Method for preparing multilayer core-shell structure transition metal oxide at one step

A multi-layer core-shell structure, transition metal technology, applied in the directions of nickel oxide/nickel hydroxide, cobalt oxide/cobalt hydroxide, etc., can solve the problems of complex steps, many impurities in the product, complex process, etc., and achieve the shape and shell. The effect of controllable number of layers, uniform composition and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

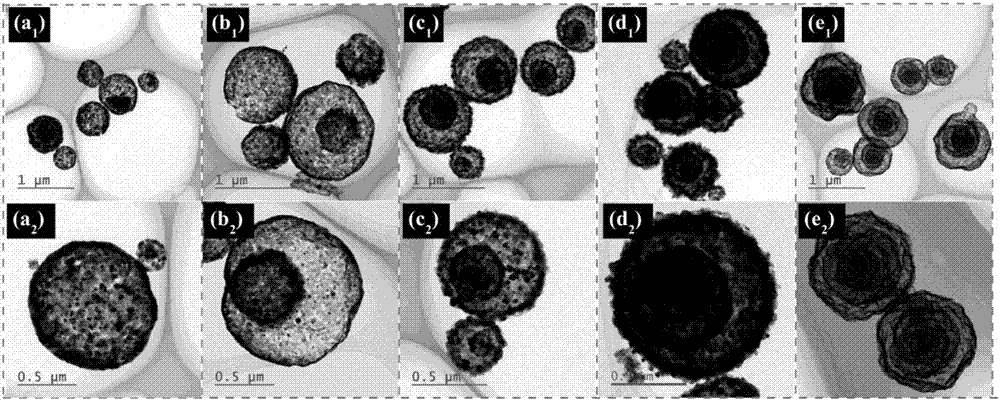

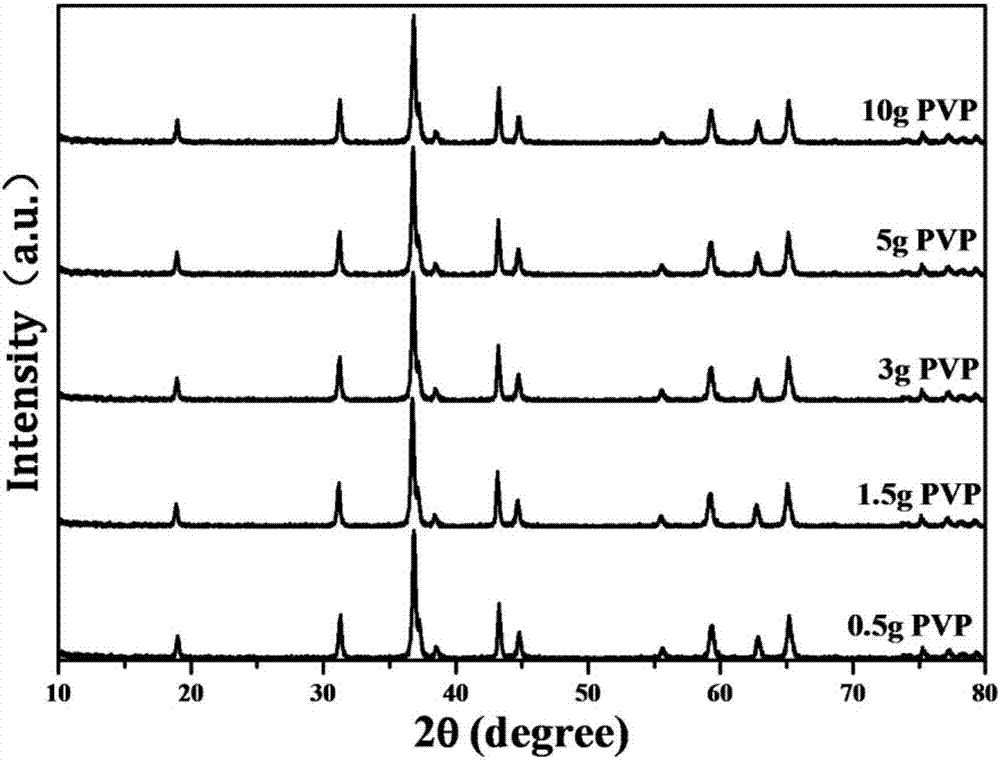

[0031] Dissolve nickel-cobalt nitrate with deionized water at a molar ratio of 1:2, and prepare a 200ml solution with a total metal ion concentration of 0.15mol / L, a spray pyrolysis temperature of 700°C, and a carrier gas (O 2 ) The flow rate is 5L / min, and the amount of PVP added is 0.5g, 1.5g, 3g, 5g, 10g respectively. The materials prepared with different PVP additions were characterized by transmission electron microscopy (TEM) and X-ray diffraction (XRD). Test results such as figure 1 , figure 2 shown. Depend on figure 1 It can be seen that when the PVP addition is 0.5g, the prepared material is a single-layer hollow structure; when the PVP addition is 1.5g, the core-shell structure begins to appear; when the PVP addition is 3g, the obtained material is a double layer. The core-shell structure; as the content of PVP continues to increase, the number of shells in the core-shell structure continues to increase to more than three layers. From figure 2 It can be seen ...

Embodiment 2

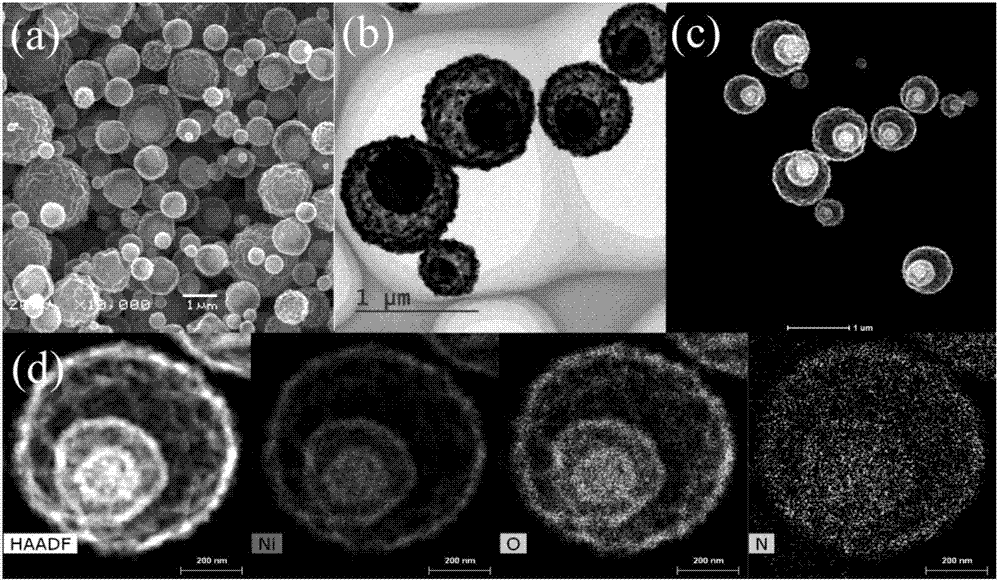

