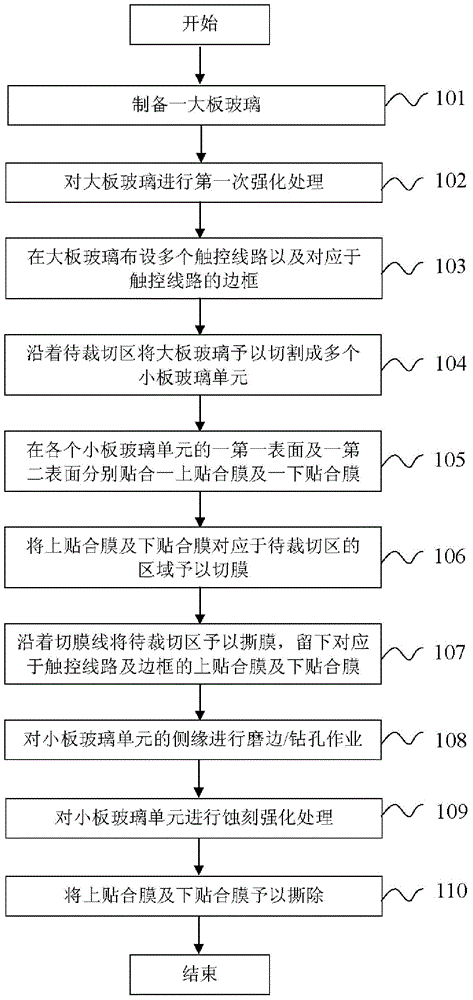

Method for carrying out edge etching and strengthening of cut one-glass-solution touch panel with one-time film lamination

A monolithic glass and touch panel technology, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of low efficiency and high mass production cost, simplify the process, reduce scratches, save equipment costs and The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific technology adopted in the present invention will be further described through the following examples and drawings.

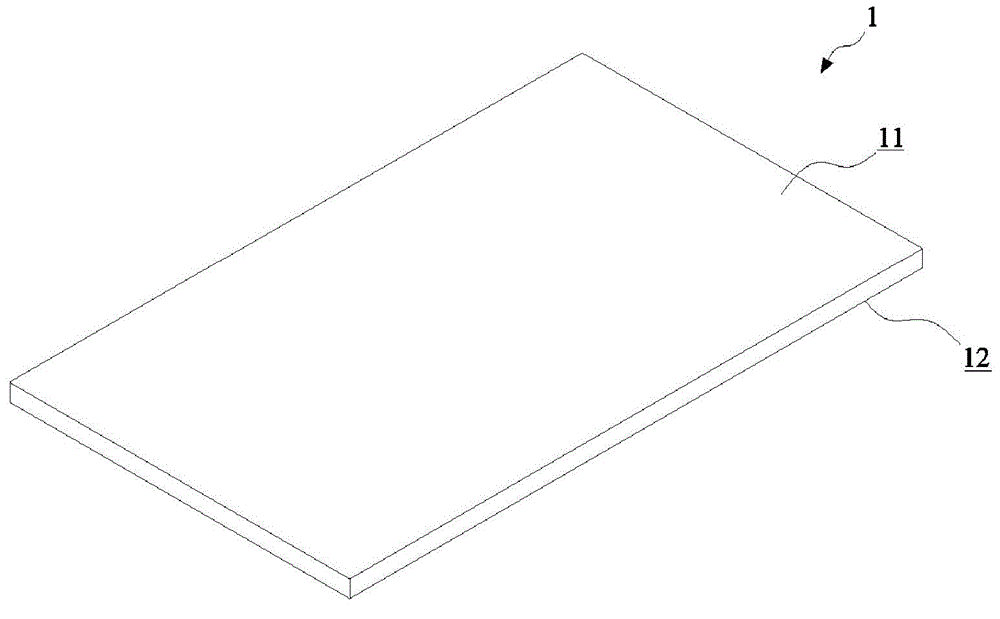

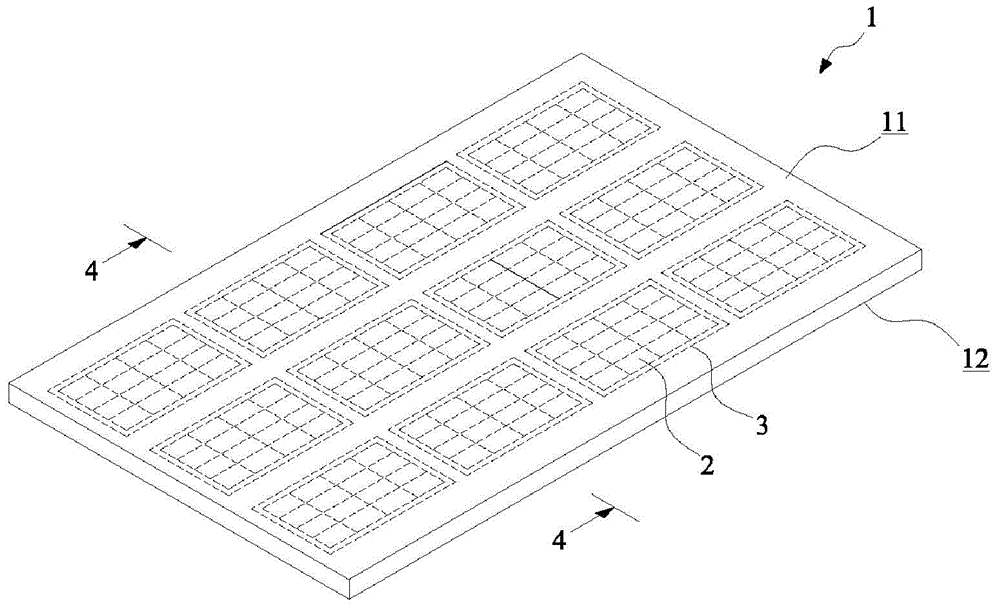

[0044] see Figure 1 to Figure 10 , when realizing the technique of the present invention, at first prepare a large plate glass 1 (step 101), this large plate glass 1 has a first surface 11 and second surface 12 (as figure 2 ), wherein the first surface 11 is used as a user operation surface for the touch function after commercialization, and the second surface 12 is used as a circuit configuration surface.

[0045] Referring to step 102, the large plate glass 1 is then strengthened for the first time. During the strengthening treatment, one of the currently known chemical strengthening methods or physical strengthening methods can be used to increase the glass hardness of the large glass plate 1 . For example, taking the chemical strengthening method as an example, generally the large plate glass 1 is subjected to sodium and potassium ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com