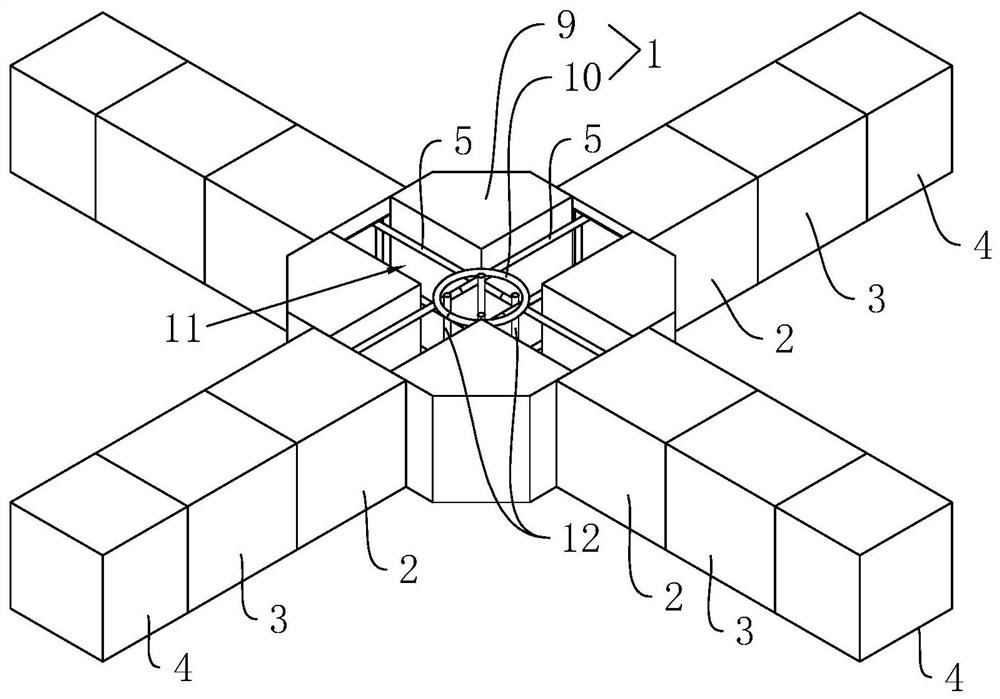

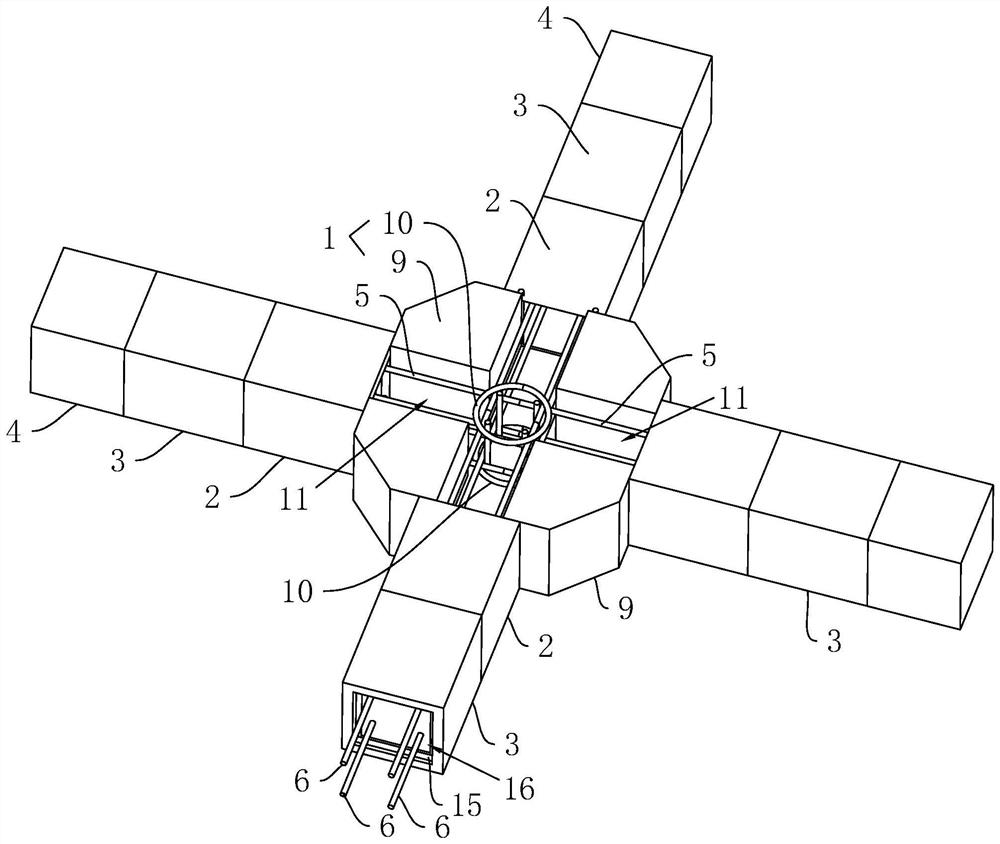

A prefabricated cross beam and its construction method

A construction method and technology for cross beams, which are used in manufacturing tools, infrastructure engineering, construction, etc., can solve the problems of low assembly efficiency, time-consuming assembly procedures of cross beams, and difficulty in positioning components quickly and accurately, and achieve the speed of improvement. and efficiency, improve the efficiency of assembly work, shorten the effect of assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

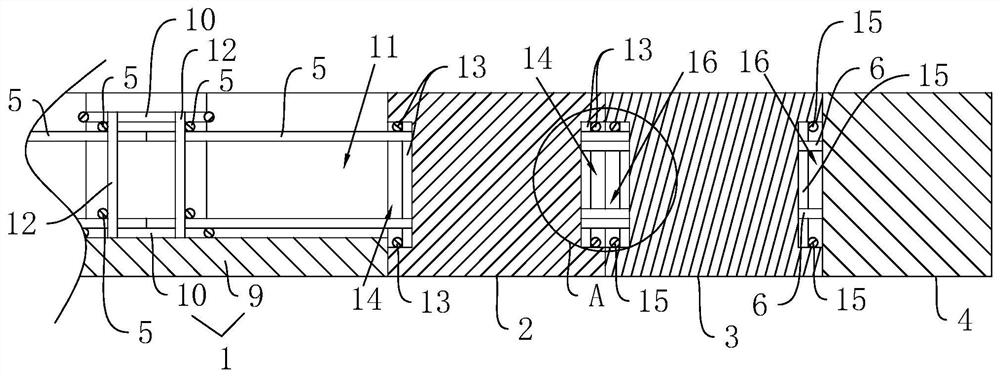

[0061] Construction Example 1: a construction method of a prefabricated cross beam, comprising the following operation steps:

[0062] Step 1. Production of inner transition piece 2:

[0063] According to the construction requirements, the reinforcement cage is bound, and the inner transition piece 2 mold is obtained after the template is fixed and installed outside the reinforcement cage, and then the four steel bars covered with plastic film are placed horizontally along the length direction of the inner transition piece 2 mold. The ends respectively extend outward and are erected outside the inner transition piece 2 mold.

[0064] Concrete is poured in the inner transition piece 2 mold, the concrete is vibrated and then stopped for 8 hours, the steel rod is rotated horizontally around the central axis of the steel rod twice, and then it is completely immersed in water for curing, and it is rotated every 1 hour. The steel rod was cured for 2 times. After curing for 8 hours,...

Embodiment 2

[0073] Construction Example 2: a construction method for a prefabricated cross beam, comprising the following operating steps:

[0074] Step 1. Production of inner transition piece 2:

[0075] According to the construction requirements, the reinforcement cage is bound, and the inner transition piece 2 mold is obtained after the template is fixed and installed outside the reinforcement cage, and then the four steel bars covered with plastic film are placed horizontally along the length direction of the inner transition piece 2 mold. The ends respectively extend outward and are erected outside the inner transition piece 2 mold.

[0076] Concrete is poured in the inner transition piece 2 mold, the concrete is vibrated and then stopped for 12 hours, the steel rod is rotated horizontally around the central axis of the steel rod 3 times, and then it is immersed in water with a water temperature of 30 ℃ for curing. Rotate the steel rod 3 times at an interval of 3 hours, cover the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com