Transition metal based catalyst electrode of honeycomb macroporous structure as well as preparation method and application thereof

A transition metal and transition metal salt technology, applied in physical/chemical process catalysts, chemical instruments and methods, battery electrodes, etc., can solve the problems of simple preparation and complex steps that are not suitable for large-area electrodes, and achieve the improvement of effective specific surface area, Easy to maintain, small volume change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a honeycomb-shaped macroporous structure transition metal-based catalyst electrode and a preparation method and application thereof. The preparation method of the honeycomb-shaped macroporous structure transition metal-based catalyst electrode includes the following steps:

[0032] S1: Synthetic polystyrene submicron sphere aqueous solution; specifically, polystyrene submicron spheres are prepared by using styrene as the monomer, persulfate as the oxidant, and mixed with a solvent and then heated and reacted. The styrene monomer The volume concentration of the persulfate is 5%-20%, the persulfate is potassium persulfate, and the concentration is 0.2-3mol / L, the solvent is water, and the heating reaction temperature is 70-95°C; The size of styrene submicron spheres is 100-1000 nm.

[0033] S2: Prepare a transition metal salt solution, mix the transition metal salt solution with the polystyrene submicron sphere aqueous solution to obtain a mixed solutio...

Embodiment 1

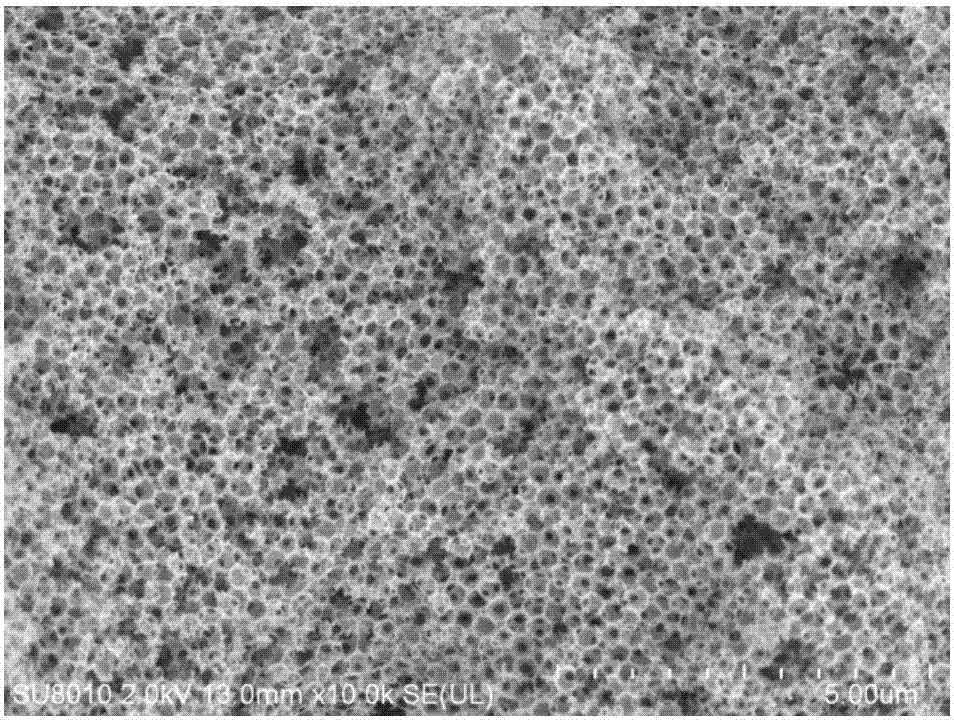

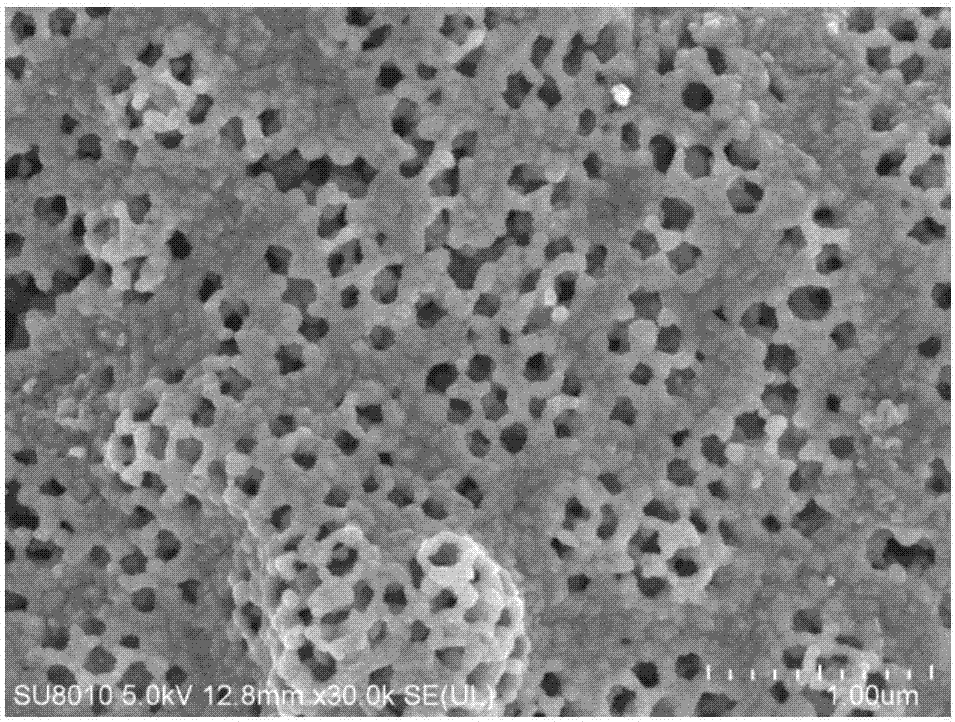

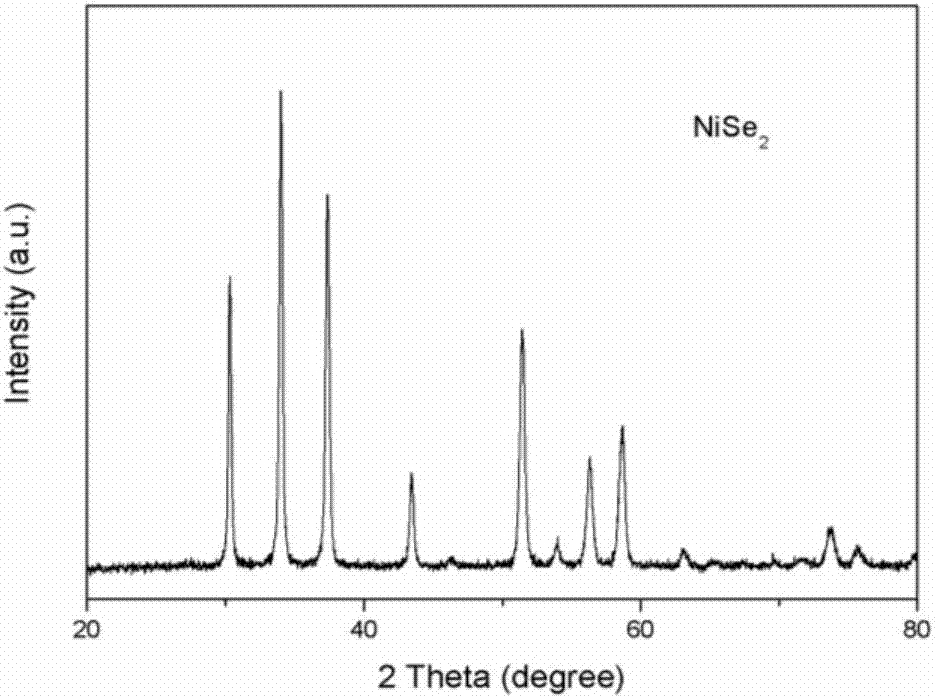

[0040] Preparation method and application of honeycomb macroporous nickel selenide electrode

[0041] This embodiment discloses a preparation method and application of a honeycomb macroporous nickel selenide electrode. The preparation method includes the following steps:

