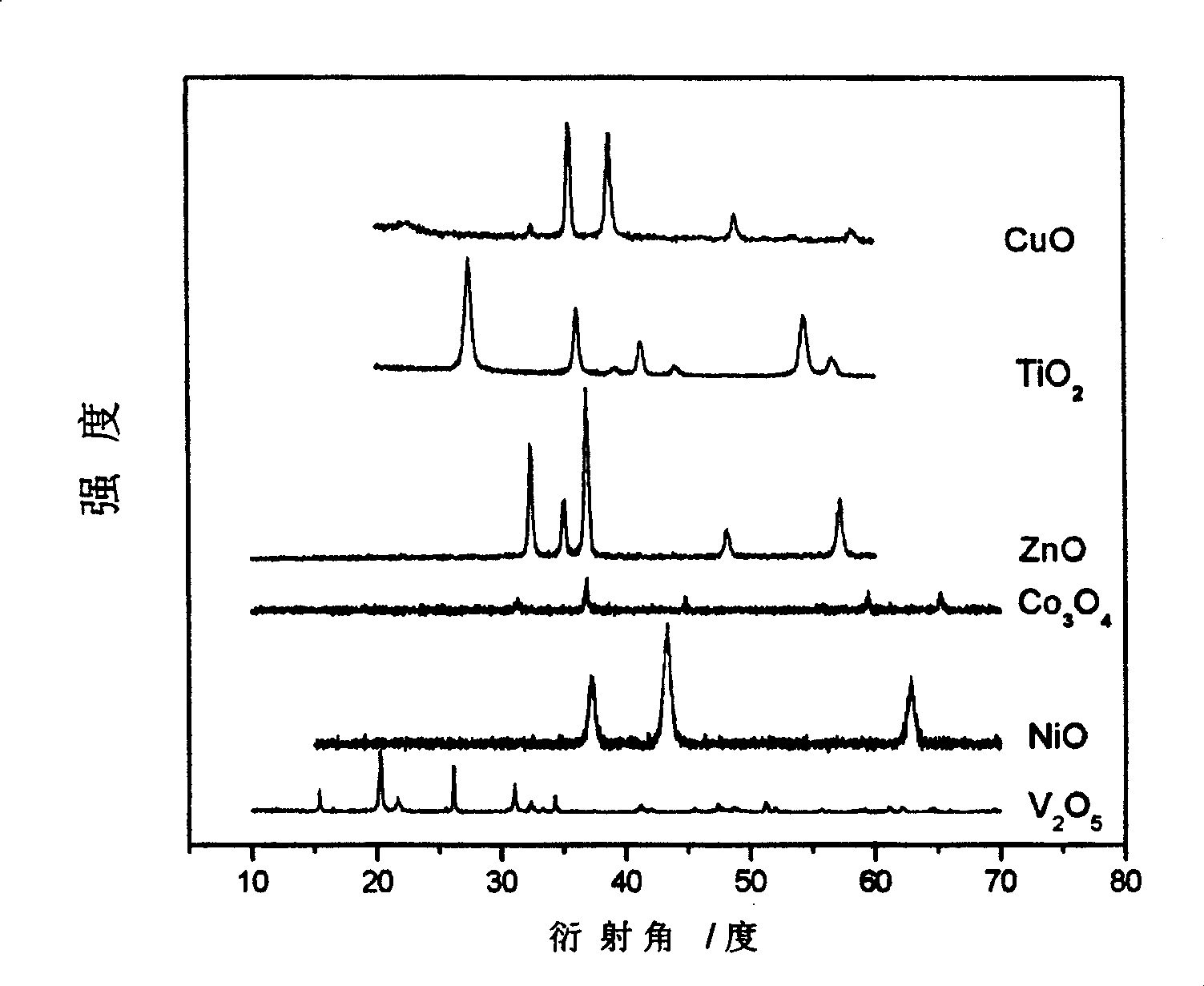

Preparation of graduated nano-structural transition metal oxide by two-phase solvent soft interface process

A technology of transition metals and nanostructures, applied in the direction of titanium oxide/hydroxide, vanadium oxide, titanium dioxide, etc., can solve the problems of low solar energy utilization and achieve good versatility, high photocatalytic activity, and simple synthesis routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of hierarchical nanostructured titania. The preparation steps are:

[0030] Step 1, adding hydrochloric acid in 50 milliliters of water, the pH value of adjusting solution is 1;

[0031] Step 2, adding titanium tetrachloride dropwise to the prepared solution in step 1 to form a titanium-containing aqueous solution with a concentration of 0.1 mol / liter;

[0032] Step 3, add 20 milliliters of chloroform to the prepared solution in step 2;

[0033] Step 4, solvent heat treatment is carried out in the solution prepared in step 3, the temperature is 100° C., and the time is 36 hours;

[0034] Step 5, after the reaction is finished, the solid product is filtered, and the product is rinsed with distilled water or ethanol several times;

[0035] Step 6, the product was dried under vacuum at 60° C. for 12 hours to obtain white titanium dioxide powder.

[0036] The SEM image of the titanium dioxide powder is shown in figure 2 .

[0037] It can be seen from the ...

Embodiment 2

[0039] Preparation of hierarchical nanostructured titania. The preparation steps are:

[0040] Step 1, adding nitric acid in 50 milliliters of water, the pH value of adjusting solution is 2;

[0041] Step 2, adding titanium tetrachloride dropwise to the prepared solution in step 1 to form a titanium-containing aqueous solution with a concentration of 0.02 mol / liter;

[0042] Step 3, add 4 milliliters of chloroform to the prepared solution in step 2;

[0043] Step 4, solvent heat treatment is carried out in the solution prepared in step 3, the temperature is 100° C., and the time is 36 hours;

[0044] Step 5, after the reaction is finished, the solid product is filtered, and the product is rinsed with distilled water or ethanol several times;

[0045] Step 6, the product was dried under vacuum at 60° C. for 12 hours to obtain white titanium dioxide powder.

[0046] The SEM image of the titanium dioxide powder is shown in figure 2 .

Embodiment 3

[0048] Preparation of hierarchical nanostructured titania. The preparation steps are:

[0049]Step 1, adding nitric acid in 50 milliliters of water, the pH value of adjusting solution is 2;

[0050] Step 2, adding titanium tetrachloride dropwise to the prepared solution in step 1 to form a titanium-containing aqueous solution with a concentration of 0.001 mol / liter;

[0051] Step 3, add 4 milliliters of chloroform to the prepared solution in step 2;

[0052] Step 4, performing solvent heat treatment in the solution prepared in step 3, the temperature is 100°C, and the time is 96 hours;

[0053] Step 5, after the reaction is finished, the solid product is filtered, and the product is rinsed with distilled water or ethanol several times;

[0054] Step 6, the product was dried under vacuum at 100° C. for 3 hours to obtain white titanium dioxide powder.

[0055] The SEM image of the titanium dioxide powder is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com