A kind of pcb board soldering method

A technology of PCB board and welding method, which is applied in the field of PCB board processing technology, can solve the problems of wasting PCB board materials and low welding firmness, and achieve the effects of improving aesthetics, increasing tension, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Such as figure 1 As shown, a kind of PCB board welding method provided by the present invention comprises:

[0026] a. Move the PCB board from the anti-static bag into the metal plate through the removal device;

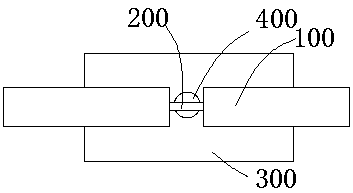

[0027] b. Completely peel off part of the sheath 100 on the wire;

[0028] c. Solder the stripped copper wire 200 on the pad 400 of the PCB 300 .

[0029] Among them, the surface temperature of the welding resistance during welding is lower than 60°C; the total current during welding is 15±1mA; the welding process uses no-cleaning non-conductive flux or no-cleaning non-conductive solder paste.

Embodiment 2

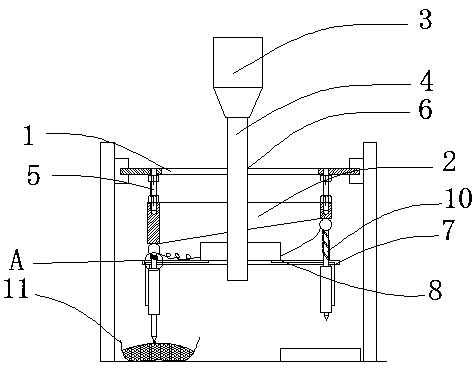

[0031] as attached figure 2 , attached image 3 And attached Figure 4 As shown, the present invention discloses a removal device, which includes an upper fixed plate 1, an arc-shaped cam 2 with an inclined slope, and a rotating shaft 4 connected to a driving motor 3 by transmission at the top, and the cam passes through the fixing member 5. Connect the upper fixing plate; the center of the upper fixing plate is provided with a central hole 6, the rotating shaft is inserted into the central hole, the bottom of the rotating shaft has a lower fixing plate 7, and the middle part of the lower fixing plate is provided with a battery 8; Six fixed sliding holes 9 are evenly installed on the upper circumference of the lower fixed plate; six transfer components 10 are arranged on the outer circumference of the rotating shaft, and an antistatic bag 11 is provided below the lowest point of the transfer component.

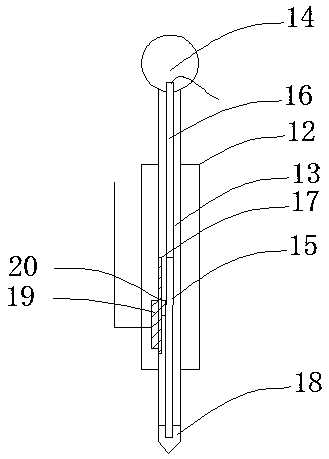

[0032] The removal assembly includes an outer sleeve 12 and a slide ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com