[0033] Preparation 200ml concentration is 0.15mol / L Ni(NO 3 ) 2 solution, adding 5g of PVP to configure the precursor solution, the spray pyrolysis temperature is 700°C, the carrier gas (O 2 ) with a flow rate of 5 L / min. The collected materials were characterized by scanning electron microscope (SEM), transmission electron microscope (TEM), elemental distribution (EDS) and XRD diffraction. Test results such as image 3 and 4 shown. Depend on image 3 The scanning electron microscope picture shows that the material prepared by spray pyrolysis has good dispersion and uniform particle size distribution; the transmission electron microscope picture shows that nickel nitrate with PVP can be sprayed and pyrolyzed, and NiO powder with multilayer core-shell structure can be prepared in one step Material. The element distribution shows that all the constituent elements are evenly distributed inside the core-shell structure, indicating that the prepared NiO powder material is un...

Embodiment 3

[0035] Prepare 200ml of nickel-cobalt mixed solution with a total metal ion concentration of 0.15mol / L, wherein the molar ratio of Ni:Co is 1:2, the spray pyrolysis temperatures are 500°C, 600°C, and 800°C respectively, and the carrier gas (O 2 ) The flow rate is 5L / min, and the amount of PVP added is 5g. The powder materials prepared under different temperature conditions were characterized by scanning electron microscope (SEM), transmission electron microscope (TEM), element distribution (EDS) and X-ray diffraction (XRD). Test results such as Figure 5 , Figure 6 , Figure 7 and Figure 8 shown. Depend on Figure 5 , Figure 6 and Figure 7 It can be seen that the powder materials prepared at different temperatures have good dispersion, uniform particle size distribution and typical multi-layer core-shell structure. The element distribution shows that for the materials prepared at different temperatures, the constituent elements are uniformly dispersed inside the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com