Two-dimension gradient structure transition layer

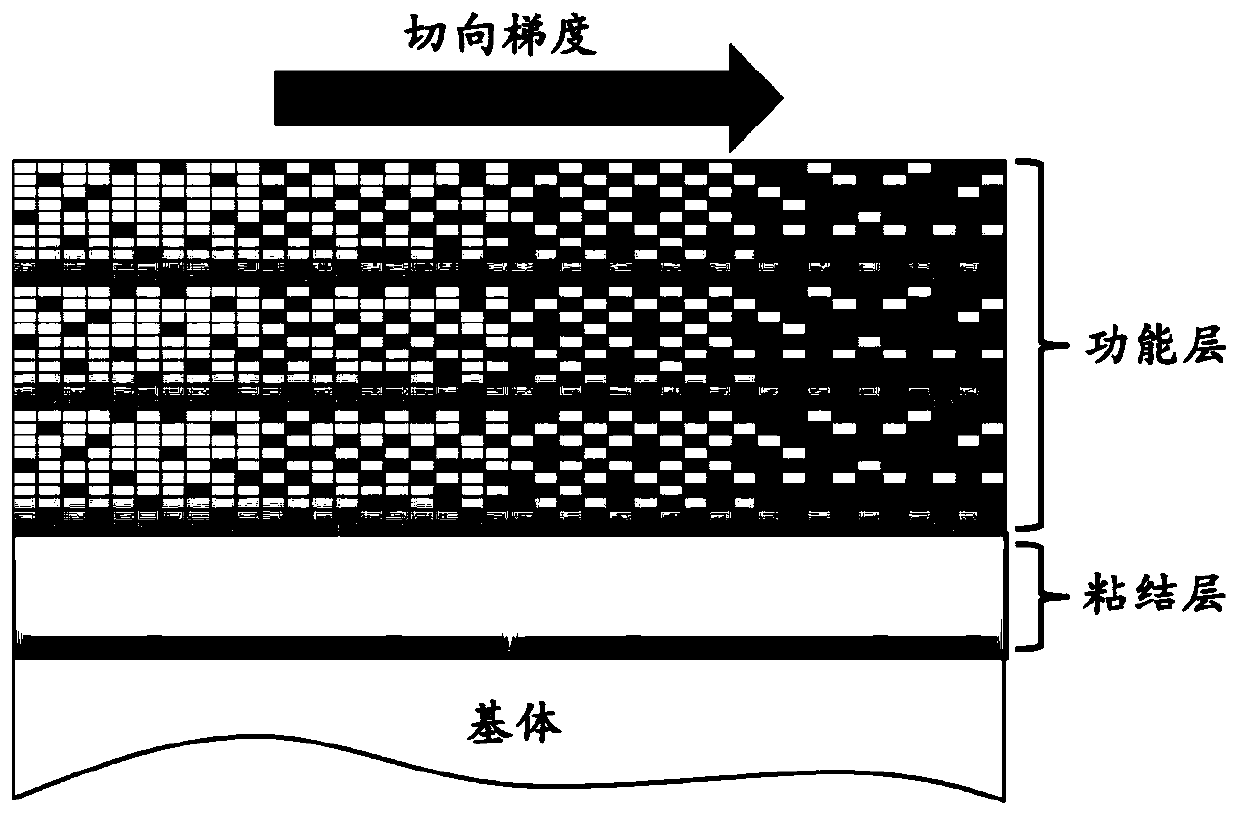

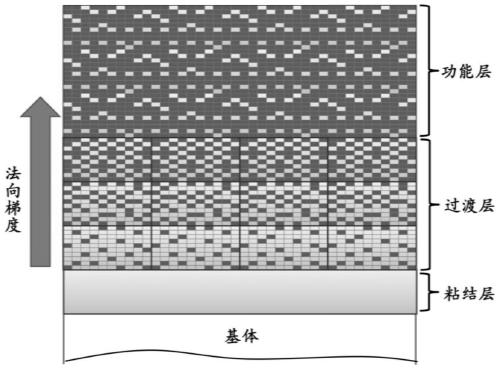

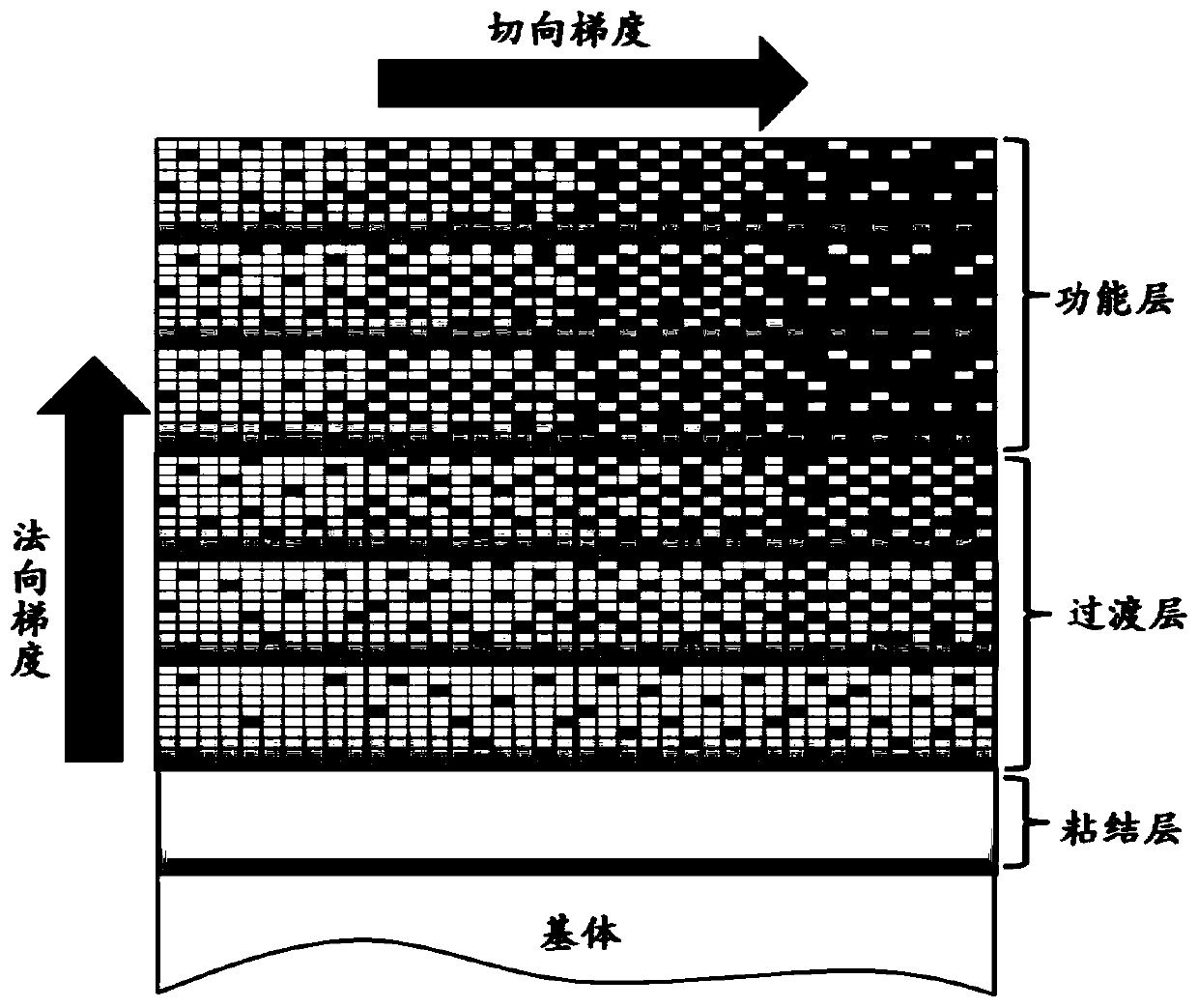

A two-dimensional gradient and transition layer technology, used in coatings, metal material coating processes, melt spraying, etc. Peeling and other problems, to achieve the effect of good thermal stress consistency along the tangential direction, excellent comprehensive service performance of the coating, and good bonding strength of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0041] Below in conjunction with specific embodiment 1, the present invention is described in detail:

Embodiment 1

[0043] Taking a certain type of blade as an example, the surface is thermally sprayed with Cr 3 C 2 -NiCr and NiCr composite tangential gradient coating, the technical scheme is as follows:

[0044] A two-dimensional gradient structure transition layer, the material compatibility of the transition layer changes along the normal direction and the tangential two-dimensional gradient.

[0045] The substrate is metal material FV520B, and the functional layer is Cr 3 C 2 -NiCr and NiCr composite material (Cr 3 C 2 -NiCr powder is mainly composed of Cr 3 C 2 It is composed of NiCr, its mass ratio is about 75:25, and its chemical composition is shown in Table 1; NiCr powder is mainly composed of Ni and Cr, its mass ratio is about 20:80, its chemical composition is shown in Table 2), and the transition layer is also Cr 3 C 2 -NiCr and NiCr composite materials, the material compatibility is characterized by the composite ratio.

[0046] Table 1 Cr 3 C 2 -NiCr powder chemical...

Embodiment 2

[0061] In this embodiment, the setting of the transition layer is the same as that of Embodiment 1, the difference is that a bonding layer is also set between the transition layer and the substrate to enhance the bond strength between the transition layer and the workpiece substrate, and the bonding layer adopts the existing The materials for the adhesive layer can be used, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com