Manufacturing method of corrosion reference block and method for determining corrosion damage by using block

A technology for comparing test blocks and production methods, which is applied in the direction of instruments, measuring devices, and material analysis through electromagnetic means, can solve the problems of missed quantification, low accuracy, and difficult detection, so as to prevent missed defects and prevent Inaccurate quantification, the effect of improving sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

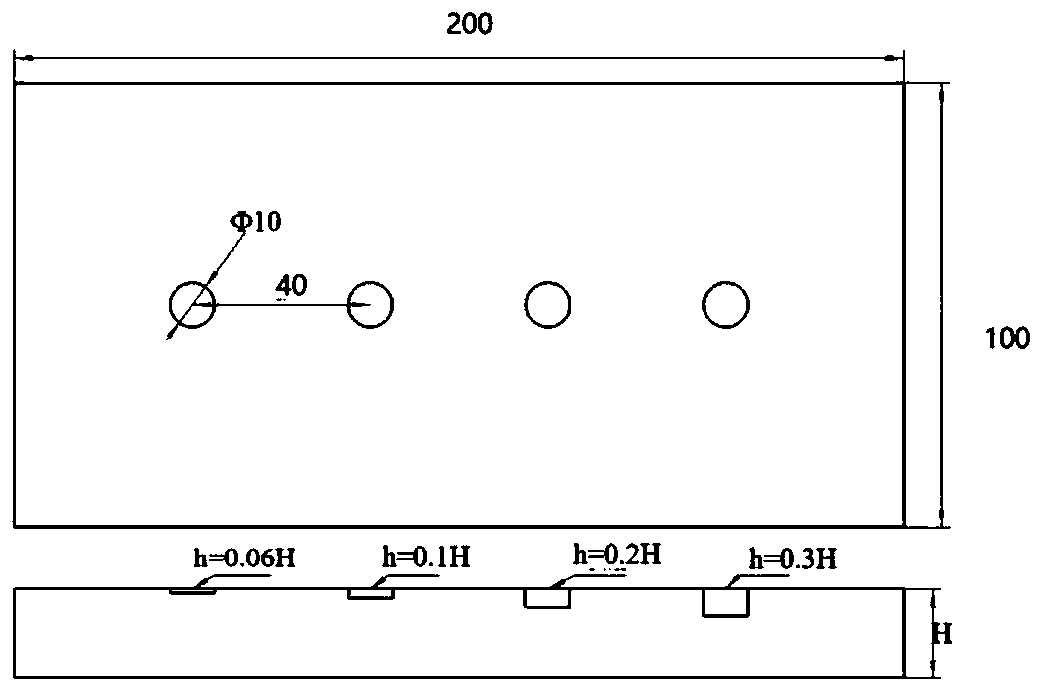

[0033] The study found that cracking and corrosion are the main damage forms in various types of damage, while corrosion pits, corrosion areas ( figure 1 ) is often the basic cause of cracking, and stress corrosion, like corrosion fatigue, is the main cause of crack growth.

[0034] In the conventional detection of corrosion damage by the eddy current method, the eddy current detection is actually a detection method based on signal comparison, which requires the signal of the reference object as a reference. The comparison test block is the reference material for determining the detection benchmark in the non-destructive testing process. The study found that it plays a vital role in the determination of the detection parameters, the adjustment of the detection sensitivity, and the evaluation of the detection results. Therefore, the simulated corrosion damage of the comparison test block plays a decisive role in the final result of corrosion detection and damage assessment. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com