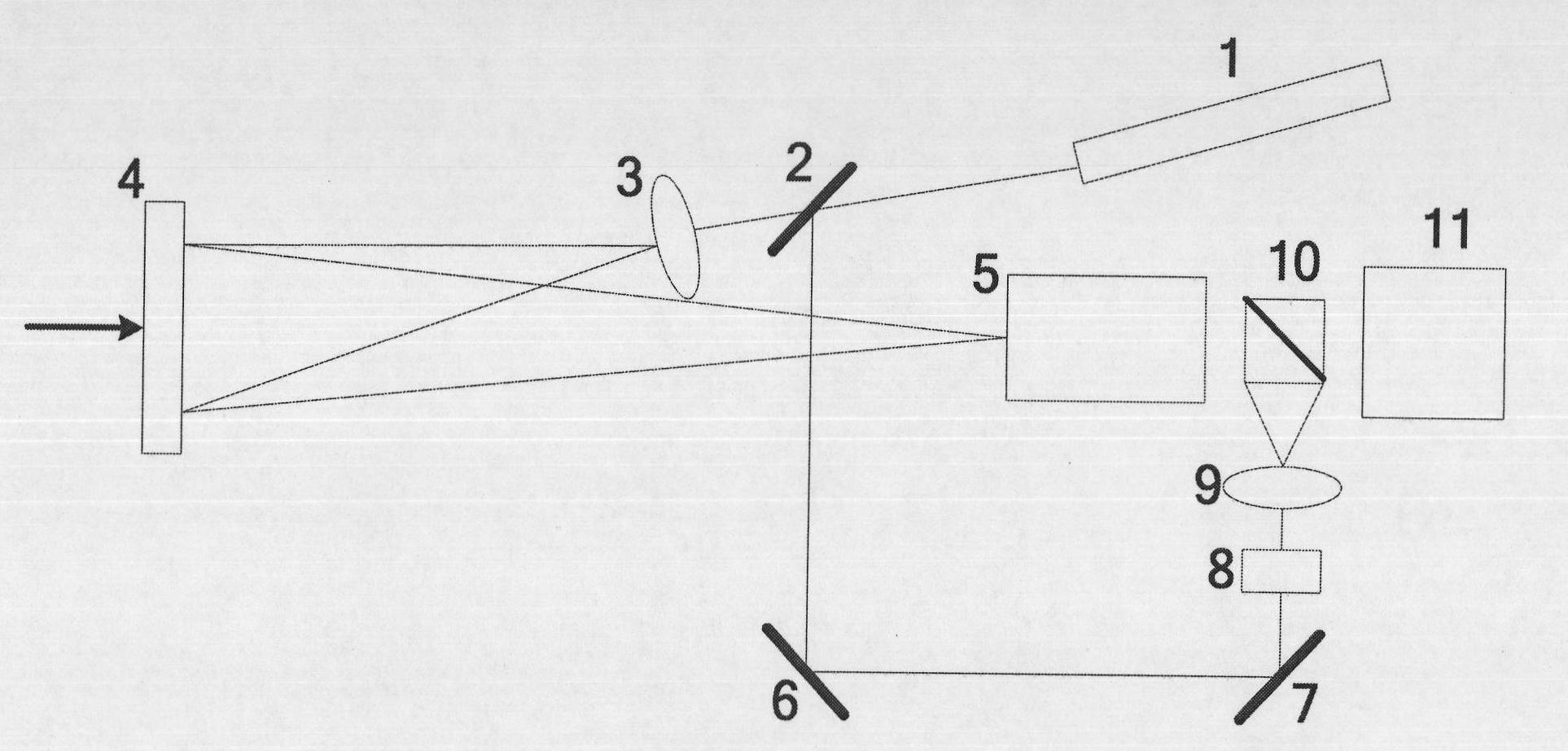

[0046] Reference figure 1 Describes the optical path part of the off-plane di...

