Paper-feeding mechanism against tilt

A paper-feeding and sheet-feeding technology, applied in the field of paper-feeding mechanisms that can prevent skewed paper feeding, can solve the problems of inability to adjust the size accordingly, difficult paper feeding, repeated paper feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

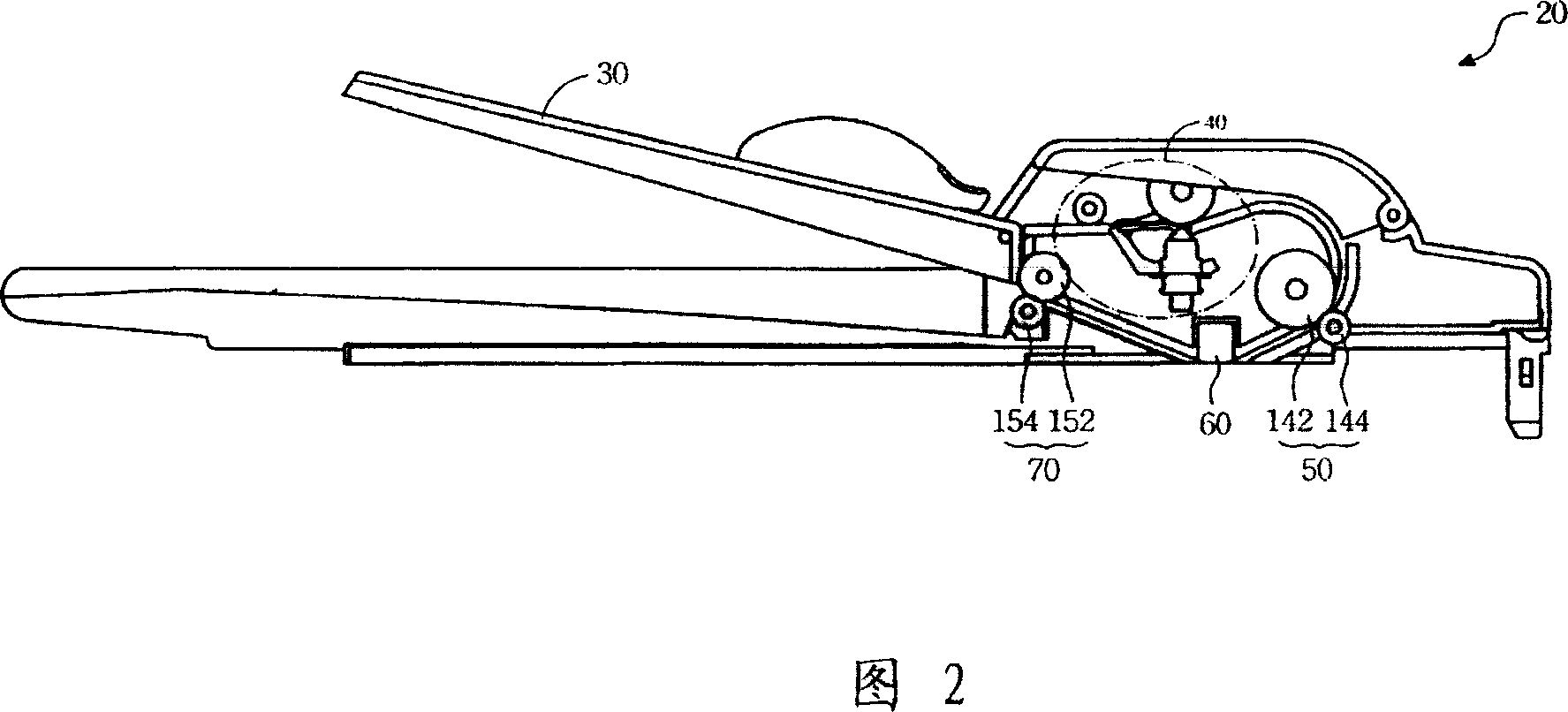

[0021] Please refer to FIG. 2 , which is a schematic cross-sectional view of a preferred embodiment of the automatic document feeder (Automatic Document Feeder, ADF) 20 of the present invention. As shown in the figure, the automatic document feeder 20 has a paper input box 30 , a paper feeding mechanism 40 , a relay roller set 50 and a paper output roller set 70 . Wherein, the paper tray 30 is used for carrying papers (not shown). The paper feeding mechanism 40 is used to drive the papers in the paper tray 30 to be fed into the automatic paper feeder 20 one by one. The relay roller set 50 is located at the downstream of the paper feeding mechanism 40 and is used to transport the paper leaving the paper feeding mechanism 40 to a reading and writing position 60 for scanning, photocopying and other operations. The paper output roller set 70 is located downstream of the relay roller set 50 , and is used to drive the paper away from the reading and writing position 60 and send the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com