Damping rubber plate molding machine

A technology of shock-absorbing rubber sheet and setting machine, which is applied in printing, stamping, household components, etc., can solve the problems of high cost, complex structure and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

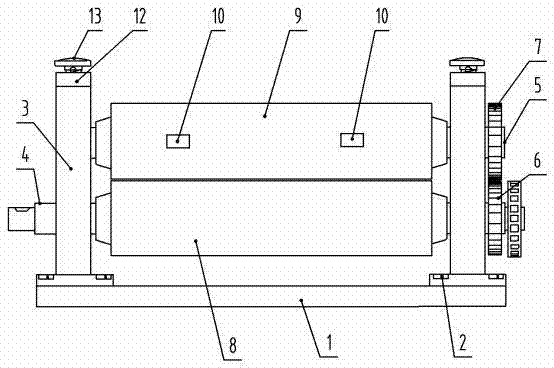

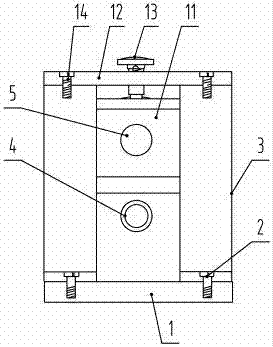

[0011] Such as figure 1 and figure 2 As shown, the shock-absorbing rubber sheet setting machine of the present invention comprises a base 1, a frame 3 provided by bolts 2 on the base 1, the frame 3 is provided with a drive shaft 4 and a driven shaft 5, and the drive shaft 4 and The same end of the driven shaft 5 is respectively provided with a driving gear 6 and a driven gear 7 for meshing transmission. The driving shaft 4 and the driven shaft 5 are respectively provided with a flat roller 8 and a flower roller 9, and the flower roller 9 is provided with a Groove 10 ( figure 1 There are also two grooves 10) on the back of the illustrated pattern roller 9). Frame 3 comprises two movable plates 11 that are rotationally connected with driven shaft 5 two ends, is positioned at movable plate 11 top and is located at two fixed plates 12 that frame 3 both sides tops are provided with by bolt 14, each fixed plate 12 An adjustment handwheel 13 whose lower end is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com