Embodiment 2

[0049] Example 2 Electronic speckle interference test method for solder ball failure in ball grid array package

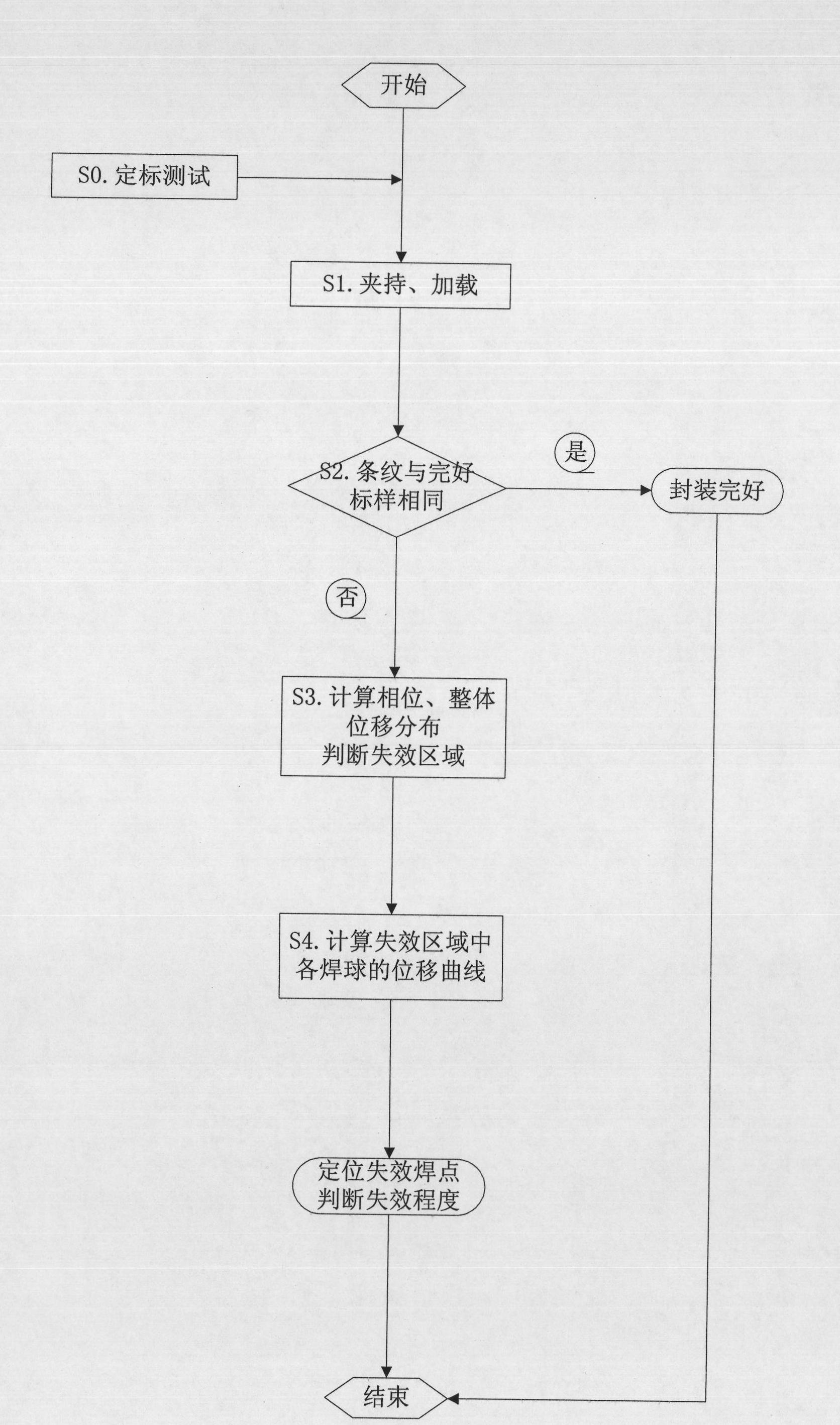

[0050] Reference image 3 Describes the electronic speckle interference test method for detecting the failure of solder balls in the ball grid array package corresponding to the embodiment of the present invention. image 3 It is the flow chart of the test method. First, in step S0, a calibration test is performed on a known intact ball grid array package of the same model. The packaged device is fixed by the fixing and loading part, and a mechanical load is applied to the back of the packaged device. The load should remain unchanged during the entire stripe extraction and phase shift process. At the same time, the fringe pattern is obtained by the off-plane displacement test optical path of the electronic speckle interference, and collected by the computer. The computer data processing part performs a series of calculations on the input information, including the ov...

