Weld bead residual stress eliminating device and method

A residual stress and weld bead technology, applied in the field of weld bead residual stress elimination devices, can solve the problems of high operating intensity, hidden dangers of equipment safety, and inability to completely eliminate residual stress, and achieve the effect of ensuring fatigue strength and improving welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

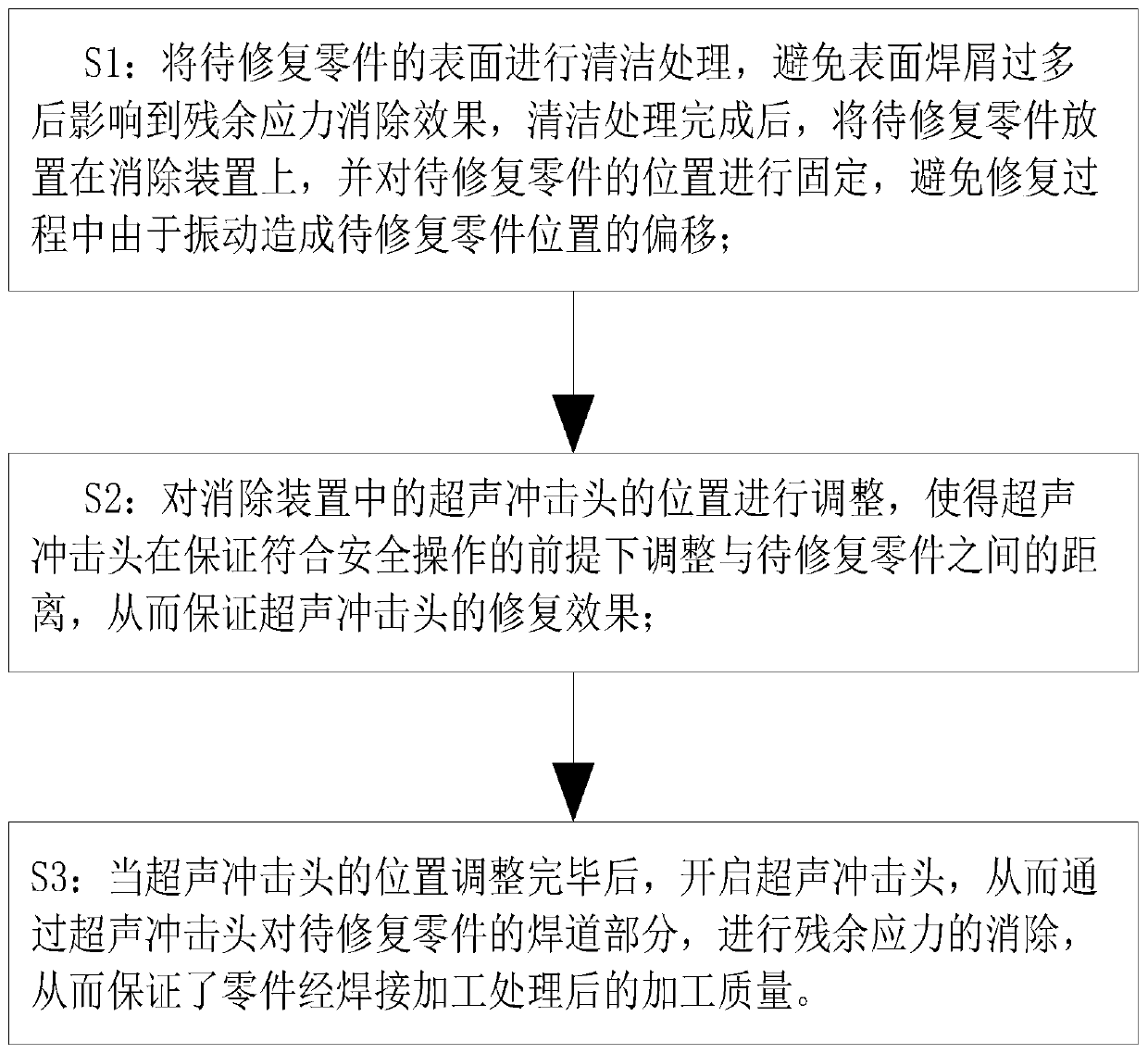

Method used

Image

Examples

Embodiment approach

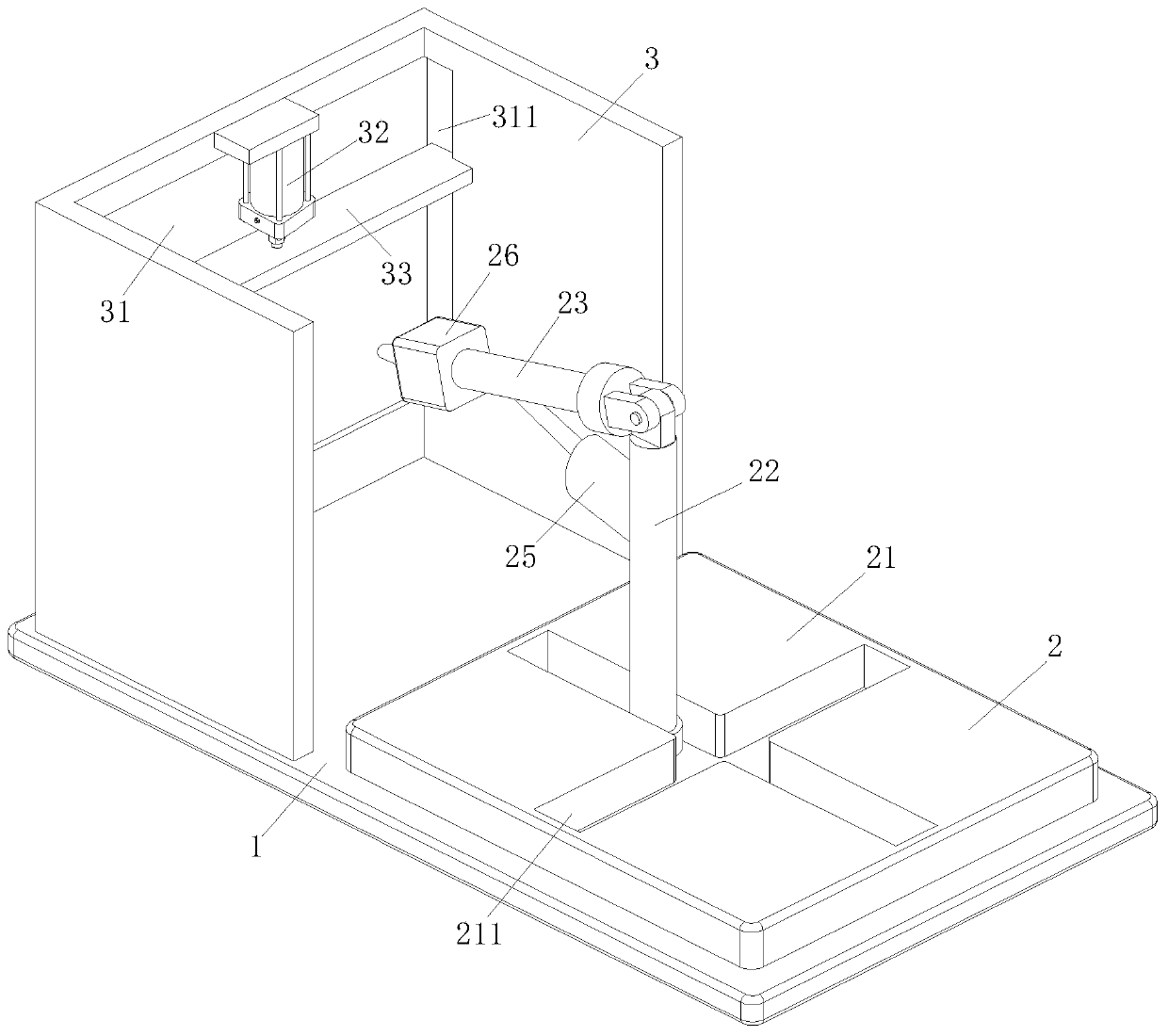

