Vibrating diaphragm and vibrating diaphragm manufacturing method

A diaphragm production and thin-film technology, which is applied in the field of loudspeakers, can solve the problems of high cost, high difficulty, and low efficiency, and achieve the effects of reducing production costs, easy operation, and reducing defective rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

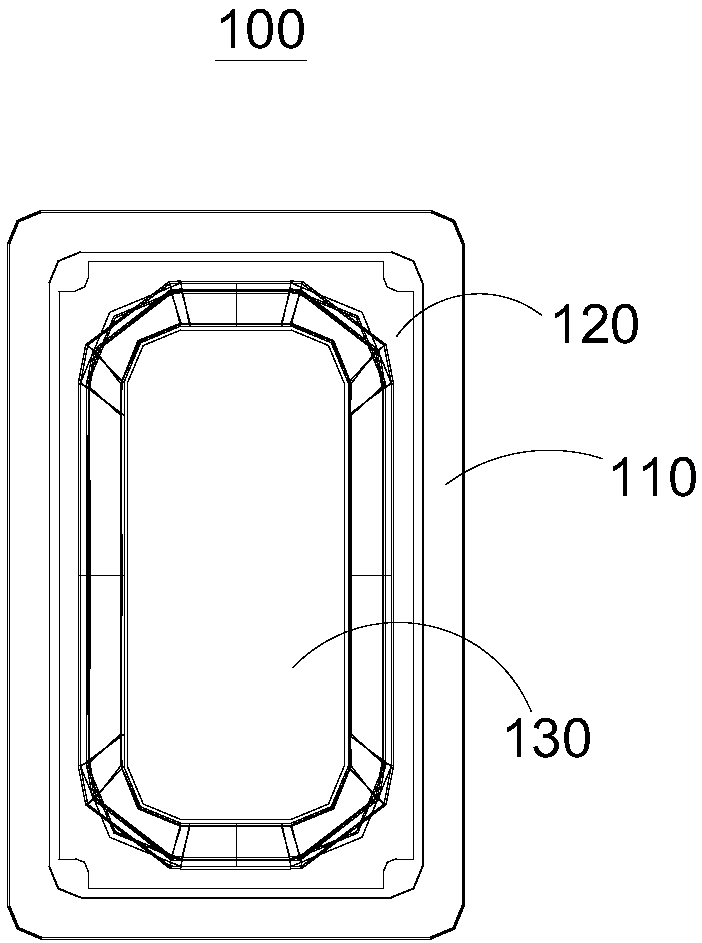

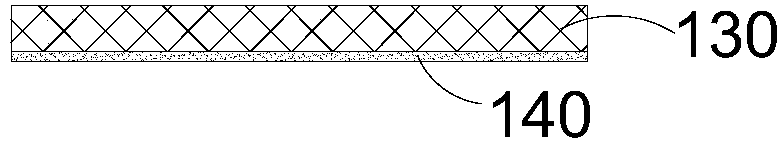

[0038] see figure 1 , the embodiment of the present invention provides a diaphragm 100 , the diaphragm 100 includes a frame 110 , a dome 130 and a film 120 , the edges of the film 120 are connected to the frame 110 , and the film 120 is connected to the dome 130 .

[0039] Specifically, in this embodiment, as the sounding unit of the speaker, the thin film 120 must be thin and soft, so that when the speaker is about to make sound, the dome 130 and the diaphragm 100 vibrate simultaneously, and then the sound is emitted. Due to the soft characteristics of the thin film 120, during the processing of the diaphragm 100, when the outer diameter of the diaphragm 100 is cut (i.e. cutting off the excess thin film 120), the prior art utilizes a cold stamping die or a knife die for cutting. It is more difficult. At the same time, during installation, the assembly between the soft film 120 and the loudspeaker shell is difficult, and because the film 120 is thin, it is easy to be damaged,...

