Patents

Literature

36results about How to "Quick Position Assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

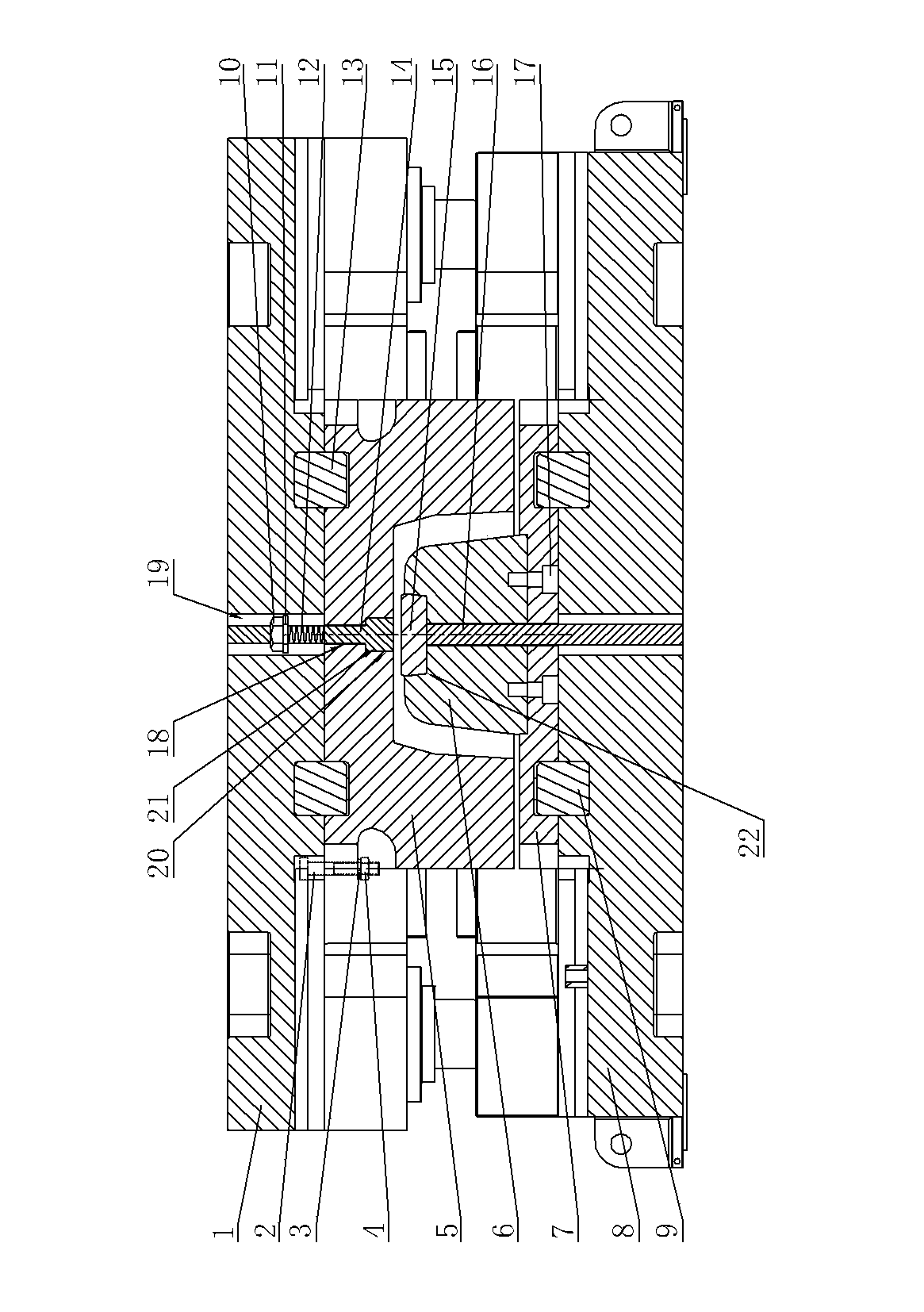

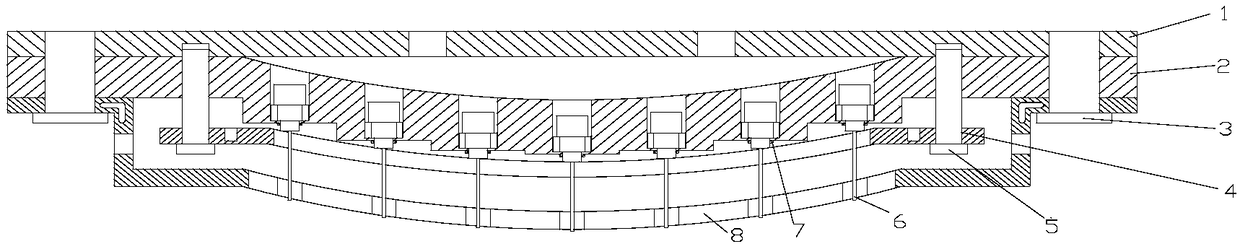

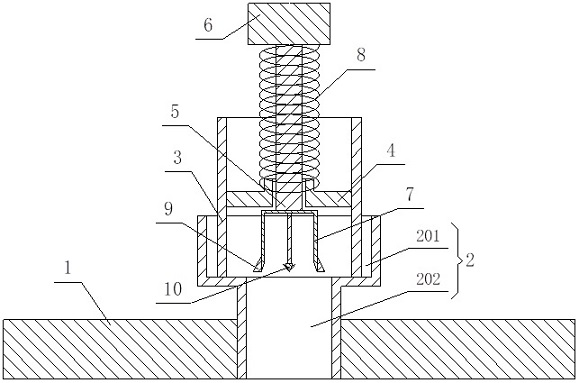

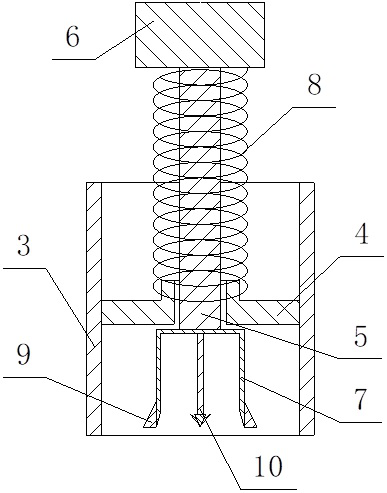

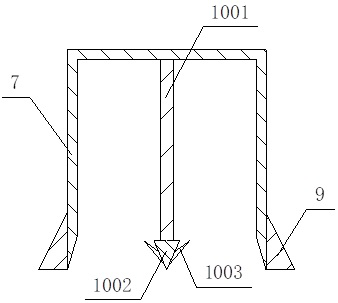

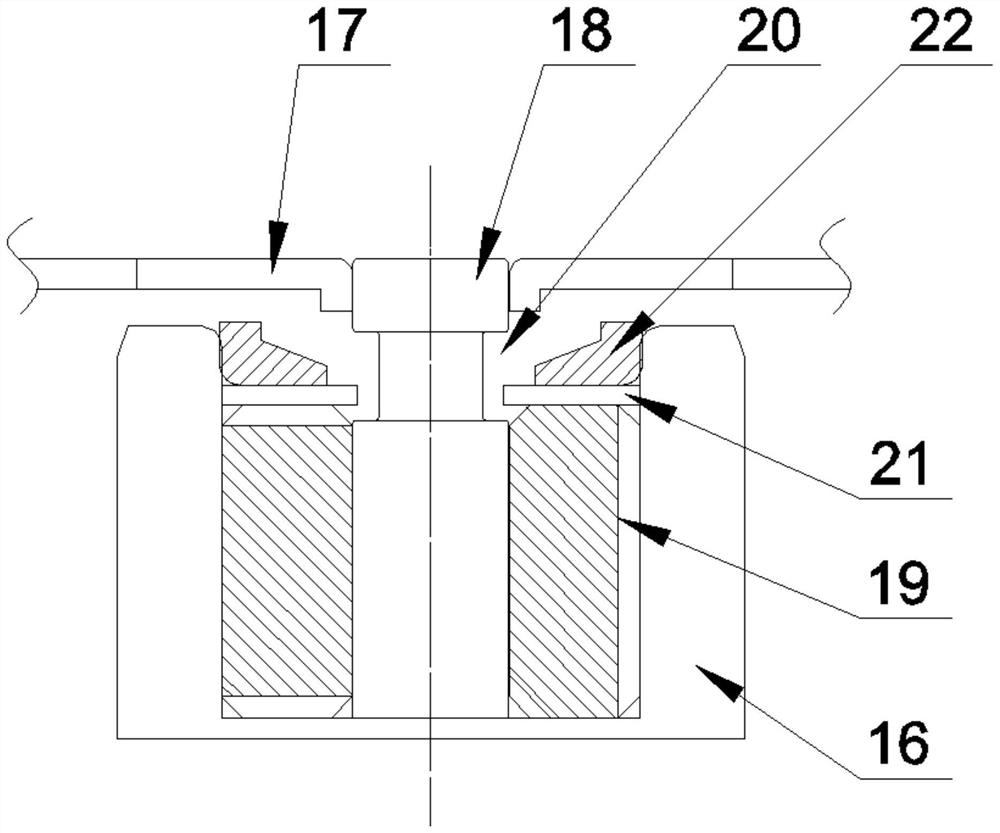

Large combined dual-jacking mould structure

InactiveCN103658491AAvoid damageReduce processing and repair costsForging/hammering/pressing machinesForgeMaterials science

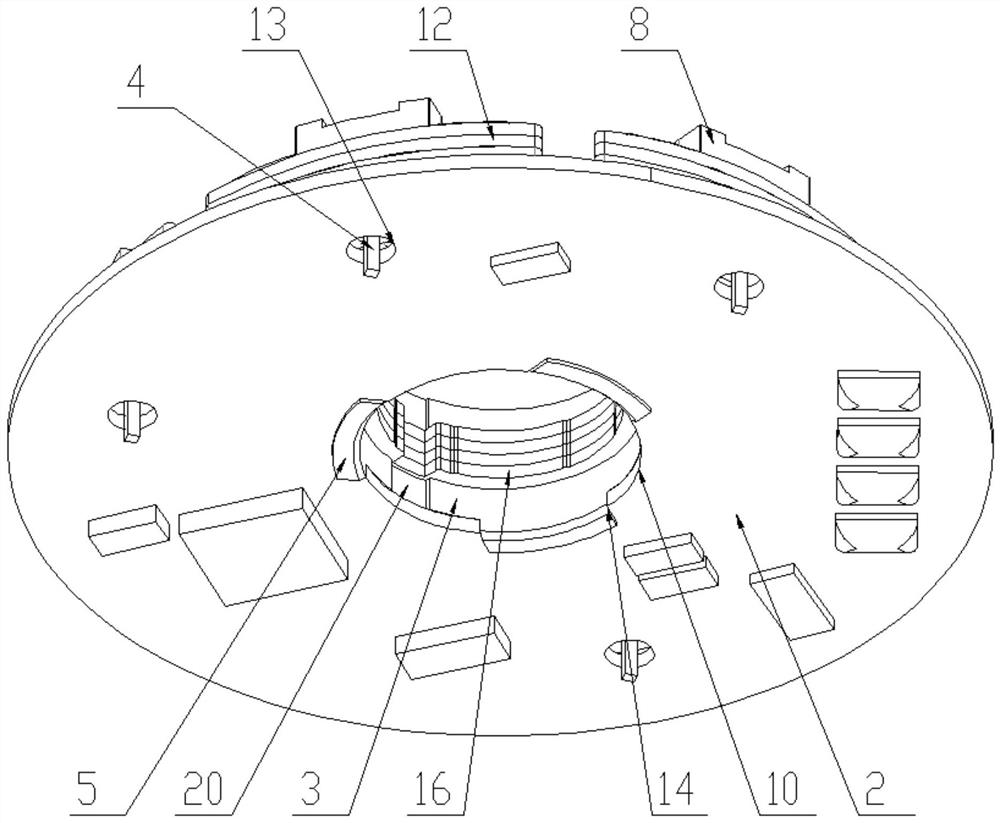

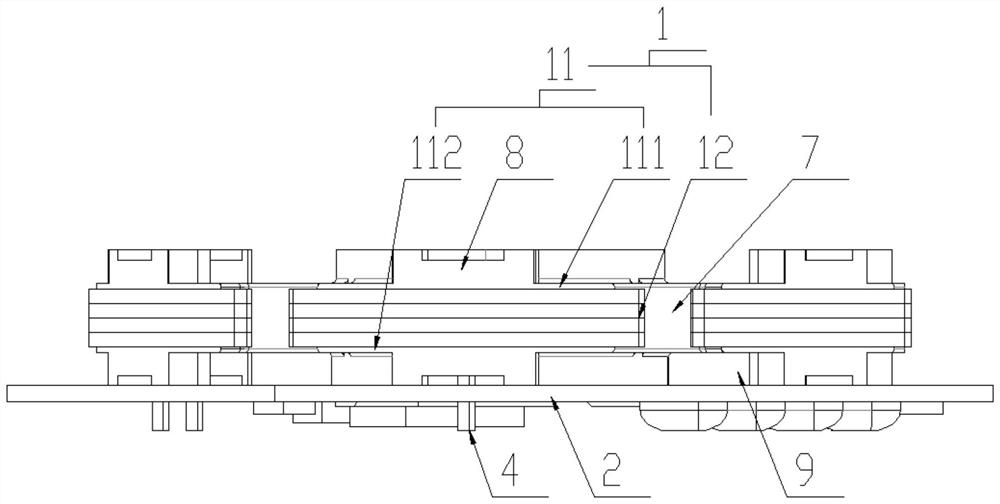

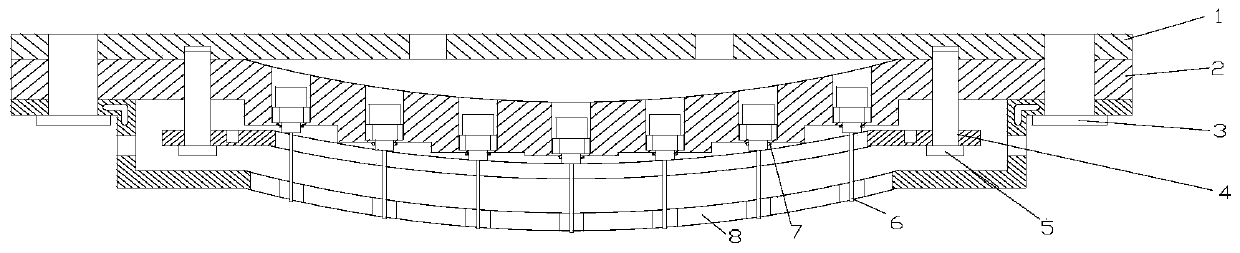

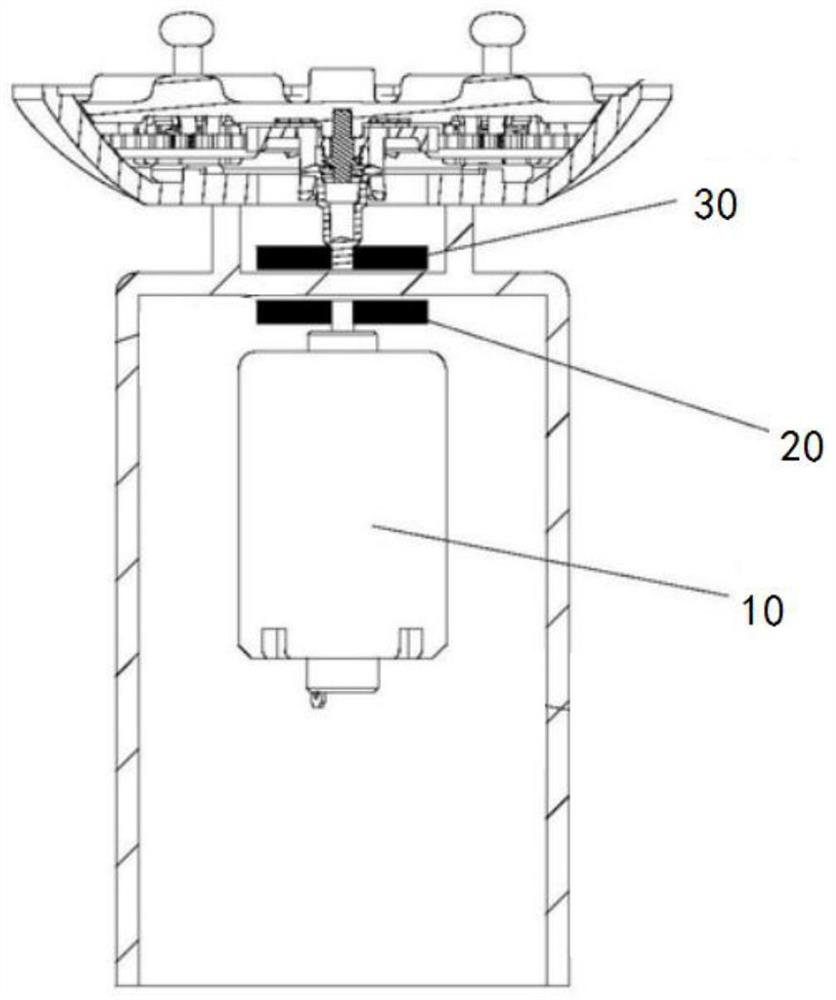

The invention provides a large combined dual-jacking mould structure. The large combined dual-jacking mould structure can solve the problem that an upper mould cannot perform demoulding when an existing single-jacking mould is used for forging a large deep-cavity thin-walled forge piece. The large combined dual-jacking mould structure is simple and convenient to process and assemble; and the upper mould and a lower mould can both achieve demoulding of the forge piece in a jacking mode. The large combined dual-jacking mould structure comprises an upper mould structure and a lower mould structure; the upper mould structure comprises an upper mould base and the upper mould, wherein the upper mould is mounted beneath the upper mould base; a lower mould jacking mechanism is mounted in the lower mould structure. The large combined dual-jacking mould structure is characterized in that an upper mould jacking mechanism is mounted in the upper mould structure; the upper mould jacking mechanism comprises an upper jacking rod and a compression spring; the upper jacking rod sequentially penetrates through the upper mould and an upper jacking rod mounting hole of the upper mould base from bottom to top; the flange at the bottom of the upper jacking rod is in clearance fit with a groove of the upper mould; the diameter of the upper jacking rod mounting hole of the upper mould base is larger than that of an upper jacking rod mounting hole of the upper mould; the part, located in the upper jacking rod mounting hole of the upper mould base, of the upper jacking rod is sleeved with the compression spring which is locked on the top surface of the upper mould through a tight nut and a flat washer.

Owner:WUXI TURBINE BLADE

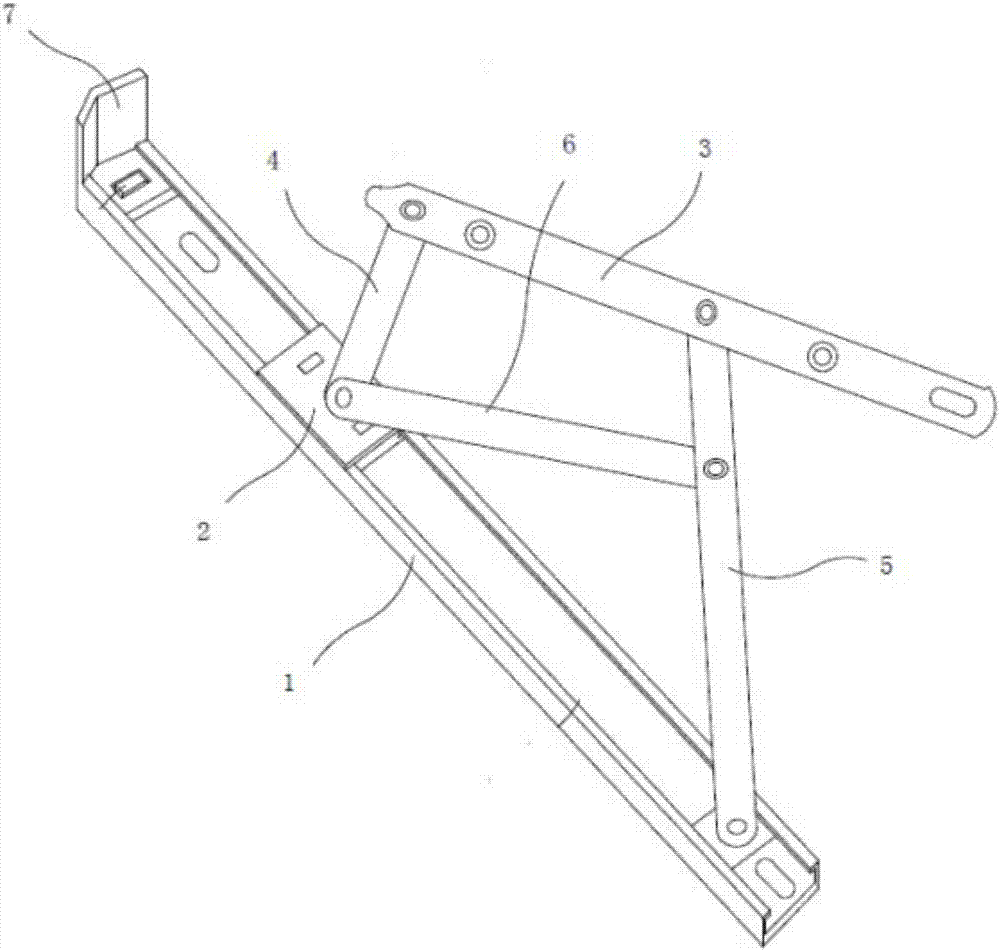

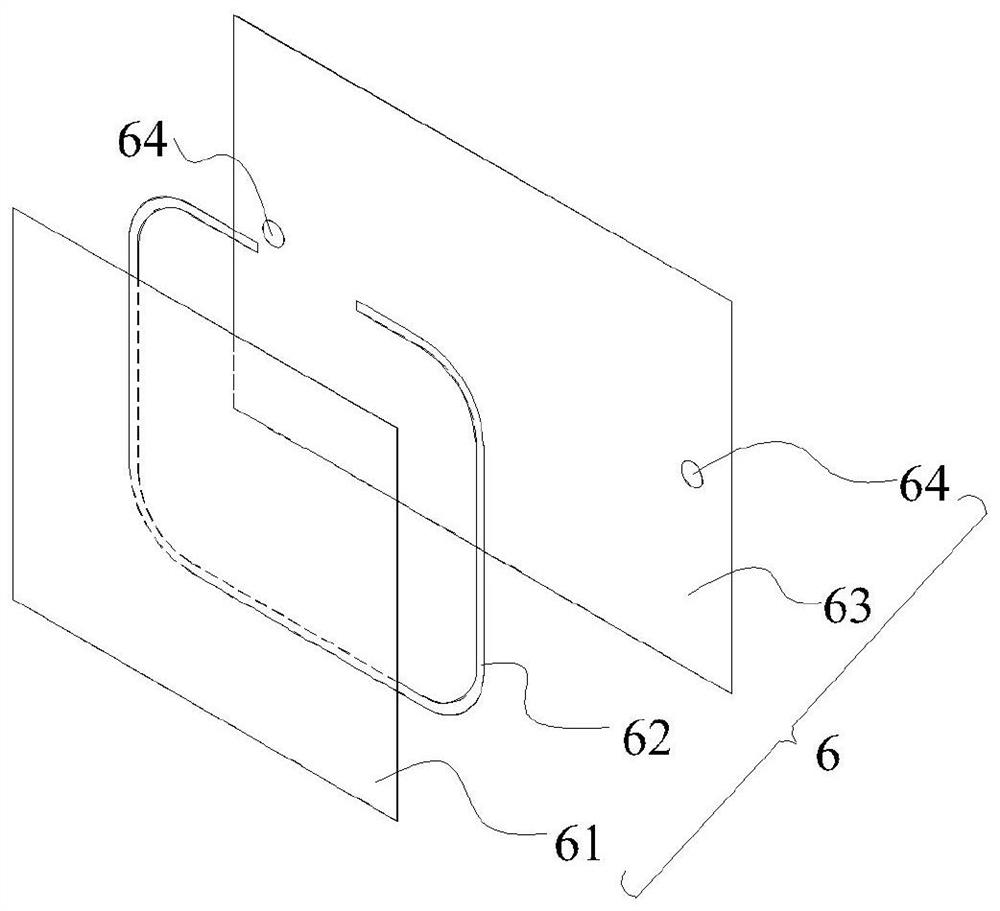

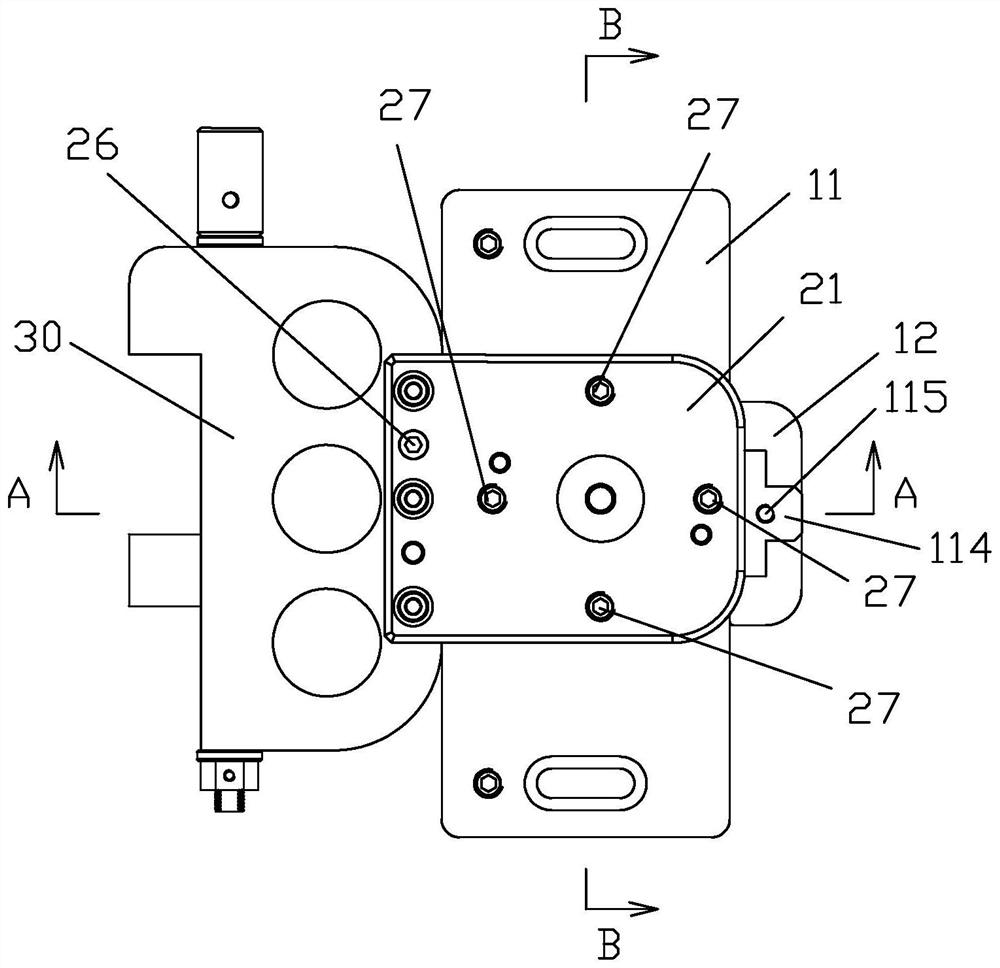

Casement window hinge, manufacturing method of casement window hinge, and casement window using casement window hinge

ActiveCN107503605ADoes not damage the mechanical structureQuick Position AssemblyPin hingesEngineeringClosed state

The invention discloses a casement window hinge. The casement window hinge comprises a slide rail, a pull rod, a hinge fixing part fixed to one end of the slide rail, and a sliding part installed in the slide rail and capable of sliding; the pull rod is fixed to the sliding part through a connecting part; the pull rod makes the angular movement relative to the slide rail when the sliding part slides; when the pull rod and the slide rail are in a closed state, one end of the pull rod abuts against the hinge fixing part; the slide rail comprises a first groove and a second groove which are in perpendicular intersection; the hinge fixing part comprises a corner wrapping end, a connecting end and a fixing end; the corner wrapping end and the fixing end are connected by the connecting end; the corner wrapping end and the fixing end are perpendicular to each other; the connecting end is contained in the first groove; the fixing end is installed in the second groove; and the casement window hinge further comprises a limiting block which is fixed to the slide rail and used for fixing the fixing end, and therefore the fixing strength of the hinge fixing part fixed to the slide rail is improved.

