Composite soft magnetic powder magnetic conducting material for slot wedge of electric machine and preparation thereof

A technology of magnetic conductive material and motor slot wedge, applied in the direction of inorganic material magnetism, electrical components, electromechanical devices, etc., can solve the problems of motor eddy current loss rise, shedding and cracking, low mechanical properties, etc., to reduce additional losses and eddy currents Loss, effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment makes carbonyl iron powder / MnZn ferrite soft magnetic composite powder to prepare the magnetic material, and the process steps are as follows:

[0017] (1) Ingredients: glass fiber 30%; soft magnetic composite powder 20% (MnZn ferrite powder: Fe powder = 4: 1); epoxy resin 50%. The above percentages are volume percentages. The glass fiber is added in the form of glass cloth, and the resin is fully impregnated on the glass cloth.

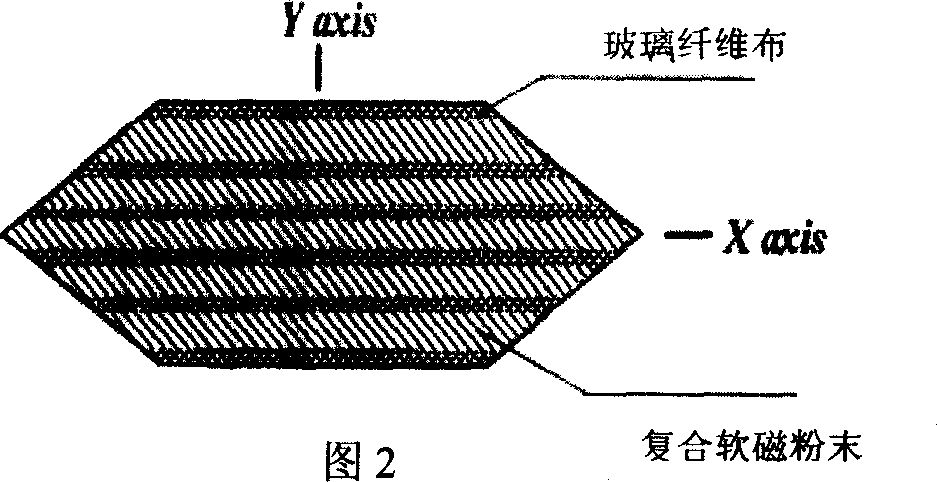

[0018] (2) Lamination: Divide the evenly mixed composite soft magnetic powder according to the number of glass cloth layers, and then place the uniformly distributed composite powder on the glass cloth to obtain a prepress. The pre-press material is overlapped layer by layer to obtain the structure shown in Fig. 2 .

[0019] (3) Hot pressing: Put the laminated prepress into the template for hot pressing, so that the resin melts and flows to bond the composite magnetic powder and fiber. The hot pressing temperature is the cur...

Embodiment 2

[0023] This embodiment makes the magnetic permeable material prepared by FeSiAl / MnZn ferrite soft magnetic composite powder, and the process steps are as follows:

[0024] (1) Ingredients: glass fiber 25%; soft magnetic composite powder 25% (MnZn ferrite powder: FeSiAl powder = 3: 2); epoxy resin 50%. The above percentages are volume percentages. The glass fiber is added in the form of glass cloth, and the resin is fully impregnated on the glass cloth.

[0025] (2) Lamination: Divide the evenly mixed composite soft magnetic powder according to the number of glass cloth layers, and then place the uniformly distributed composite powder on the glass cloth to obtain a prepress. The pre-press material is overlapped layer by layer to obtain the structure shown in Fig. 2 .

[0026] (3) Hot pressing: Put the laminated prepress into the template for hot pressing, so that the resin melts and flows to bond the composite magnetic powder and fiber. The hot pressing temperature is the cu...

Embodiment 3

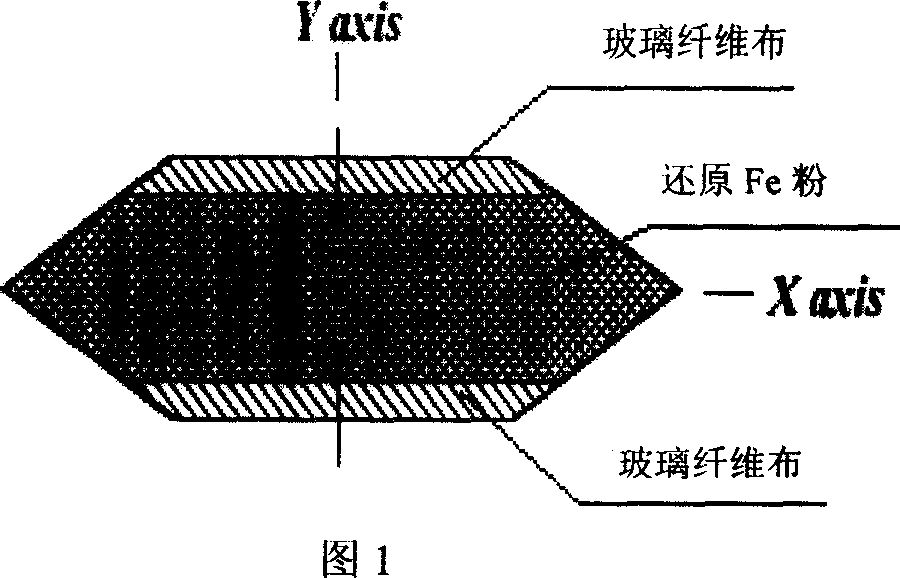

[0030] In this embodiment, the magnetic conductive material prepared by reduced iron powder / MnZn ferrite soft magnetic composite powder is prepared, and the process steps are as follows:

[0031] (1) Ingredients: glass fiber 20%; soft magnetic composite powder 20% (MnZn ferrite powder: reduced Fe powder=1:4); epoxy resin 60%. The above percentages are volume percentages. The glass fiber is added in the form of glass cloth, and the resin is fully impregnated on the glass cloth.

[0032](2) Lamination: Divide the evenly mixed composite soft magnetic powder according to the number of glass cloth layers, and then place the uniformly distributed composite powder on the glass cloth to obtain a prepress. The pre-press material is overlapped layer by layer to obtain the structure shown in Fig. 2 .

[0033] (3) Hot pressing: Put the laminated prepress into the template for hot pressing, so that the resin melts and flows to bond the composite magnetic powder and fiber. The hot pressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com