Full-color emission glass phosphor and preparation method thereof

A technology of glass fluorescence and glass body, which is applied in the field of near-ultraviolet or blue-light excited full-color emission glass phosphor for white light LED and its preparation, can solve the problem of poor resistance to ultraviolet radiation and temperature stability, reducing the service life of white light LED light source, fluorescence Problems such as uneven thickness of powder coating layer, to achieve the effect of improving aging problem, stable luminous performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

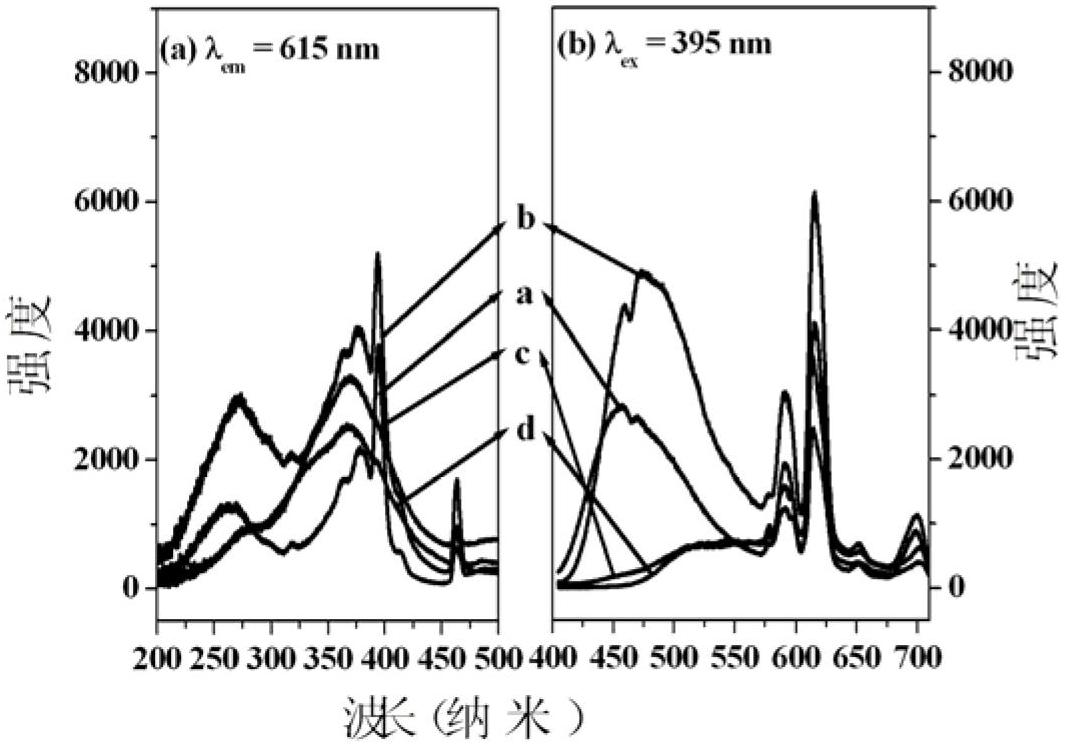

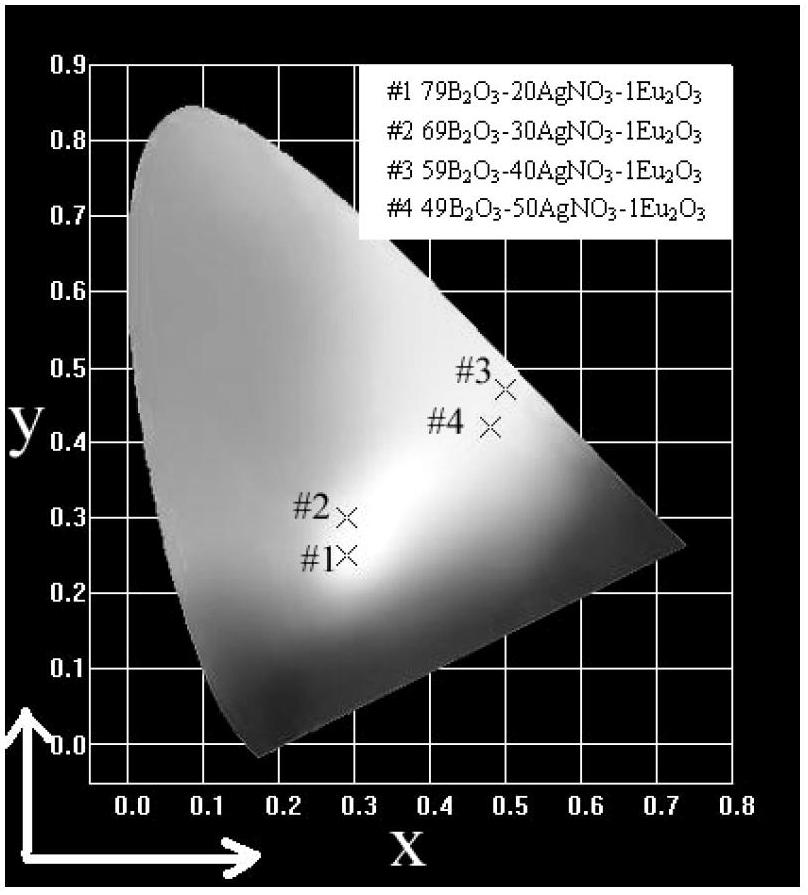

Examples

Embodiment 1

[0054] A kind of raw material that the preparation method of full-color emission glass phosphor takes, by molar percentage, comprises the following components:

[0055] B 2 o 3 79mol%,

[0056] AgNO 3 20mol%,

[0057] Eu 2 o 3 1mol%,

[0058] First weigh B according to the above stoichiometric ratio 2 o 3 , AgNO 3 and Eu 2 o 3 raw materials, and grind to mix well. Put the uniformly mixed raw materials into a corundum crucible, heat at 1200°C and keep the temperature constant for 1h, pour the molten liquid onto the preheated copper mold to form the primary glass, anneal in an electric furnace at 400°C for 1h, and finally the final glass obtained Cut and polished, made into 10×10×1mm 3 sample.

Embodiment 2~4

[0060] A kind of raw material that the preparation method of full-color emission glass phosphor takes, by molar percentage, comprises the following components:

[0061] B 2 o 3 69mol%,

[0062] AgNO 3 30mol%,

[0063] Eu 2 o 3 1mol%,

[0064] First weigh B according to the above stoichiometric ratio 2 o 3 , AgNO 3 and Eu 2 o 3 raw materials, and grind to mix well. Put the uniformly mixed raw materials into a corundum crucible, heat at 1200°C and keep the temperature constant for 1h, pour the molten liquid onto the preheated copper mold to form the primary glass, anneal in an electric furnace at 400°C for 1h, and finally the final glass obtained Cut and polished, made into 10×10×1mm 3 sample.

Embodiment 3

[0066] A kind of raw material that the preparation method of full-color emission glass phosphor takes, by molar percentage, comprises the following components:

[0067] B 2 o 3 59mol%,

[0068] AgNO 3 40mol%,

[0069] Eu 2 o 3 1mol%,

[0070] First weigh B according to the above stoichiometric ratio 2 o 3 , AgNO 3 and Eu 2 o 3 raw materials, and grind to mix well. Put the uniformly mixed raw materials into a corundum crucible, heat at 1200°C and keep the temperature constant for 1h, pour the molten liquid onto the preheated copper mold to form the primary glass, anneal in an electric furnace at 400°C for 1h, and finally the final glass obtained Cut and polished, made into 10×10×1mm 3 sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com