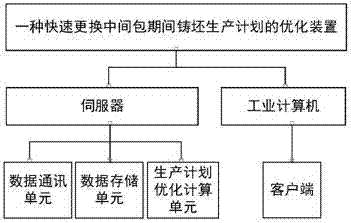

Optimization device and method for casting blank production plan during period of rapidly exchanging tundish

A technology of production planning and tundish applied in the field of continuous casting automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention provides a device and method for optimizing the casting billet production plan during the rapid replacement of the tundish. By optimizing the production plan and reducing the generation of waste billets, it is suitable for the adjustment and optimization control of the production plan during various rapid replacement of the tundish, and improves the metal Yield rate, reduce production cost.

[0038] In order to clearly illustrate the technical characteristics of the method, the following describes the solution through a specific implementation mode:

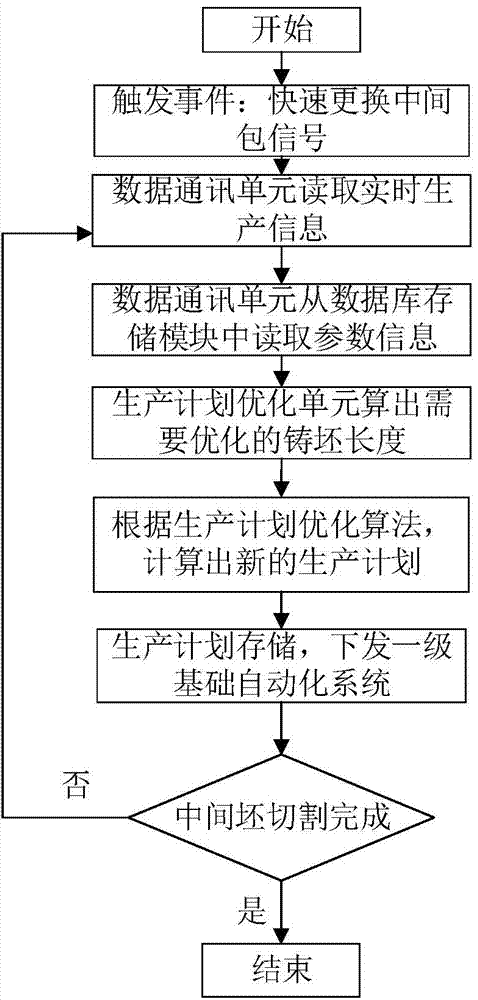

[0039]After the data communication unit collects the on-site basic automation equipment event "quick replacement of tundish", it triggers the production plan optimization calculation unit to optimize the length of the uncut slab during the replacement of the tundish and in the previous furnace. The specific steps are:

[0040] Step 1. The data communication unit reads the length of 35.8 from the head of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com