Railway wagon swing bolster and side frame cooling and cleaning method and system

A railway freight car and a cleaning method technology, which is applied to the cooling and cleaning method and system field of the bolster side frame of the railway freight car, and can solve the problems of large site area required for cleaning castings, increased probability of safety accidents, and easy product quality problems. , to achieve the effect of reducing the labor intensity of workers, taking advantage of space advantages and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

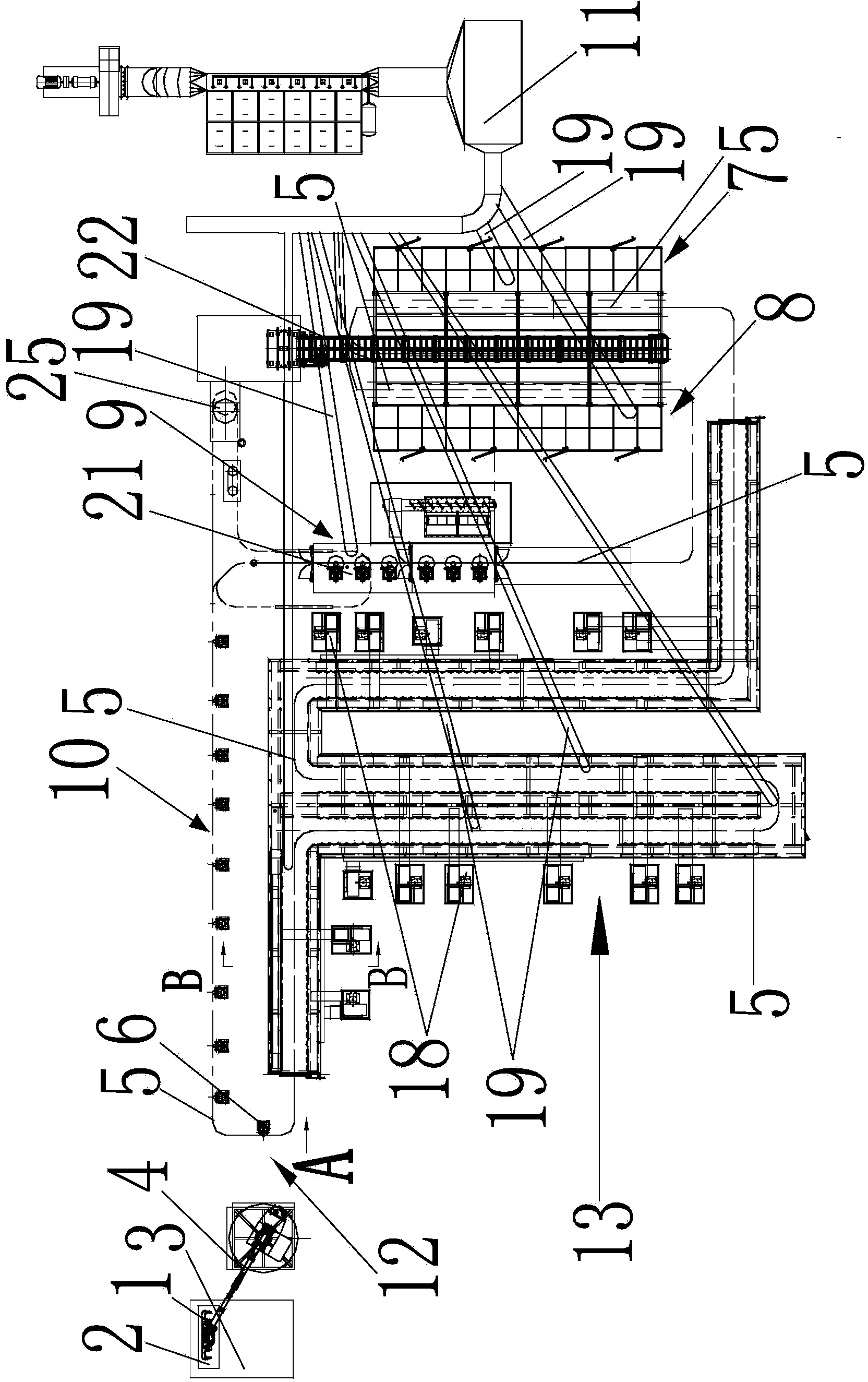

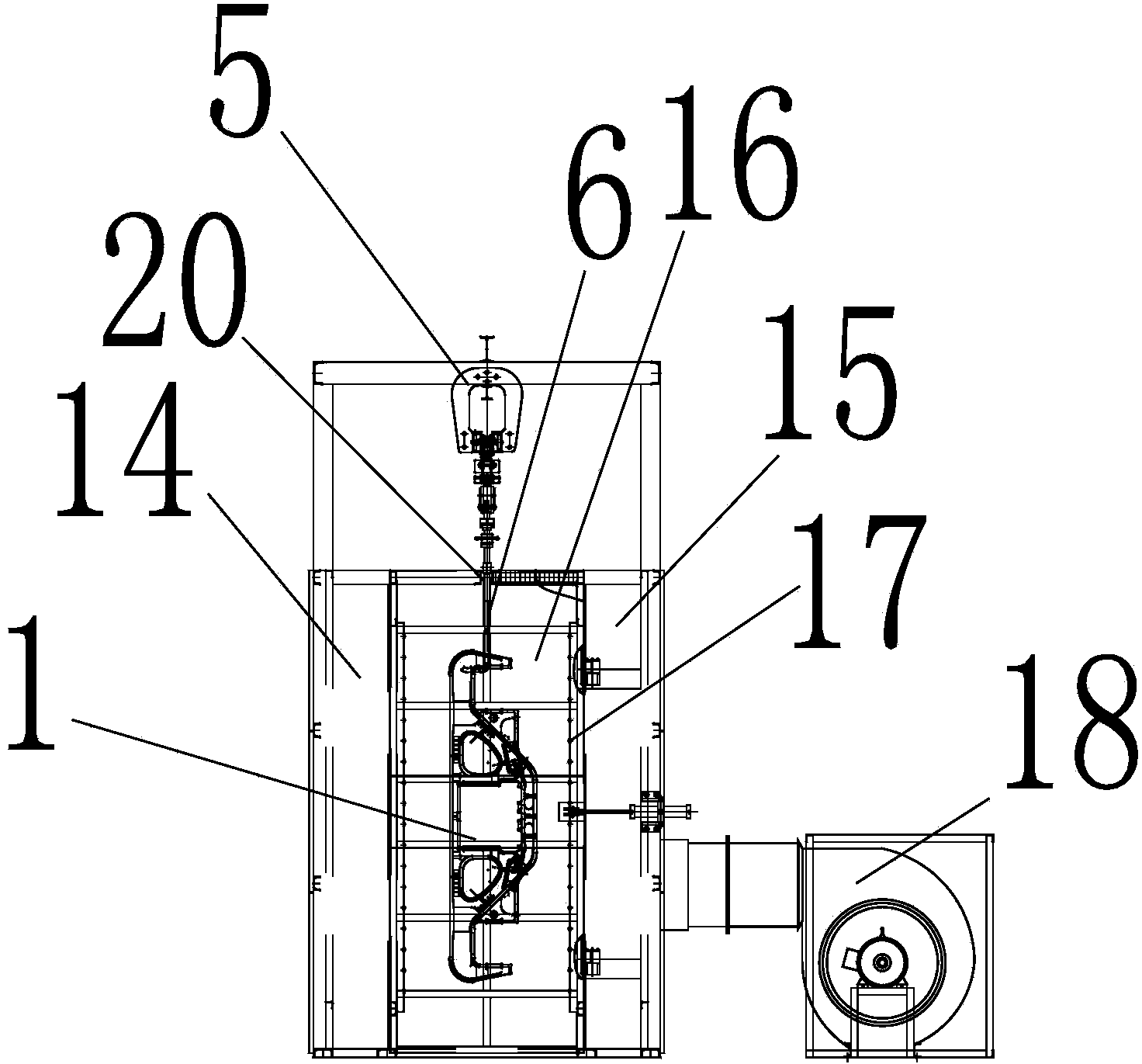

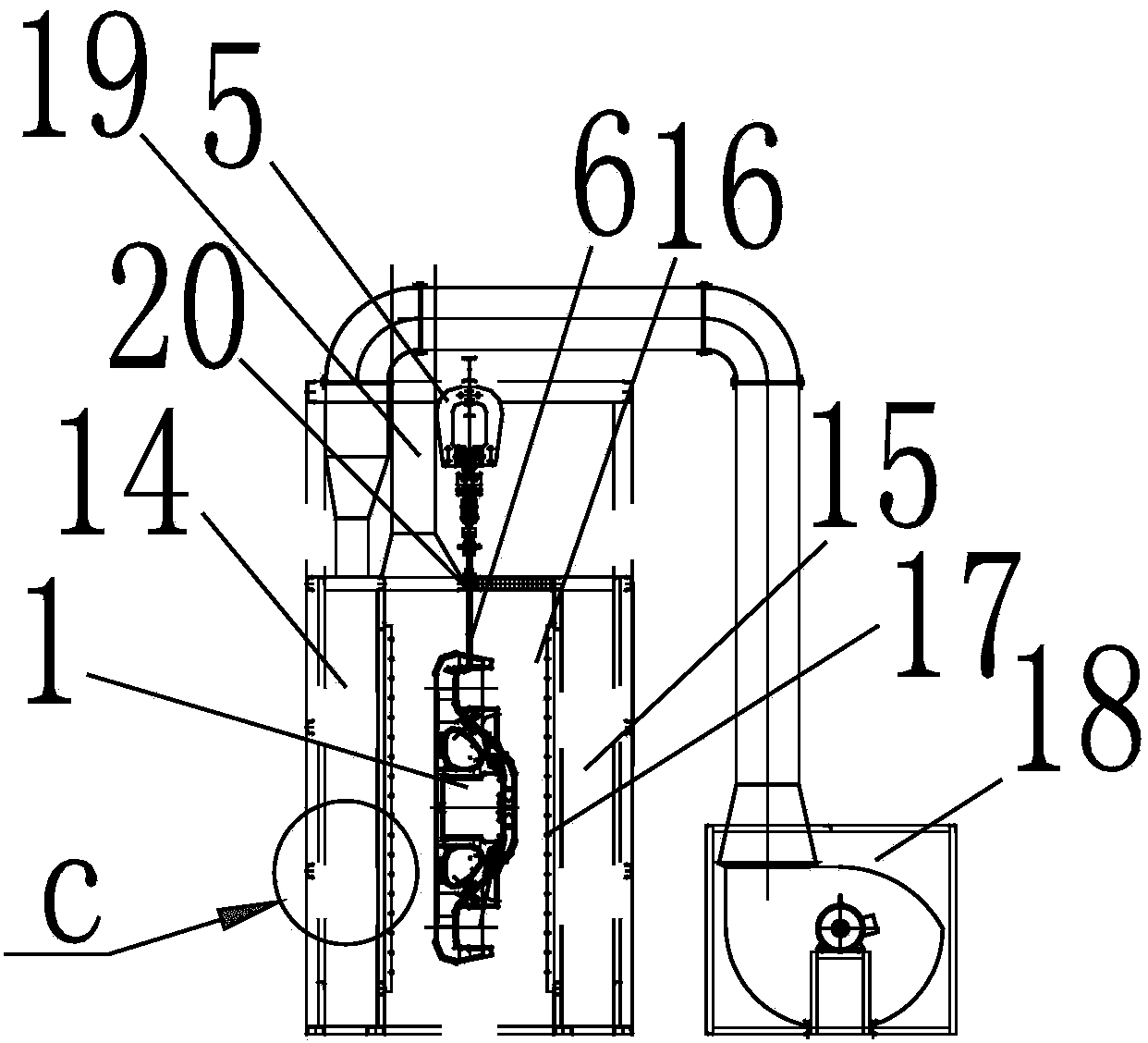

[0045] like Figure 1~5The shown truck bolster side frame cooling and cleaning system includes a platform 3, a manipulator 4, a dust removal device 11, a fan 18, and passes through a feeding area 12, a cooling area 13, a casting riser cutting area 7, and a casting defect cleaning area. 8. The accumulation type suspension chain 5 in the shot blasting area 9 and the off-line area 10 also includes an accumulation type suspension chain driver 25, wherein the hook 6 of the accumulation type suspension chain 5 is connected to the accumulation type suspension chain driver. Driven by 25, it can shuttle and move between the feeding area 12, the cooling area 13, the casting riser cutting area 7, the casting defect cleaning area 8, the shot blasting area 9 and the off-line area 10;

[0046] The manipulator 4 is used to transport the truck bolster side fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com