Construction method and installation structure of glazed decorative components of roof ridge of antique buildings

A technology for antique buildings and decorative components, applied in building structures, buildings, roofs, etc., can solve the problems of easy cracking, large impact of block weight, construction safety and construction difficulty, etc., to prevent cracking, light weight, increase Effects of reliability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

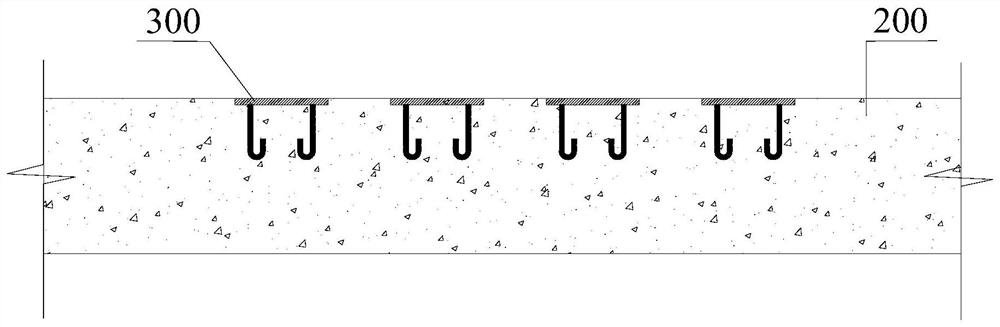

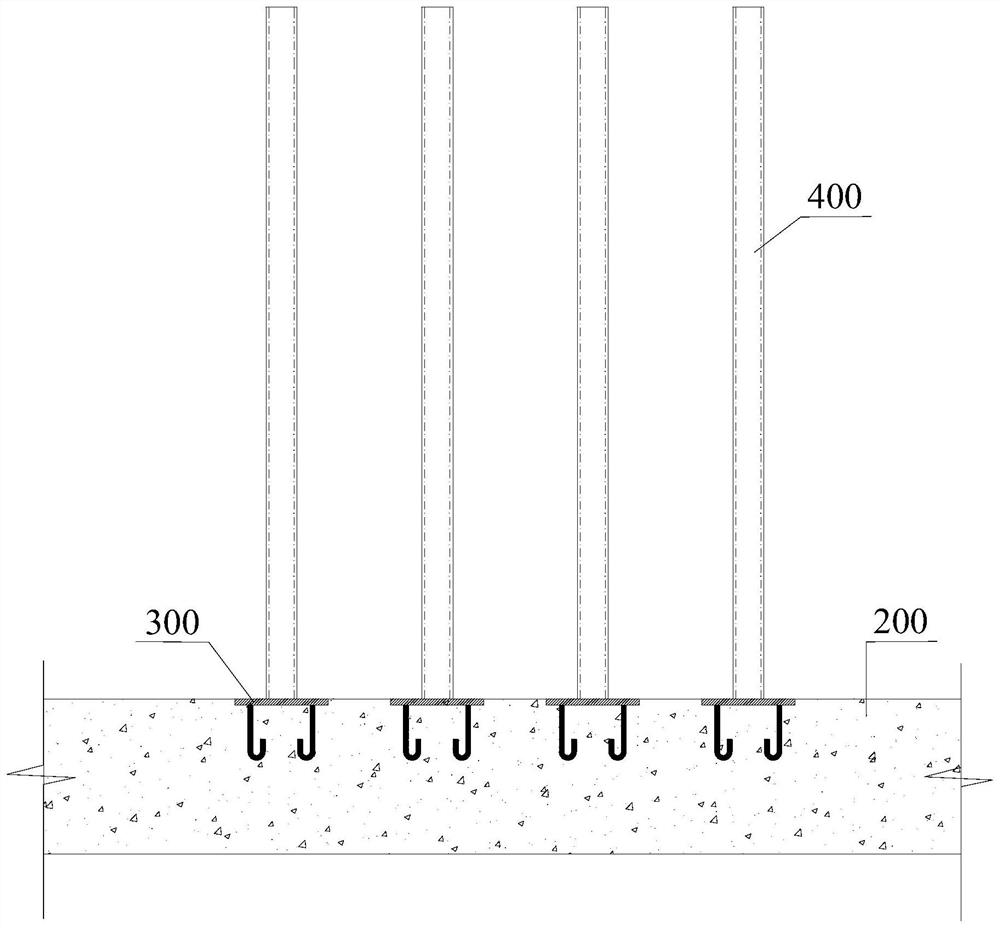

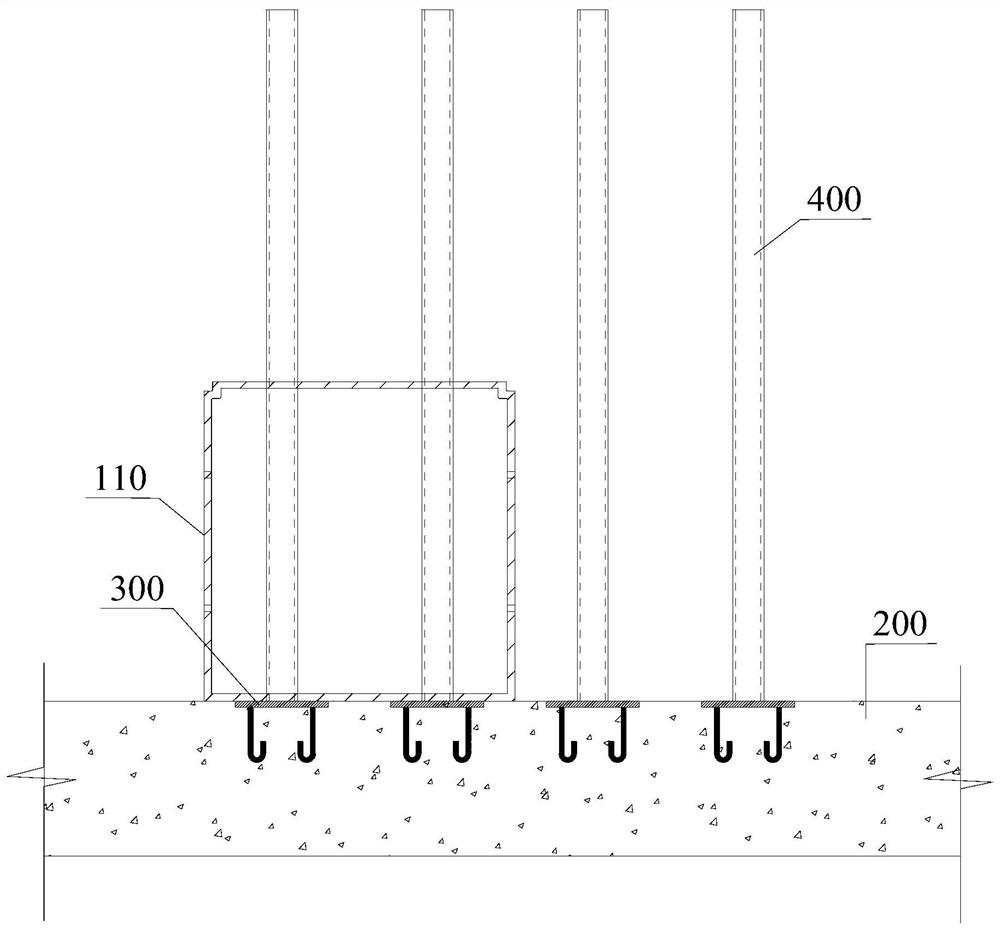

[0071] The present invention will be described in detail below with reference to the accompanying drawings: The advantages and features of the present invention will be more clearly understood from the following description. It should be noted that, the accompanying drawings are all in a very simplified form and in inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

[0072] The embodiment of the present invention provides a construction method for the roof ridge beast glazed decorative component 100 of an antique building, which may include:

[0073] Step S0, please refer to Figure 17 to Figure 23 , dividing the beast beast glaze decorative member 100 into several pieces of the beast beast glaze assembly 110 of multi-layer and multi-column, on the beast beast glaze assembly 110 is provided with a fire hole 117, in the horizontal adjacent two pieces of the kiss The beast glass assembling co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com