Transition beam of truss type structure

A truss structure and transition beam technology, applied in the field of automobiles, can solve the problems of fan swing phenomenon, affecting the running stability of the whole vehicle, aggravating the running jitter of the vehicle, etc., and achieve the effects of improving the stability, small deformation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

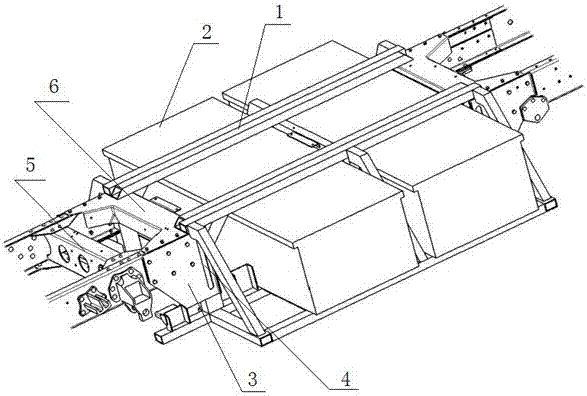

[0016] Such as figure 1 In the transition beam with a truss structure shown, the power battery 2 is arranged in the transition beam 1, and the truss structure is set as a trapezoidal structure. The structural transitional beam 1 is connected to the overlapped part of the vehicle frame 5, and a transverse reinforcing plate 3 and a longitudinal reinforcing plate 4 are respectively provided at the transverse and longitudinal stress places for strengthening and fixing.

[0017] The truss structure transition beam 1 is formed by drilling, cutting and welding rectangular steel pipes.

[0018] The overlap between the transition beam 1 and the vehicle frame 5 is formed by welding and bolting.

[0019] In this embodiment, two power batteries 2 are provided, located in the trapezoidal structure of the truss structure, and fixed with bolts.

[0020] The transition beam 1 is provided with a reinforcing plate U-shaped groove 6 at the lap joint of the frame 5, and the U-shaped groove 6 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com