Owner:LIP HING YEUNG S IND (SHENZHEN) CO LTD

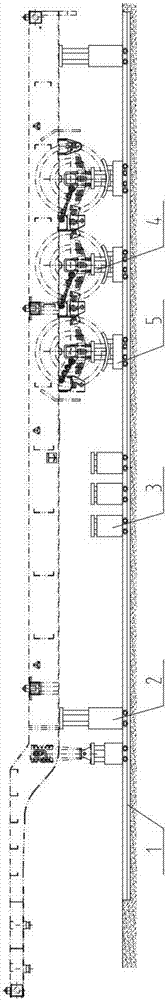

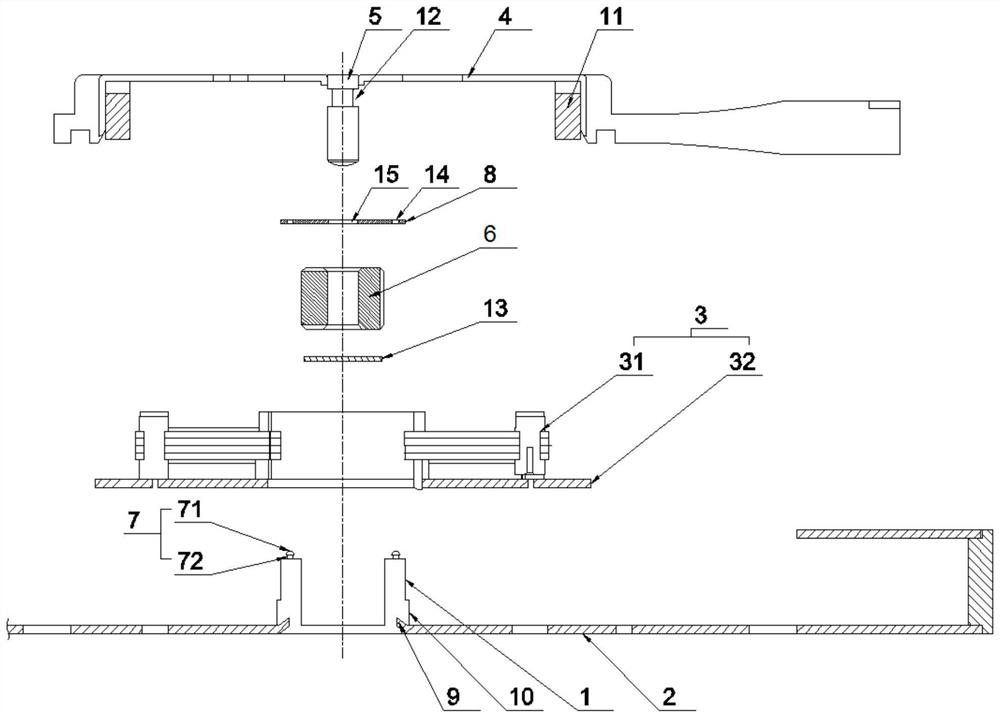

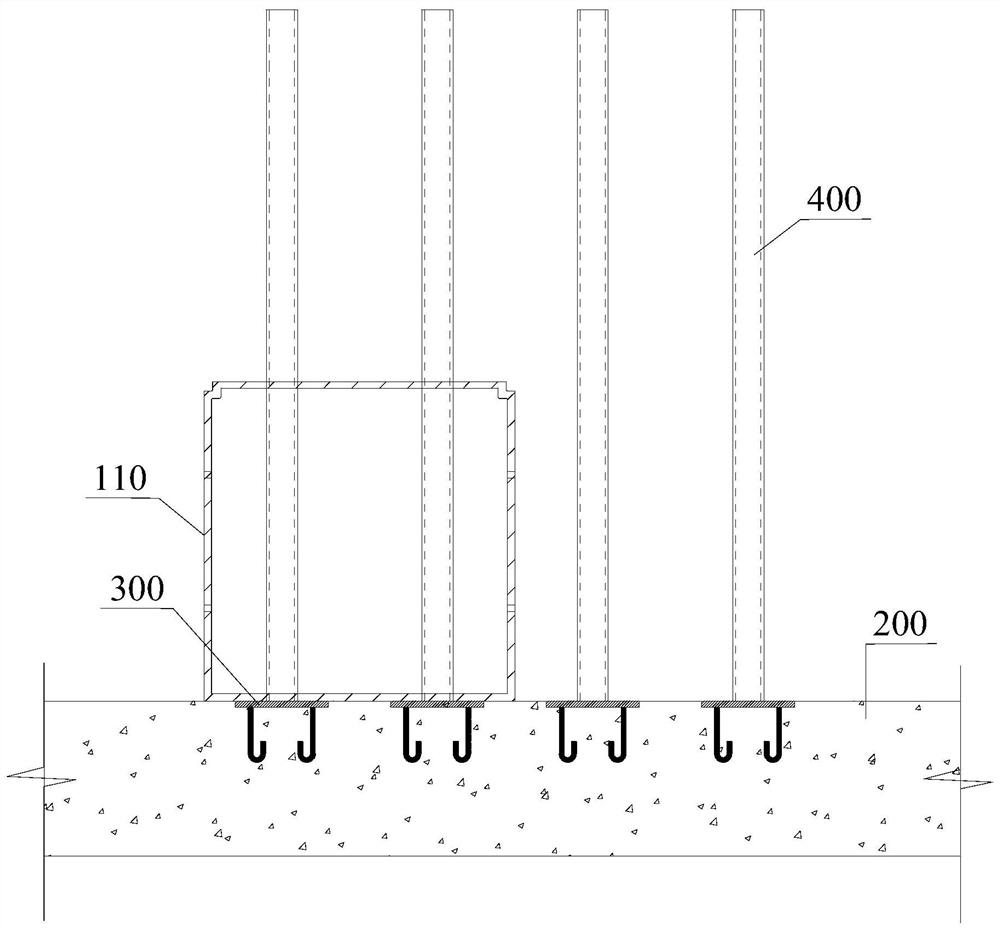

Usage method of trailer assembling system

ActiveCN107200082AEasy and fast assemblyAccurate control of assembly installation distanceVehiclesVehicle frameEngineering

The invention discloses a usage method of a trailer assembling system. The usage method comprises the steps of self adjustment of guide rail separation distances, self movement of supporting parts, erection of taking-off assembly parts, erection of frame assembly, hanging installation, axle installation, wheel installation, electrical installation, trailer tape-out and the like. A frame supporting part, a hanging supporting part, an axle supporting part and a wheel supporting part move in the front-back direction of a horizontal linear guide rail part through supporting rollers or are positioned on the horizontal linear guide rail part through roller positioning mechanism, the parts are not interfered in the assembling-installing process, and rapid assembly is promoted. Accurate assembly and installation distance control can be achieved. Accurate, positioned and rapid hoisting can be achieved. By adopting the usage method of the trailer assembling system, overall and rapid positioning and assembly of a trailer can be achieved, the assembly efficiency is high, and the potential safety hazard of hanging swing installation can be avoided.

Owner:江苏富华交通运输设备股份有限公司

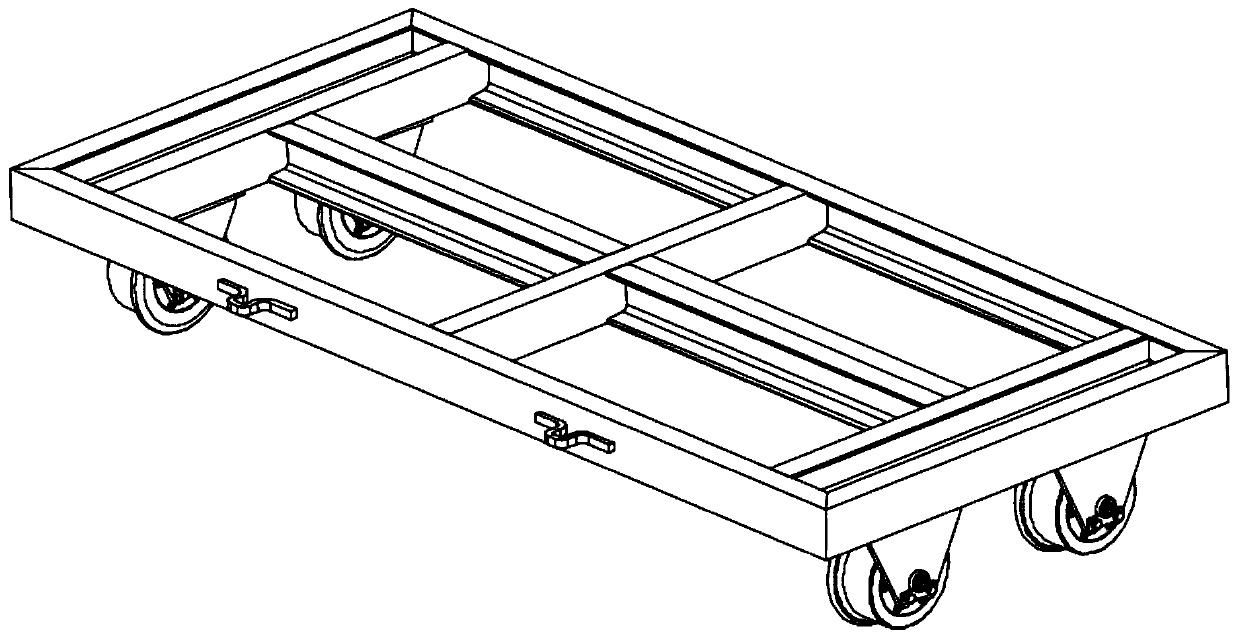

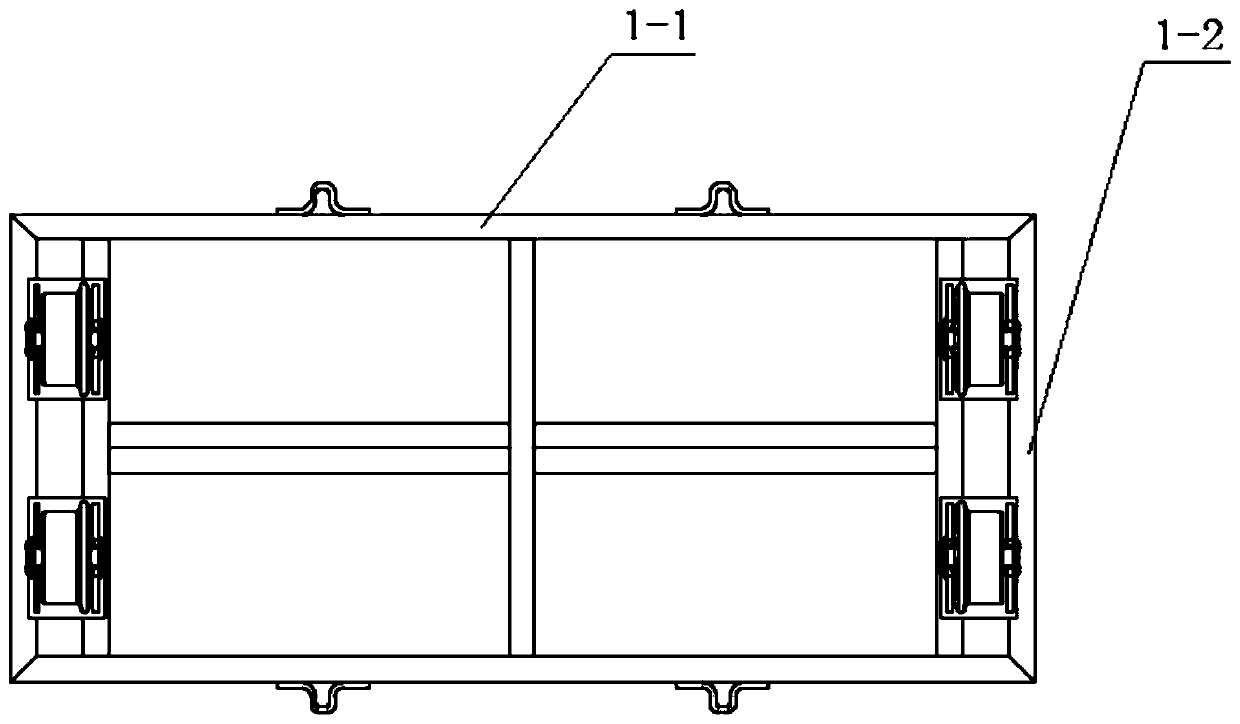

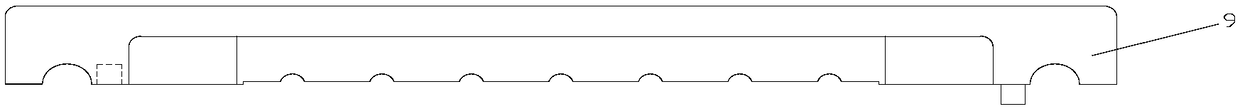

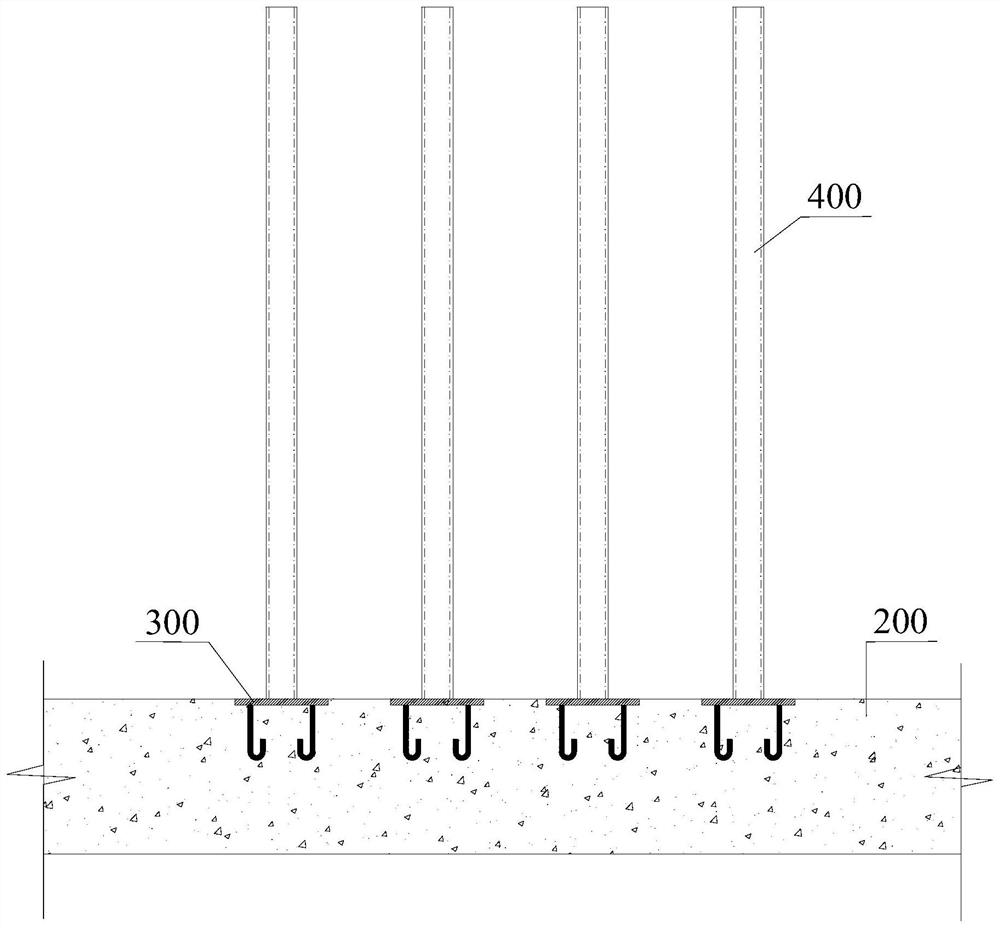

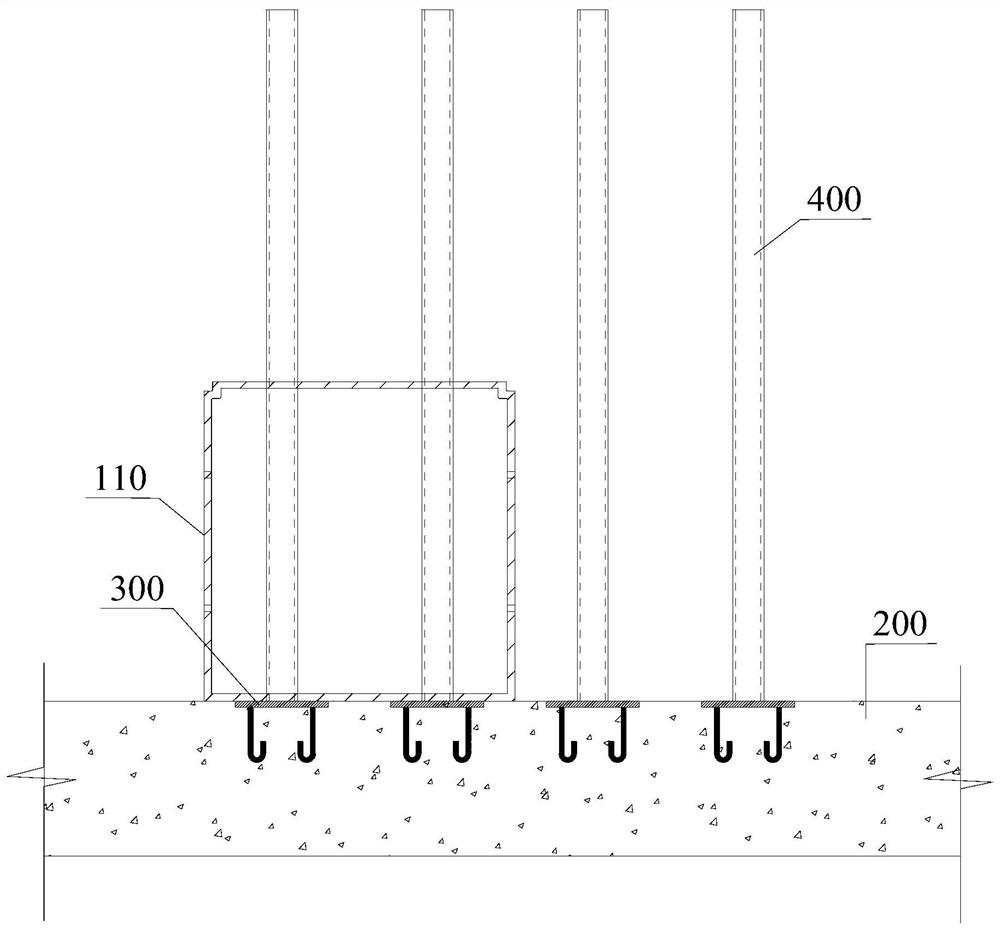

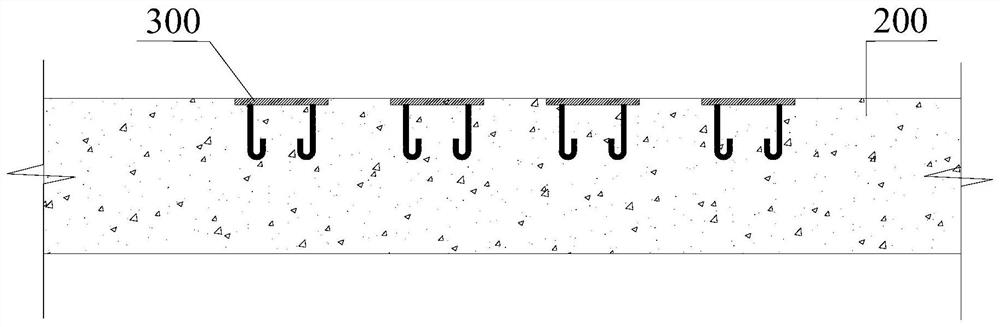

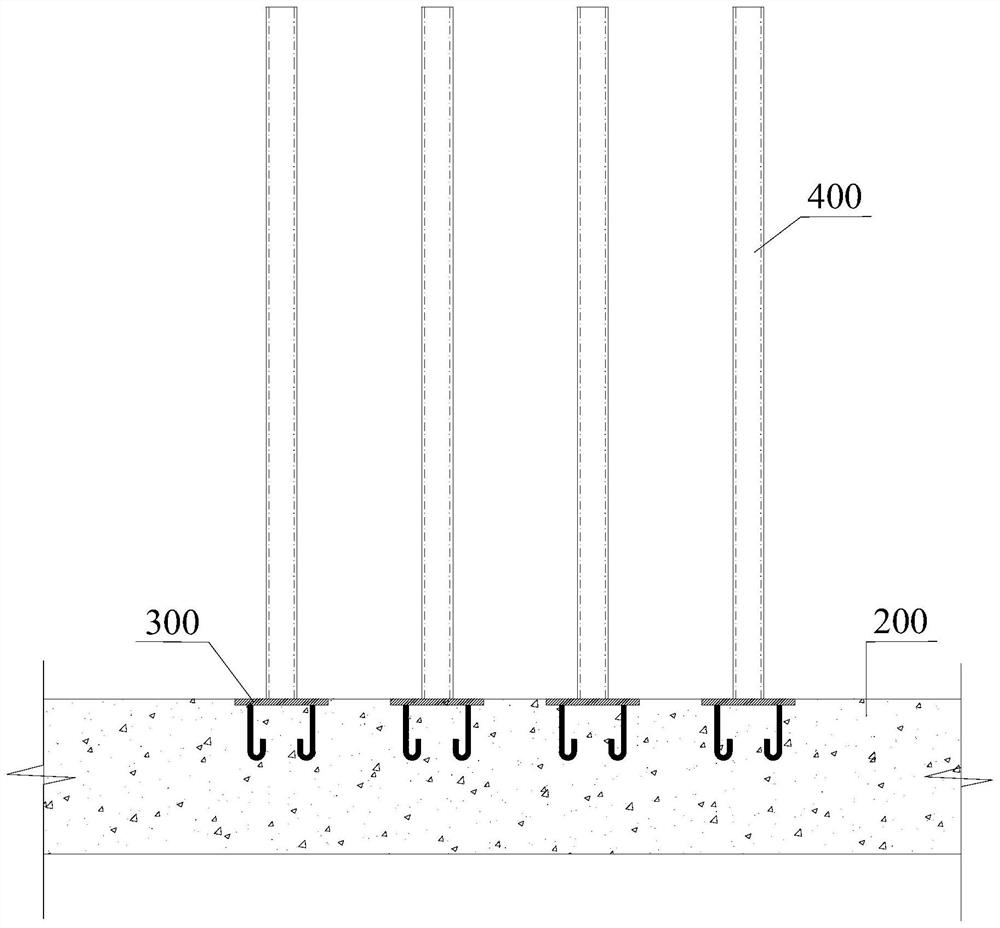

Four-wheel small platform lorry for pre-assembled turnout slippage and construction method

PendingCN111254762ACombination structure is simple and feasibleEasy to installTrack superstructureRailway track constructionVehicle frameEngineering

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

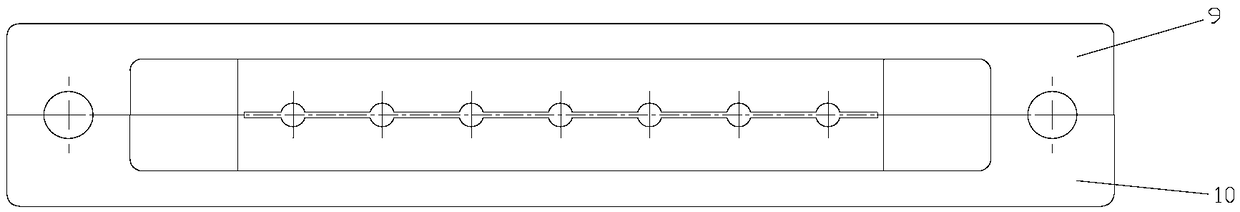

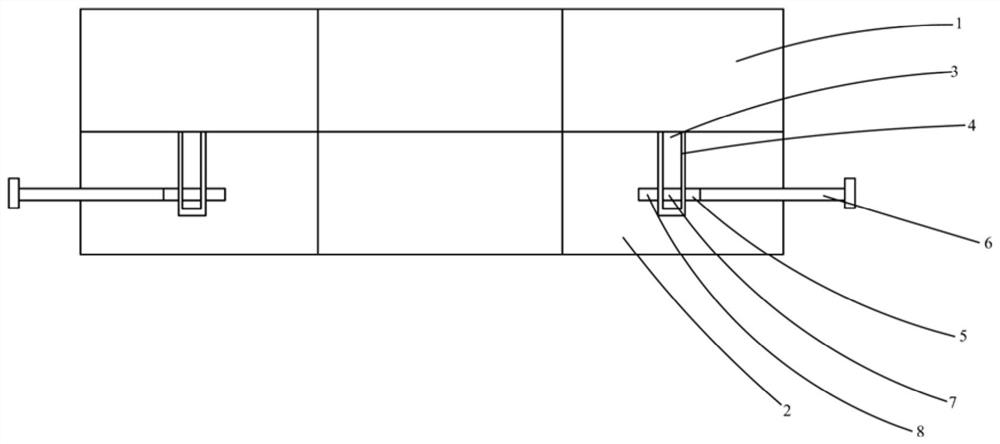

Electrostatic spinning spray nozzle capable of achieving quick multi-needle-tip positioning

ActiveCN109267159AOvercome conductivityOvercoming Microporous Problems on Gas MasksArtificial thread manufacturing machinesFilament/thread formingFiberTip position

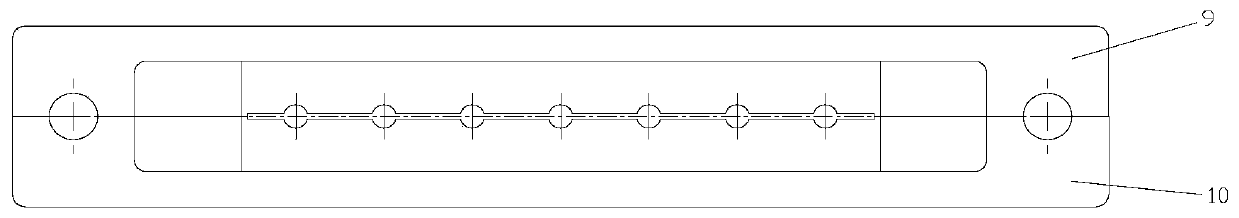

The invention relates to an electrostatic spinning spray nozzle capable of achieving quick multi-needle-tip positioning and relates to electrostatic spinning. The spray nozzle comprises an upper coverplate, a needle tip mounting plate, an electric conduction plate, a needle tip array and an air cover; the upper cover plate is provided with a liquid inlet and connected with a liquid supply devicethrough a hose; the needle tip mounting plate is of a step structure, the step height difference is identical to the height difference of needle tips at the corresponding positions, and the needle tipmounting plate is provided with a needle tip positioning hole; the electric conduction plate is connected with a positive electrode of a high-voltage supply source and is of a separated structure; the needle tip array is provided with the needle tips distributed in an arc array, the needle tip at the middle position of the needle tip array is located at the lowest point, and the needle tips of the two sides of the needle tip array are symmetrically distributed; the air cover is provided with two air inlets and connected with an air supply device through an air guide pipe, and a pressure adjustment valve is used for controlling flow of air and magnitude of pressure intensity. Sheath air constraint is introduced, spinning jet injection is accelerated, the fiber spraying efficiency is improved, the jet flow is thinned, the diameter of a nano fiber is reduced, and the film formation uniformity and quality of an electrostatic spinning fiber are improved.

