Three-segment profiled H-shaped steel rapid saw cutting device and method

A technology of sawing device and H-shaped steel, which is applied in the direction of sawing machine, cutting tool of sawing machine, metal sawing equipment, etc. It can solve the problems of not being suitable for offline cutting, small application range, high transportation cost, etc., and achieve improved sawing stability , Reduce the difficulty of cutting, the effect of high sawing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

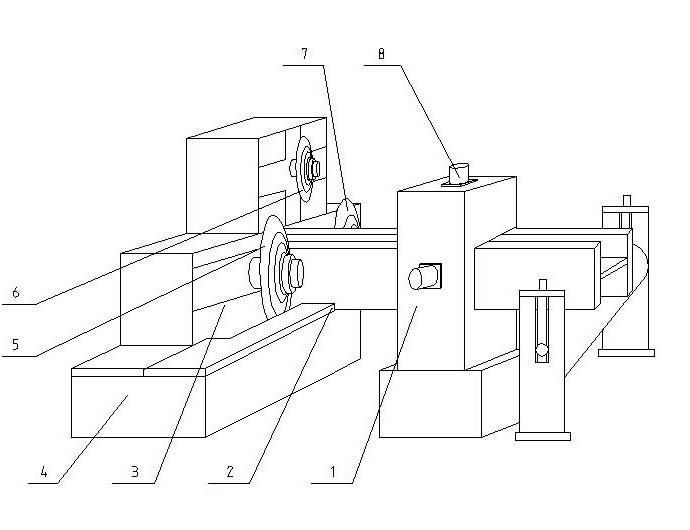

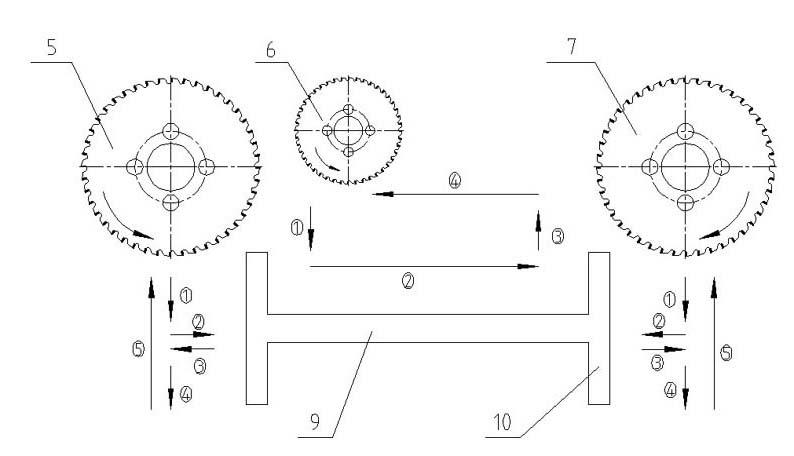

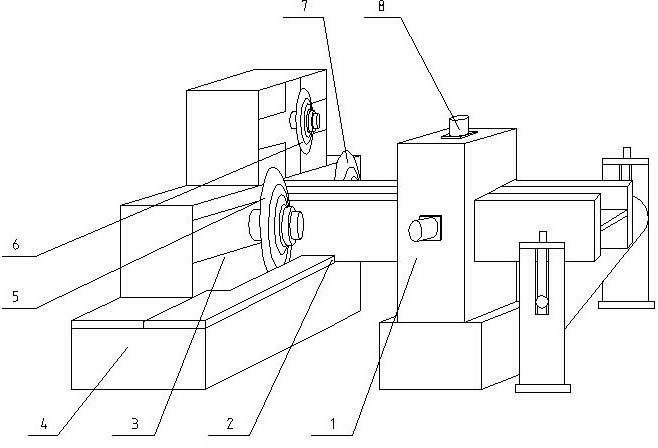

[0017] See attached Figure 1-2 , the three-stage imitation form H-shaped steel quick sawing device disclosed in the present invention includes a saw machine 3 equipped with a circular saw blade, the bottom of the saw machine 3 is installed on a feeding table 4, and the feeding table 4 A raceway 2 is provided, and the saw machine 3 is equipped with a horizontal saw blade 6 for cutting the H-shaped steel web 10 and a vertical saw blade for cutting the H-shaped steel flange 9, and the vertical saw blades include a first vertical saw blade 5 and a second vertical saw blade. Vertical saw blades 6, two vertical saw blades are respectively arranged on both sides of the H-shaped steel, and a horizontal saw blade 6 is arranged between the two vertical saw blades and above the H-shaped steel. The thickness of the flange 9 of H-shaped steel is generally 13-15mm, so the diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com