Distribution conveyor

A cloth conveying and conveyor belt technology, which is applied in the field of cloth conveyors, can solve the problems of restrained conveying efficiency, inconvenient operation, complicated operation, etc., and achieve the effects of improved site utilization, stable equipment operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

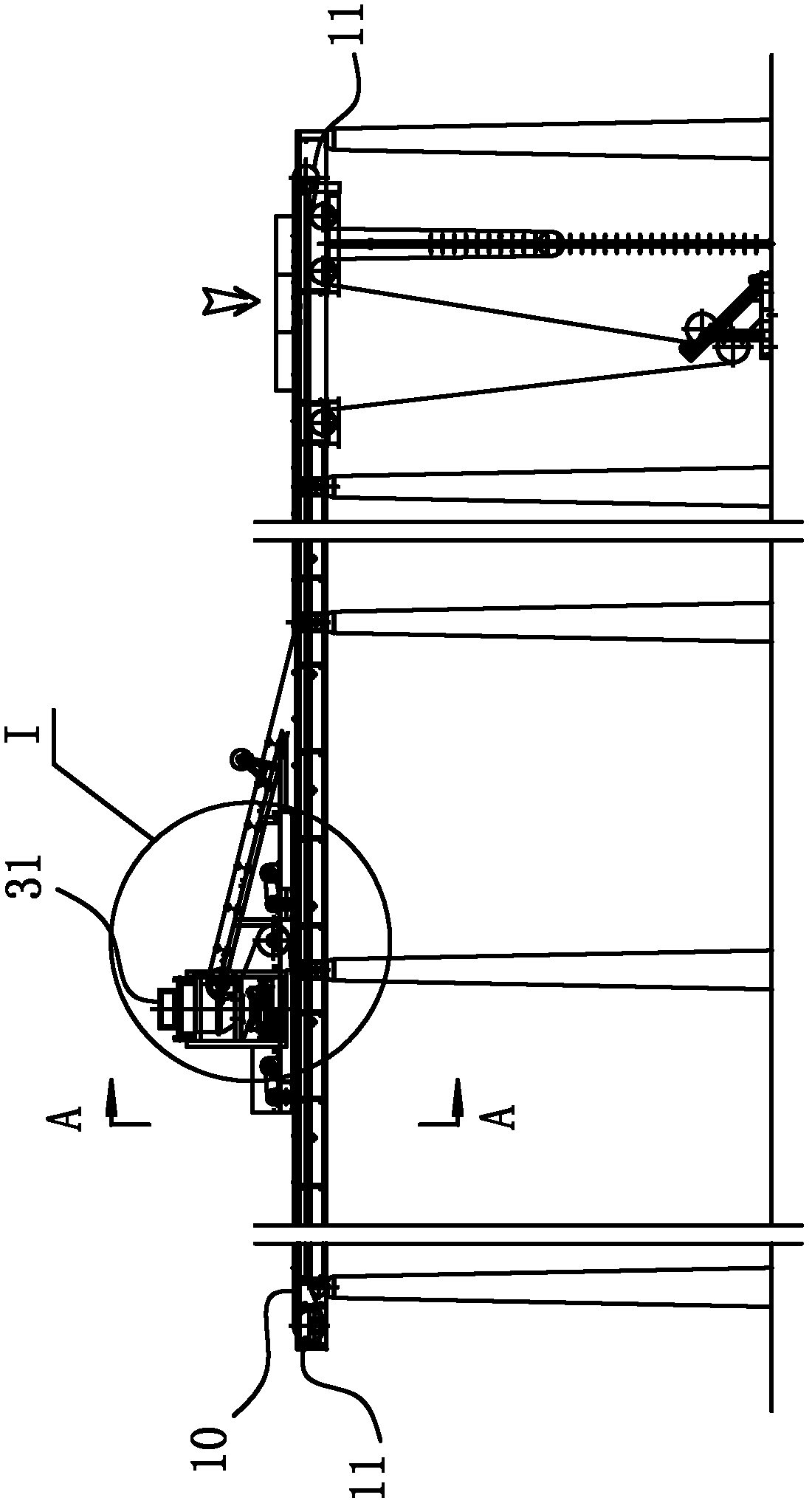

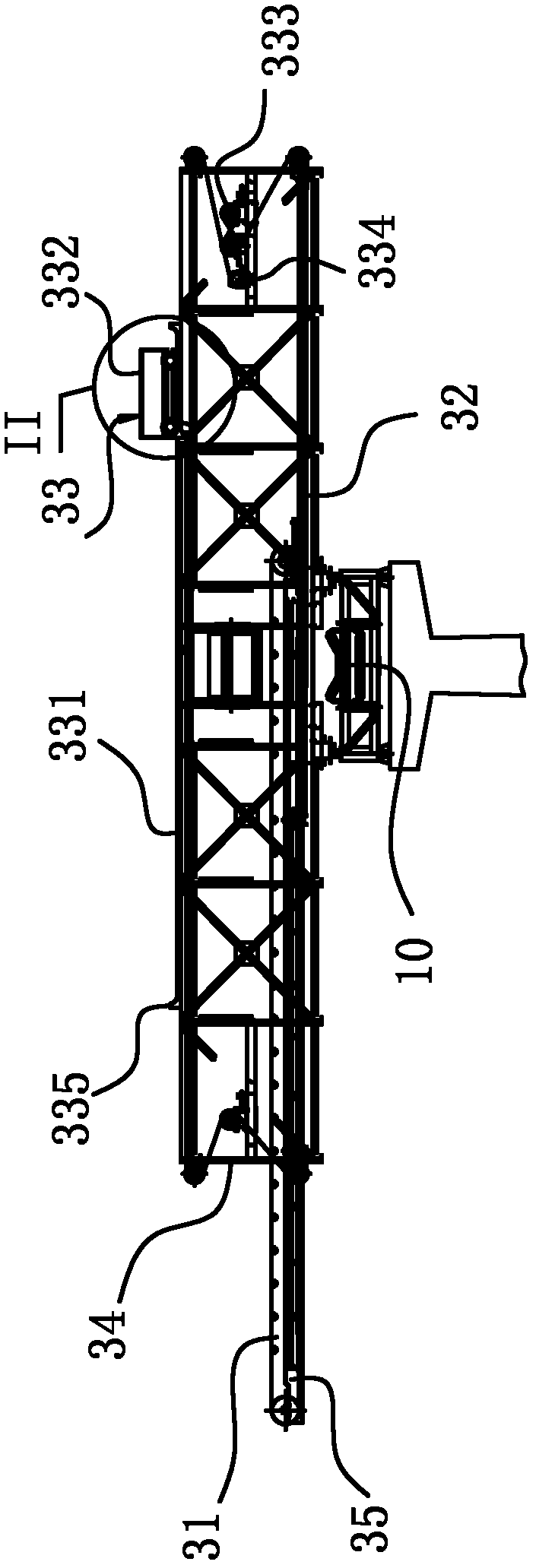

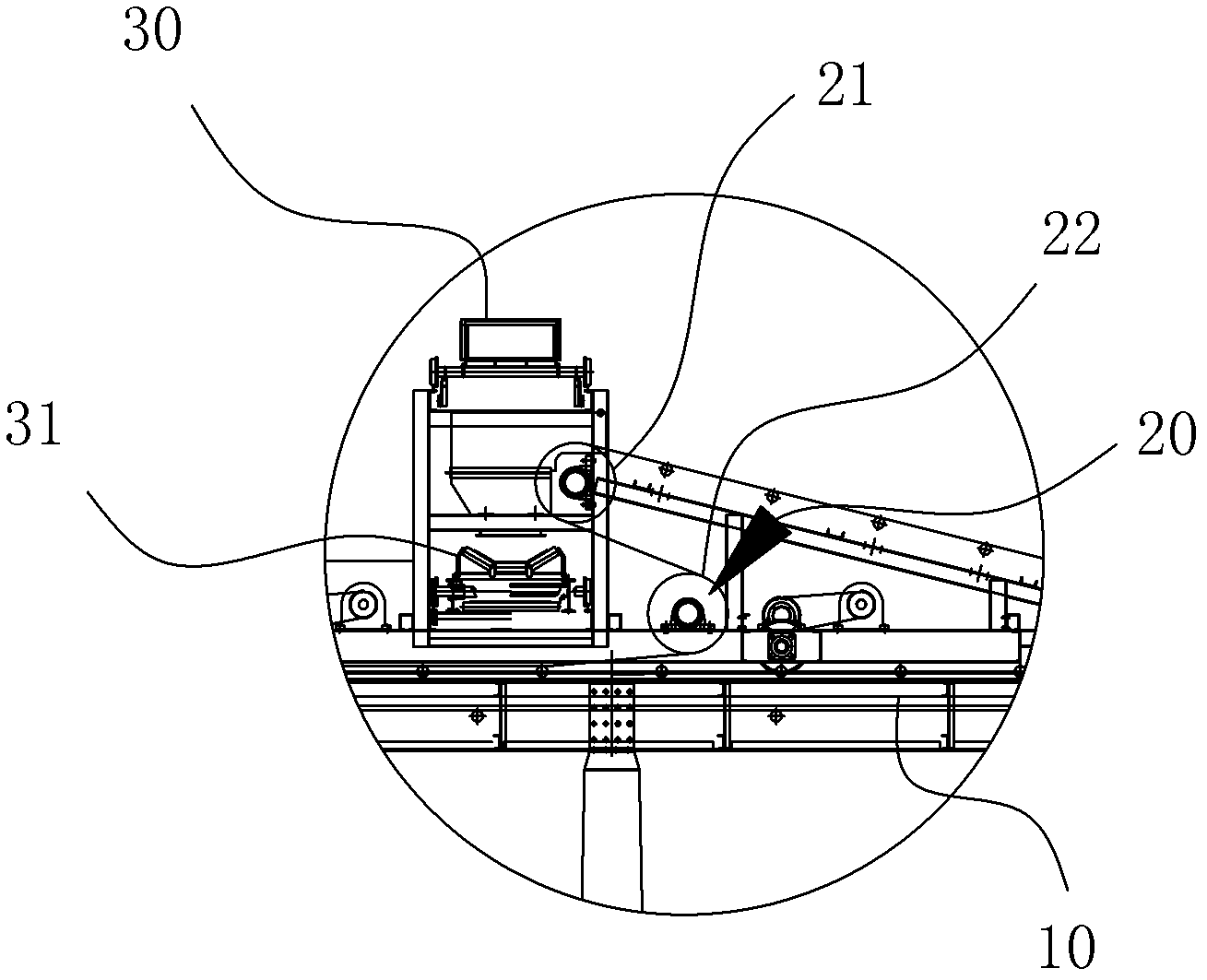

[0010] A cloth conveyor, comprising a first conveyor belt 10, the belt body between the guide rollers 11 at both ends constituting the first conveyor belt 10 is provided with a steering wheel that can make the belt body turn back obliquely upwards in a suspended state Roller 20, said first conveyor belt 10 is also erected with a driving device 30 that can reciprocate along the first conveyor belt 10, said driving device 30 is provided with an extension mechanism 31, and said extension mechanism 31 is for conveying Belt, the blanking point of the suspended belt body of the first conveyor belt 10 is always located above the belt body of the extension mechanism 31, such as Figure 1-3 shown.

[0011] Further, the turning rollers 20 are two and arranged in parallel, and the turning rollers 20 and the driving device 30 follow up, so as to realize the follow-up between the blanking point of the first conveyor belt 10 and the belt body of the extension mechanism 31 , so that the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com