Process for manufacturing high-strength bolt

A technology of high-strength bolts and manufacturing technology, applied in the field of bolt manufacturing technology, can solve problems such as bolt longitudinal fatigue, achieve consistent tensile strength, high mechanical and physical properties, and improve the effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

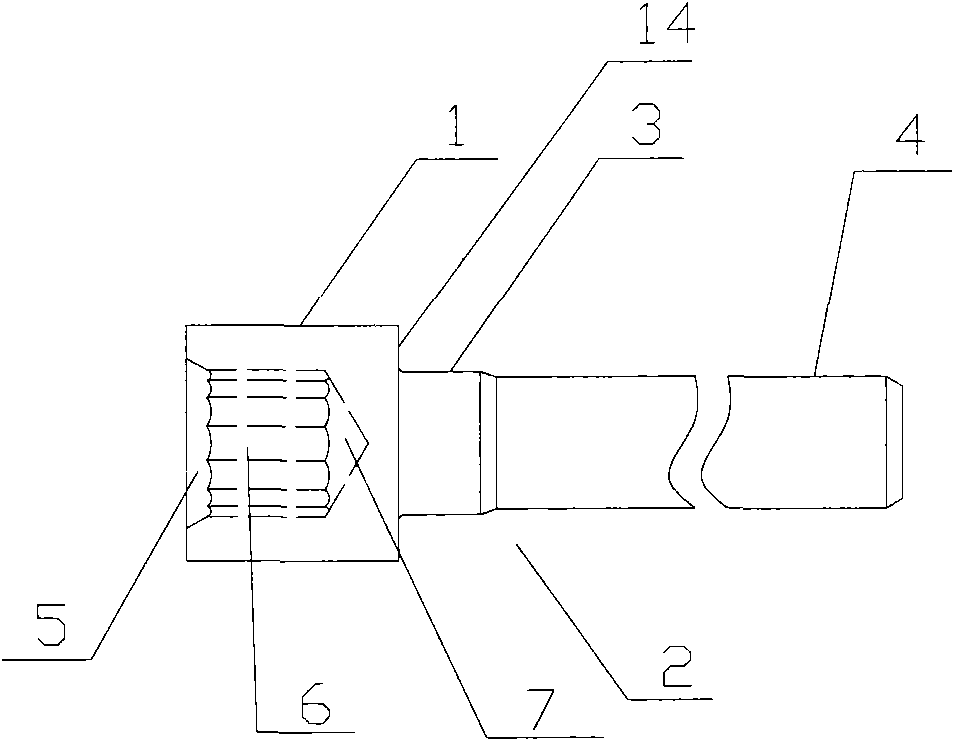

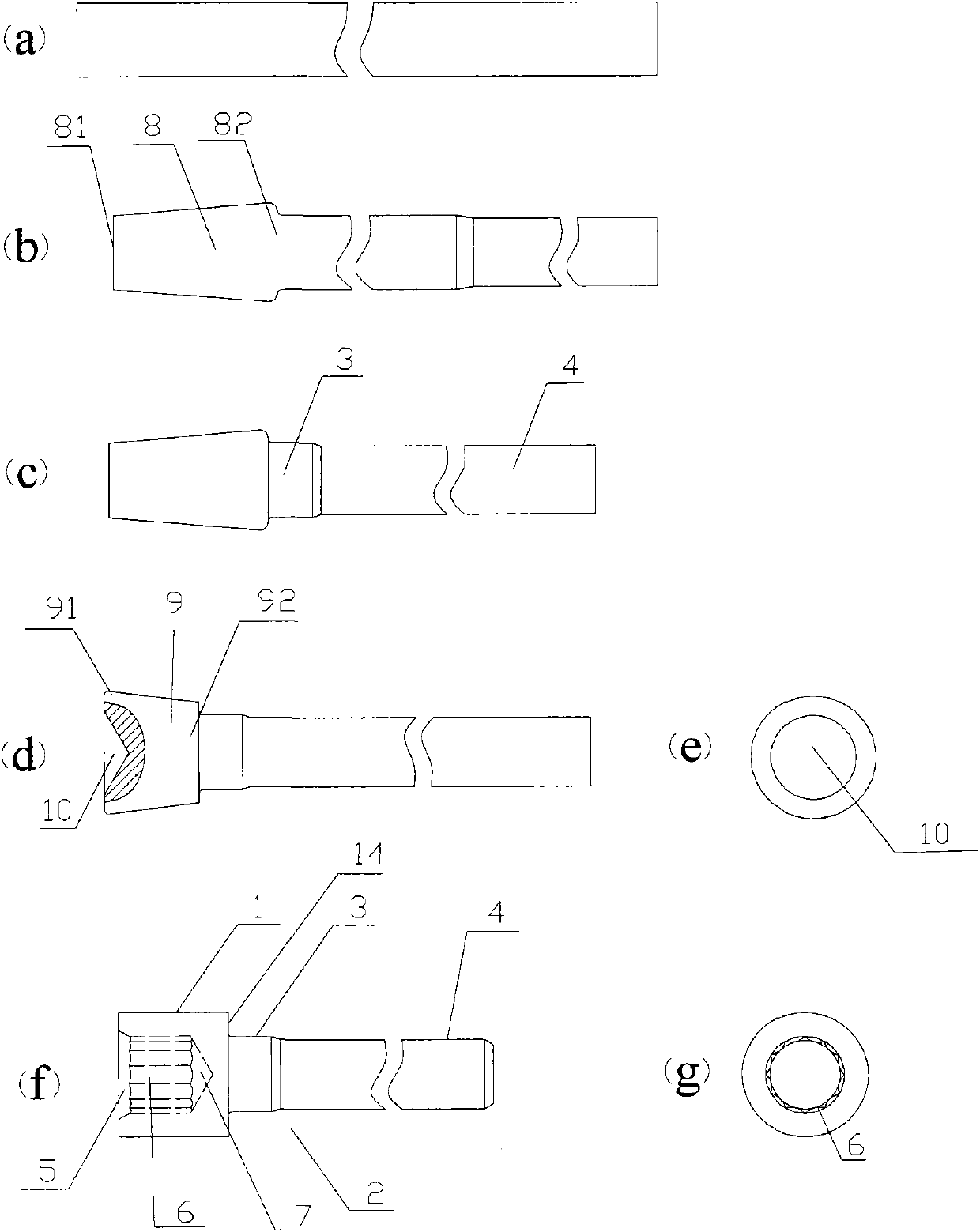

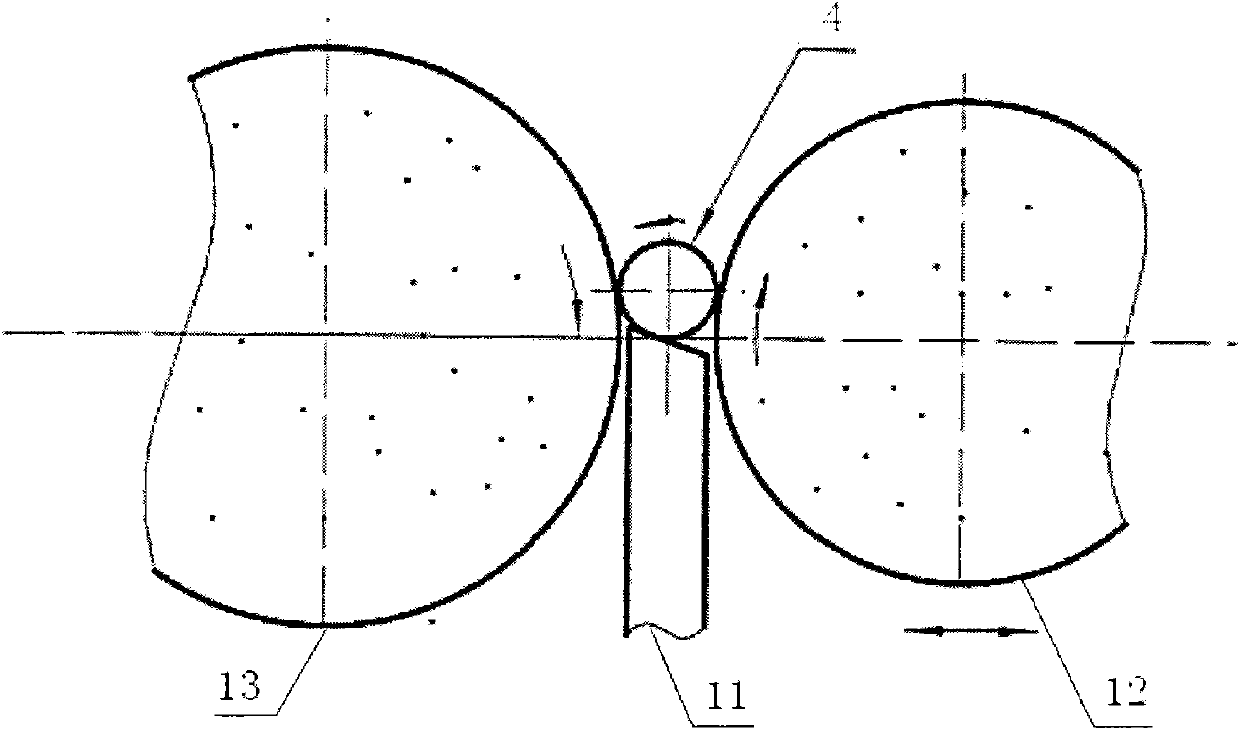

[0034] figure 1 , figure 2 It is a specific embodiment of the manufacturing process of the high-strength bolts described in the present invention. Taking the production of a bolt used for the cylinder head of an automobile engine as an example, the bolt includes a bolt head 1 and a stem 2, and the stem The length of the part 2 is about 102 mm, including a guide neck 3 with a length of about 5 mm and a screw 4 with a diameter of 97 mm. The guide neck 3 is a cylinder with a diameter of about 9.6 mm, and the screw 4 is a cylinder with a diameter of about 8.4 mm. The bolt head The part 1 is cylindrical, with a diameter of about 15mm and a length of 13.5mm. It has an open cavity built in. The cavity is from the outer surface of the bolt head 1 to the inner 12-point flower-shaped chamfer, and the inner 12 Corner flower-shaped cylinder 6 and bottom cone 7, such as figure 1 shown. The manufacturing process steps of described bolt are as follows:

[0035] ①Choose the appropriate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com