Owner:厦门定慧力教育科技有限公司

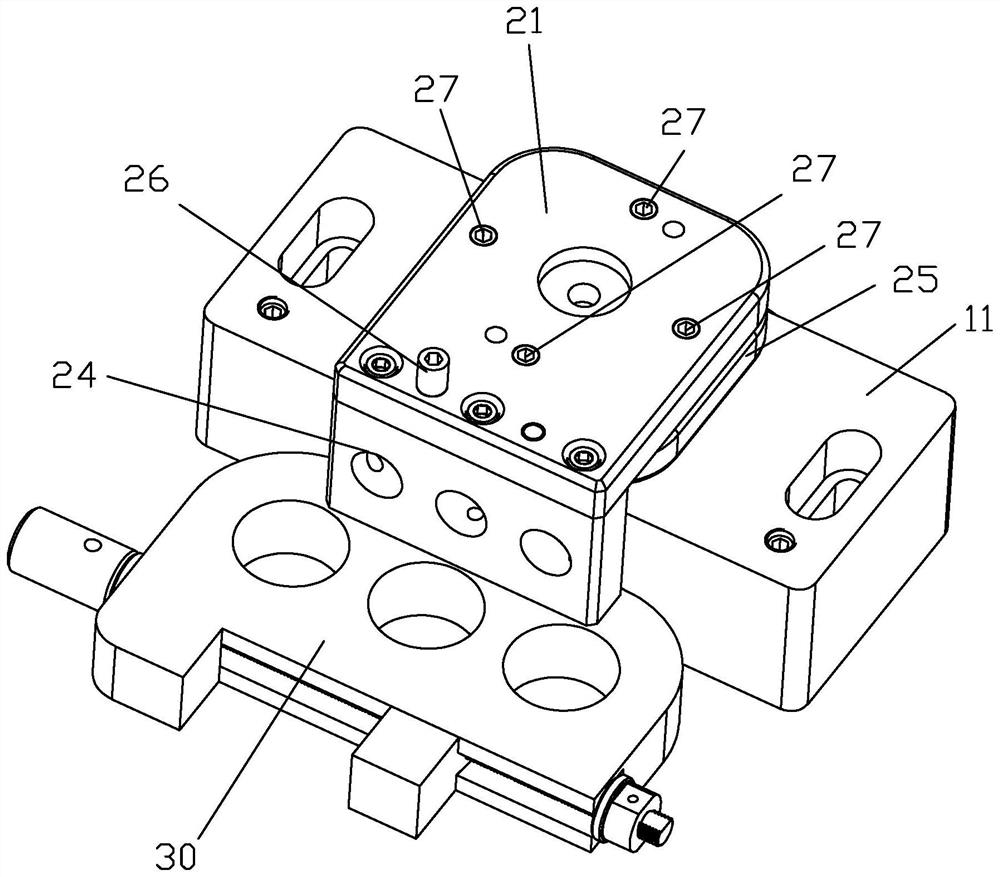

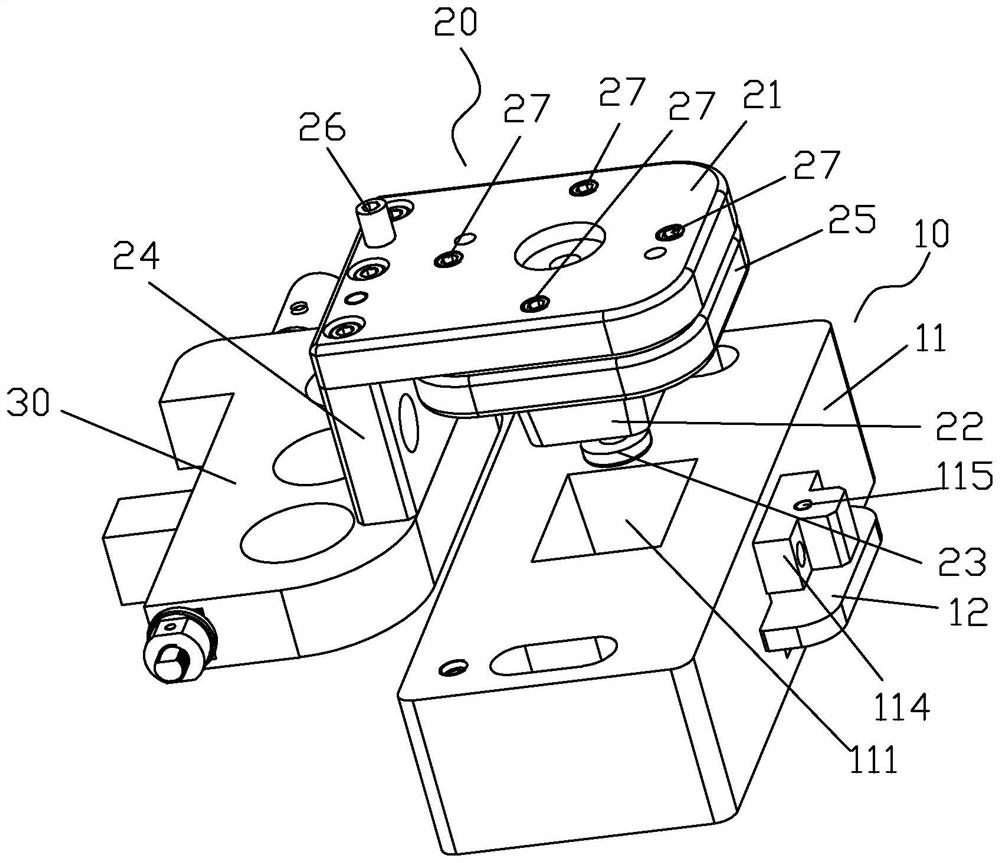

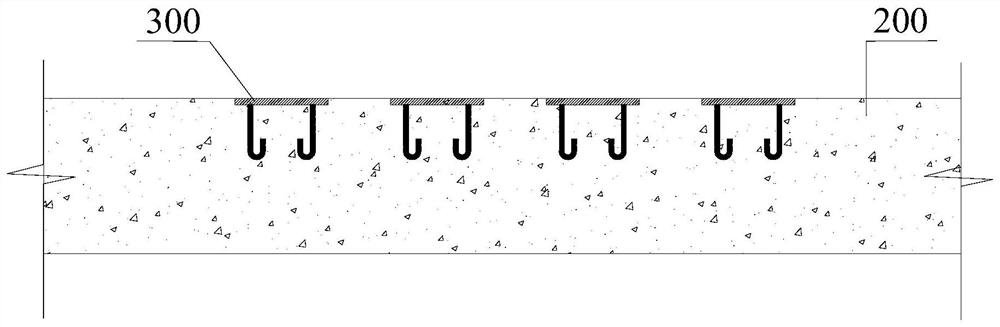

Floatable positioning tool for welding support of heliostat bracket main beam

InactiveCN112404849AQuick positioning assemblyReduce assemblyWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringSteel tube

The embodiment of the invention provides a floatable positioning tool for a welding support of a heliostat support main beam. The floatable positioning tool comprises a base, a welding support positioning die, a linear guide rail and an air cylinder; the welding support positioning die comprises a positioning bottom plate, a first positioning column, a second positioning column, a third positioning column, a fourth positioning column, a first positioning column mounting base and a second positioning column mounting base; the first positioning column mounting base comprises a first mounting bottom plate, a first longitudinal plate, a top plate, a vertical plate and two first fixed blocks; the second positioning column mounting base comprises a second mounting bottom plate, a second longitudinal plate and two second fixed blocks; a sliding block is slidably connected with the linear guide rail; the linear guide rail is mounted on a mounting plate; and the air cylinder is mounted at the lower end of the mounting plate. The positioning precision of a push rod support weldment, a main beam support weldment and a main beam steel pipe during welding is guaranteed, quick positioning and assembling of a workpiece before welding and quick disengaging of a positioning die after welding can be achieved, the welding positioning time and the positioning labor amount are greatly reduced, andthe manufacturing and production period is shortened.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

