Age-hardening steel

A technology of age hardening and hardness, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of cutting resistance and poor tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

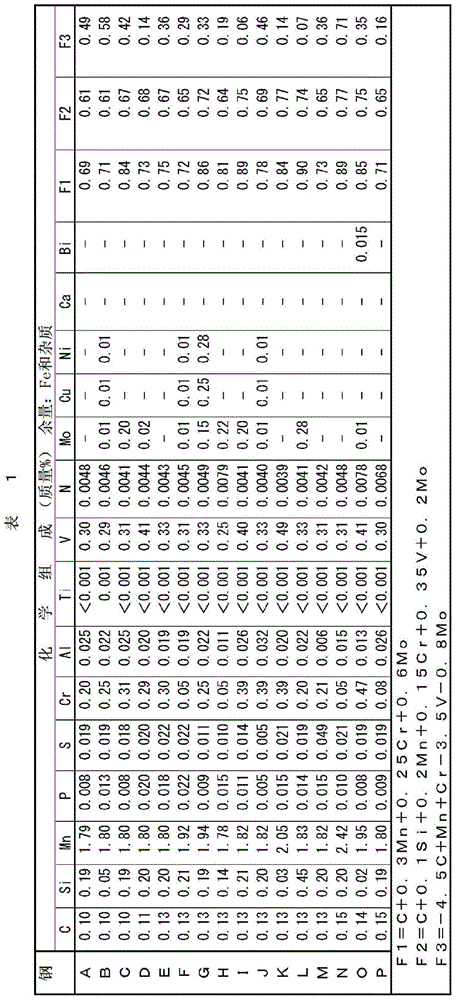

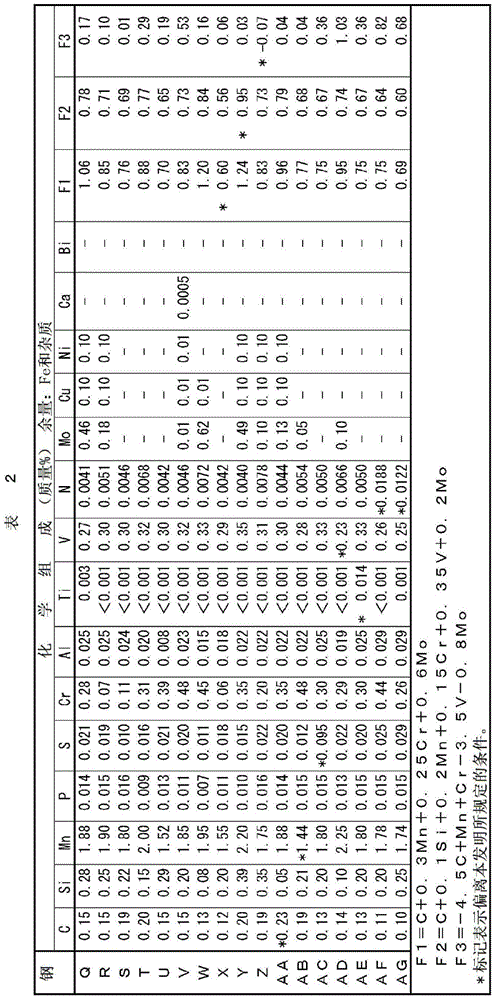

[0146] Steels A to AG having the chemical compositions shown in Table 1 and Table 2 were melted in a 50 kg vacuum melting furnace.

[0147]Steels A to W in Table 1 and Table 2 are steels whose chemical compositions are within the range specified by the present invention. On the other hand, steels X to AG in Table 2 are steels whose chemical compositions deviate from the conditions specified in the present invention.

[0148] It should be noted that "<0.001" in the column of Ti indicates that the content of Ti as an impurity is less than 0.001%.

[0149] [Table 1]

[0150]

[0151] [Table 2]

[0152]

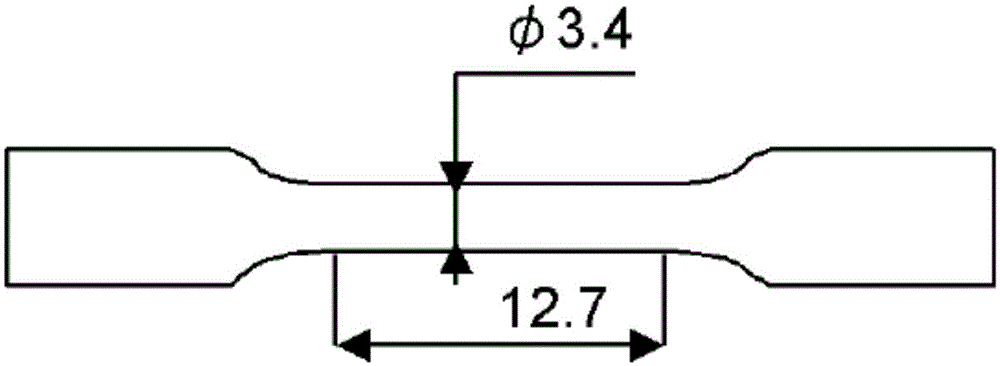

[0153] The ingots of the respective steels were heated at 1250° C., and then hot forged into steel bars with a diameter of 60 mm. Each hot-forged steel bar was left to cool in the atmosphere and cooled to room temperature. Then, it was further heated to 1250°C for 30 minutes, assumed to be forged into a part shape, and the surface temperature of the forged material at t...

Embodiment 2

[0177] A part of steel bars with a diameter of 60 mm of steel P and steel Y produced in Example 1 by hot forging and cooling to room temperature were cut out. The cut steel bar was further heated to 1250°C for 30 minutes, and was forged into a component shape assuming that the surface temperature of the forged material during finishing was 950-1100°C, and hot forged into a steel bar with a diameter of 35mm. After the hot forging, it was cooled to a temperature of 400° C. or lower by letting it cool in the air, or using a blower and a liquid mist (mist) at various cooling rates.

[0178] With regard to each test number, the hardness before aging treatment was measured using a part of steel bars that were finished by hot forging to the above-mentioned diameter of 35 mm and then cooled to 400° C. or lower using a blower and a liquid sprayer. temperature, thereby cooling the room temperature.

[0179] On the other hand, with respect to each test number, aging treatment was perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com