Composite microalloyed large-section non-quenched and tempered steel

A non-quenched and tempered steel, micro-alloying technology, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of affecting the quality of parts, oil fume pollution of the environment, consumption of quenching oil, etc., to improve fatigue strength, The effect of saving energy and improving the performance of the half shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

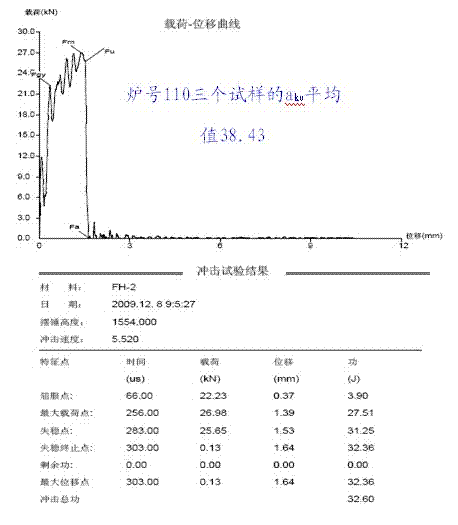

[0016] Embodiment, a large-section non-quenched and tempered steel with composite microalloying, its chemical composition is calculated by weight percentage: C 0.39, Si 0.30, Mn 1.20, P 0.014, S 0.008, Cr 0.50, Al 0.016, Ti 0.028, V 0.119, Nb 0.018, B 0.0012.

[0017] The bulldozer semi-shaft process that the above-mentioned embodiment material is made is as follows:

[0018] 100t EAF→100tLF→100t VD→CCM (340*300mm)→slow cooling or warm delivery→heating and rolling→controlled cooling→cutting→straightening→chamfering→inspection, grinding→packing and storage. The smelted steel is cast into a 340×300 mm continuous casting slab, and then forged and rolled. The heating temperature is 1180±20°C, the initial rolling temperature is 1100°C, the final rolling temperature is 900°C, and the cooling is controlled after rolling. The rolled product size is ?60mm, cooling rate 10℃ / s;

[0019] Round steel blanking→straightening→cutting—rolling or milling splines→induction hardening→cleaning, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com