Oil-scrap separating and oil cooling centrifugal device

A technology of oil debris separation and centrifugal device, which is applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of high cost of oil debris separation, inability to efficiently and conveniently separate oil debris, etc., and achieve convenient transportation and recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

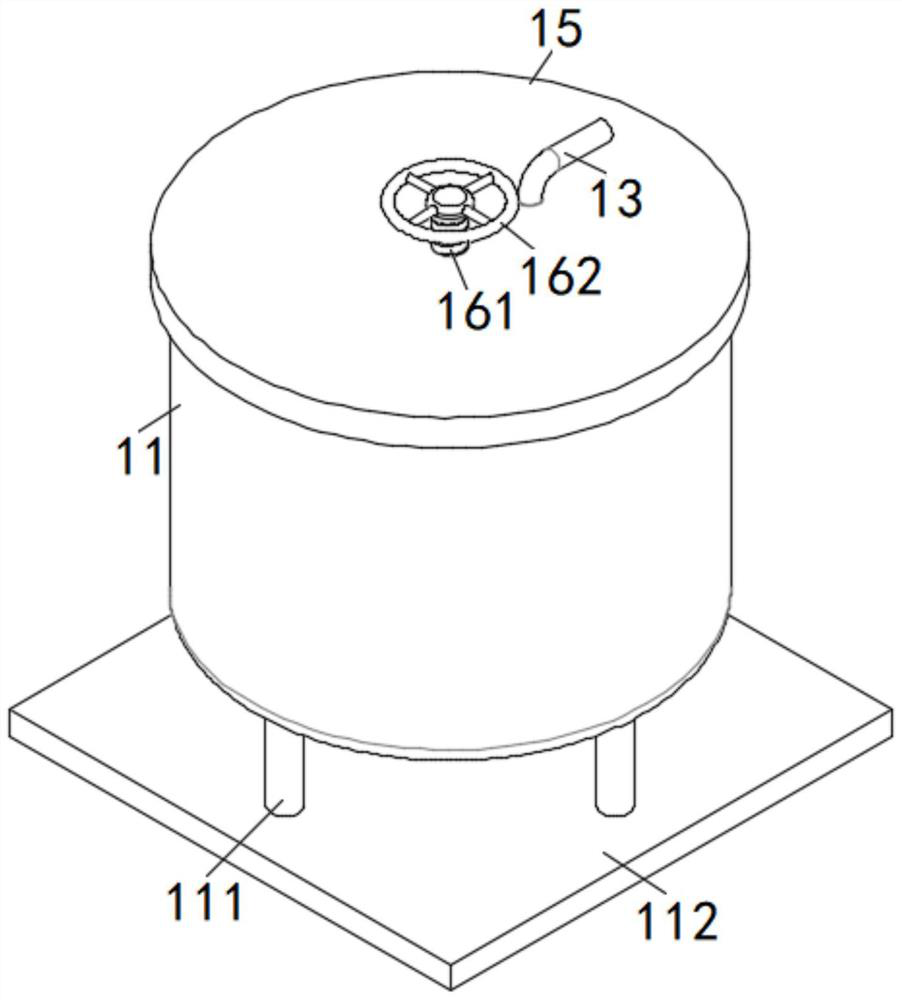

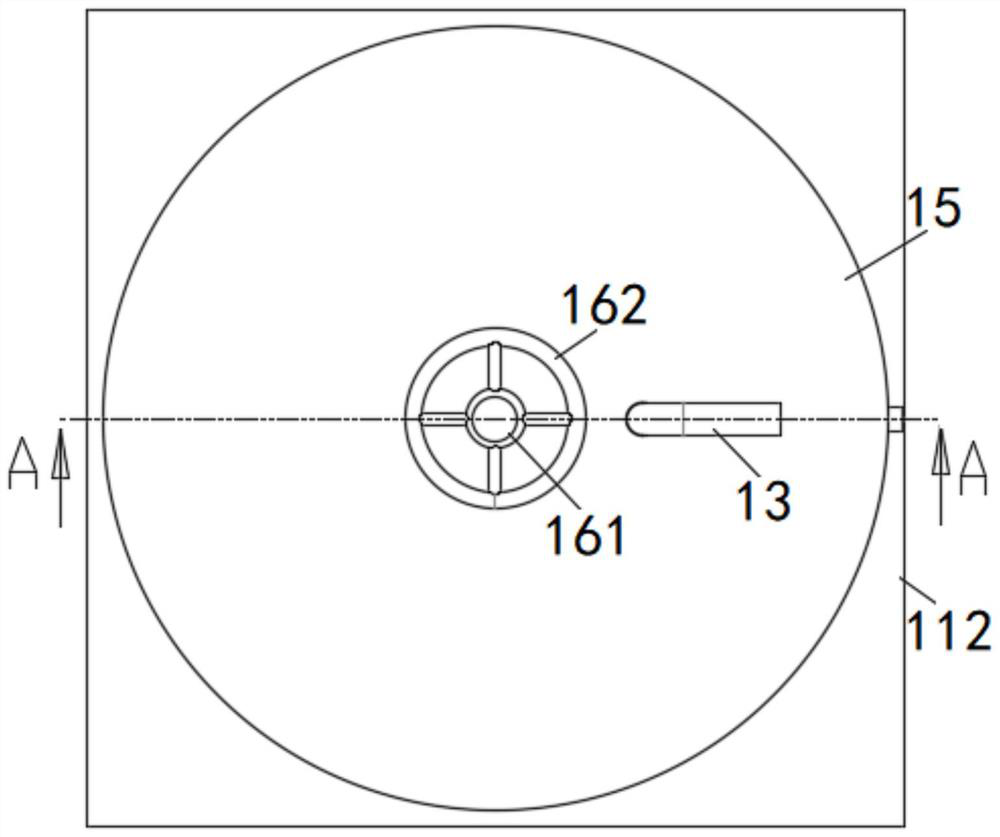

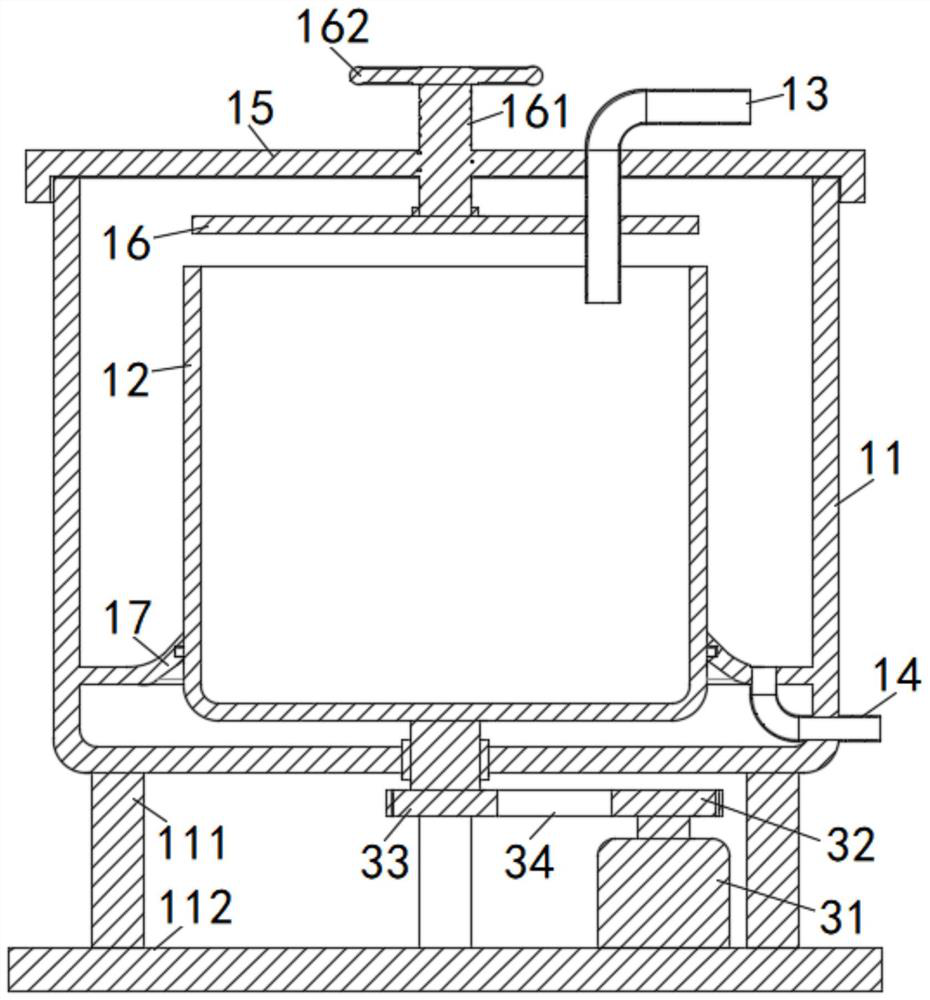

[0030] like Figure 1 to Figure 3 As shown, the present invention provides a kind of oil debris separation and oil cooling centrifugal device, comprising: oil debris separation mechanism and oil cooling mechanism; oil debris separation mechanism includes centrifuge housing 11, centrifuge drum 12, oil inlet pipe 13 and The oil outlet pipe 14; the centrifuge drum 12 is rotated and installed on the inner bottom surface of the centrifuge housing 11; the centrifuge drum 12 is driven to rotate by the driving device; specifically, several support columns 111 are installed at the bottom of the centrifuge housing 11, and the support columns 111 are installed On the support base plate 112; in addition, the driving device includes a servo motor 31, a driving wheel 32, a driven wheel 33 and a drive belt 34; the rotating shaft at the bottom of the centrifuge drum 12 extends out of the bottom surface of the centrifuge housing 11 and is connected to the driven wheel 33 Servomotor 31 is insta...

Embodiment 2

[0036] see Figure 3 to Figure 5 As shown, on the basis of retaining all the technical features in Embodiment 1, the inlet end of the oil cooler pump 23 is connected to the oil pump inlet pipe 231; the outlet end of the oil cooler pump 23 is connected to the oil pump outlet pipe 232; the oil pump inlet pipe 231 extends into Inside the oil cooling box 21 ; the cooled oil is pumped out and recycled through the oil cooler pump 23 to improve the utilization rate of the cooling oil.

[0037] At the same time, an oil level monitoring device is installed on the oil cooling box 21; the oil level monitoring device includes a float 41, a float guide rod 42, a non-contact switch 43 and a signal block 44; A floating ball 41 is installed at one end inside; the floating ball 41 floats on the oil liquid surface in the oil cooling tank 21; Concrete, guide rod support 45 and switch support 46 are installed vertically on oil cooling box 21; Guide rod support 45 upper and lower end sides all in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com