Improved moving suspension device

A suspension device and mobile seat technology, applied in safety devices, transportation and packaging, load suspension components, etc., can solve the problems of damage to both ends of the track, heavy weight, too simple structure, etc., and achieve reasonable structural design and reduce impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

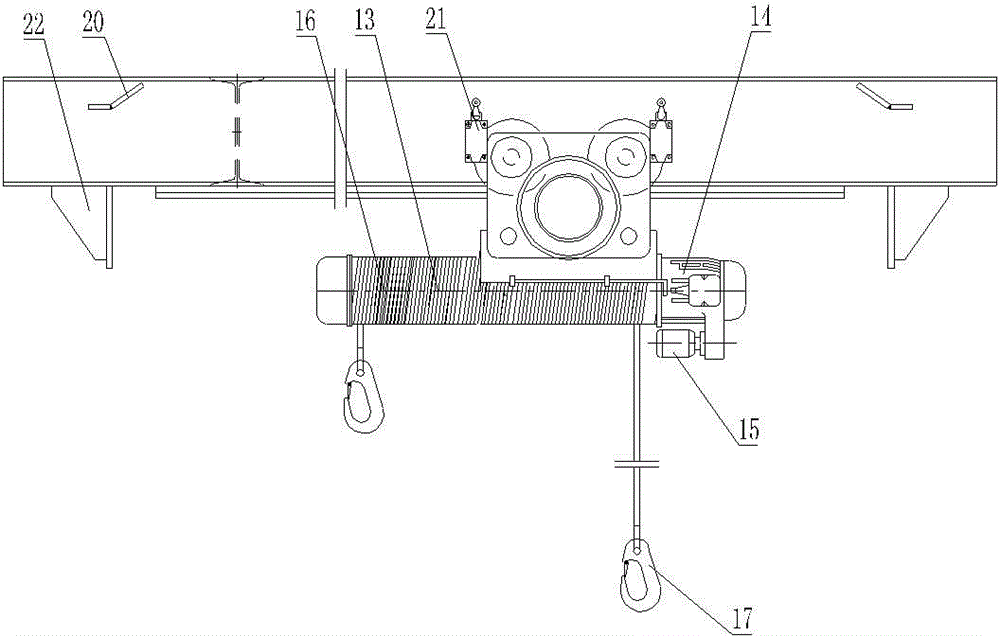

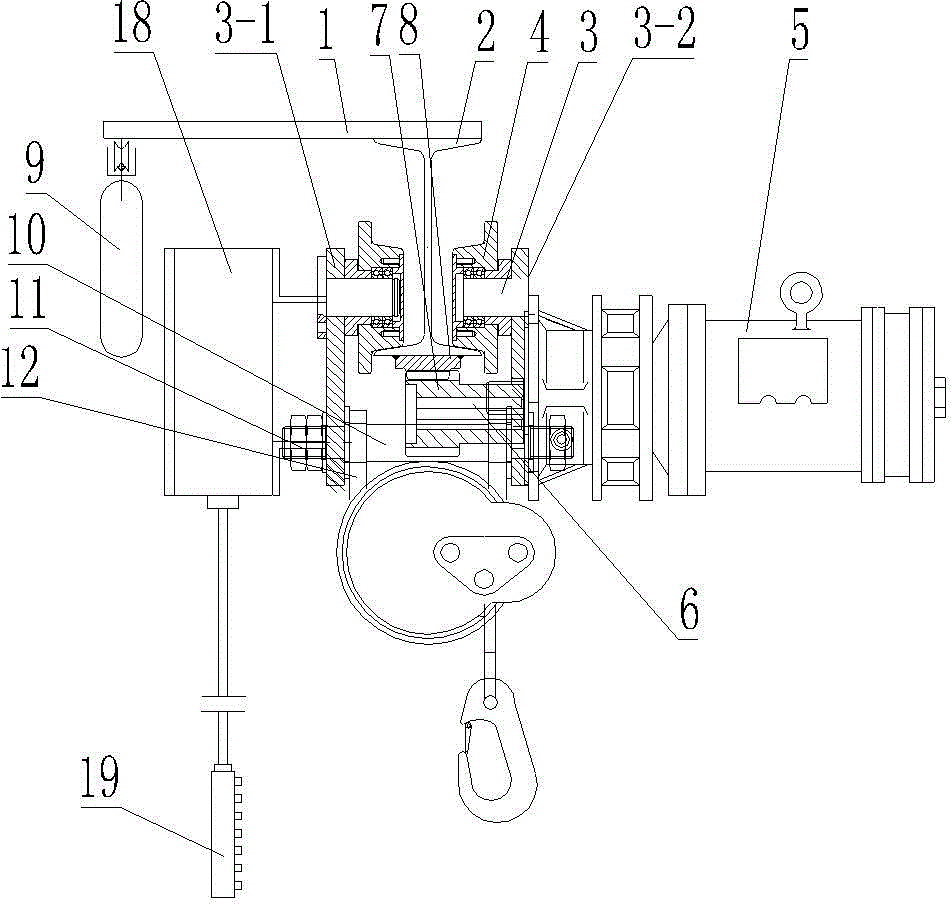

[0013] See figure 1 , figure 2 As shown, the improved mobile suspension device includes a top beam 1, one end of the top beam 1 is fixedly installed with an I-shaped steel track 2, a mobile seat 3 is hung on the I-shaped steel track 2, and rollers are respectively installed on both sides of the upper end of the mobile seat 3. 4. The rollers 4 on both sides are mounted on both sides of the I-steel track 2 respectively. The drive motor 5 is installed on one side of the moving seat 3. The motor shaft 6 of the drive motor 5 is equipped with a fixed gear 7, and the lower end of the I-steel track 2 is installed. The rack 8 meshed with the gear 7, the material suspension device is installed at the lower end of the moving seat 3, the suspension device includes a reel device 13 installed on the main shaft, a reducer 14 is installed on one end of the main shaft, and the reducer 14 is in phase with the suspension motor 15 connection, the reel device 13 is provided with a steel wire rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com