Embodiment 3

[0056] Example 3 Sample detection

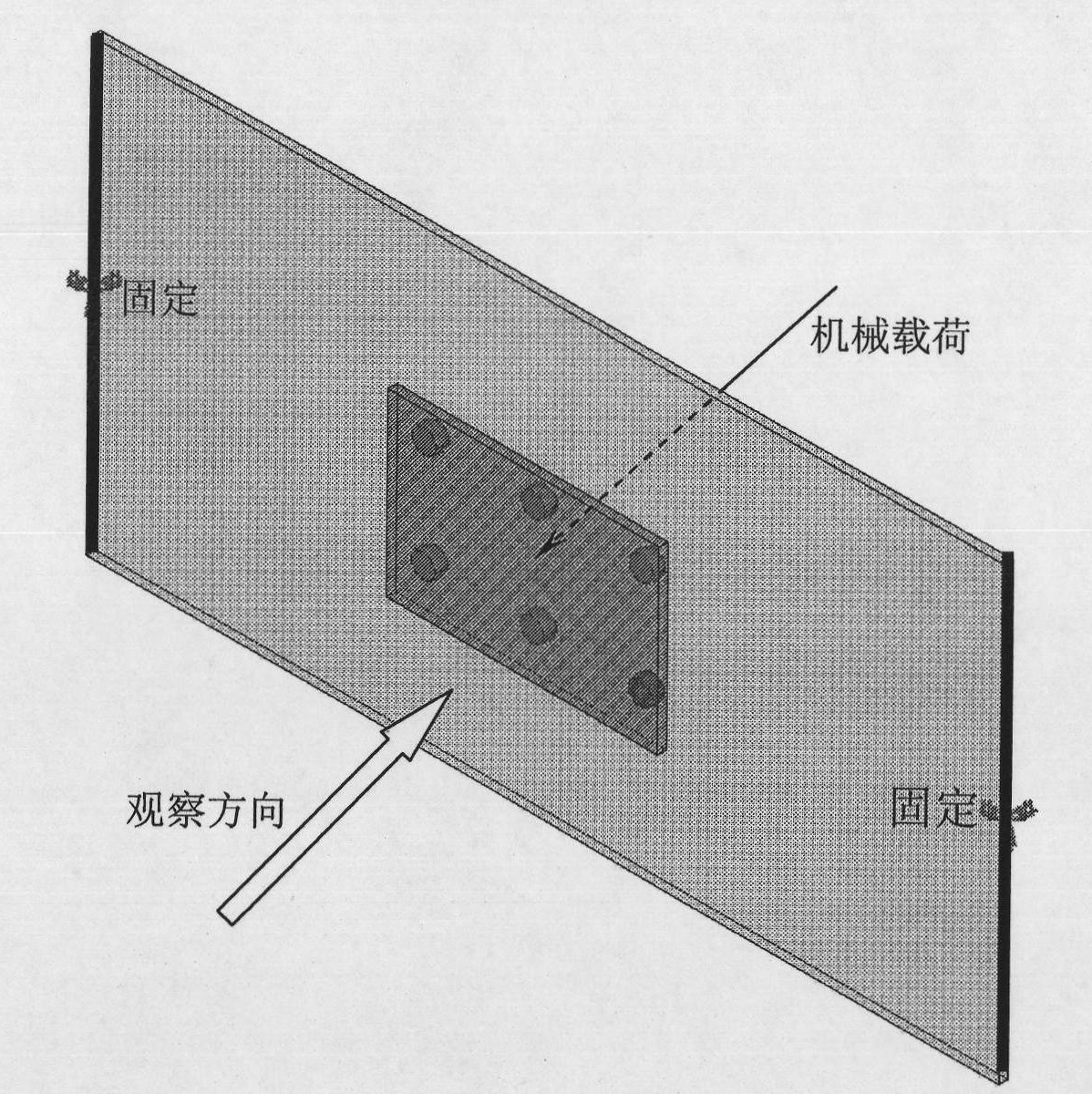

[0057] figure 2 It is a schematic diagram of the sample to be tested. The sample is a PCB board with a length, width and thickness of 14.60×10.68×0.92mm through electroplating, etching and other processes to generate basic interconnections such as pads and leads, and planting a 3×2 lead-tin solder ball array as an analog device. The diameter of the solder balls is 0.76mm, the lateral spacing is 4.00mm, and the longitudinal spacing is 6.00mm. Then the analog device is reflow soldered to a PCB board with length, width and thickness of 100, 40, and 0.92 mm. Samples under three conditions of intact formation, delamination of the solder ball on the lower right corner of the device, and drop off of the solder ball on the lower right corner of the device.

[0058] Figure 4-6 It is an out-of-plane displacement fringe diagram obtained by using the electronic speckle interference test system corresponding to the present invention to separately detect s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com