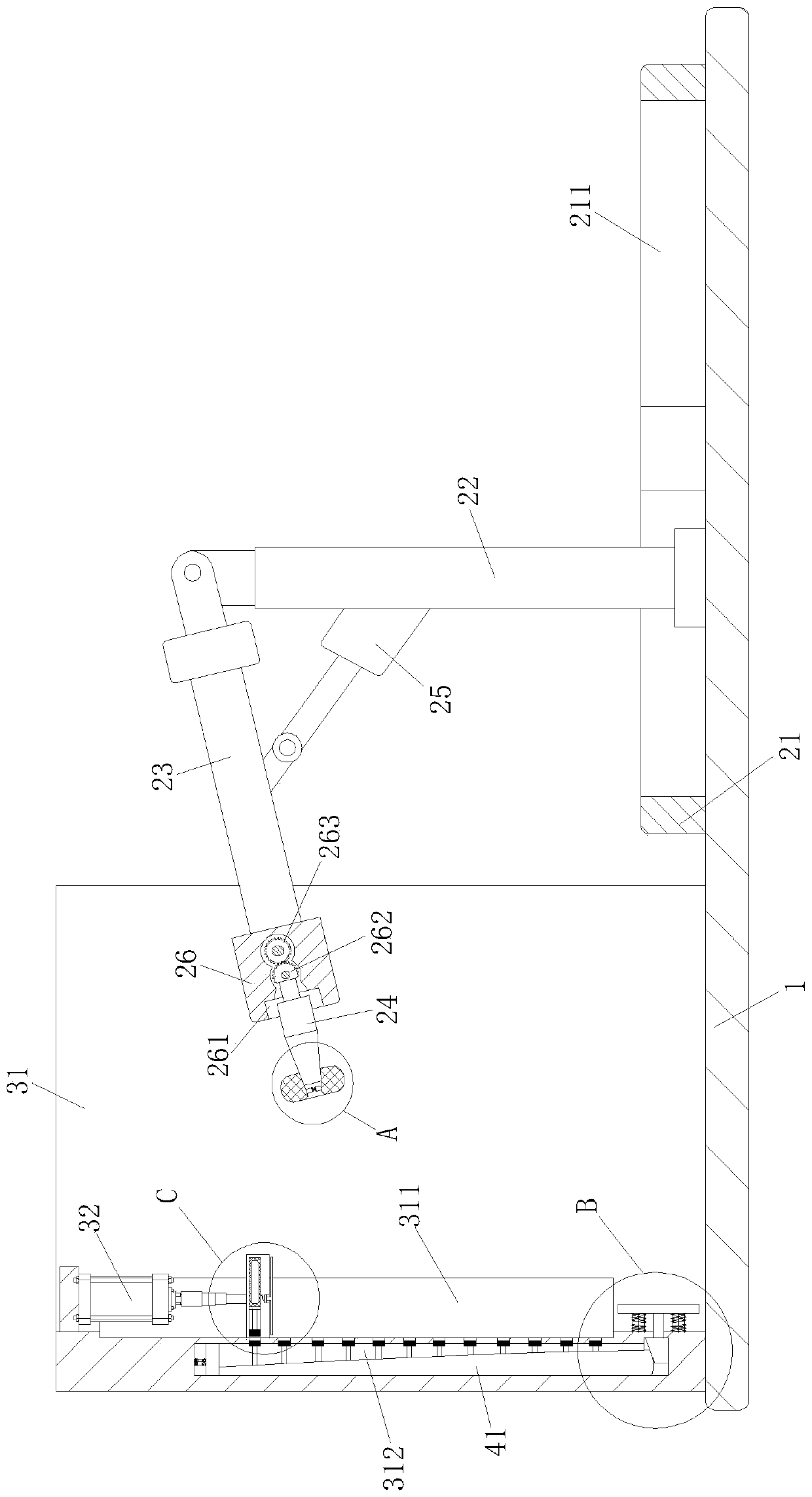

[0029] As an embodiment of the present invention, the fixed plate 31 is provided with a second cavity 312, and the fixed plate 31 is provided with an elastic plate 313 through a spring on the side wall close to the base 1; the side wall of the elastic plate 313 A trapezoidal slider 314 is provided, and the trapezoidal slider 314 penetrates into the second cavity 312 and can slide in the second cavity 312; the second cavity 312 is provided with a fastening unit 4; the fastening Unit 4 includes an arc plate 41 and a No. 1 magnet 42; the arc plate 41 is slidably connected in the second cavity 312, and the bottom end of the arc plate 41 is always in contact with the side wall of the trapezoidal slider 314; the No. The number of magnet 42 is multiple, and No. 1 magnet 42 is slidably connected on the side wall of No. 2 cavity 312, and the tail end of No. 1 magnet 42 contacts with arc plate 41 side walls all the time; There is a No. 3 cavity 331, and a No. 2 chute 332 is opened on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com