Functional solar cell module backboard and manufacture method thereof

A technology of solar cells and manufacturing methods, applied in the direction of electrical components, chemical instruments and methods, circuits, etc., can solve problems such as high cost, complicated production process, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

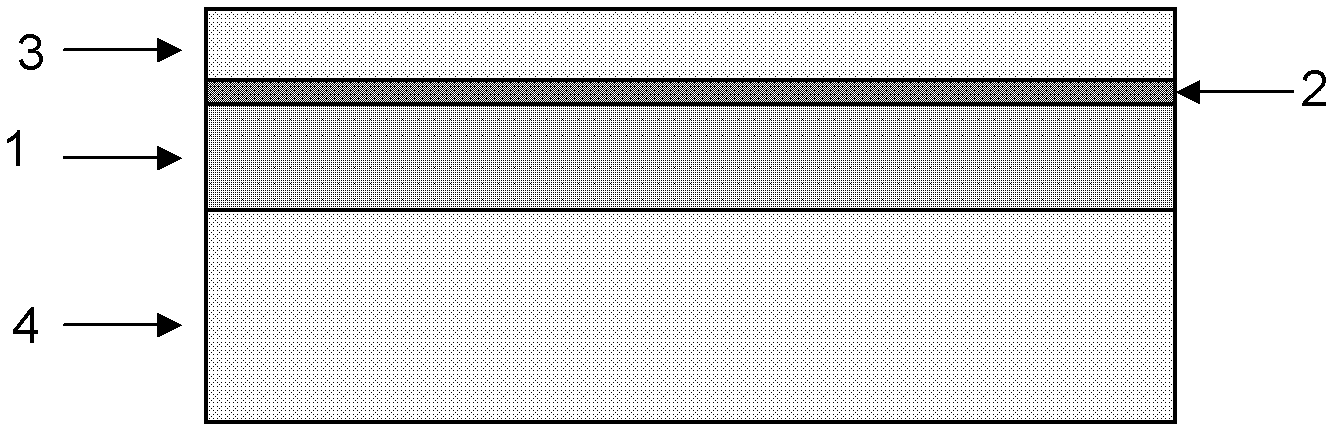

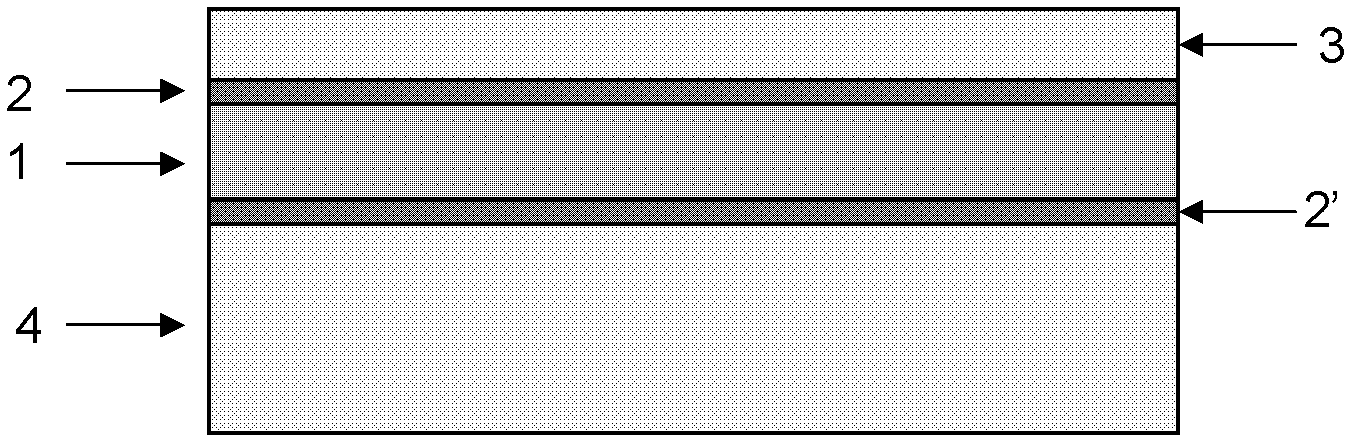

Method used

Image

Examples

Embodiment 1

[0060] Fluoroplastic film adopts Akema's PVDF film, thickness 20 microns; Base film adopts biaxially stretched PET film, thickness 250 microns; Adhesive layer material adopts maleic anhydride grafted polyethylene plastic particle (maleic anhydride grafting amount 1.7%), wherein contains 0.1 weight % antioxidant tetrakis (methylene (3,5-di-(tert)-butyl-4-hydroxyhydrocinnamate)) methane; encapsulation layer material adopts ethylene-vinyl acetate copolymer plastic particles (vinyl acetate ester content is 33% by weight), which contains 0.5% by weight peroxide crosslinking agent, o,o-tert-amyl-o-(2-ethylhexyl)-mono-peroxycarbonate, 0.2% by weight of Silane coupling agent vinyltriethoxysilane, 0.2% by weight of antioxidant tetrakis(methylene(3,5-di-(tert)-butyl-4-hydroxyhydrocinnamate))methane and 0.2 % by weight of UV stabilizer cetyl 3,5-di-tert-butyl-4-hydroxy-benzoate.

[0061] Through the process of melt extrusion, the adhesive layer maleic anhydride grafted polyethylene pl...

Embodiment 2

[0064] Fluoroplastic film adopts Akema's PVDF film with a thickness of 20 microns; the base film adopts biaxially stretched PET film with a thickness of 250 microns; the adhesive layer material adopts ethylene butyl acrylate copolymer plastic particles (21% butyl acrylate content), which contains 0.1% by weight of antioxidant Agent tetrakis (methylene (3,5-di-(tert)-butyl-4-hydroxyhydrocinnamate)) methane; the encapsulation layer material adopts ethylene-vinyl acetate copolymer plastic particles (the content of vinyl acetate is 33% by weight), which contains 0.5% by weight of peroxide crosslinking agent, o, o-tert-amyl-o-(2-ethylhexyl)-mono-peroxycarbonate, 0.1% by weight of silane coupling Agent vinyltriethoxysilane, 0.2% by weight of antioxidant tetrakis(methylene(3,5-di-(tert)-butyl-4-hydroxyhydrocinnamate))methane and 0.2% by weight of UV stabilizer cetyl 3,5-di-tert-butyl-4-hydroxy-benzoate.

[0065] Through the process of melt extrusion, the adhesive layer ethylene but...

Embodiment 3

[0068] Fluoroplastic film adopts DuPont's PVF film, thickness 25 microns; Base film adopts biaxially stretched PET film, thickness 400 microns; Adhesive layer material adopts ethylene acrylic acid copolymer plastic particle (acrylic acid content 12%), wherein contains 0.1 weight % antioxidant tetra(sub- Methyl (3,5-di-(tert)-butyl-4-hydroxyhydrocinnamate)) methane; encapsulation layer material adopts ethylene-vinyl acetate copolymer plastic particles (vinyl acetate content is 33% by weight) , which contains 0.3% by weight of peroxide crosslinking agent, o, o-tert-amyl-o-(2-ethylhexyl)-mono-peroxycarbonate, 0.3% by weight of silane coupling agent vinyl tri Ethoxysilane, 0.2 wt% antioxidant tetrakis(methylene(3,5-di-(tert)-butyl-4-hydroxyhydrocinnamate))methane and 0.2 wt% UV stabilizer 3 , 5-di-tert-butyl-4-hydroxy-benzoic acid hexadecyl ester.

[0069] Through the process of melt extrusion, the adhesive layer maleic anhydride grafted polyethylene plastic particles are melt-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com