Method and device for monitoring the quality, particularly the stiffness and the phase, of a hydroelastic joint

An elastic joint, hydro-elastic technology, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of not allowing to test the characteristics of hydraulic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

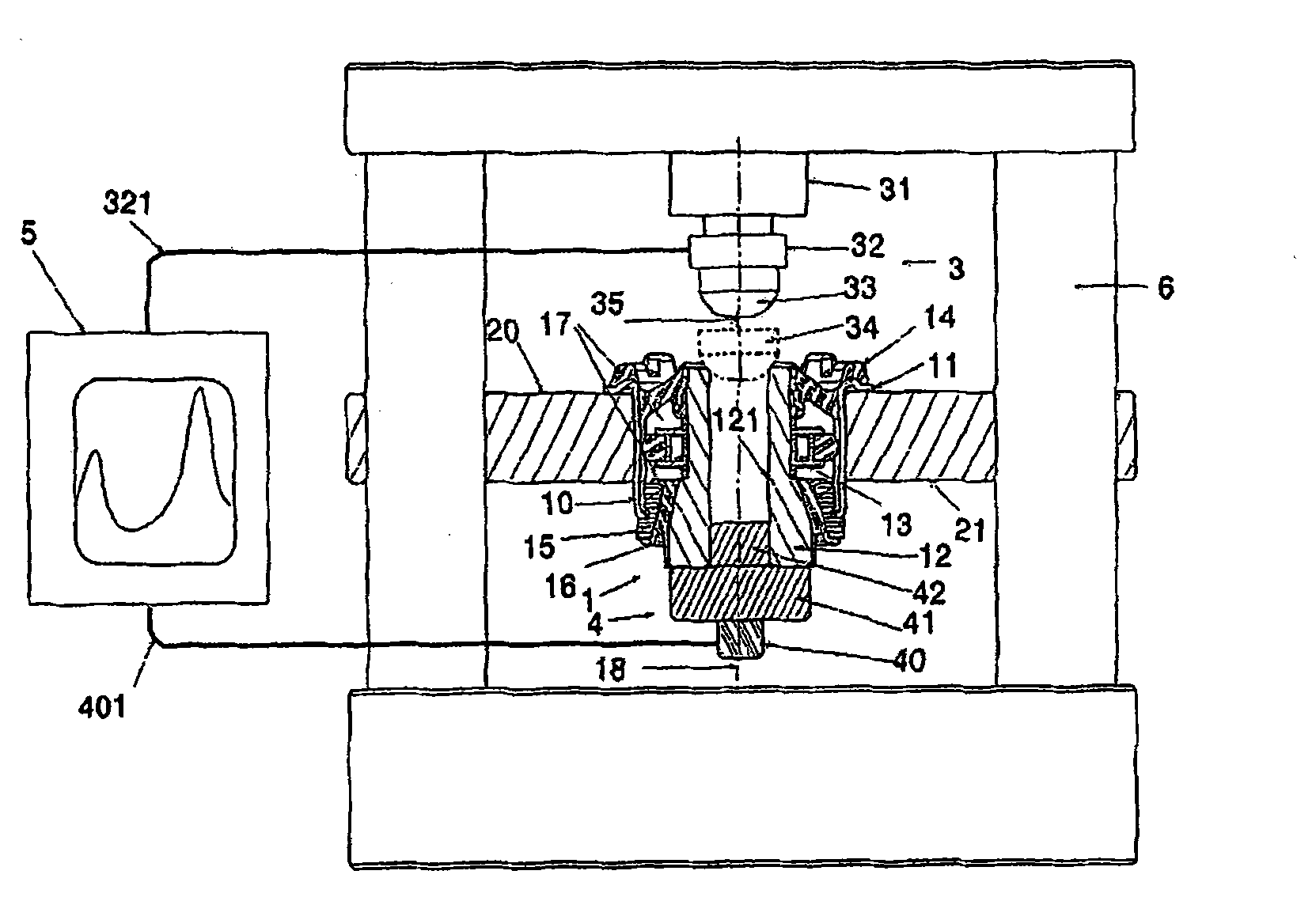

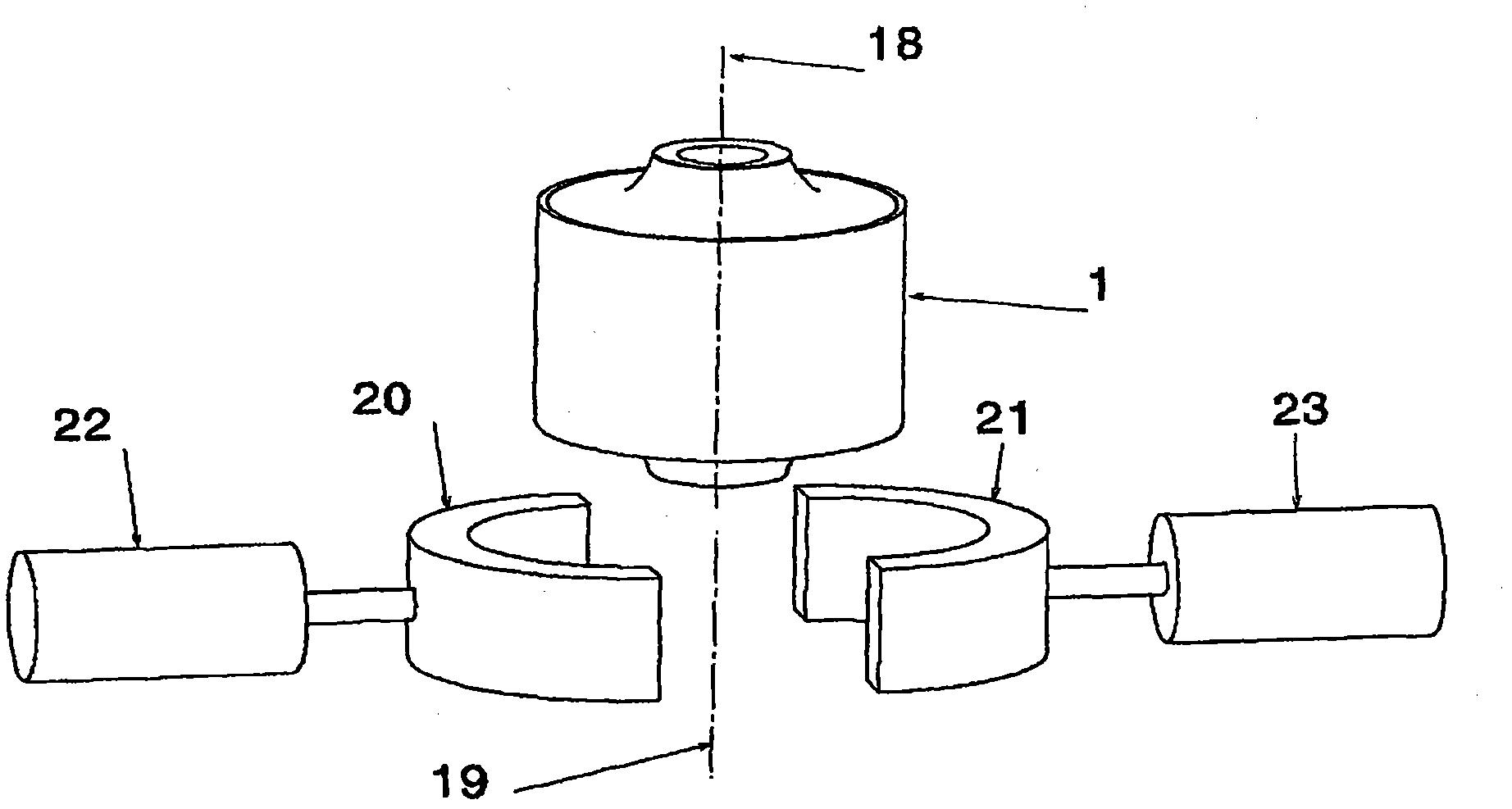

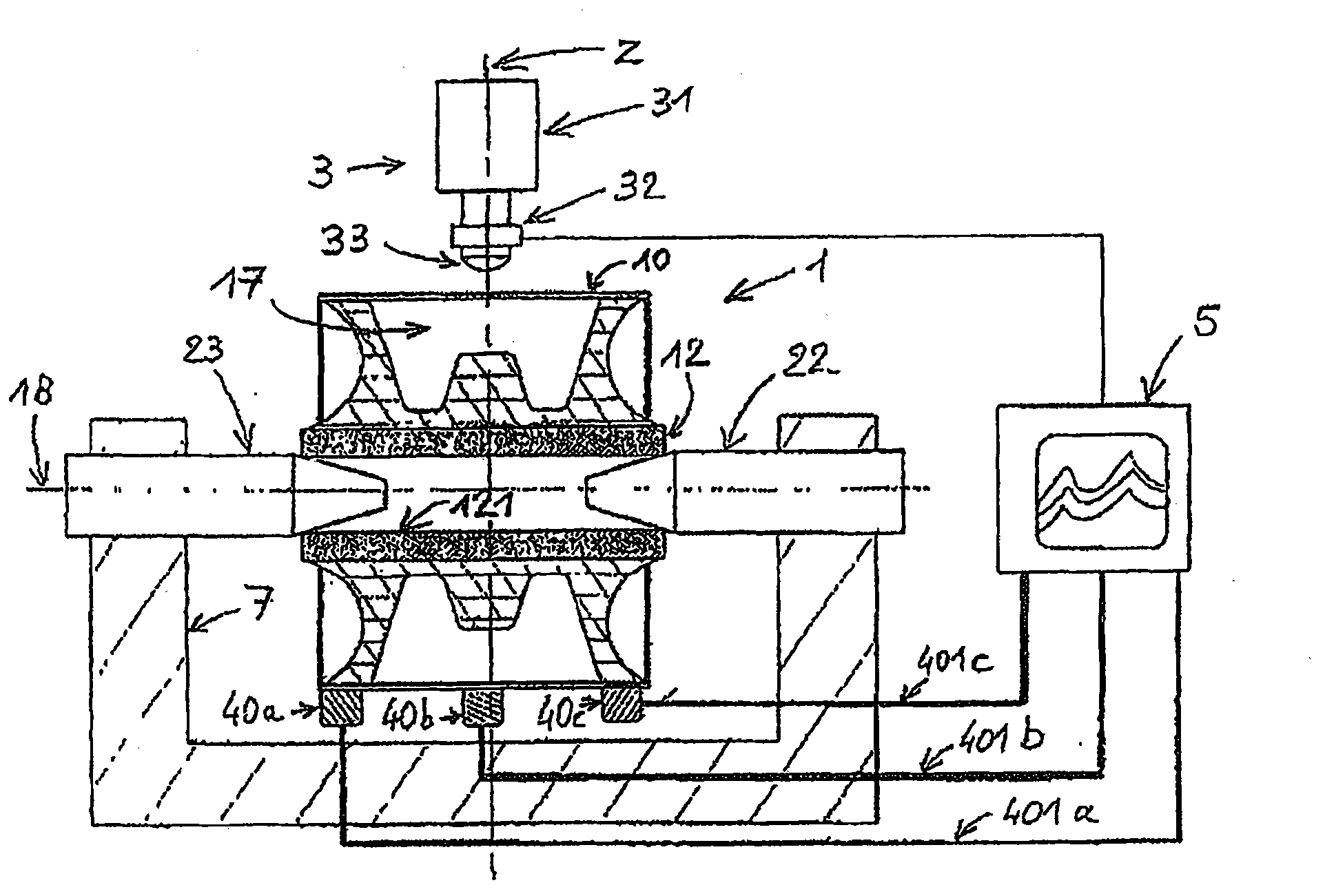

[0044] exist figure 1In it, a hydroelastic joint 1 comprises an outer cylindrical metal support element 10 with a collar 11 folded down, an inner support element 12 initially coaxial with the outer support element 10, a plastic spacer fitted on the inner support element 12 13. Several elastic sections 14, 15 and 16 machined to increase the viscosity and glued or fitted on one or the other support element, and two hydroelastic cavities 17. In the present exemplary embodiment, the elastic joint 1 has a theoretical working axis 18 which is likewise the axis of symmetry of the elastic joint. During the production cycle, this elastic joint is placed between two housings 20 and 21 which press the elastic joint on the outer support element 10 with a force sufficient to avoid any slipping of the elastic joint during impacts, while Permanent deformation thereof is also avoided. In this embodiment, the circular collar 11 of the outer support element 10 rests on the two half-shells 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com