no. 2 example

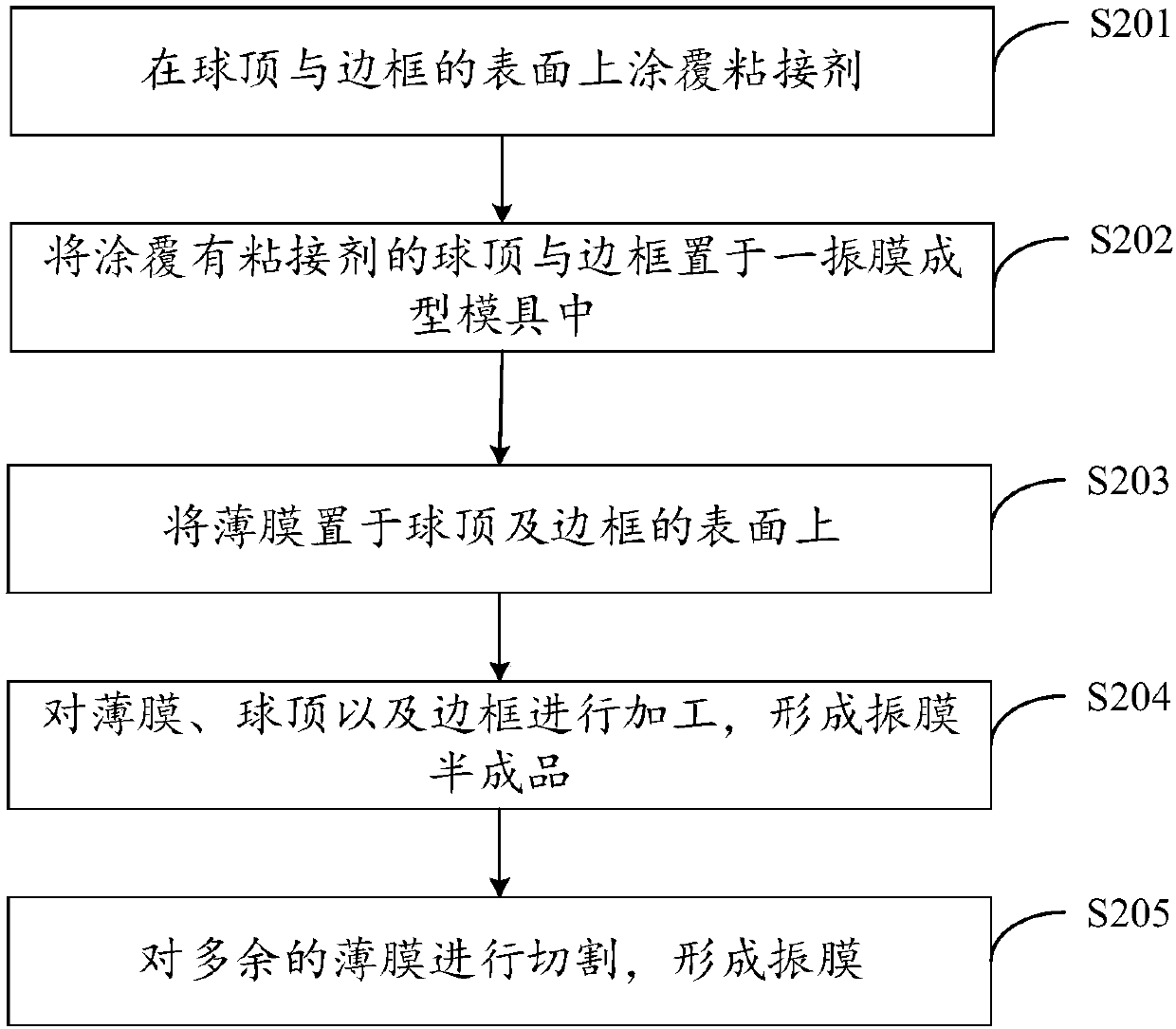

[0051] see Figure 4 , the embodiment of the present invention also provides a diaphragm manufacturing method, the diaphragm manufacturing method includes the following steps:

[0052] Step S201 , coating adhesive on the surface of the dome 130 and the frame 110 .

[0053] In order to realize the connection of the dome 130 , the frame 110 and the film 120 , an adhesive needs to be coated on one side of the dome 130 and the frame 110 to bond the dome 130 , the frame 110 and the film 120 . In this embodiment, thermosetting glue is selected as the adhesive.

[0054] Step S202 , placing the dome 130 and the frame 110 coated with adhesive in a diaphragm forming mold 150 .

[0055] After coating the adhesive on one side of the dome 130 and the frame 110, and drying the surface with the adhesive, the dome 130 and the frame 110 are placed in a diaphragm forming mold 150, and the diaphragm forming mold 150 is provided with The positioning groove, the ball top 130 and the frame 110 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com