[0042] S1: Synthesize an aqueous solution of polystyrene submicron spheres with a size of 400 nm. Specifically, 360mL of water and 40mL of styrene monomer were sequentially added to a 500mL flask, and after stirring, potassium persulfate (K 2 S 2 O 7 ), the potassium persulfate concentration was 2.76mmol / L, and the reaction was conducted at 95°C for 24h. After the reaction is over, continue to stir until it cools to room temperature for later use.

[0043] S2: Weigh nickel chloride (NiCl 2 ) And citric acid, dissolved in ethanol to prepare 10mM NiCl 2 And 10mM citric acid in ethanol, which is NiCl 2 Salt solution; press NiCl 2 The volume ratio of salt solution and polystyrene submicron sphere aqueous solution (v / v...

Embodiment 2

[0050] Preparation method and application of honeycomb macroporous nickel selenide electrode

[0051] This embodiment discloses a preparation method and application of a honeycomb macroporous nickel selenide electrode. The preparation method includes the following steps:

[0052] S1: Synthesize an aqueous solution of polystyrene submicron spheres with a size of 600 nm. Specifically, in a 500mL flask, add 350mL of water and 40mL of styrene monomer in sequence, stir well and then add potassium persulfate (K 2 S 2 O 7 ), the potassium persulfate concentration is 1.8mmol / L, and the reaction is carried out at 70°C for 24h. After the reaction is over, continue to stir until it cools to room temperature for later use.

[0053] S2: Weigh nickel nitrate and citric acid in proportion and dissolve them in ethanol together to prepare an ethanol solution of 20 mM nickel nitrate and 15 mM citric acid, that is, nickel nitrate solution; according to nickel nitrate solution and polystyrene The volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com