Scanning electron microscopy sample production method of coated white cardboard fracture

A technology of scanning electron microscopy and white paperboard, which is applied in the preparation of test samples, etc., can solve the problem of affecting the observation effect of scanning electron microscopy on the surface coating of paper, it is difficult to obtain a flat fracture, and the difference in mechanical properties between inorganic coating and core fiber is relatively large. Large and other problems, to achieve the effect of simple and fast sample preparation method, no pollutant blocking, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

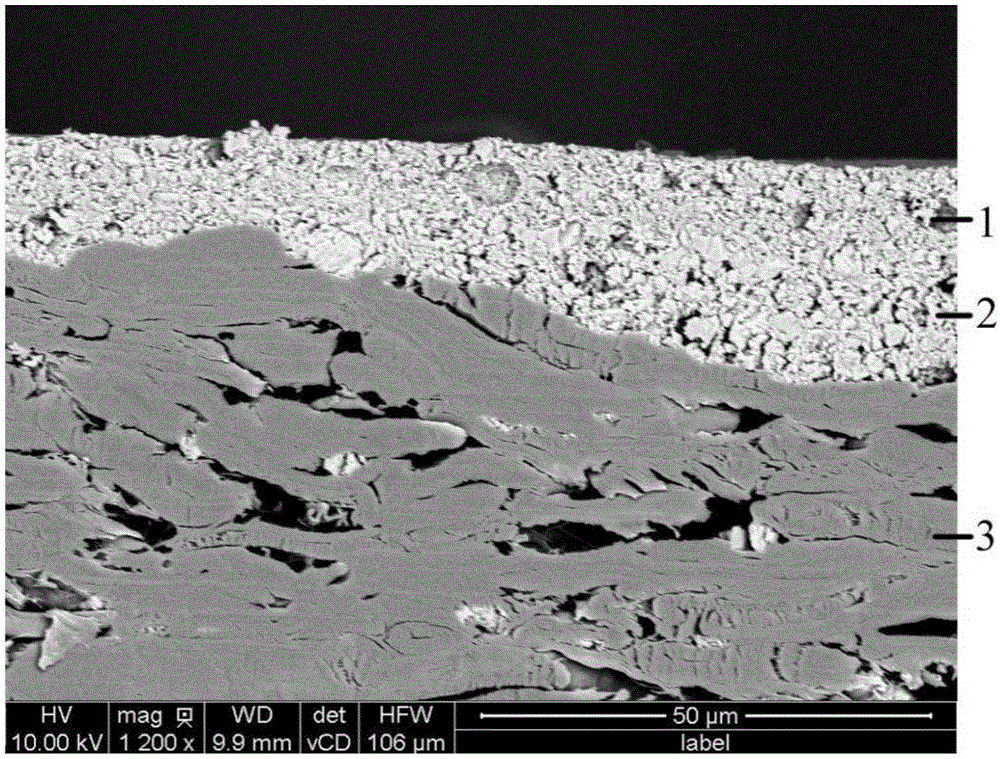

[0030] Function in this example embodiment, coated white cardboard thickness is 0.3mm, and cardboard surface is double-layer calcium carbonate coating, and the scanning electron microscope sample preparation method of its fracture is as follows:

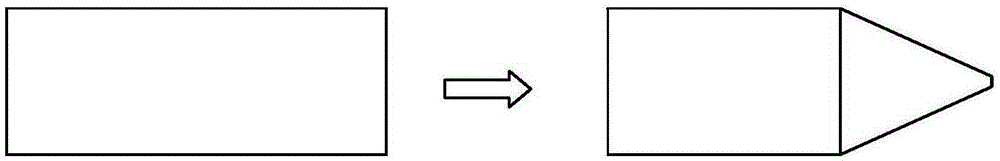

[0031] (1) if figure 1 As shown, use scissors to cut the coated white cardboard into a strip sample with a width of 10mm and a length of 20mm, and then trim one end of the strip sample along the length direction into a pointed shape with a length of 5mm and a thickness of 0.3mm, and the width of the tip is 2mm;

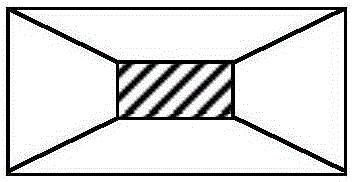

[0032] (2) Fix the tip of the sample upwards on the sample stage of a mechanical pusher ultramicrotome equipped with a microscope; adjust the magnification of the microscope to 4.6 times, and use a blade to modify the tip of the sample under the microscope, and trim the width of the tip to About 1mm; then adjust the magnification of the microscope to 20 times, continue to modify the tip with a blade, and finally trim the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com