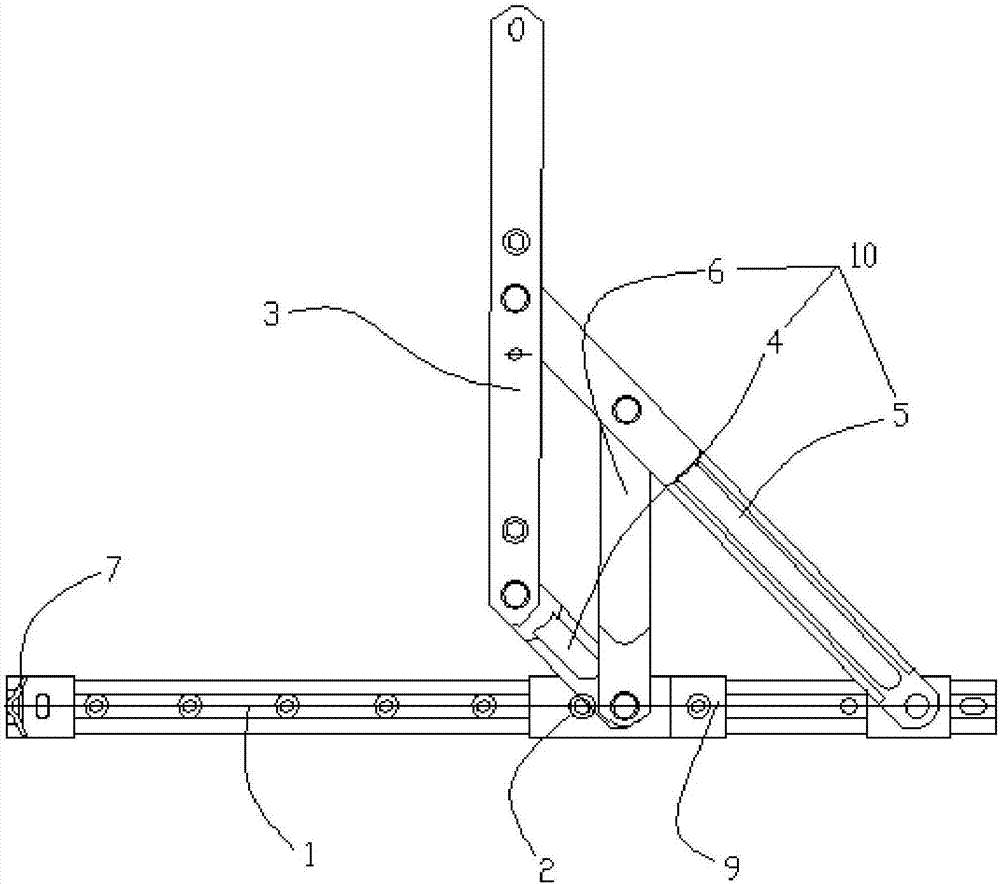

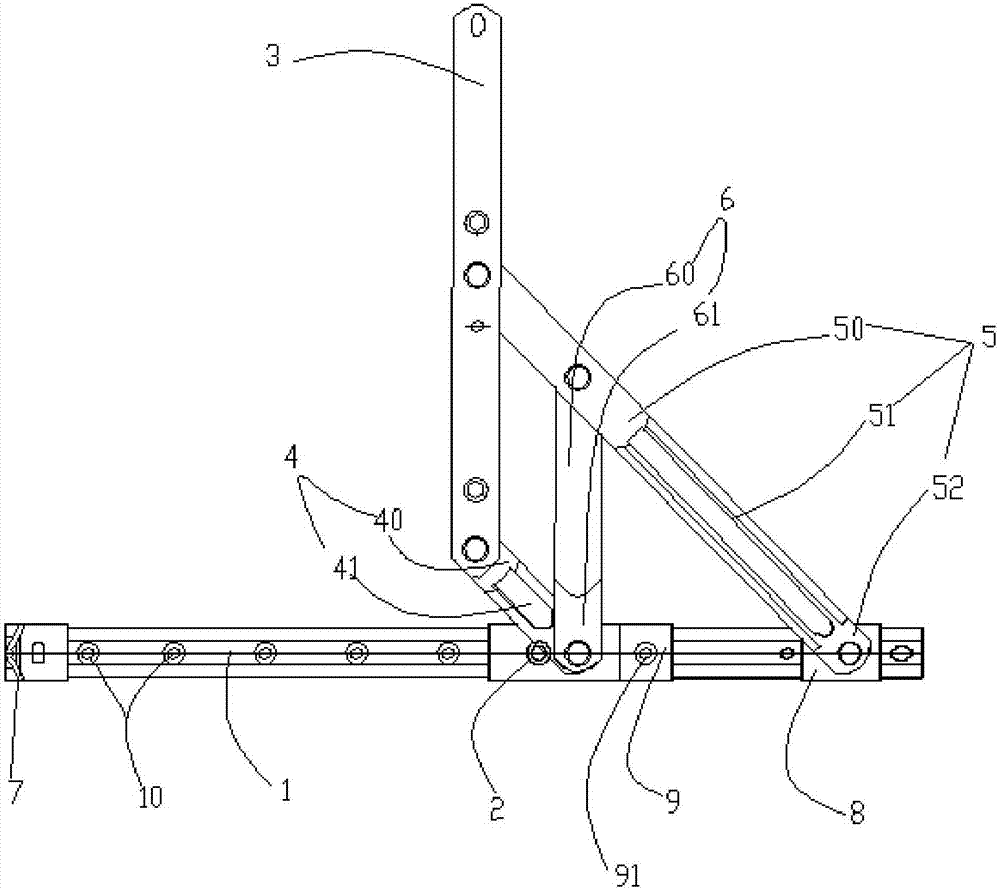

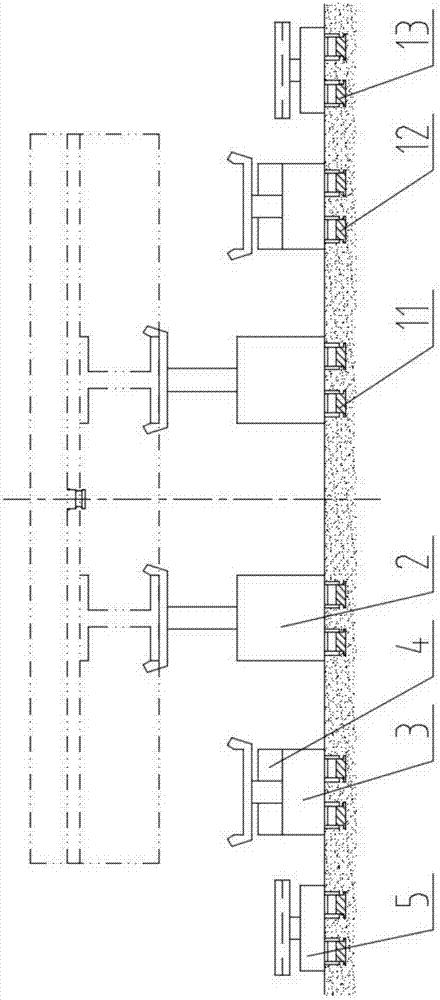

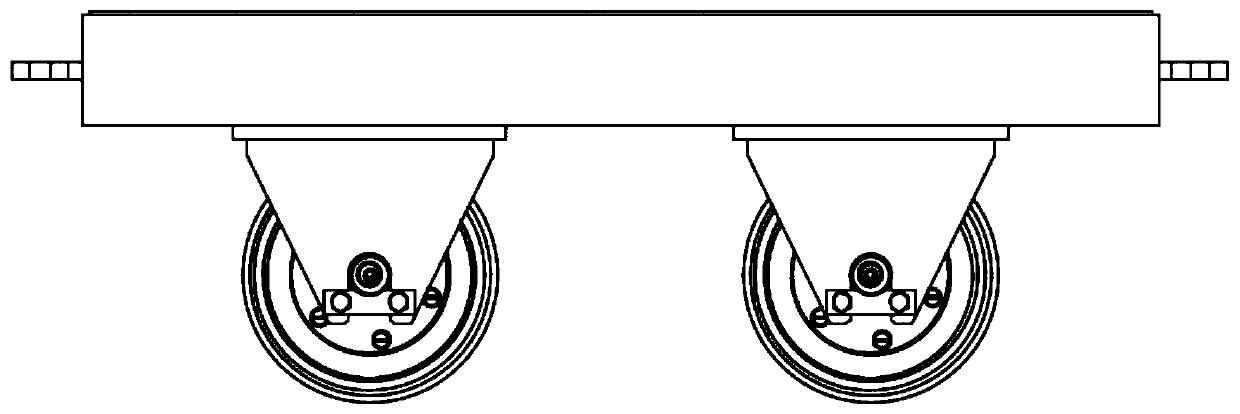

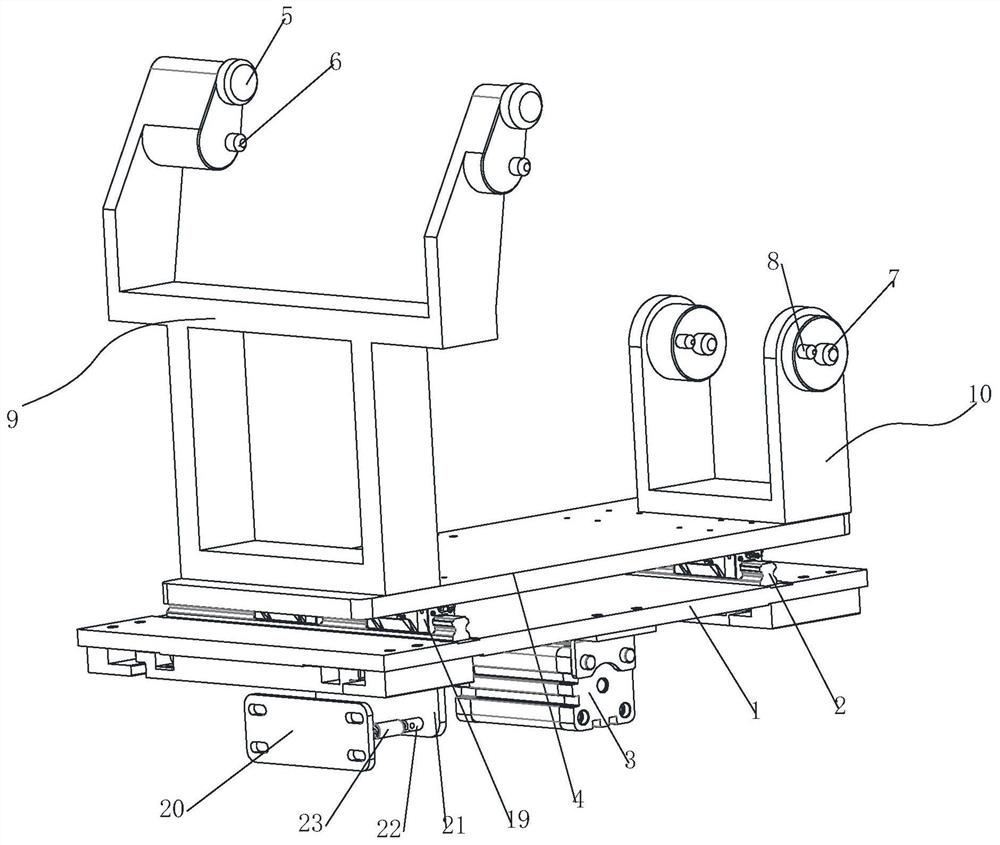

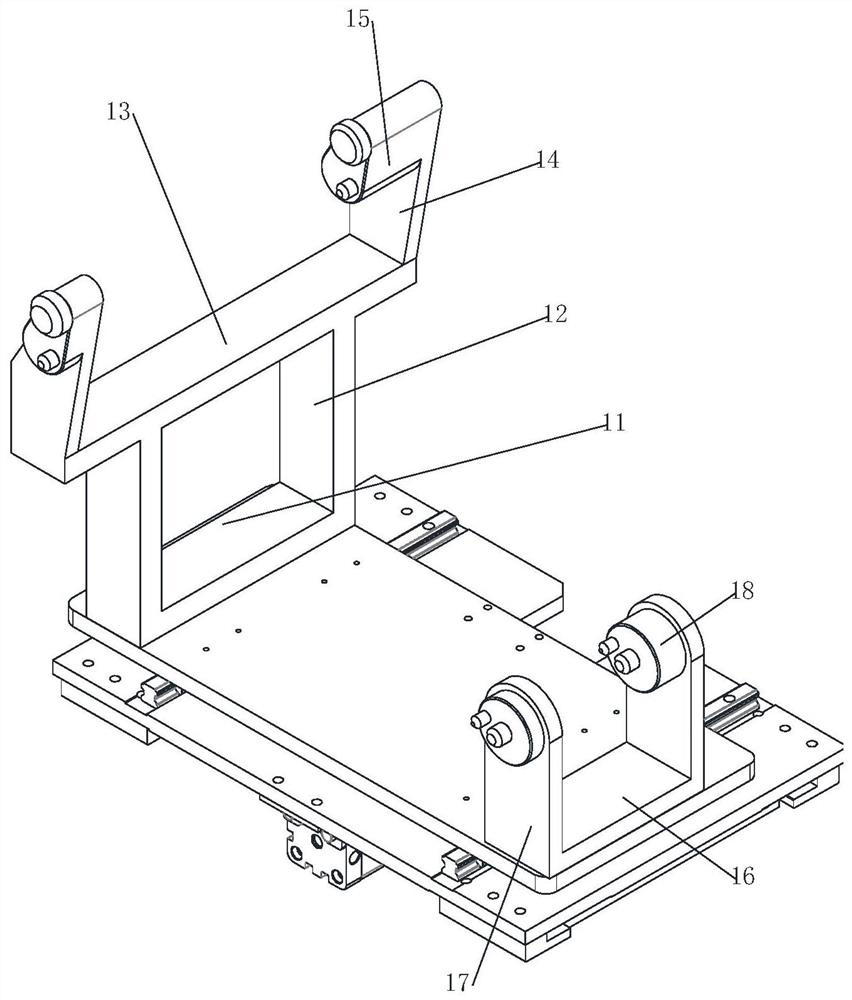

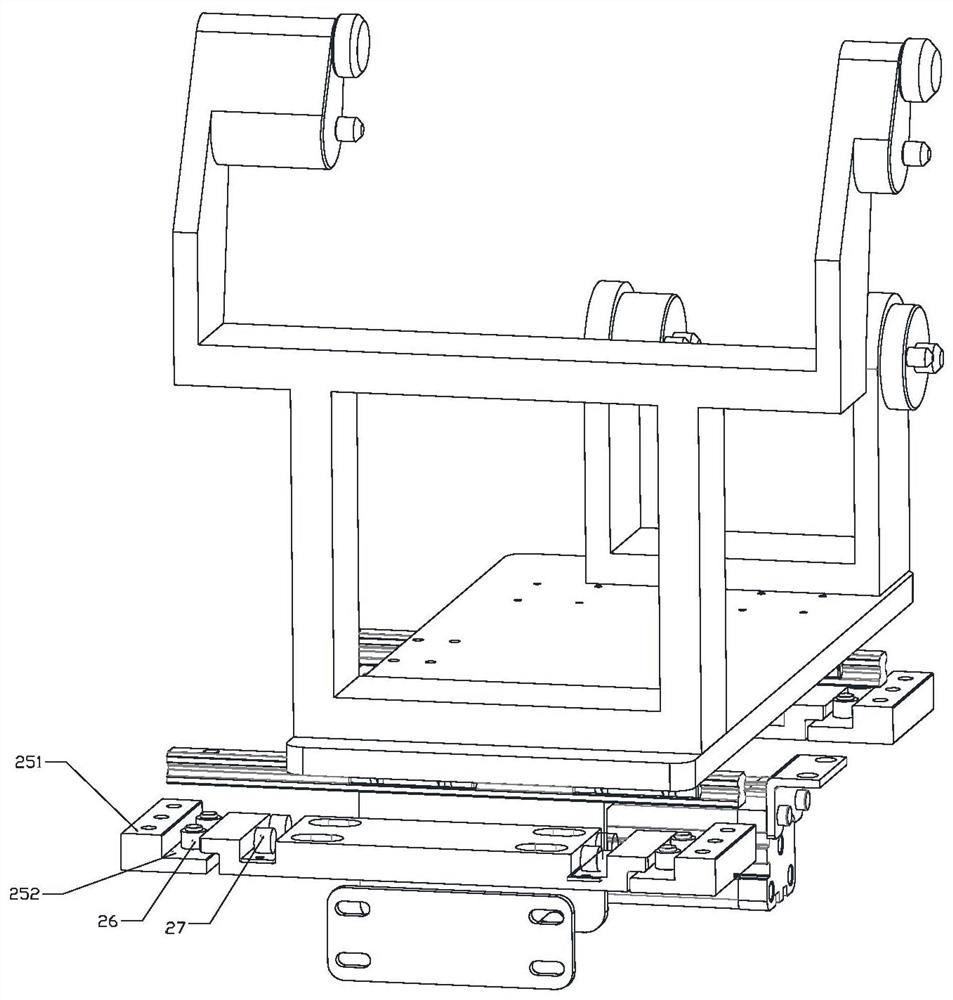

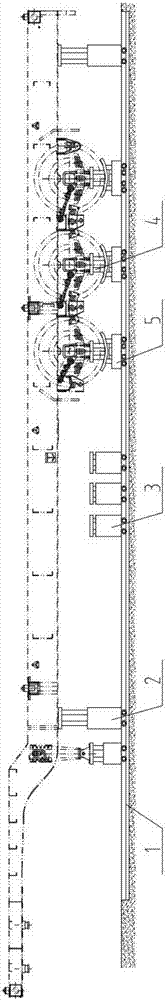

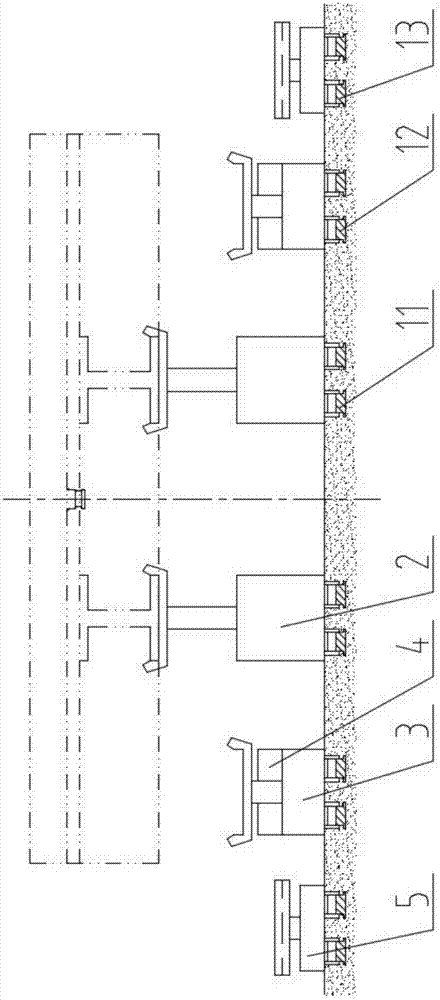

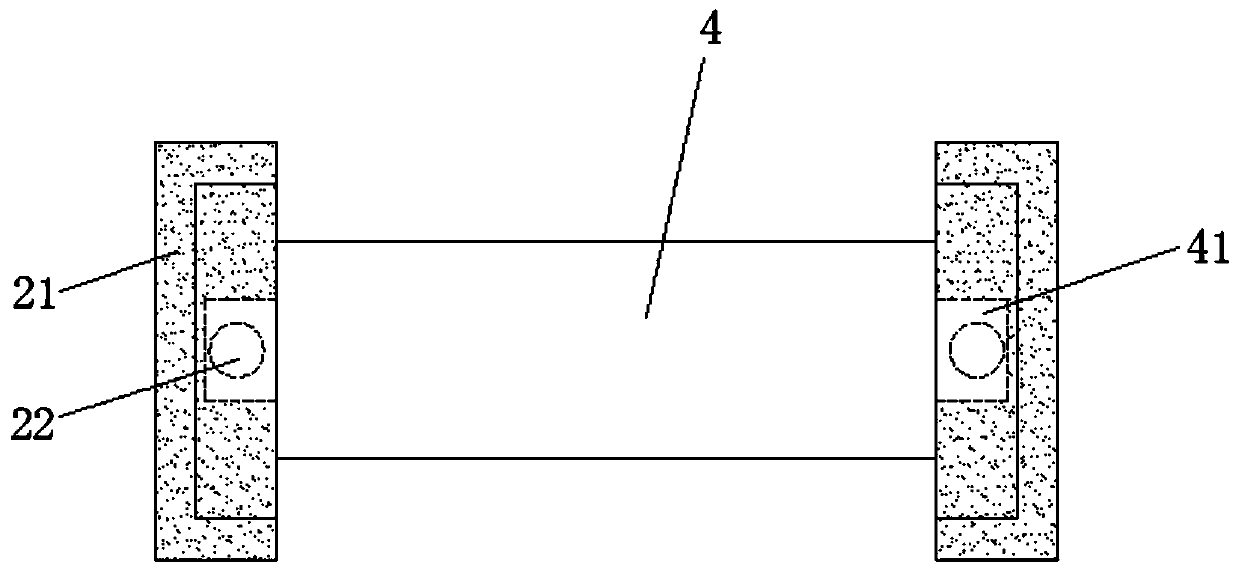

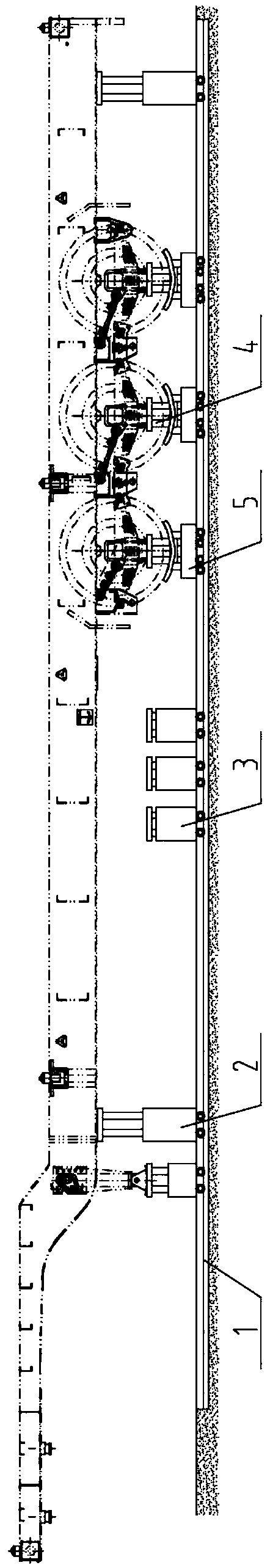

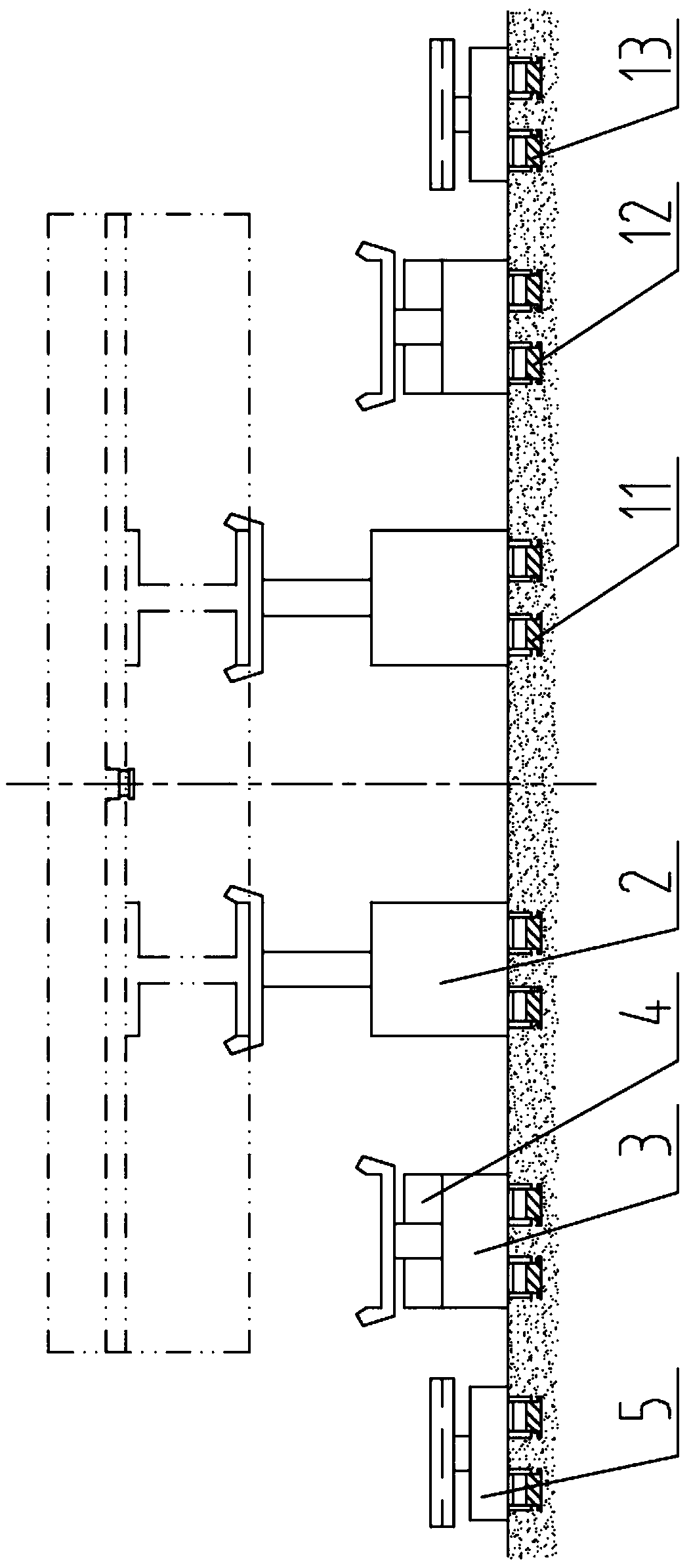

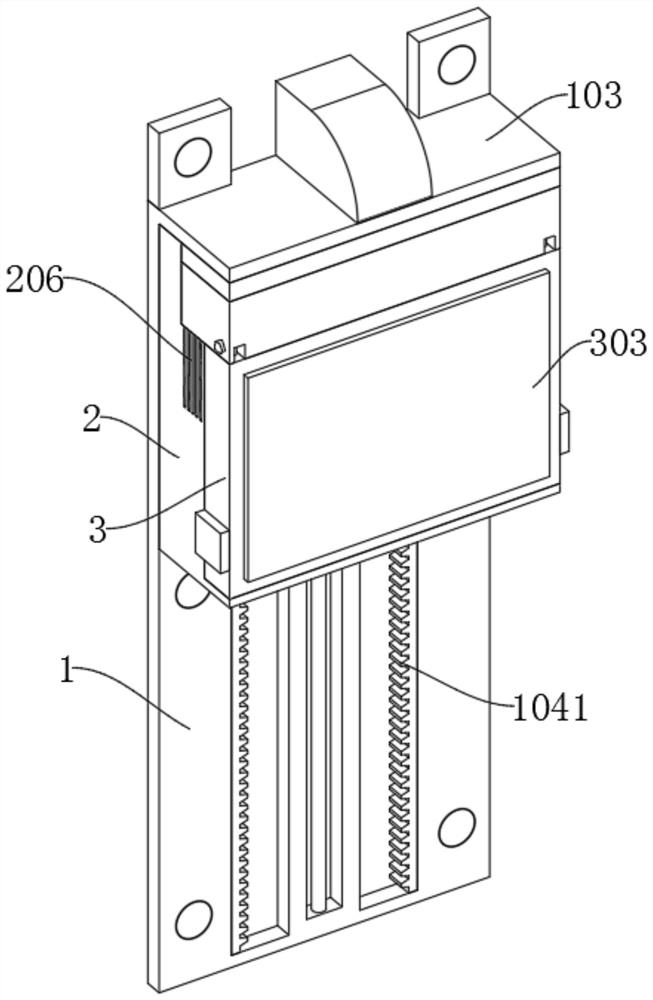

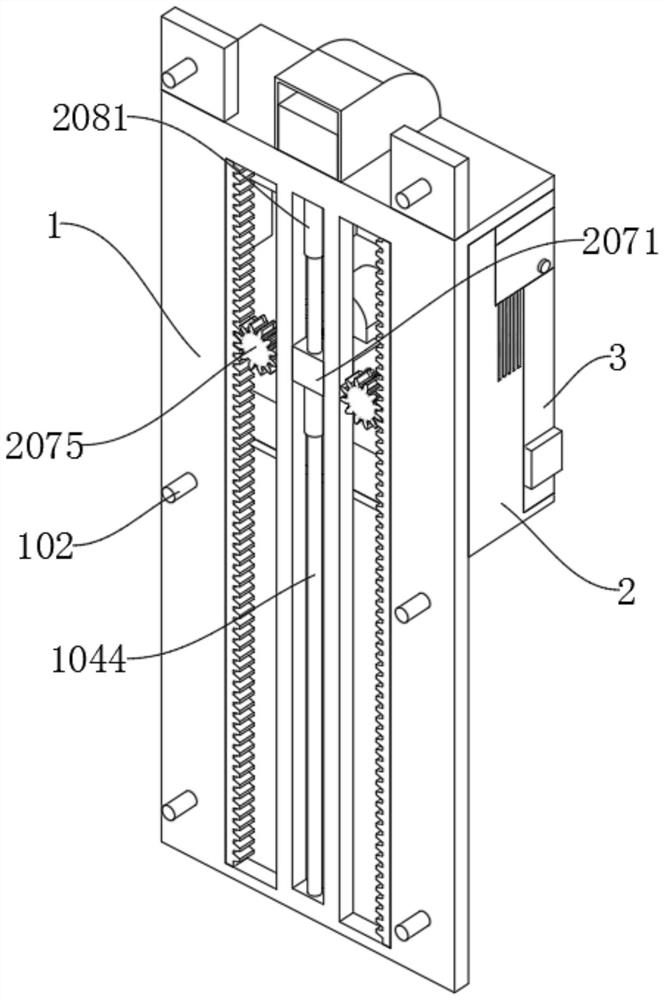

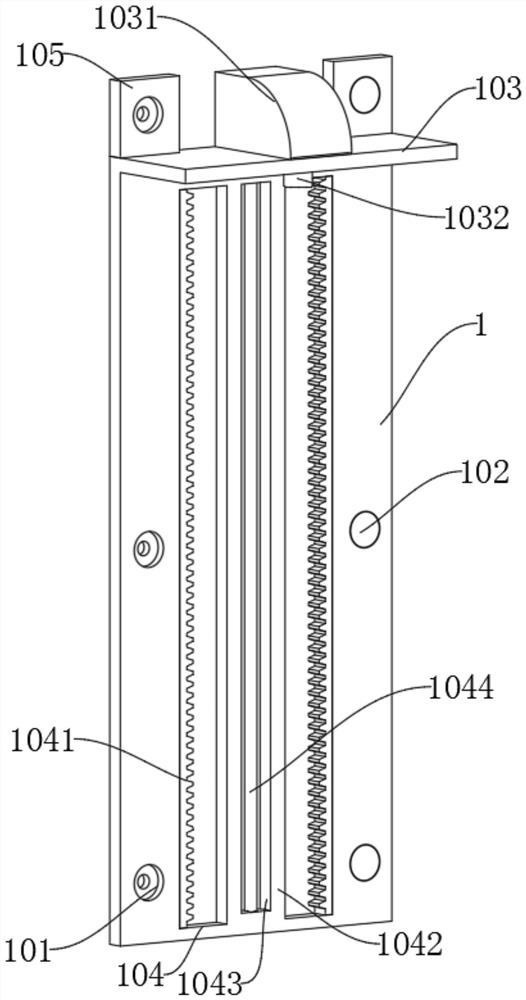

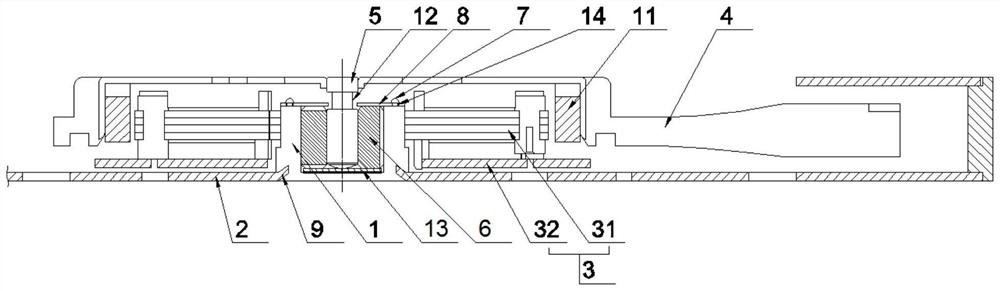

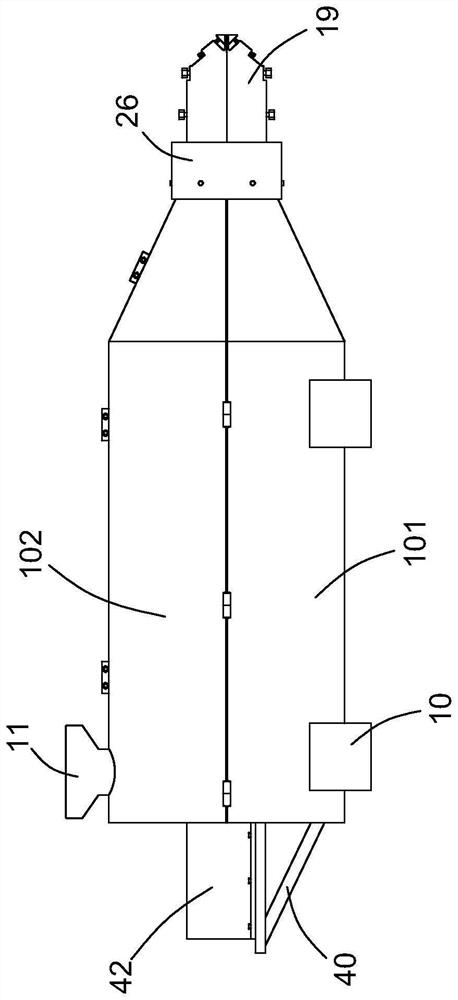

Trailer assembly system

ActiveCN107226148ARapid positioningQuick Position AssemblyLoad-engaging elementsVehiclesVehicle frameEngineering

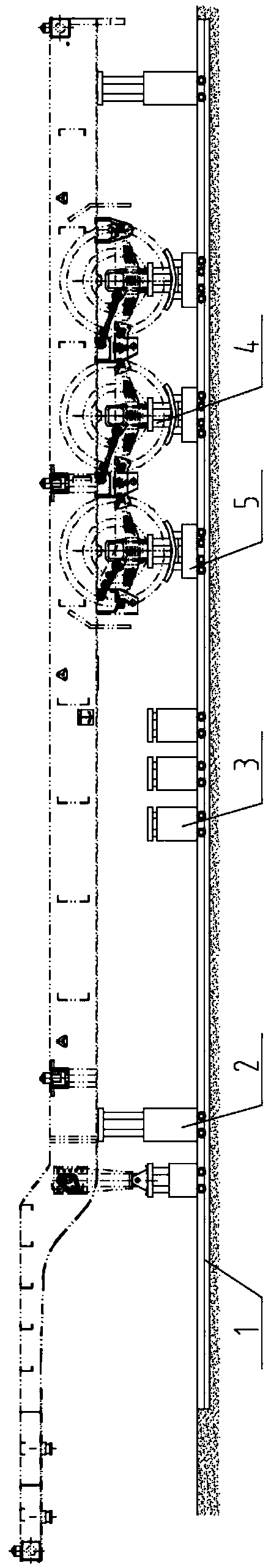

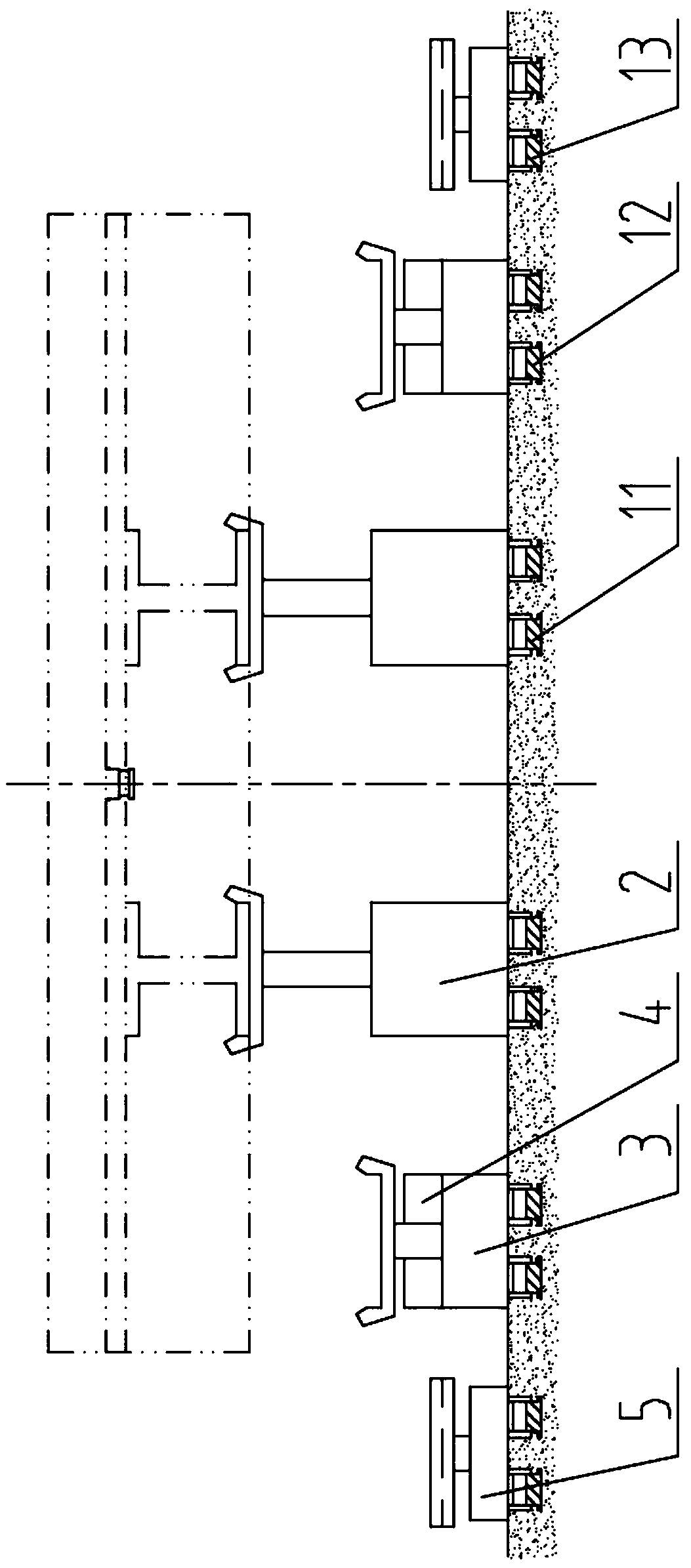

The invention discloses a trailer assembly system which comprises horizontal linear guide rail parts (1), vehicle frame supporting parts (2), suspension supporting parts (3), axle supporting parts (4), wheel supporting parts (5) and an electronic control device. The horizontal linear guide rail parts at least comprise vehicle frame mounting guide rails (11), axle mounting guide rails (12) and wheel mounting guide rails (13) which are arranged in a left-right symmetry mode; the bottoms of the vehicle frame supporting parts, the bottoms of the suspension supporting parts, the bottoms of the axle supporting parts and the bottoms of the wheel supporting parts comprise supporting rollers and roller positioning mechanisms correspondingly, and the supporting rollers are arranged to roll in the front-rear direction; and the vehicle frame supporting parts, the suspension supporting parts, the axle supporting parts and the wheel supporting parts are provided with up-down telescopic mechanisms arranged in the up-down direction and workpiece supporting surfaces located at the telescopic ends of the up-down telescopic mechanisms correspondingly. According to the trailer assembly system, overall quick positioning and assembling of a trailer can be achieved, the assembling efficiency is high, and the safety hidden trouble of hoisting and swinging mounting can be avoided.

