Orthotropic steel bridge deck ductile concrete composite structure and construction method

A steel bridge deck and orthotropic technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as inability to coordinate force, poor coordinated deformation ability of orthotropic steel bridge decks, etc., to reduce the risk of fatigue cracking , strong shear resistance, and the effect of reducing weld fatigue cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

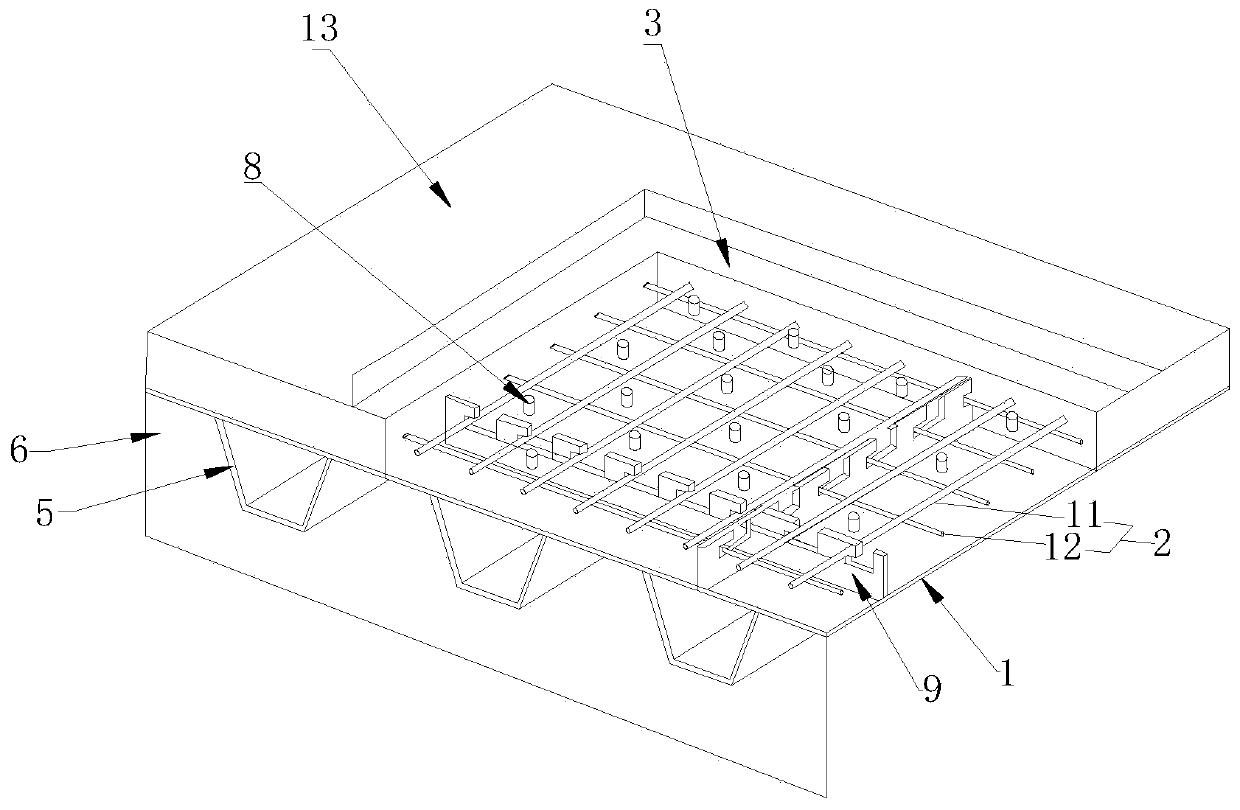

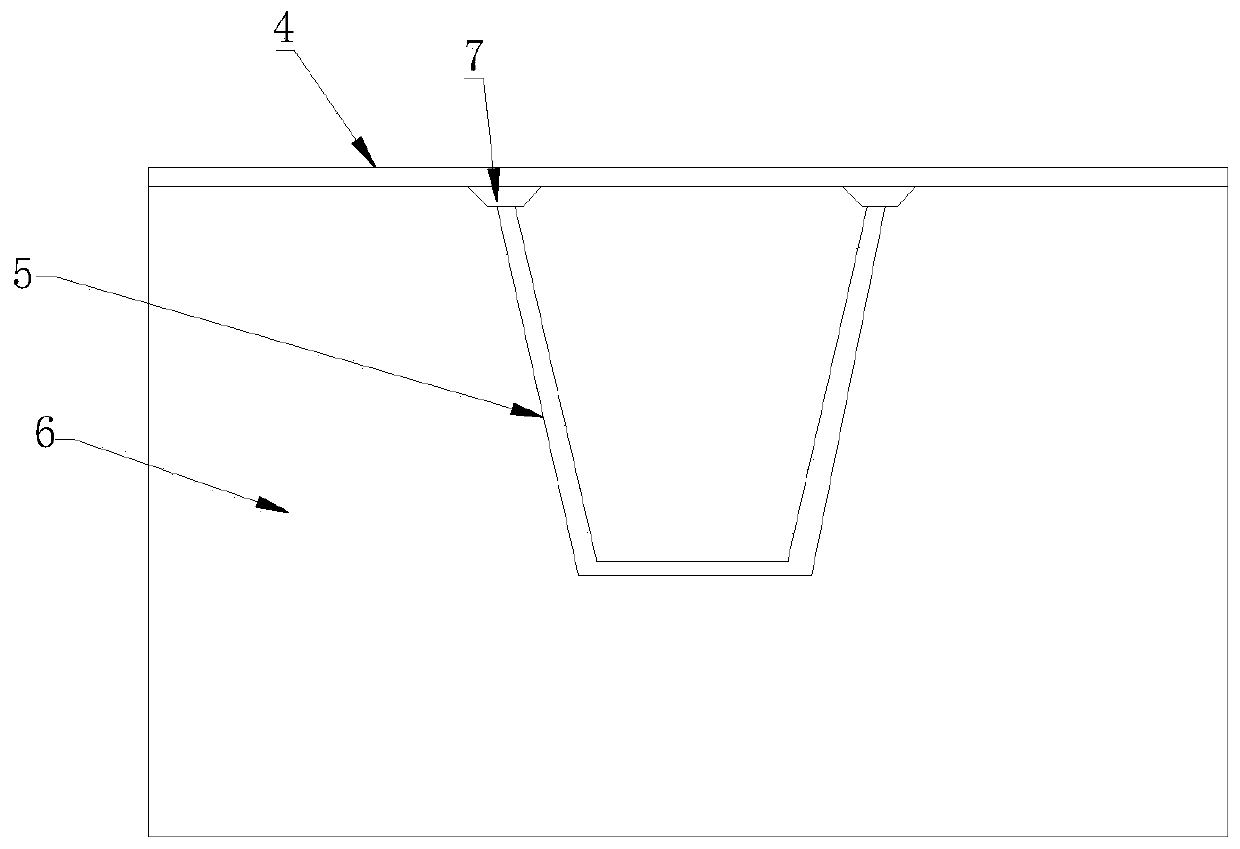

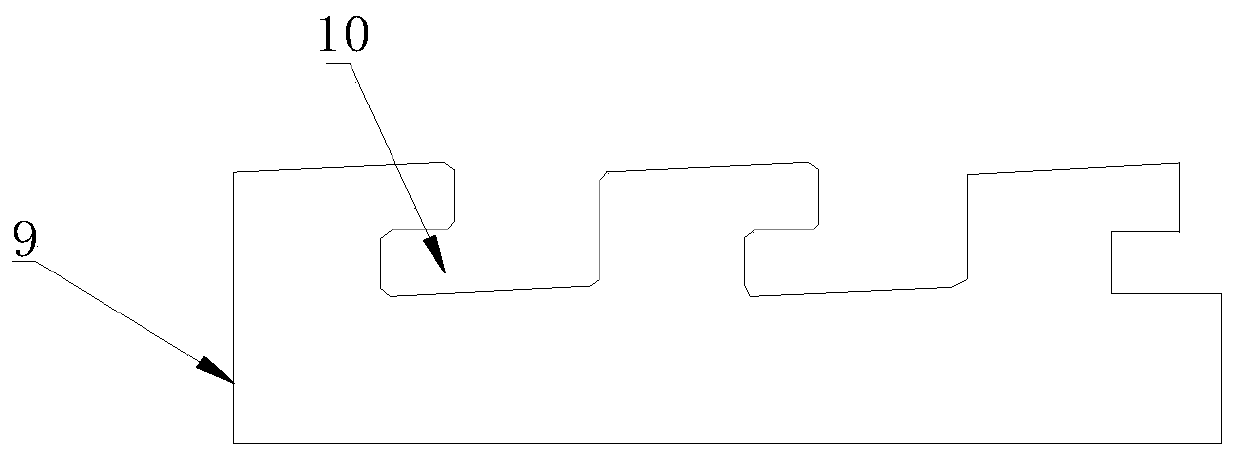

[0041] Embodiment 1: a kind of orthotropic steel deck ductile concrete composite structure, such as figure 1 , figure 2 with image 3 As shown, it includes an orthotropic steel bridge deck 1 , a grid mesh 2 and a ductile concrete layer 3 , and the grid mesh 2 is laid on the top of the orthotropic steel bridge deck 1 . The orthotropic steel bridge deck 1 is composed of a steel bridge deck 4, longitudinal rib members 5 and transverse rib members 6, the bottom of the steel bridge deck 4 is welded with a plurality of transversely spaced longitudinal ribs 7, and the longitudinal ribs 7 are integrated with the bottom of the steel bridge deck 4 Forming and rolling, the two sides of the longitudinal rib member 5 are fixedly welded to the bottom section of the longitudinal rib 7 . The top surface of the steel bridge deck 4 is fixedly welded with a plurality of shear studs 8 . The top surface of the steel bridge deck 4 is welded with a plurality of criss-cross vertical rib opening p...

Embodiment 2

[0057] Embodiment 2: a kind of construction method of orthotropic steel deck ductile concrete composite structure, such as Figure 4 shown, including the following steps:

[0058]S1. Prefabricate the orthotropic steel bridge deck 1 in stages in the factory, weld the shear nails in the factory, spray anti-rust paint, transport the orthotropic steel bridge deck 1 to the bridge site in sections, and lift the orthotropic steel bridge deck 1 by crane The steel bridge deck 1 is hoisted to the erected steel longitudinal girder for assembly, and adjusted accurately, then the orthotropic steel bridge deck 1 section assembly seam is welded, and then the spliced weld is not welded to the orthotropic steel bridge at the factory The shear nails on the surface of panel 1 are welded on site, and the rust is removed on site, and the anti-rust paint is sprayed for anti-rust treatment. The cleanliness of rust removal reaches Sa2.5 level, and the roughness reaches 80-120 μm.

[0059] S2. Lay ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com