Owner:江苏富华交通运输设备股份有限公司

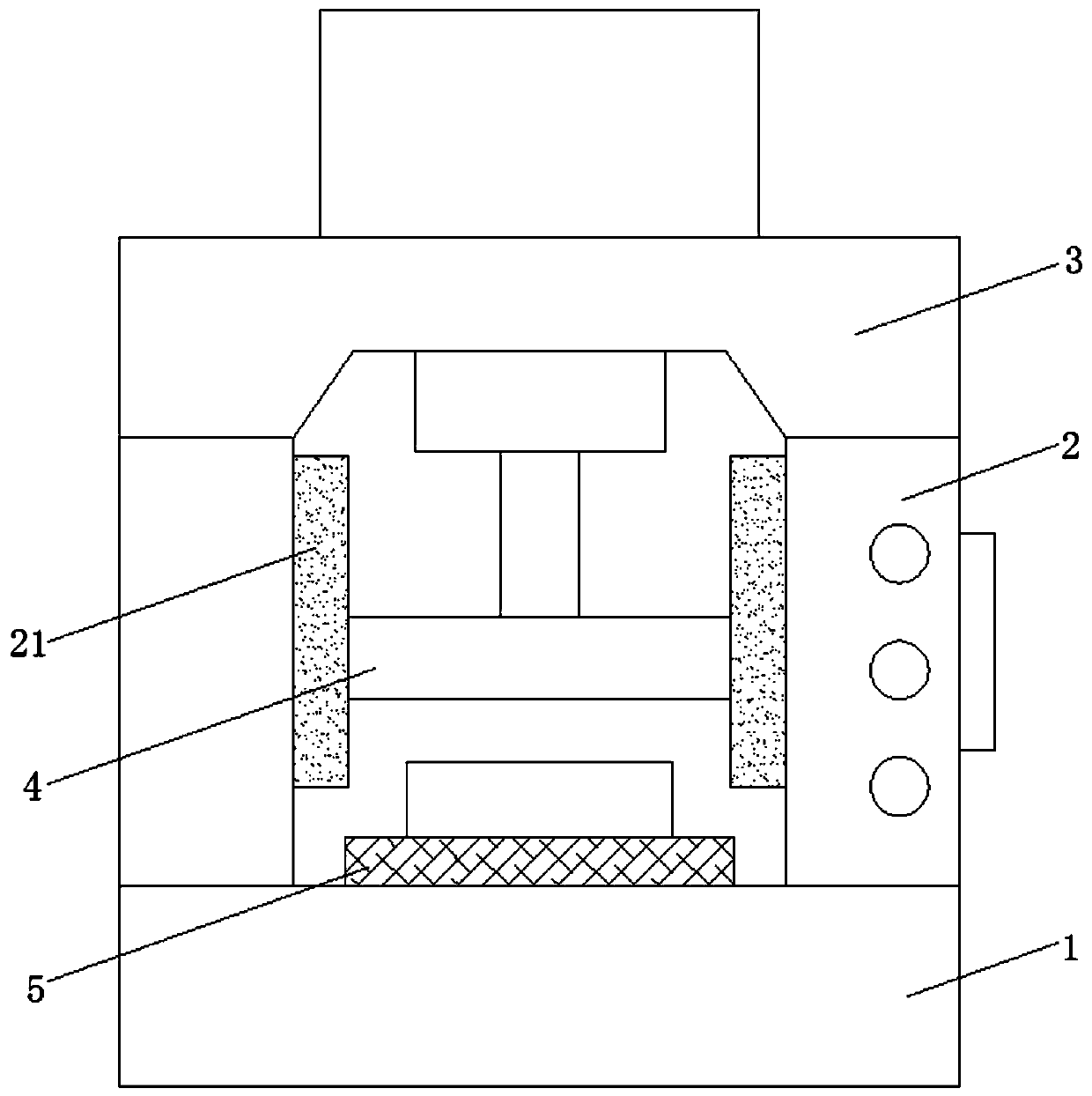

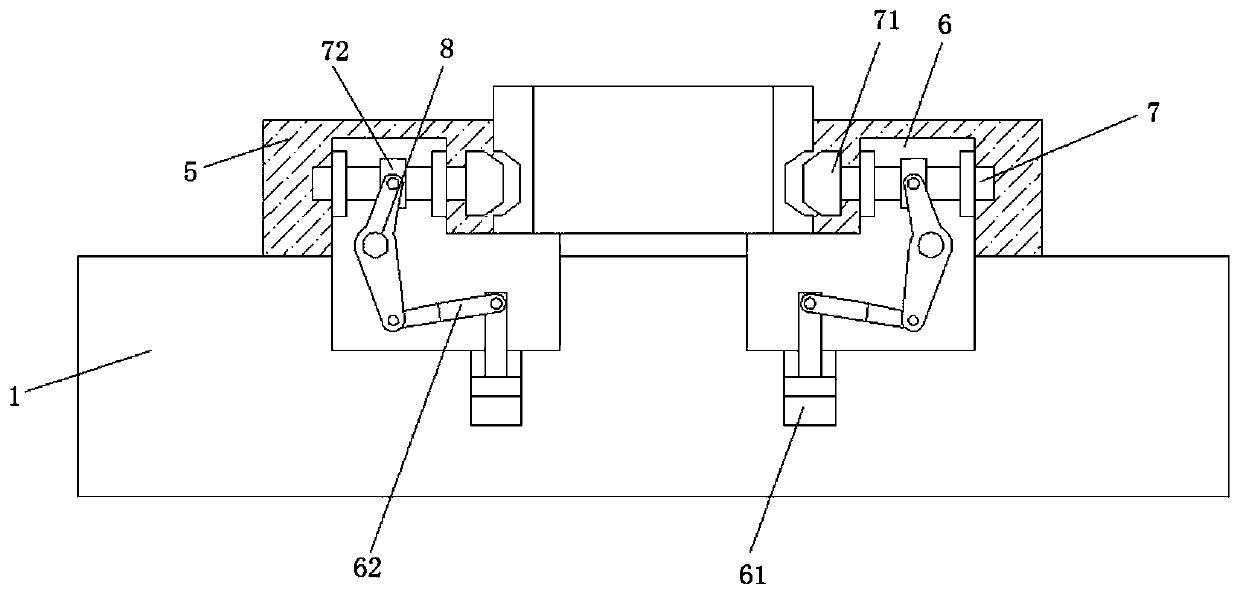

High-strength Q345C low-alloy steel forming device

PendingCN111438217AQuick assemblyQuick Position AssemblyExtrusion diesHydraulic cylinderStructural engineering

The invention relates to the technical field of alloy steel processing, in particular to a high-strength low-alloy steel forming device. The high-strength low-alloy steel forming device includes a base, supporting columns and a top seat; the supporting column is welded between the base and the top seat; the upper wall of the top seat is installed with an electric control box; the outer wall of thesupporting column is installed with a control panel; a pressure seat is movably arranged under the top seat through a hydraulic cylinder; the pressure seat is slidably arranged between the supportingcolumns on both sides through two sets of guide blocks; the upper wall of the base is welded with a fixing seat in a cavity structure; an installation cavity is opened between the fixing seat and thebase; a fixing groove is opened in the middle of the upper surface of the fixing seat; and a movable pin is slidably arranged on the inner side of the installation cavity. Compared with the prior art, the invention not only facilitates rapid positioning and assembly of the forming mold, but also improves the automation degree of the high-strength low-alloy steel forming device.

Owner:河北敬业中厚板有限公司

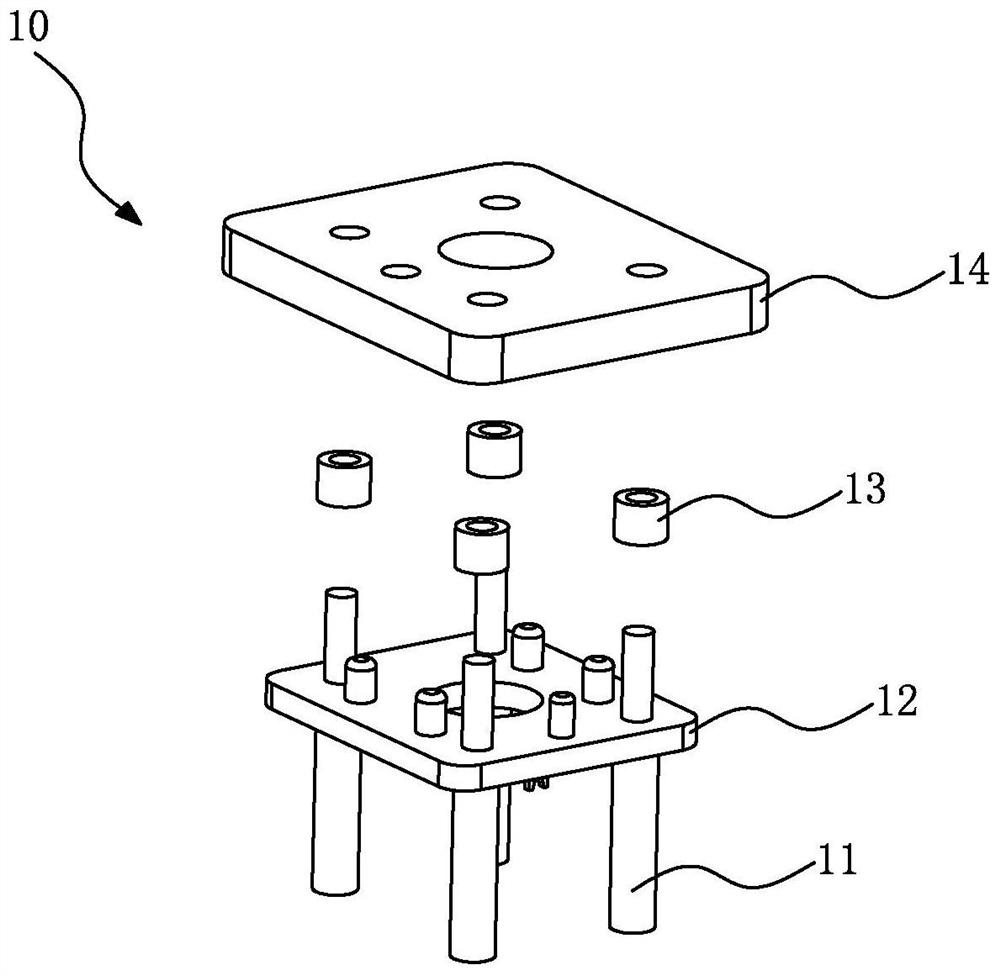

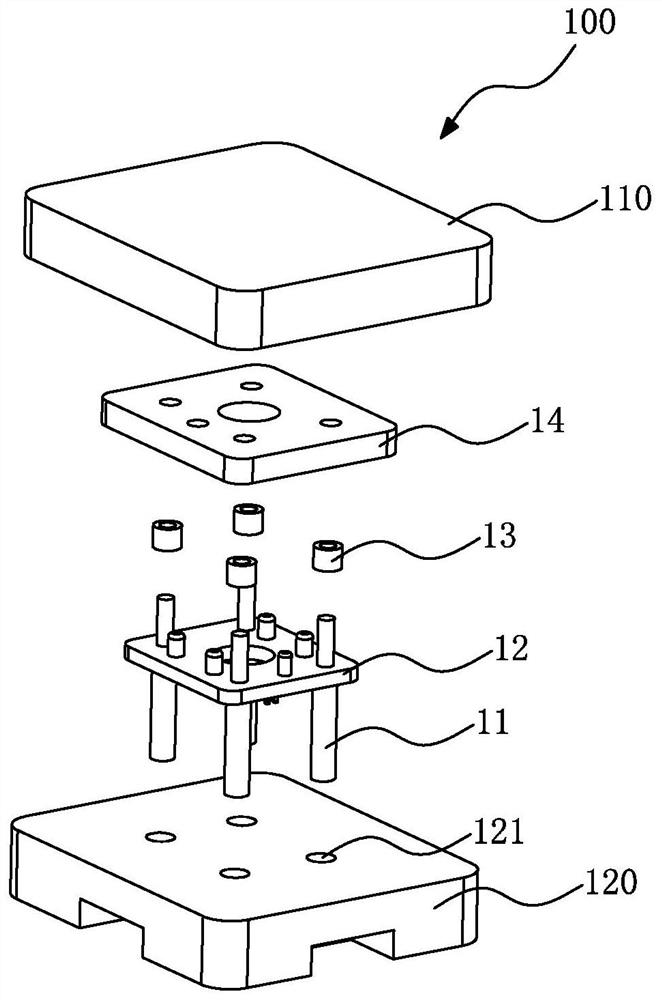

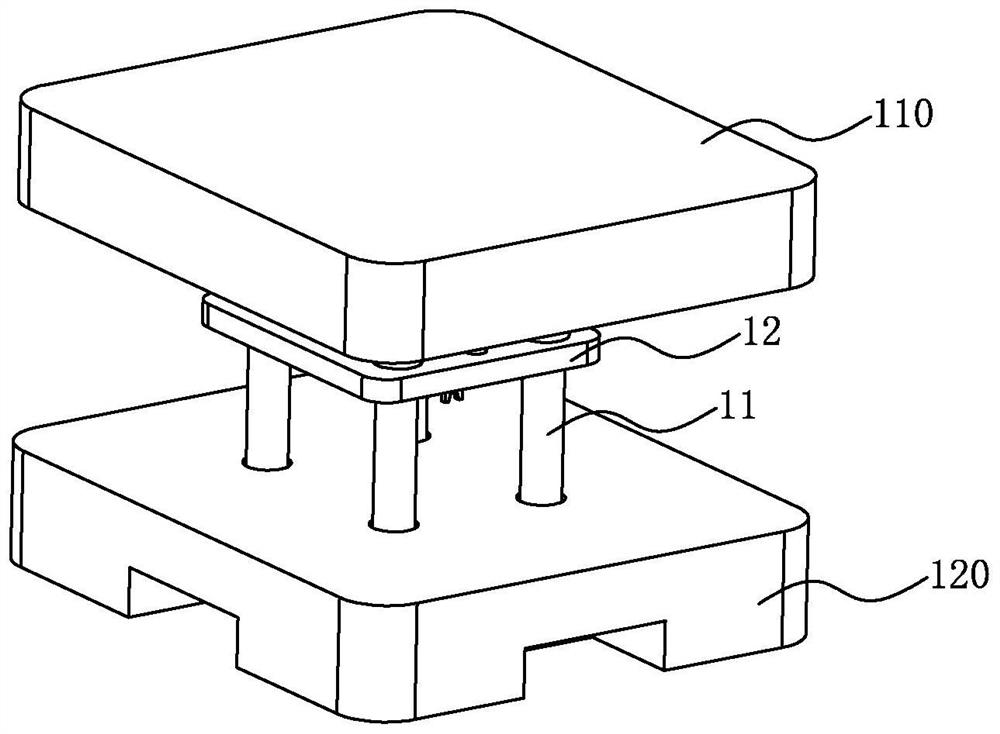

A method for assembling an electronic product

ActiveCN110315313BQuick Position AssemblyImprove efficiencyMetal working apparatusWasherIndustrial engineering

The invention discloses a positioning assembly jig for assembling an electronic product, the electronic product includes at least one stud, a main board, at least one washer sleeve and a stud base, wherein the main board is further provided with at least one first Screw holes, the stud base is provided with at least one second screw hole, the positioning and assembly jig includes: an upper fixing plate, which engages and places the stud base, and the upper fixing plate is in contact with the stud base The bottom surface of the bottom surface is provided with a positioning groove, and the structure of the positioning groove coincides with the stud base; the upper surface of the lower fixing plate is provided with at least one positioning hole, and the positioning hole places the stud. Utilizing the positioning and assembling jig of the present invention, not only can the electronic products be quickly positioned and assembled, but the locking efficiency of the studs is improved to meet the production requirements. Adjustment makes it have a wider range of applications and saves production costs.

Owner:SHENXUN COMP KUNSHAN

Buckle connection structure of injection package stator and PCBA board

PendingCN113597097ARealize positioning and fixed assemblyImprove bindingAssociation with control/drive circuitsPump installationsStructural engineeringMechanical engineering

The invention relates to a buckle connection structure of an injection package stator and PCBA board. The buckle connection structure comprises the injection package stator and the PCBA board located at the bottom of the injection package stator, the injection package stator comprises an insulation center frame and a plurality of silicon steel sheets located in the insulation center frame, the insulation center frame is provided with a center sleeve and welding columns located outside the center sleeve at intervals, the bottom of the center sleeve is provided with buckles protruding towards the bottom of the center sleeve, the PCBA board is provided with a first center hole corresponding to the center sleeve and welding holes welded and fixed corresponding to the welding columns, the first center hole is provided with a plurality of first notches corresponding to the buckles, the inner walls of the first notches are matched with the outer walls or the outer side walls of the buckles in shape, the insulation center support of the injection package stator is stably combined with the silicon steel sheets, the combination force of the injection package stator and the PCBA board is fixed through the welding points, meanwhile, the combination of the buckles and the PCBA board is added, the combination force is further enhanced, the falling risk is avoided, the stability of the fan injection package stator and PCBA board combination structure is improved, and the service life of the fan injection package stator and PCBA board combination structure is prolonged.

Owner:江苏嘉之瑞电子科技有限公司

A method of using a trailer assembly system

The invention discloses a usage method of a trailer assembling system. The usage method comprises the steps of self adjustment of guide rail separation distances, self movement of supporting parts, erection of taking-off assembly parts, erection of frame assembly, hanging installation, axle installation, wheel installation, electrical installation, trailer tape-out and the like. A frame supporting part, a hanging supporting part, an axle supporting part and a wheel supporting part move in the front-back direction of a horizontal linear guide rail part through supporting rollers or are positioned on the horizontal linear guide rail part through roller positioning mechanism, the parts are not interfered in the assembling-installing process, and rapid assembly is promoted. Accurate assembly and installation distance control can be achieved. Accurate, positioned and rapid hoisting can be achieved. By adopting the usage method of the trailer assembling system, overall and rapid positioning and assembly of a trailer can be achieved, the assembly efficiency is high, and the potential safety hazard of hanging swing installation can be avoided.

Owner:江苏富华交通运输设备股份有限公司

A trailer assembly system

ActiveCN107226148BRapid positioningQuick Position AssemblyLoad-engaging elementsVehiclesVehicle frameEngineering

The invention discloses a trailer assembly system which comprises horizontal linear guide rail parts (1), vehicle frame supporting parts (2), suspension supporting parts (3), axle supporting parts (4), wheel supporting parts (5) and an electronic control device. The horizontal linear guide rail parts at least comprise vehicle frame mounting guide rails (11), axle mounting guide rails (12) and wheel mounting guide rails (13) which are arranged in a left-right symmetry mode; the bottoms of the vehicle frame supporting parts, the bottoms of the suspension supporting parts, the bottoms of the axle supporting parts and the bottoms of the wheel supporting parts comprise supporting rollers and roller positioning mechanisms correspondingly, and the supporting rollers are arranged to roll in the front-rear direction; and the vehicle frame supporting parts, the suspension supporting parts, the axle supporting parts and the wheel supporting parts are provided with up-down telescopic mechanisms arranged in the up-down direction and workpiece supporting surfaces located at the telescopic ends of the up-down telescopic mechanisms correspondingly. According to the trailer assembly system, overall quick positioning and assembling of a trailer can be achieved, the assembling efficiency is high, and the safety hidden trouble of hoisting and swinging mounting can be avoided.

Owner:江苏富华交通运输设备股份有限公司

Wind power flange connecting structure

PendingCN112762063AQuick Position AssemblyAvoid separationSecuring devicesSheet joiningScrew threadWind power

The invention discloses a wind power flange connecting structure. The wind power flange connecting structure which comprises a first flange and a second flange and is characterized in that a plurality of inserting blocks and a plurality of inserting grooves are formed in the opposite end faces of the first flange and the second flange correspondingly, the inserting blocks correspond to the inserting grooves one to one, the inserting blocks are just inserted into the inserting grooves, a threaded hole in communication with the inserting grooves is formed in the side wall of the second flange, a locking bolt is arranged in the threaded hole, and a positioning hole allowing the locking bolt to penetrate through is formed in the inserting block. According to the wind power flange connecting structure, rapid positioning and assembling of the flanges are achieved through the inserting grooves and the inserting blocks, dislocation is prevented, then locking is conducted through bolts, flange separation is avoided, disassembling and assembling are convenient and efficient, and the assembling effect is better.

Owner:张家港市三林金泰新能源有限公司

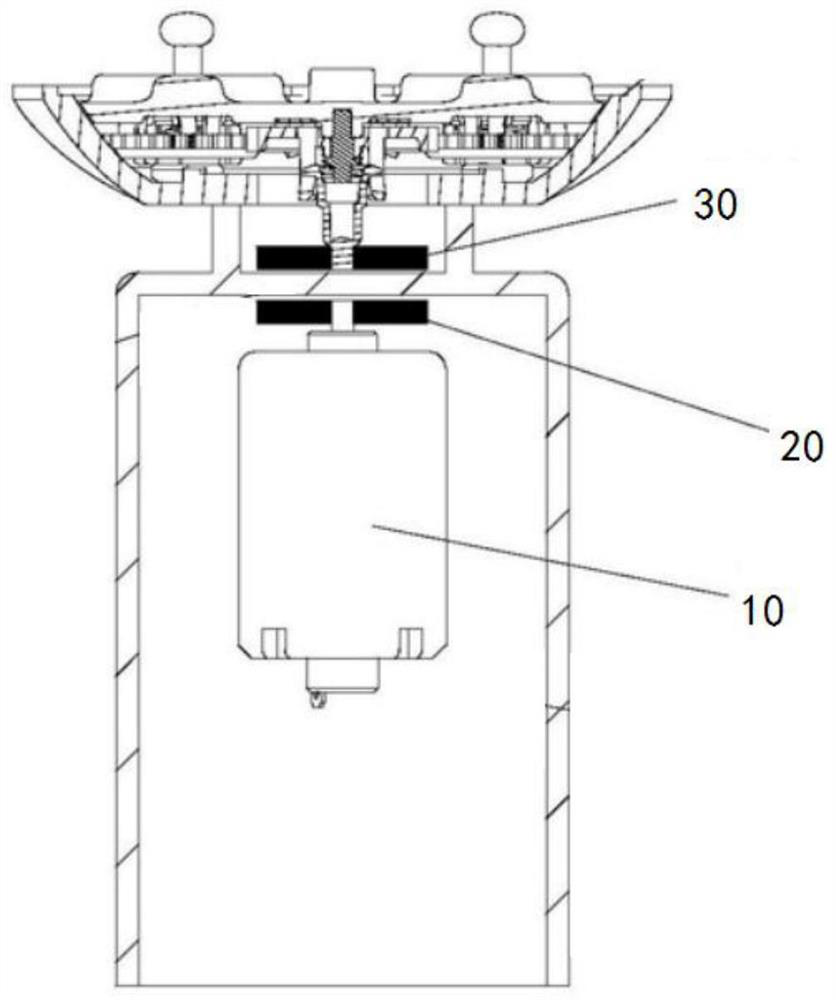

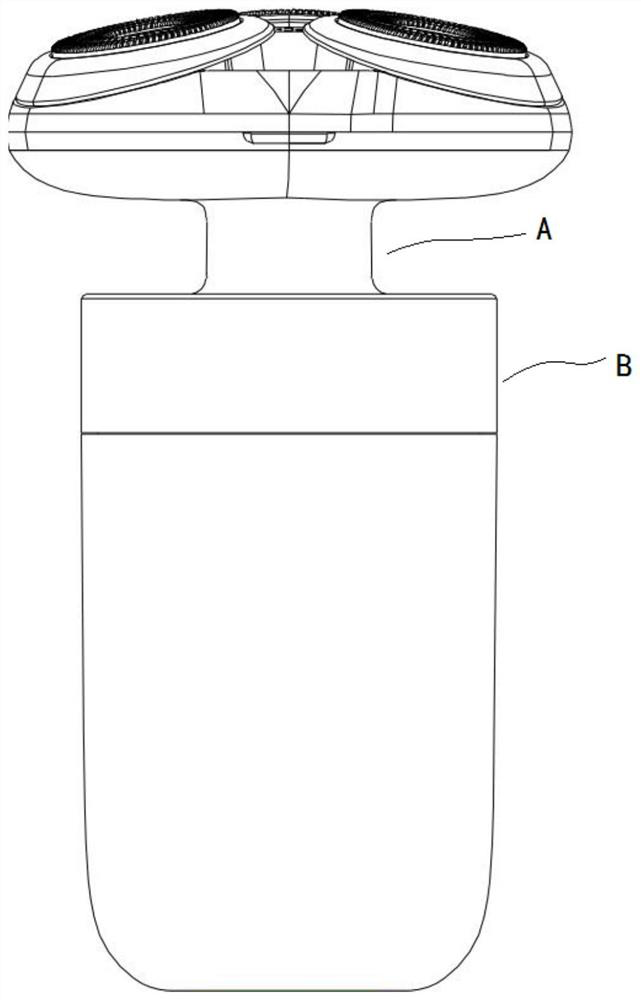

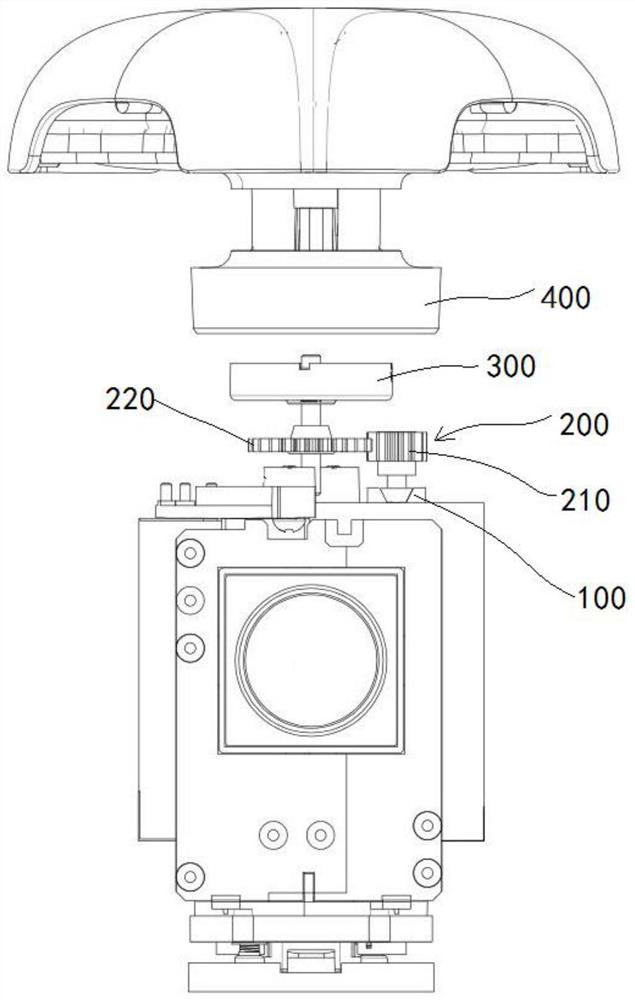

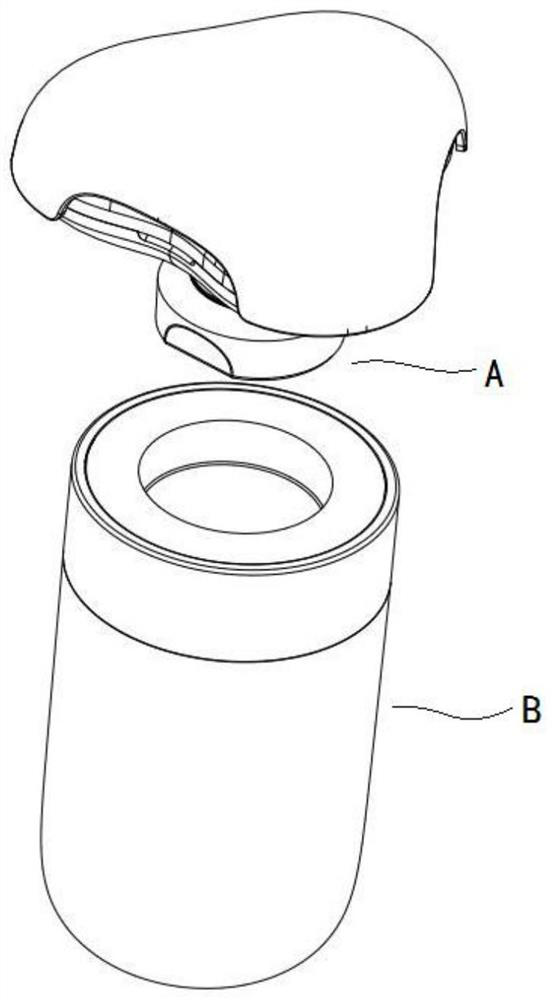

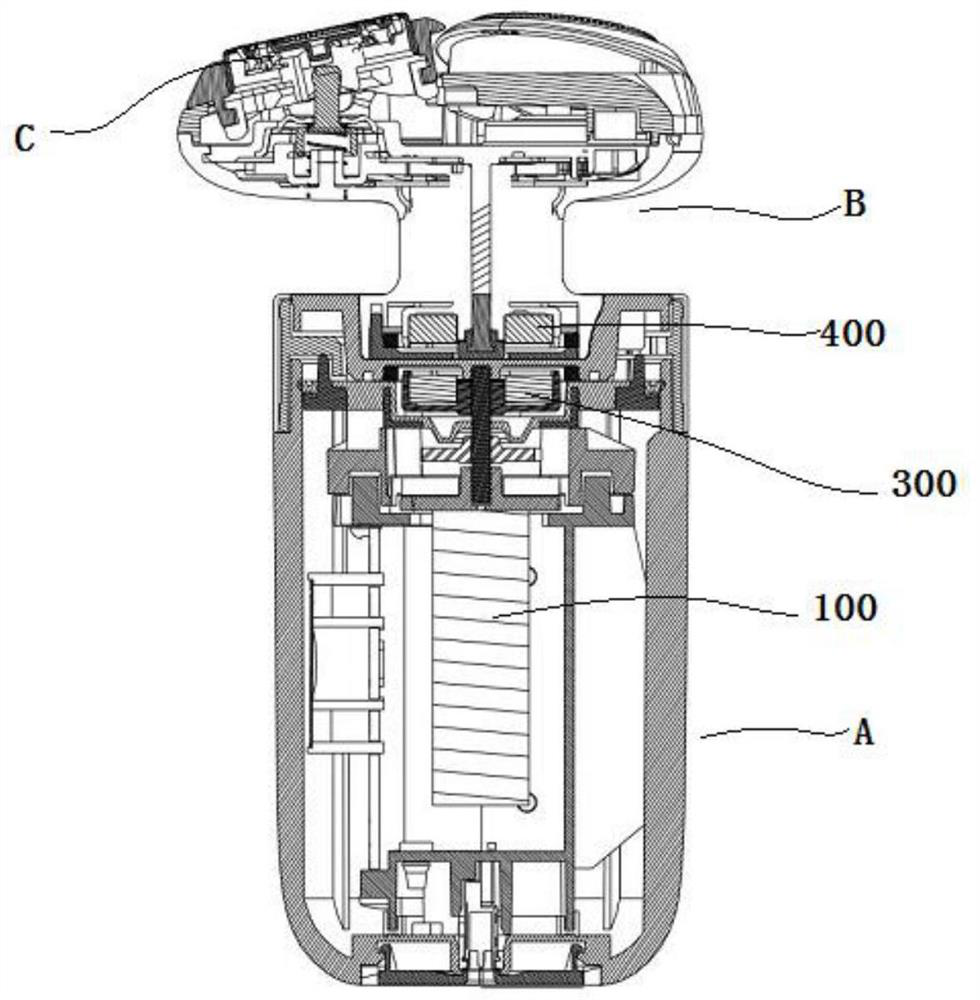

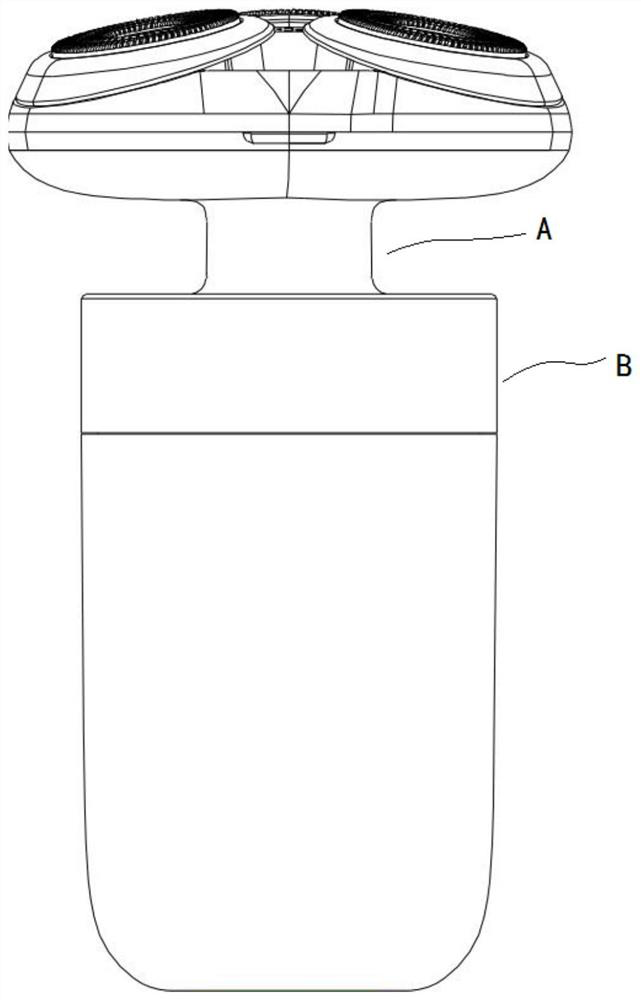

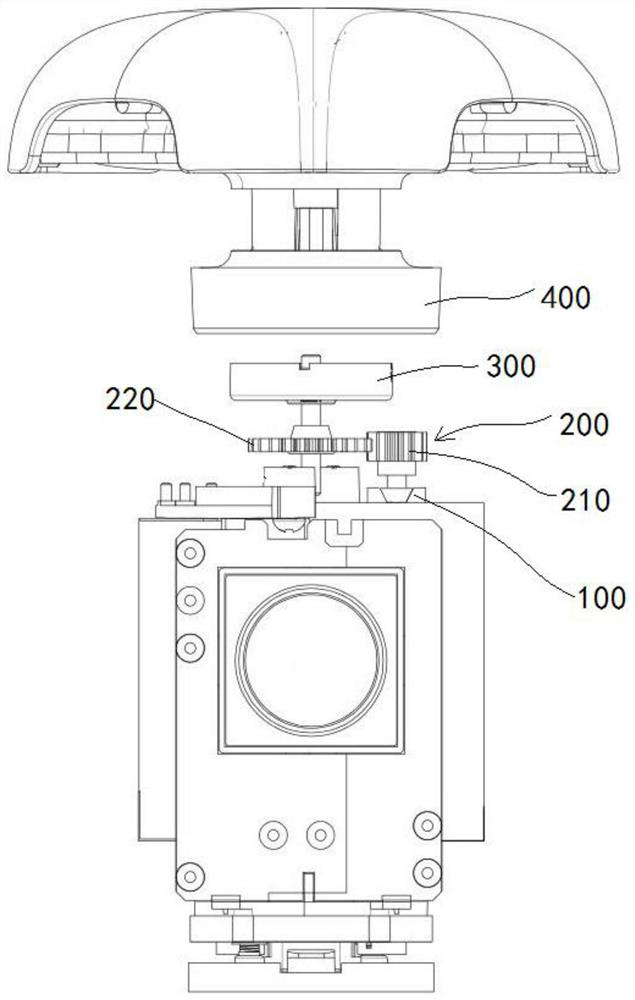

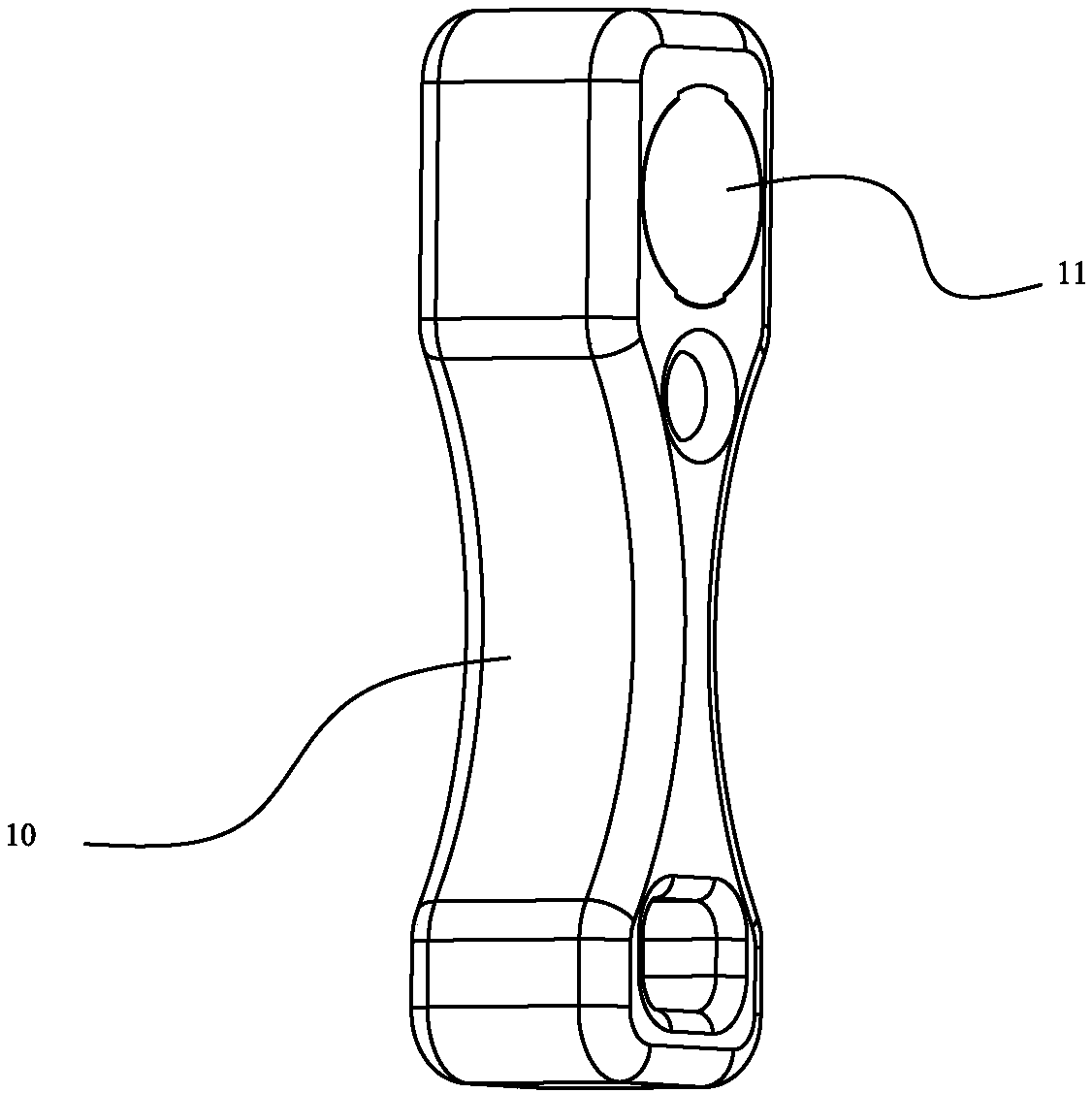

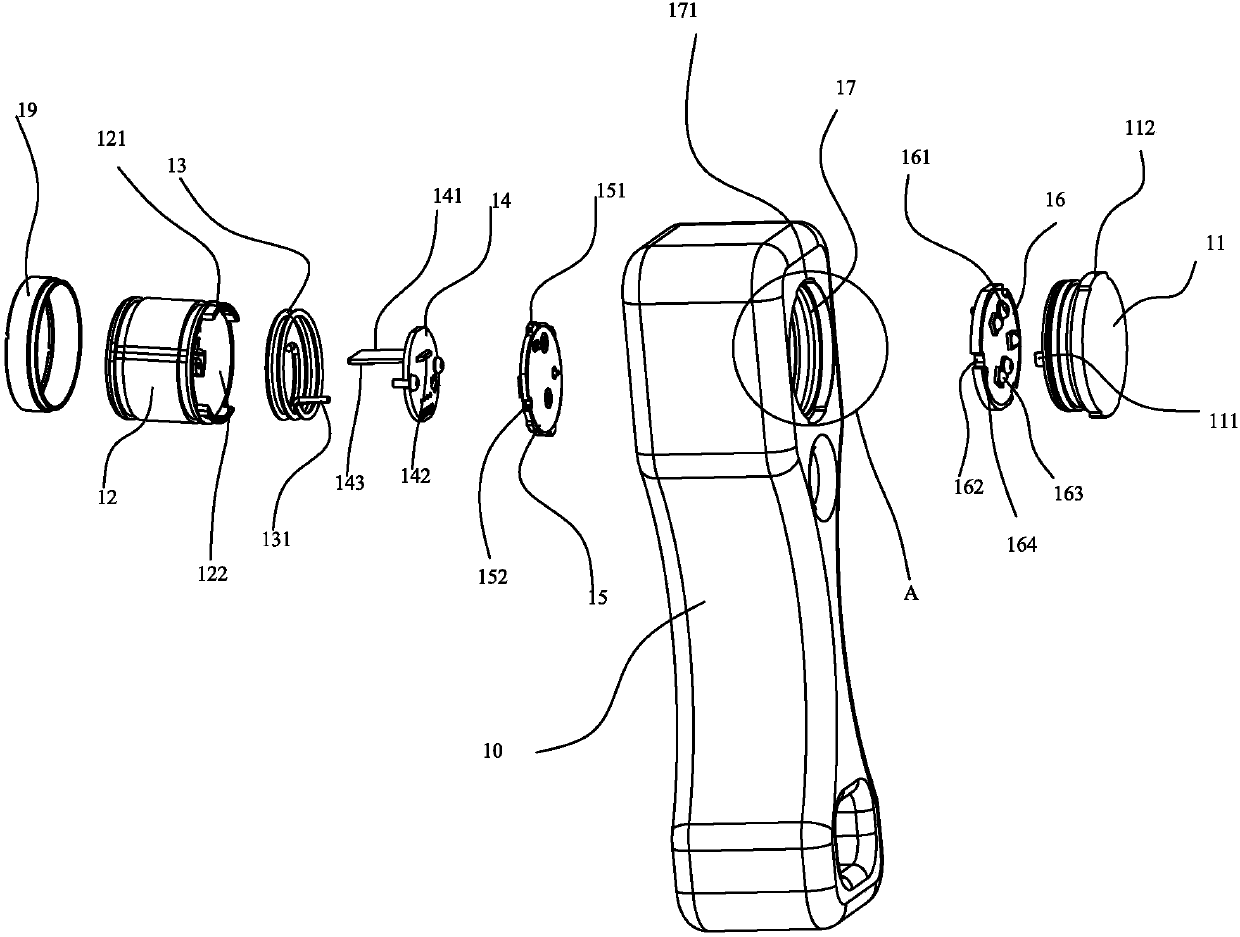

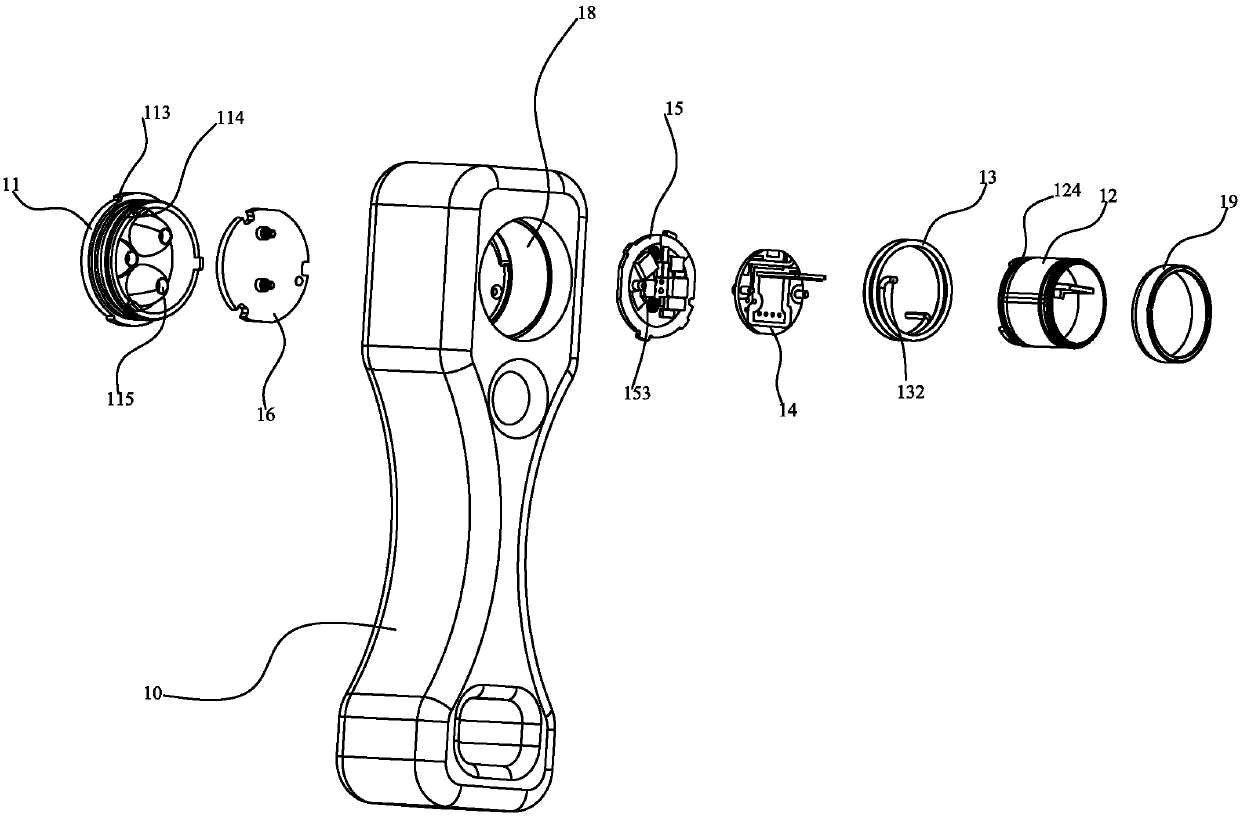

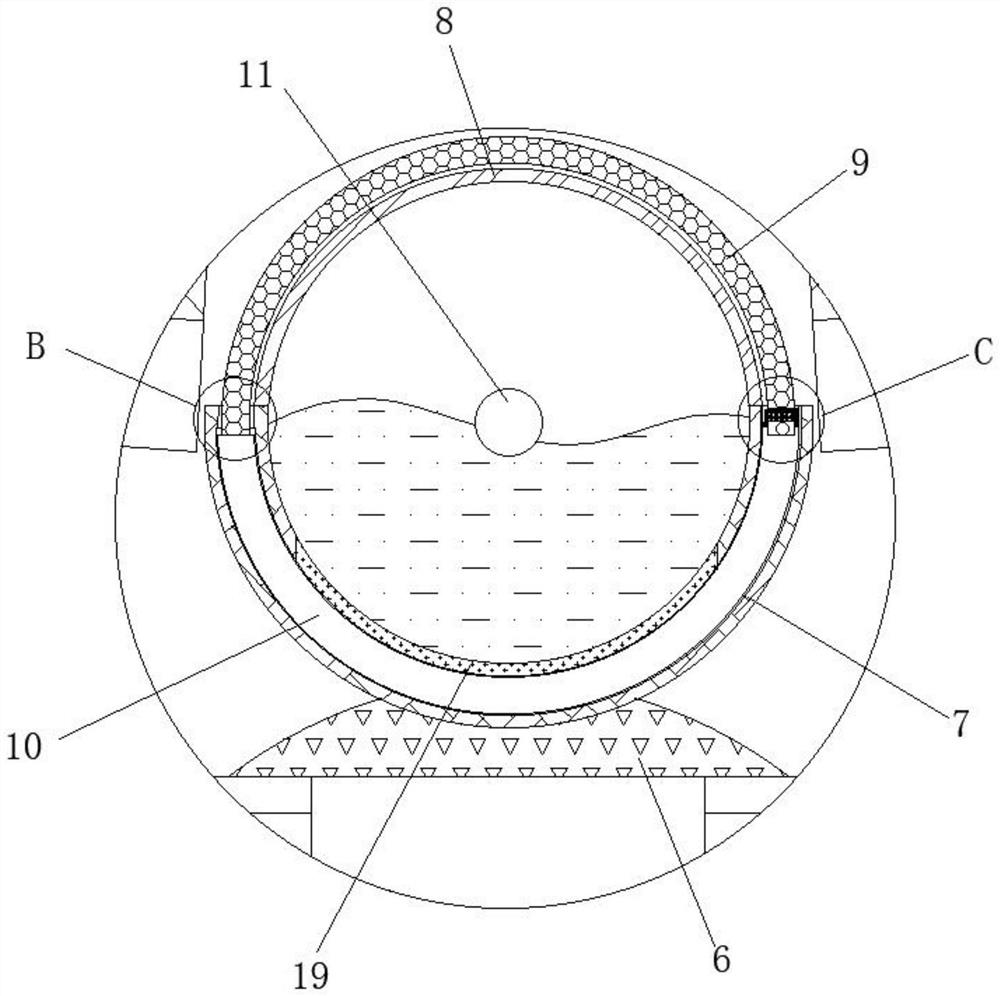

an electric shaver

ActiveCN111941473BImprove the magnetic effectQuick Position AssemblyMetal working apparatusElectric machineEngineering

The present invention provides an electric shaver, including a main body assembly and a head cover assembly, the main body assembly includes a lower casing and a drive unit disposed in the lower casing, the head cover assembly includes a moving knife unit and a user In the upper casing supporting the moving knife unit, the lower casing is embedded with an active magnetic component, and the upper casing is embedded with a driven magnetic component. When the electric shaver is stationary and placed vertically, the active magnetic The magnetism corresponding to the longitudinal direction of the component and the driven magnetic component is in a state of attraction of opposites, the driving unit includes a motor, and the moving knife unit is driven to rotate under the action of the motor, the active magnetic component and the driven magnetic component; the The central axes of the active magnetic assembly and the driven magnetic assembly coincide with the central axis of the electric shaver, and the central axis of the motor is deviated from the central axis of the electric shaver by 4-8 mm. Wherein the motor is deviated from the central axis of the electric shaver, and the vibration generated by the rotation of the motor has the least influence on the magnet itself.

Owner:HUANXING TECH HANGZHOU CO LTD

Electric shaver adopting magnetic attraction connection

PendingCN111941470AGood sealing performanceGood waterproof effectMetal working apparatusPhysicsElectric machinery

The invention provides a electric shaver adopting magnetic attraction connection. the electric shaver comprises a main body assembly and a head cover assembly, wherein the main body assembly comprisesa lower shell and a driving unit arranged in the lower shell, the head cover assembly comprises a movable knife unit and an upper shell used for supporting the movable knife unit, a driving magnet isembedded in the lower shell, a driven magnet is embedded in the upper shell, the driving unit comprises a motor, the lower shell comprises a body casing and a body upper cover, the body upper cover and the body casing form a closed cavity, the driving unit further comprises a magnet fixing shell located in the closed cavity, the driving magnet is fixedly assembled in the magnet fixing shell, themotor is connected with the magnet fixing shell, and the movable cutter unit is driven to rotate under the action of the motor, the driving magnet and the driven magnet; and assembly clearances existbetween the magnet fixing shell, the body upper cover and the body casing. Magnetic attraction is adopted for assembly and connection, and the mechanical disassembly mode in the prior art is changed.

Owner:LESHOW ELECTRONICS TECH CO LTD

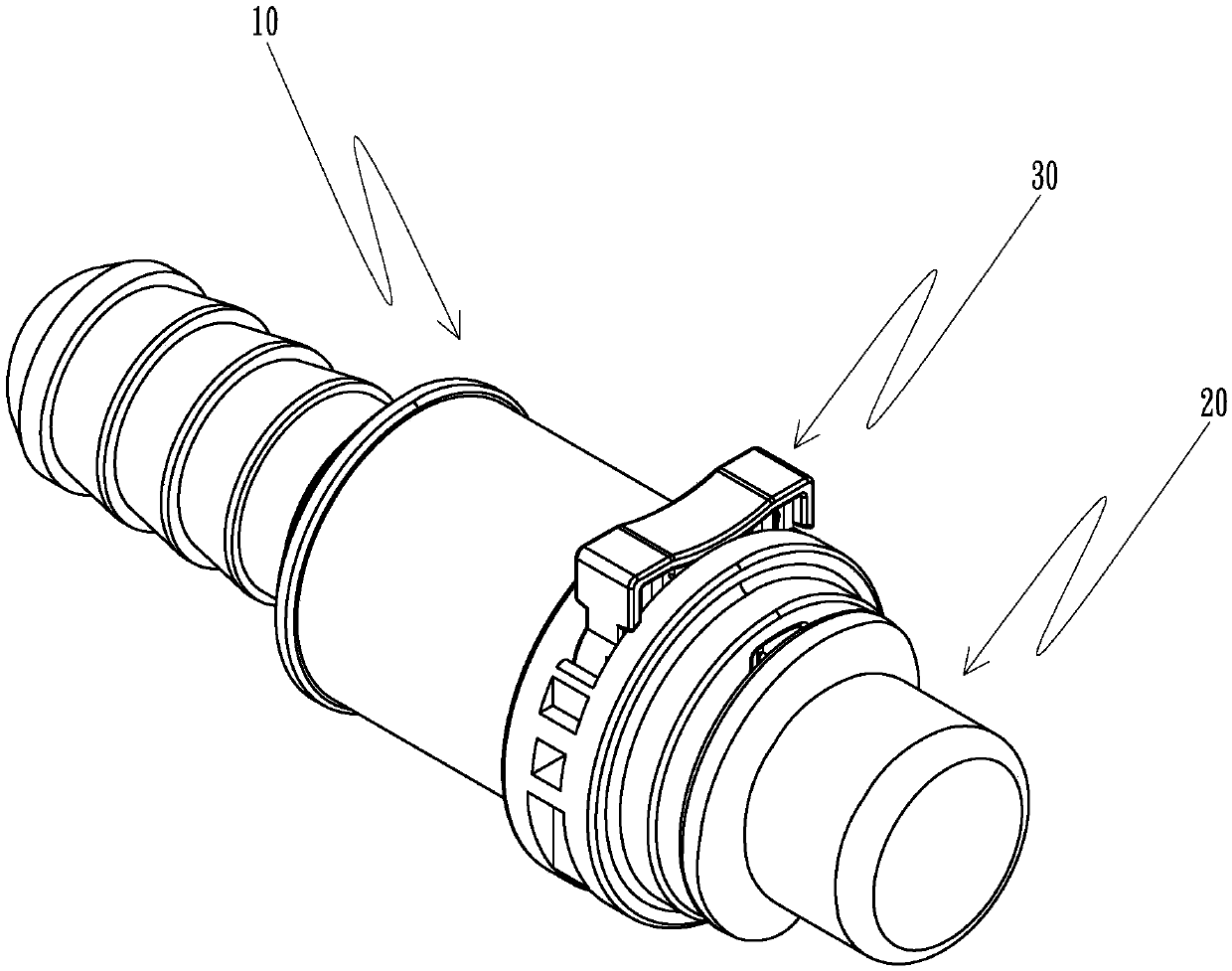

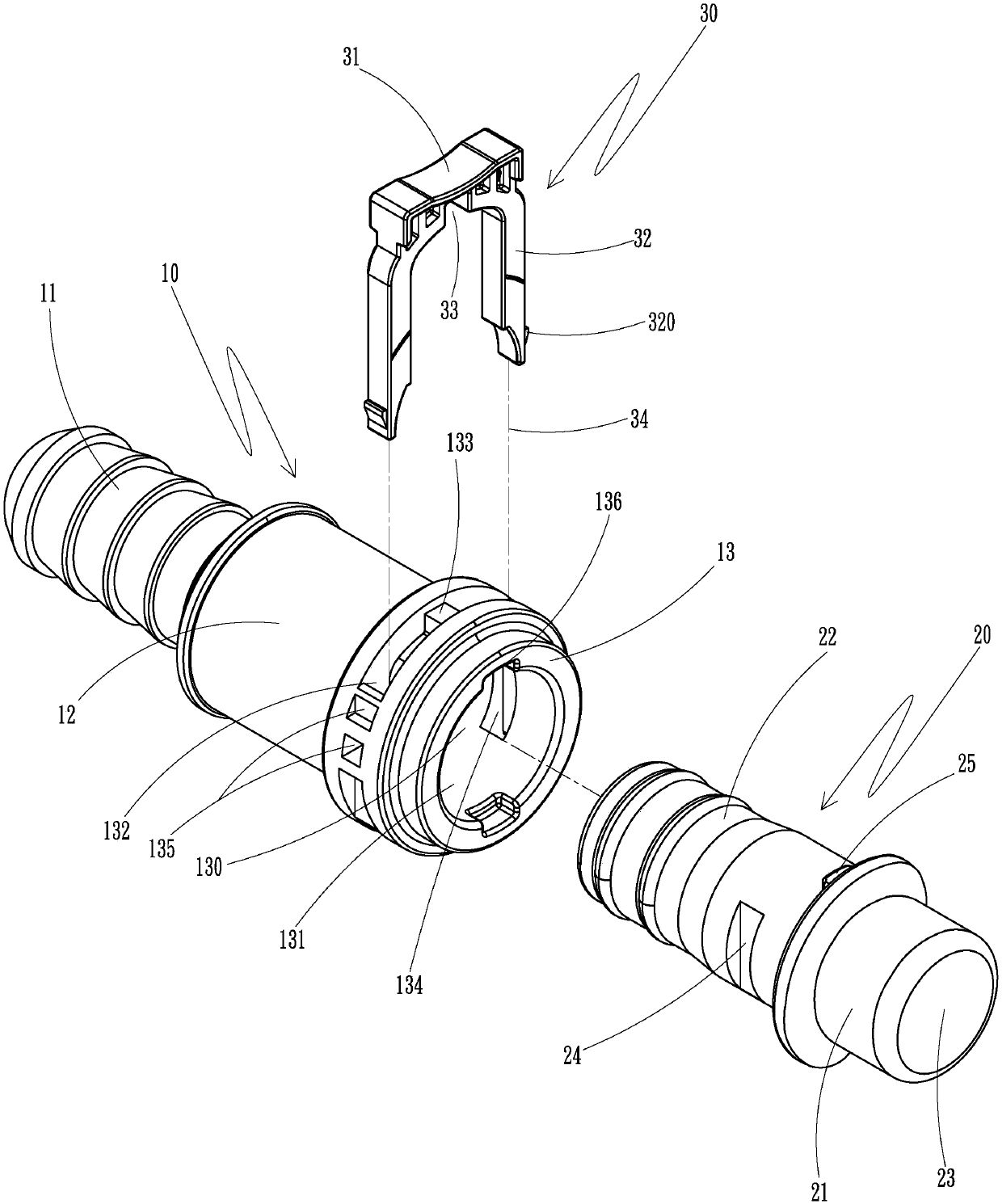

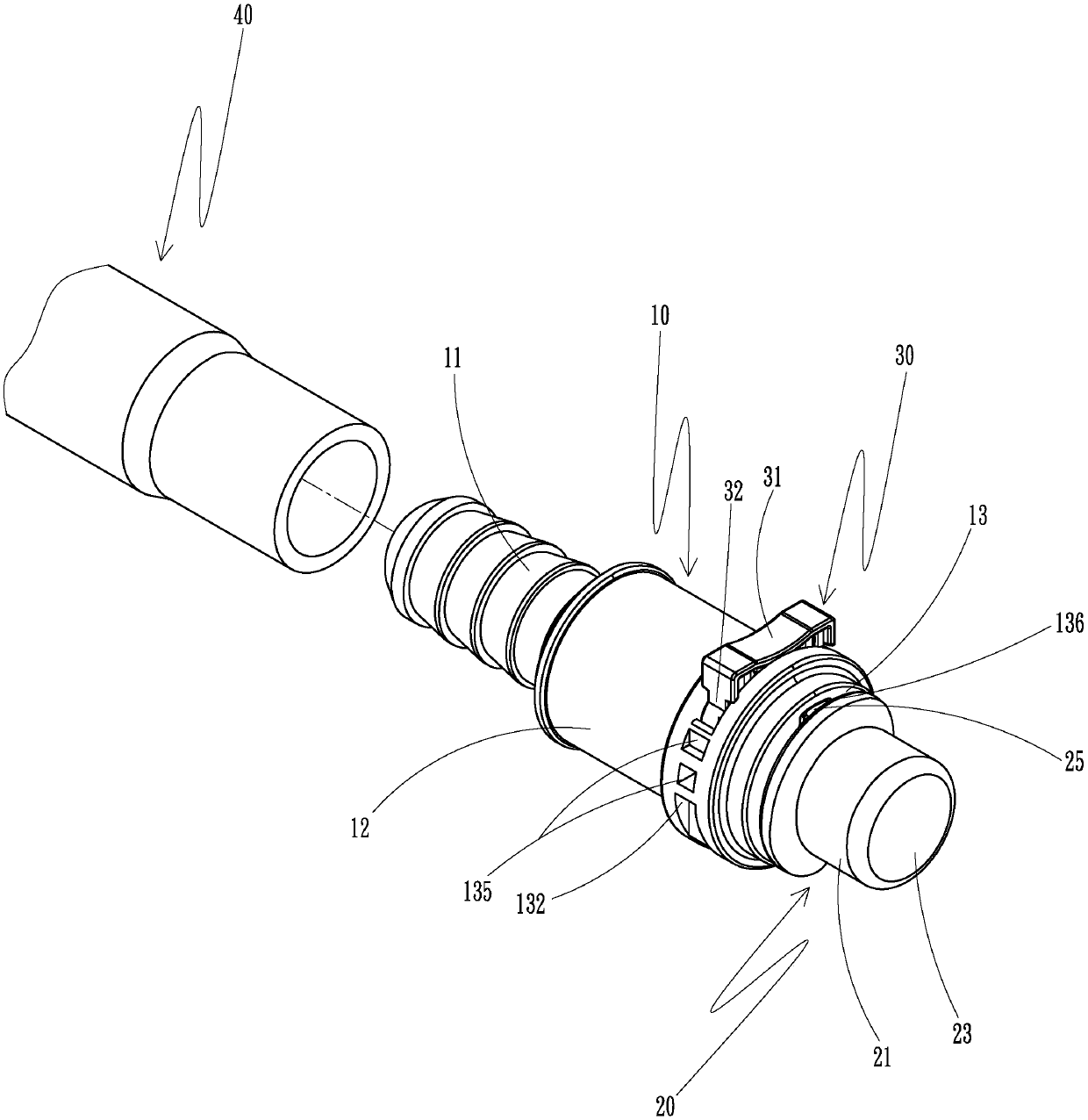

Quick connector structure

InactiveCN110081254AFirmly assembledQuick Position AssemblyPipe couplingsMultiple way valvesLaundry washing machineEngineering

The invention relates to a quick connector structure including a fitting connector, a connector, and a U-shaped positioning snap pin. The fitting connector is a pipe connector, a three-way valve connector, or a washing machine valve connector. The fitting connector is combined with a pipe body. The U-shaped positioning snap pin ensures the stability of the connection between the fitting connectorand the connector. The quick connector structure enables rapid positioning and assembly, reducing the assembly difficulty in a smaller or concealed space and achieving the effects of assembly stability and convenience.

Owner:SHOWER KAOKANG ENTERPRISE +1

An electrospinning nozzle capable of rapid multi-tip positioning

ActiveCN109267159BImprove injection efficiencyImprove deposition efficiencyArtificial thread manufacturing machinesFilament/thread formingFiberSpinning

Owner:厦门定慧力教育科技有限公司

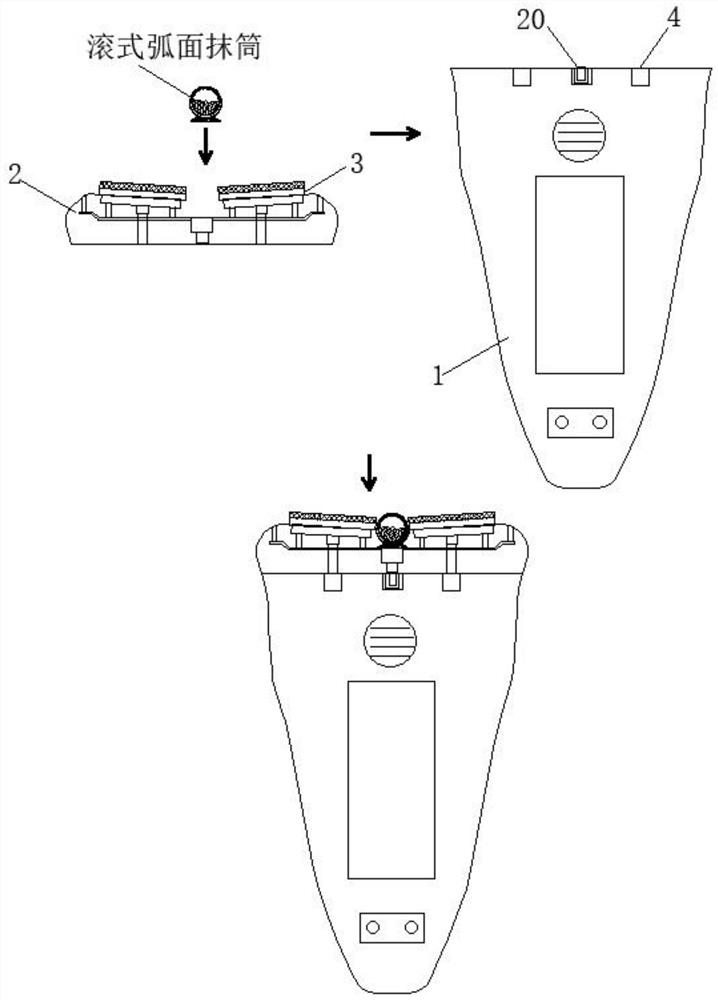

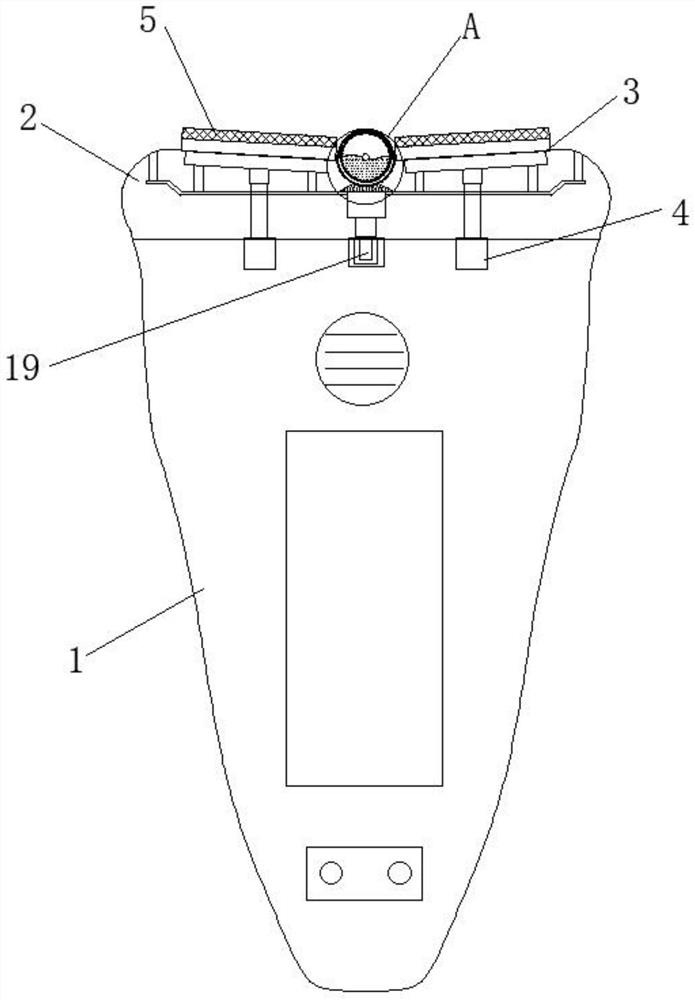

Quick positioning and assembling process for electric device

ActiveCN112297066AAvoid manual applicationQuick Position AssemblyMetal working apparatusEngineeringMechanical engineering

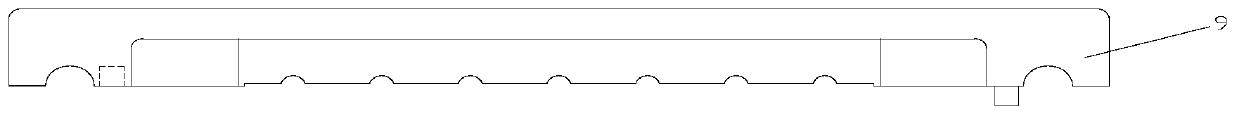

The invention discloses a quick positioning and assembling process for an electric device, and belongs to the field of hair trimmer assembling processes. According to the quick positioning and assembling process for the electric device, a buffer seat of which the upper end is fixedly connected with a rolling type cambered surface smearing cylinder is fixedly connected to the middle part of the upper end of a hair trimmer head; the hair trimmer head and an hair trimmer holding part are separated so that the hair trimmer head and the hair trimmer holding part can be separated and replaced independently, quick positioning and assembling can be achieved through the arrangement of a detection element, the existing electric hair trimmer head is provided with the rolling type cambered surface smearing cylinder, manual smearing of shaving liquid can be avoided, the hand does not need to be cleaned in advance, and smearing of the shaving liquid is more convenient; in combination with the high-speed rotation effect of a hair trimmer, the shaving liquid can be quickly beaten and foamed into finer foam, and smearing is more uniform; in addition, due to the arrangement of the rolling type cambered surface smearing cylinder, the skin can be massaged while shaving is conducted, and use by a user can be more comfortable.

Owner:倍雅电子护理制品(苏州)有限公司

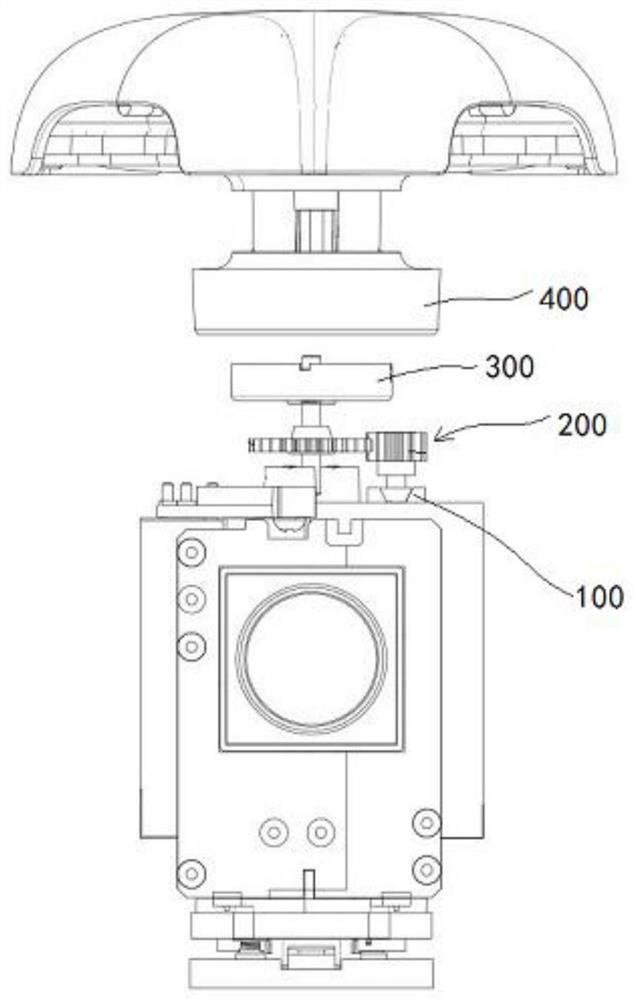

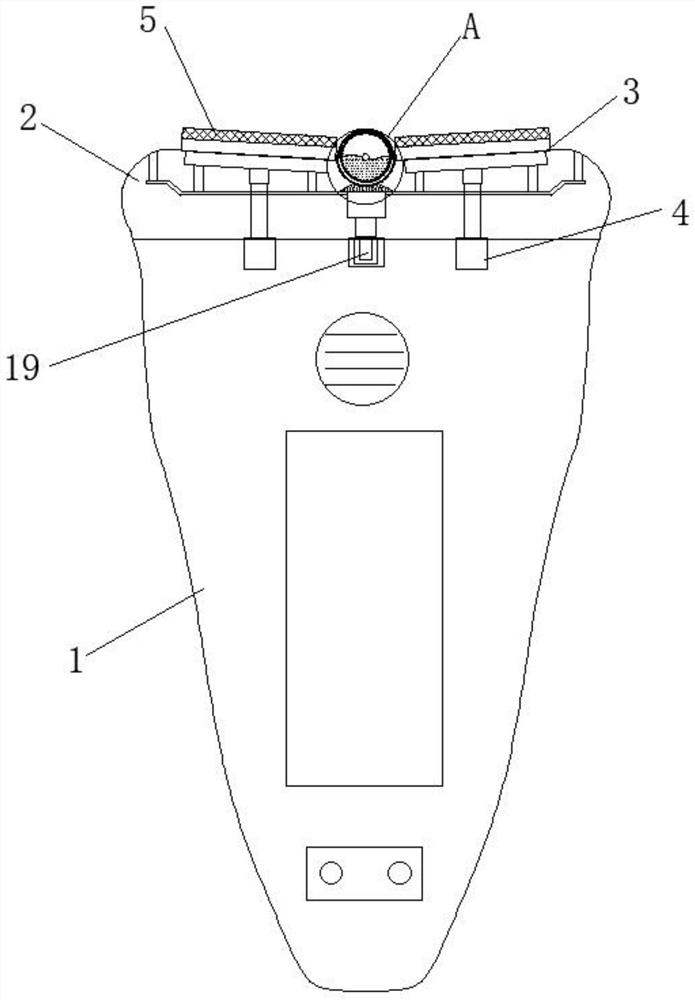

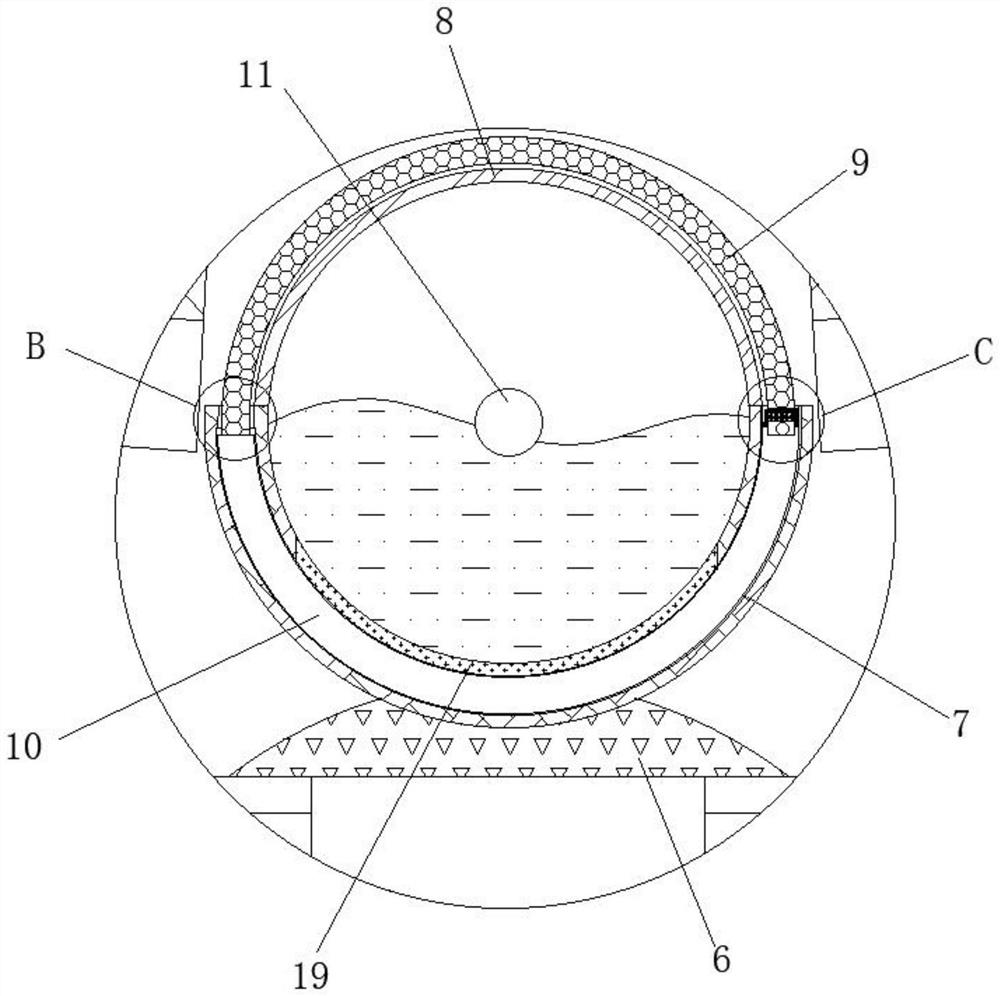

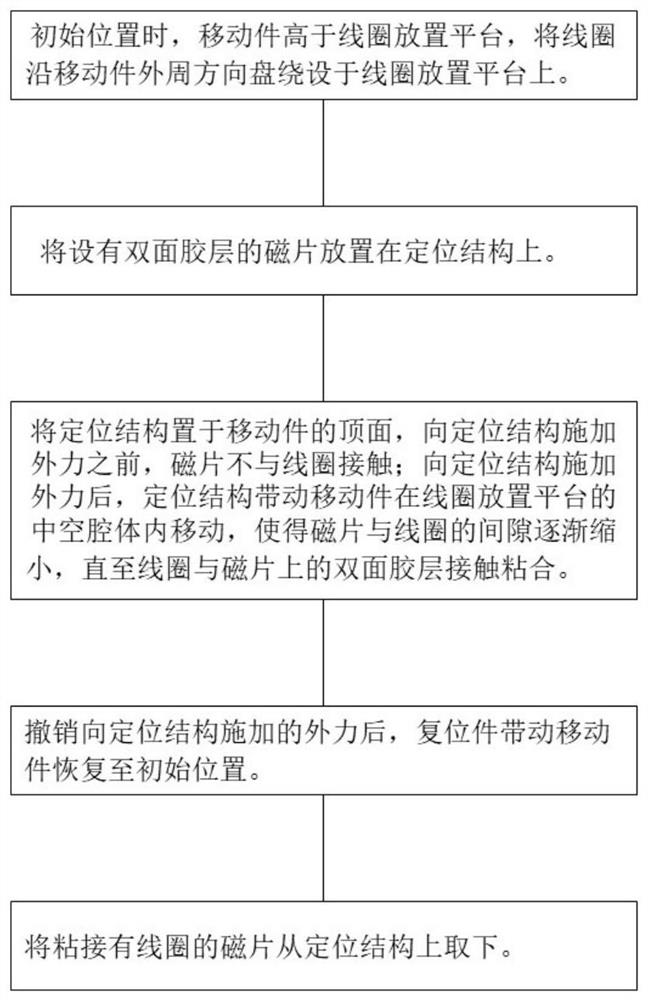

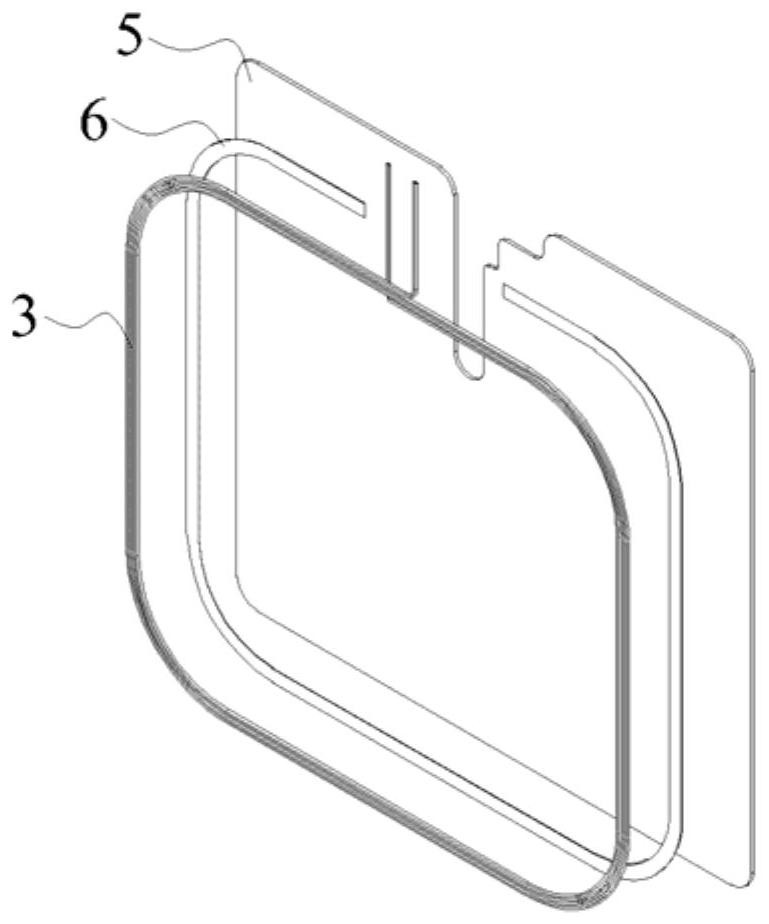

NFC antenna assembling method and equipment

ActiveCN113586571AEasy to operateImprove efficiencyMaterial gluingMoving partsStructural engineering

The invention relates to the technical field of antennas, in particular to NFC antenna assembling method and equipment. The assembling method specifically comprises the following steps that Step 1, a coil is arranged on a coil placing platform along the periphery of a moving part in a winding manner; Step 2, a magnetic sheet is arranged on a positioning structure, and a double-faced adhesive tape layer is arranged on the magnetic sheet; Step 3, the positioning structure is placed on the moving part, the positioning structure is pressed to drive the moving part to move in a hollow cavity of the coil placing platform, and the double-faced adhesive tape layer and the coil make contact with each other and are bonded; and Step 4, a reset part is arranged, and after the external force for pressing the positioning structure is removed, the reset part drives the moving part to move to achieve resetting of the moving part. The equipment is simple in structure and easy to operate, the coil can be quickly and accurately bonded to the magnetic sheet, the assembled product is good in quality, the efficiency is high, the cost is low, and the equipment is worthy of wide-range application and popularization.

Owner:麦格磁电科技(珠海)有限公司

Household terminal for Internet of Things

InactiveCN114321591AEasy to useReal-time voice reminderSubscriber signalling identity devicesStands/trestlesThe InternetElectric machinery

The invention provides a home terminal for the Internet of Things, and relates to the technical field of home terminals, the home terminal comprises an assembly sliding plate, and one end of the assembly sliding plate is integrally provided with a limiting carrier plate; the protection carrying shell is installed at the bottom of the limiting carrying plate, a driving adjusting structure is installed on the inner side of the protection carrying shell, the bearing supporting block is installed on the inner side of the protection carrying shell, meanwhile, a bearing driving structure is installed on the top of the protection carrying shell, the bearing driving structure comprises a bearing supporting frame, and the bearing supporting frame is installed on the top of the protection carrying shell; a voice instruction is recognized through a recognition device, so that a control main body controls a driving motor to be started, a transmission connecting shaft and a driving tooth block are driven to rotate, and directional position adjustment is carried out on a protection carrying shell, so that the protection carrying shell drives a terminal main body to be adjusted to a proper position, and the problem that after an existing Internet of Things terminal machine is installed, the terminal main body is damaged is solved. In the prior art, the existing device cannot be adjusted according to needs, so that the existing device is not suitable for being used by each member with different heights in families.

Owner:尚谷科技(响水)有限公司

Wing soft tissue ring cutter for dental implant surgery

PendingCN114271963AShorten treatment timeEasy to operateDental implantsDental toolsWound healingAnnular cutter

The invention discloses a winged soft tissue girdling knife for dental implant surgery, which comprises a positioning guide plate, a cutting channel is arranged on the positioning guide plate, a sleeve is arranged at the top of the cutting channel, a limiting baffle is arranged in the sleeve, a through hole coaxial with the sleeve is formed in the limiting baffle, a connecting rod in clearance fit with the through hole is arranged in the through hole, and the connecting rod is arranged in the through hole. The top end of the connecting rod is located above the limiting baffle and fixedly connected with a pressing base, the bottom end of the connecting rod penetrates through the through hole and is detachably connected with an annular cutter matched with the covering screw, the portion, between the pressing base and the limiting baffle, of the connecting rod is sleeved with a spring, and a plurality of protruding blades evenly distributed around the center of the cutter are arranged at the bottom of the outer wall of the cutter. The center of the inner bottom of the cutter is further connected with an extraction hook. The positioning device is manufactured through CBCT and oral scanning data, a covering screw is accurately positioned, and a cutting extraction device is matched, so that operation is more convenient, postoperative adverse reactions of a patient are relieved, the infection risk is reduced, and wound healing is better.

Owner:SICHUAN UNIV

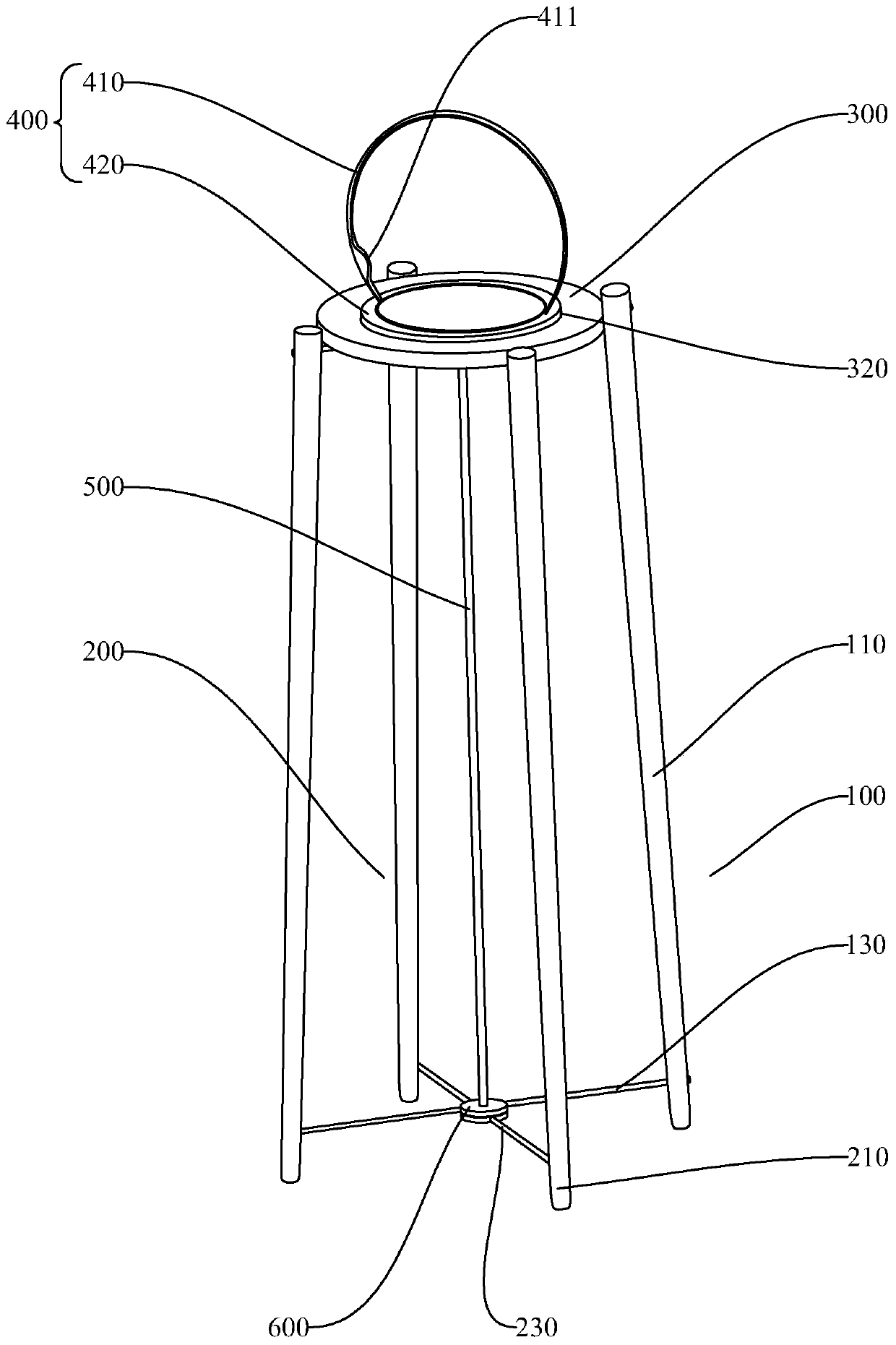

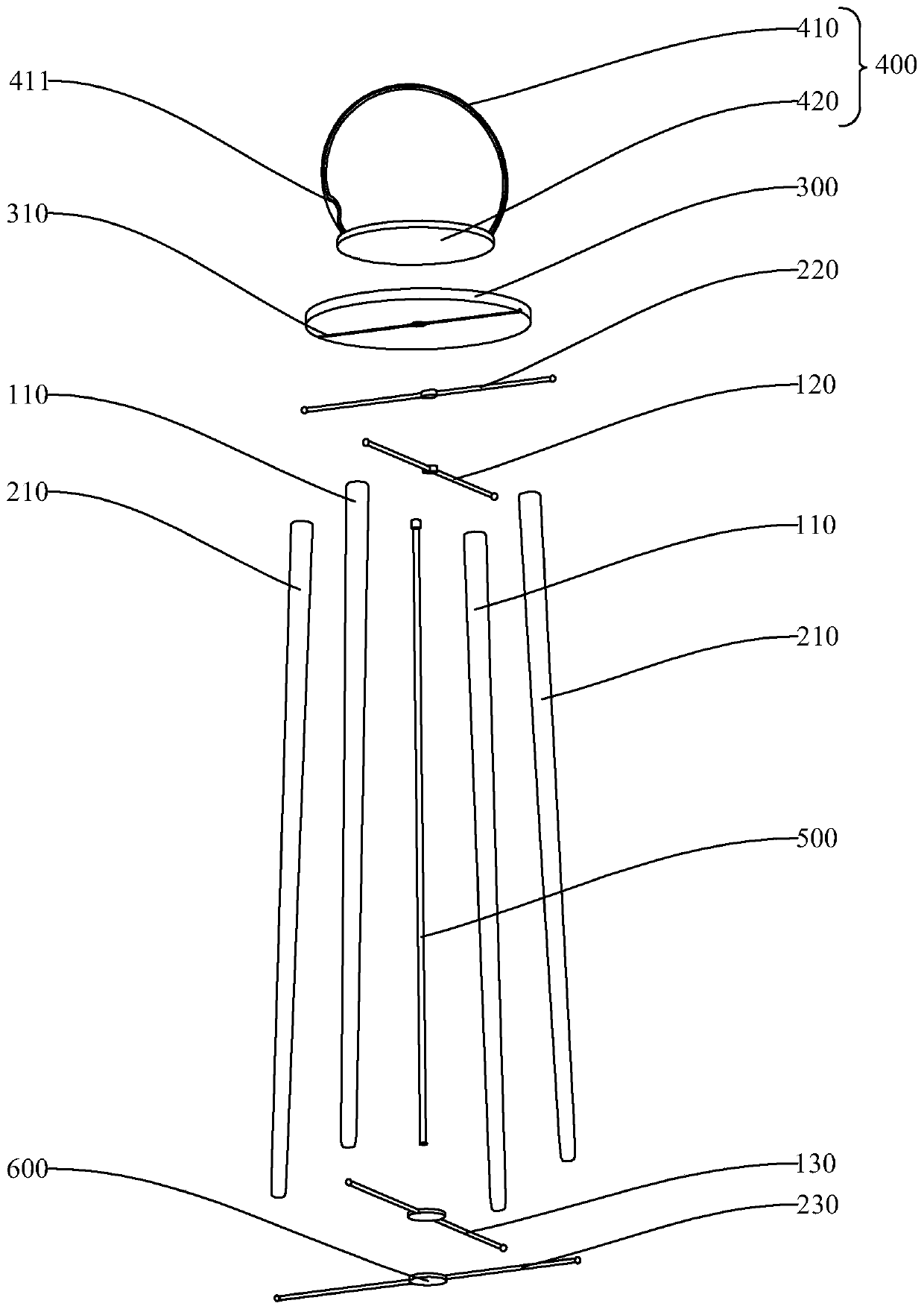

Assembled flower table

The invention discloses an assembled flower table which comprises: a first support that comprises symmetrically-arranged first supporting legs, wherein top ends of two first supporting legs are connected with first connecting rods, and bottom ends of two first supporting legs are connected with second connecting rods; a second support that is connected with the first support and comprises symmetrically-arranged second supporting legs, the top ends of the two second supporting legs are connected with third connecting rods, the bottom ends of the two second supporting legs are connected with fourth connecting rods, the third connecting rod is hinged to the first connecting rod, and the fourth connecting rod is hinged to the second connecting rod, so that the first support and the second support have a folded state and an unfolded state; a supporting seat that is arranged on a supporting surface formed by the first connecting rod and the third connecting rod, and a receding groove matchedwith the third connecting rod is formed in the bottom of the supporting seat. The first support and the second support have a folded state and an unfolded state through hinge joint, state switching is convenient, packaging and transportation are convenient during folding, cost is reduced, the supporting seat is installed during unfolding, the supporting seat and the supports are assembled, disassembly and assembly are convenient, and storage are convenient.

Owner:WUYI UNIV

Rapid clamping structure and mechanical clamping device

PendingCN114434178AQuick Position AssemblyAccurate positioning and assemblyPositioning apparatusMetal-working holdersEngineeringFrustum

The invention provides a quick clamping structure and a mechanical clamping device.The quick clamping structure comprises a fixing device and an interchanging device, the fixing device comprises a fixing base and a clamping plate, the fixing base is provided with a frustum-shaped positioning through groove with the wide upper portion and the narrow lower portion, and the clamping plate is movably arranged at the bottom of the positioning through groove in a drawable mode; the large opening and the small opening are communicated with each other; the interchanging device comprises a fixing plate, a positioning block and a connecting block, the positioning block and the connecting block are fixed to the fixing plate, the connecting block is used for being connected with an operation jig, the positioning block is of a frustum-shaped structure matched with the positioning through groove in appearance, and a clamping head is arranged at the bottom of the positioning block. The interchanging device is positioned by inserting the positioning block into the positioning through groove of the fixing base, the clamping head penetrates through the large opening of the clamping plate, and the clamping plate is pulled to enable the small opening to be connected with the clamping head in a clamping mode so as to achieve fixation of the fixing device and the interchanging device. And the operation jig can be quickly and accurately clamped.

Owner:厦门宏发精密机械有限公司

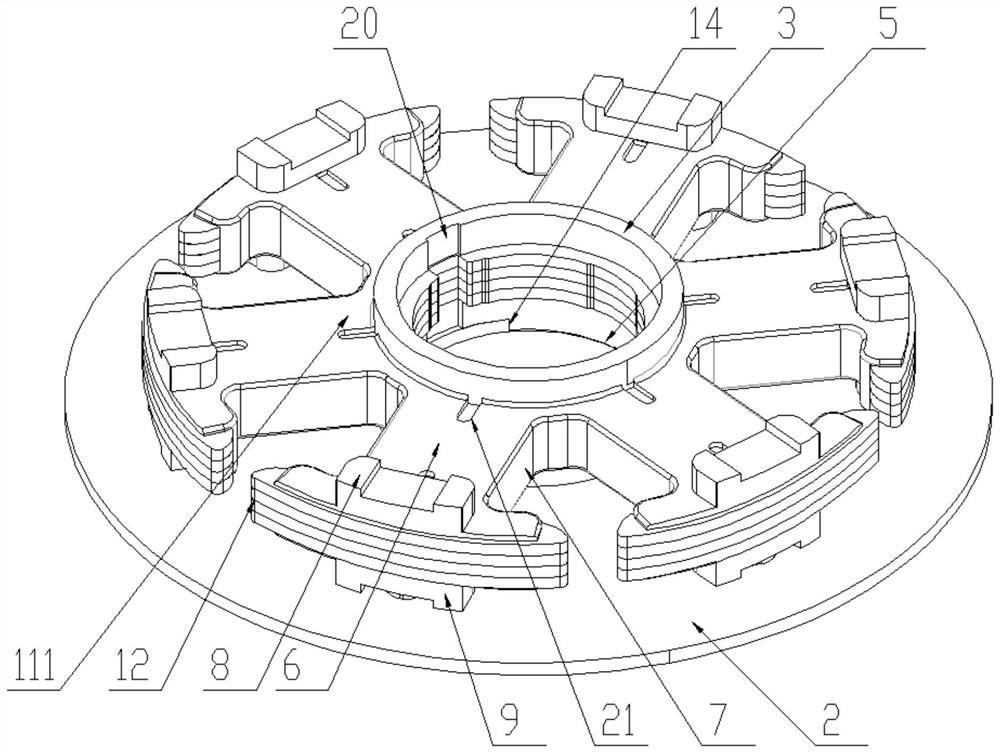

Hot melting framework for retaining ring of fan

InactiveCN113464470AImprove bindingAchieve fixationAssociation with control/drive circuitsMagnetic circuit rotating partsHot meltFan blade

The invention relates to a hot melting framework for a retaining ring of a fan. The hot melting framework comprises an outer frame with a plastic middle pipe, a motor assembly and a fan blade assembly, wherein an axis is arranged in the center of the fan blade assembly; an oil bearing is arranged between the outer wall of the axis and the inner wall of the plastic middle pipe; the motor assembly is fixed to the outer portion of the plastic middle pipe; a magnet is arranged on the inner wall of the fan blade assembly; a limiting groove is formed in the axis; hot melting columns are arranged on the top of the plastic middle pipe; the retaining ring matched with the limiting groove in a limiting mode is arranged on the top of the plastic middle pipe and the top of the oil bearing; a plurality of first through holes are formed in the retaining ring; and the hot melting columns penetrate through the corresponding through holes and protrude out of the edge to be connected with the top of the retaining ring in a hot melting mode. The hot melting columns on the plastic middle pipe are connected with the retaining ring in a hot melting mode to package the oil bearing, and the retaining ring is matched with the limiting groove of the axis in a limiting mode, so that the axis and the outer frame of the fan blade assembly are reliably, stably and rapidly positioned and assembled, the cost is reduced, the technology is saved, the risk of axis loosening caused by floating or falling of a positioning ring is avoided, and the reliability and stability of fan operation are improved.

Owner:江苏嘉之瑞电子科技有限公司

Electric shaver

ActiveCN111941473AImprove convenienceImprove sealingMetal working apparatusElectric machineEngineering

The invention provides an electric shaver which comprises a main body assembly and a head cover assembly, wherein the main body assembly comprises a lower shell and a driving unit arranged in the lower shell, the head cover assembly comprises a movable knife unit and an upper shell used for supporting the movable knife unit, a driving magnetic assembly is embedded in the lower shell, and a drivenmagnetic assembly is embedded in the upper shell; when the electric shaver is in a static and longitudinally-placed state, the magnetism, corresponding to the longitudinal direction, of the driving magnetic assembly and the magnetism, corresponding to the longitudinal direction, of the driven magnetic assembly are in an unlike attraction state, the driving unit comprises a motor, and the movable shaver unit is driven to rotate under the action of the motor, the driving magnetic assembly and the driven magnetic assembly; and the central axis of the driving magnetic assembly and the central axisof the driven magnetic assembly coincide with the central axis of the electric shaver, and the central axis of the motor deviates from the central axis of the electric shaver by 4-8 cm. The motor deviates from the central axis of the electric shaver, and the influence of vibration generated by rotation of the motor on the magnet is minimum.

Owner:HUANXING TECH HANGZHOU CO LTD

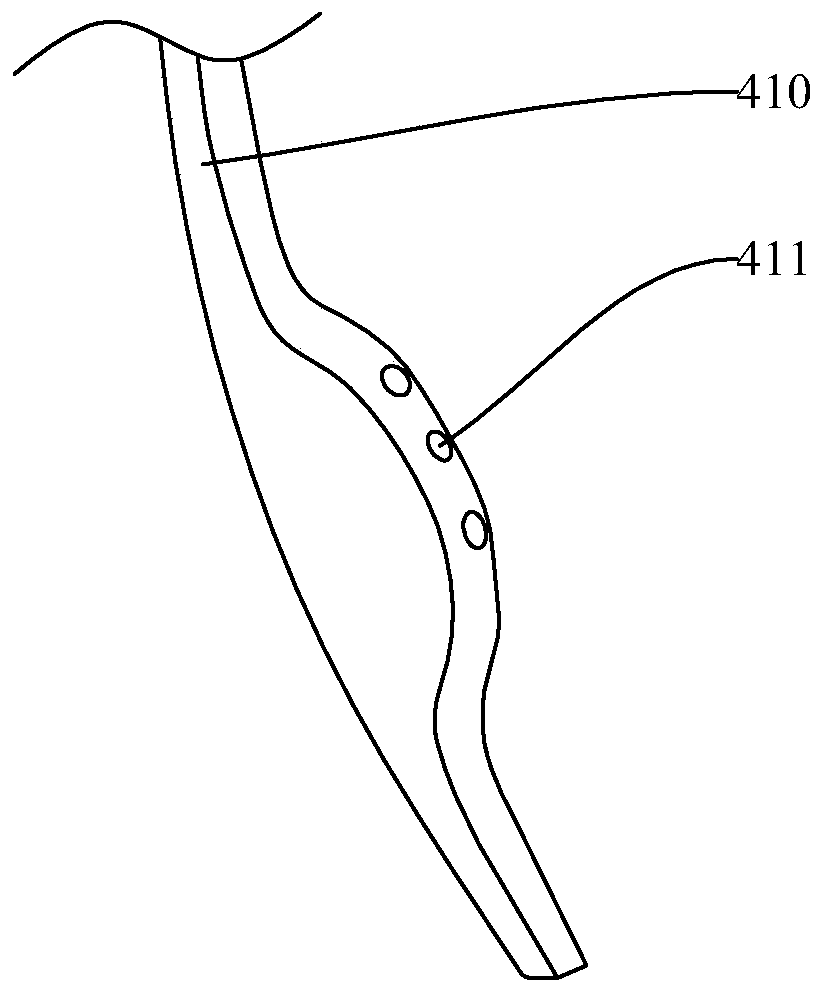

Construction method and installation structure of glazed decorative components of roof ridge of antique buildings

ActiveCN113404227BEasy to manufacturePromote fireRoof coveringArchitectural engineeringStructural engineering

Owner:SHANGHAI NO 4 CONSTR

Construction method and installation structure of archaized building ridge anastomosis colored glaze decoration component

The invention discloses a construction method and an installation structure of an archaized building ridge anastomosis colored glaze decoration component. The method comprises the following steps that the anastomosis colored glaze decoration component is divided into a plurality of anastomosis colored glaze splicing components in multiple layers and multiple columns, and a steel plate embedded part and a vertical pipe are sequentially arranged on a ridge beam; the anastomosis colored glaze splicing components penetrate through the vertical pipe layer by layer, are aligned through upper and lower wedge openings and are bonded through an adhesive layer, and two horizontally adjacent non-top-layer anastomosis colored glaze splicing components are connected through bolt assemblies and rubber gaskets on the bolt assemblies; the anastomosis colored glaze splicing components on the secondary top layer are inserted into fire passing holes to the ridge beam by sleeving the vertical pipes with sleeves, and concrete is poured to form supporting columns; a rubber wedge is inserted into a gap between the fire passing hole of the anastomosis colored glaze splicing component on the secondary top layer and the sleeve; and an anti-skid retaining piece is arranged at a wedge opening position between the secondary top layer and the top layer anastomosis colored glaze splicing component. The anastomosis colored glaze splicing component is light in weight, convenient to fire, not prone to breakage, high in installation precision, safe in construction and low in construction difficulty.

Owner:SHANGHAI NO 4 CONSTR

Lamp holder multi-mode rotation touch switch structure

PendingCN107676753AEasy loadingEasy to assembleElectric circuit arrangementsGas-tight/water-tight arrangementsEngineeringLight head

The invention discloses a lamp holder multi-mode rotation touch switch structure. The lamp holder multi-mode rotation touch switch structure comprises a shell. A containing cavity is formed in the upper end of the shell, and a partition plate is arranged in the containing cavity and divides the containing cavity into a front containing cavity and a rear containing cavity. A lighting assembly is arranged in the front containing cavity, a switch assembly is arranged in the rear containing cavity, and the lighting assembly and the switch assembly are connected through the partition plate. The lamp holder multi-mode rotation touch switch structure is simple and convenient to assemble, installation can be finished through combined connection of the lighting assembly and the control assembly, and the lamplight intensity and color can be freely converted by rotating the control assembly. The lighting assembly is provided with a sealing ring, damage to a lamp from rainwater and dust can be effectively reduced, and the service life is prolonged; the power source work modes are switched through mechanical rotation, the purposes of controlling the light source work mode and achieving market segment application and energy saving are achieved, the mechanical rotation design of the ergonomics design is met, and the best user experience is achieved.

Owner:DONGGUAN TAIYE ELECTRONICS CO LTD

A rapid positioning and assembly process of an electric device

ActiveCN112297066BAvoid manual applicationQuick Position AssemblyMetal working apparatusEngineeringMechanical engineering

The invention discloses a rapid positioning and assembling process of an electric device, belonging to the field of hair trimmer assembly technology. A rapid positioning and assembling process of an electric device is fixedly connected to the hair trimmer by a buffer seat whose upper end is fixedly connected with a rolling arc surface wiper. In the middle of the upper end of the head, by separating the hair trimmer head and the hair trimmer holding part, the two can be separated and replaced separately, and quick positioning and assembly can be realized through the setting of the detection element. The roller-type curved surface wiper can avoid manual application of shaving liquid, without pre-cleaning hands, making the application of shaving liquid more convenient, and combined with the high-speed rotation of the hair trimmer, the shaving liquid can be quickly whipped into a more delicate texture. Foam, smear more evenly; in addition, the setting of the rolling arc surface wiper can massage the skin while shaving, and the user is more comfortable to use.

Owner:倍雅电子护理制品(苏州)有限公司

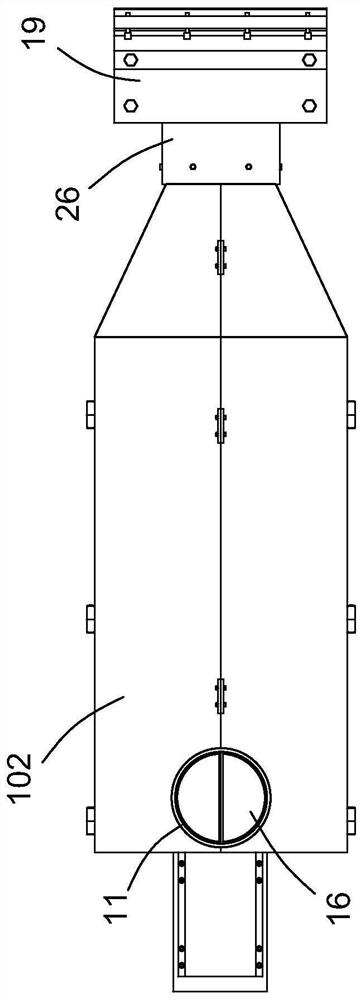

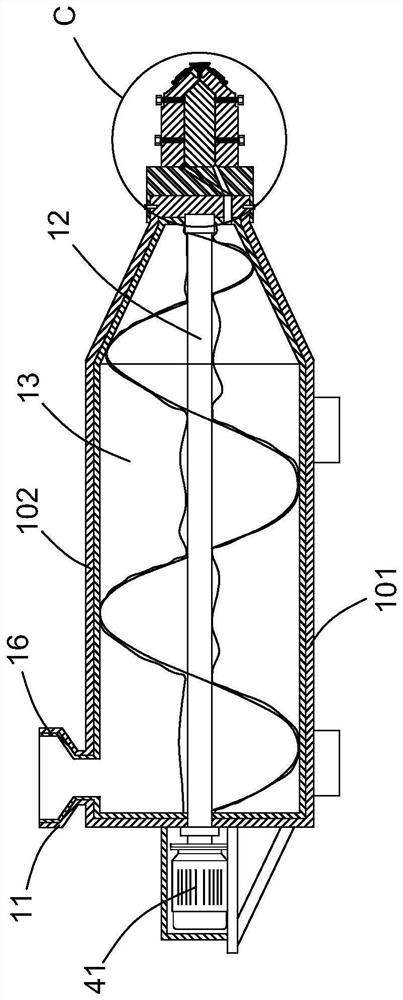

Composite material extrusion die pressing device

The invention relates to the technical field of material manufacturing, and provides a composite material extrusion die pressing device, which is reasonable in structural design, easy to operate and capable of simultaneously extruding two materials for compounding, the composite material extrusion die pressing device comprises a barrel, a first discharging hopper communicated with the interior is arranged at the upper end of the barrel, and a spiral material pushing rod used for pushing out the materials is arranged in the barrel; two charging drums used for pushing materials are detachably arranged in the barrel, a second discharging hopper communicated with the interiors of the charging drums is arranged at the upper ends of the charging drums, the second discharging hopper is arranged in the first discharging hopper, and a discharging pipe communicated with the interiors of the charging drums is arranged at the right end of each charging drum; the right end part of the barrel is provided with two discharge ports for the discharging pipes of the two groups of charging drums to pass through, the right end part of the barrel is provided with a die head assembly for compounding two materials together, and the left end part of the barrel is provided with a driving structure for driving the spiral material pushing rod to rotate.

Owner:蔡金牌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com