Four-wheel small platform lorry for pre-assembled turnout slippage and construction method

A construction method and pre-assembled technology, which are applied in the field of four-wheeled flatbed trucks and construction, can solve the problems of potential safety hazards, rising maintenance costs, and poor track smoothness, and achieve a simple and feasible combined structure, easy installation and disassembly, and reduced construction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

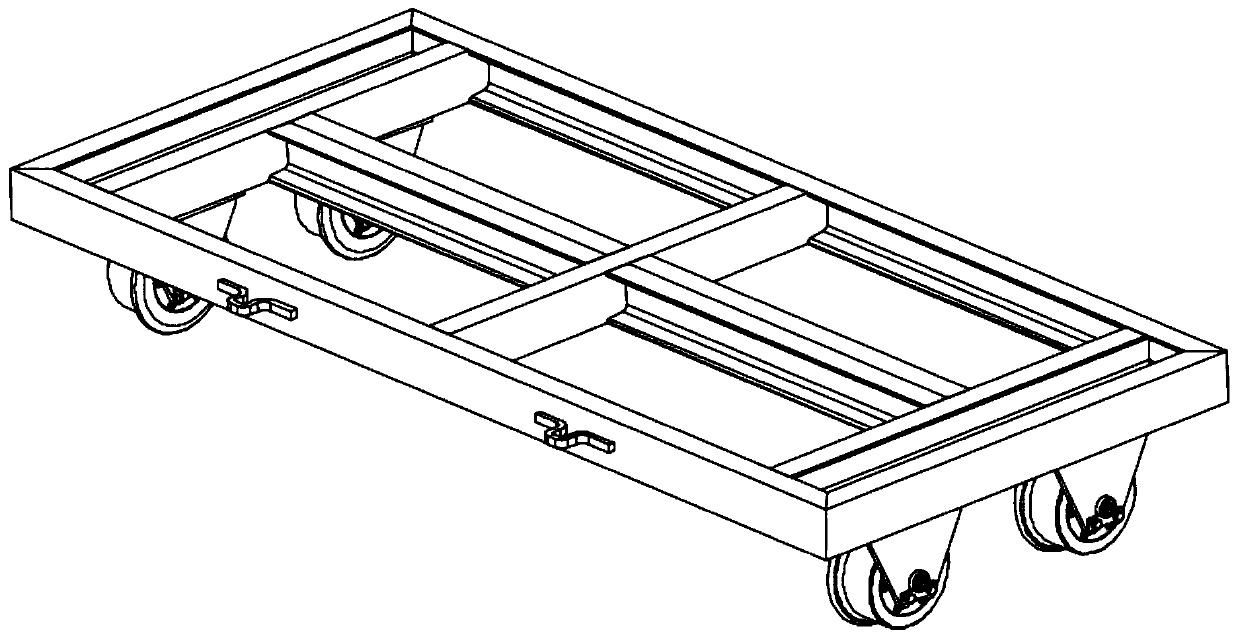

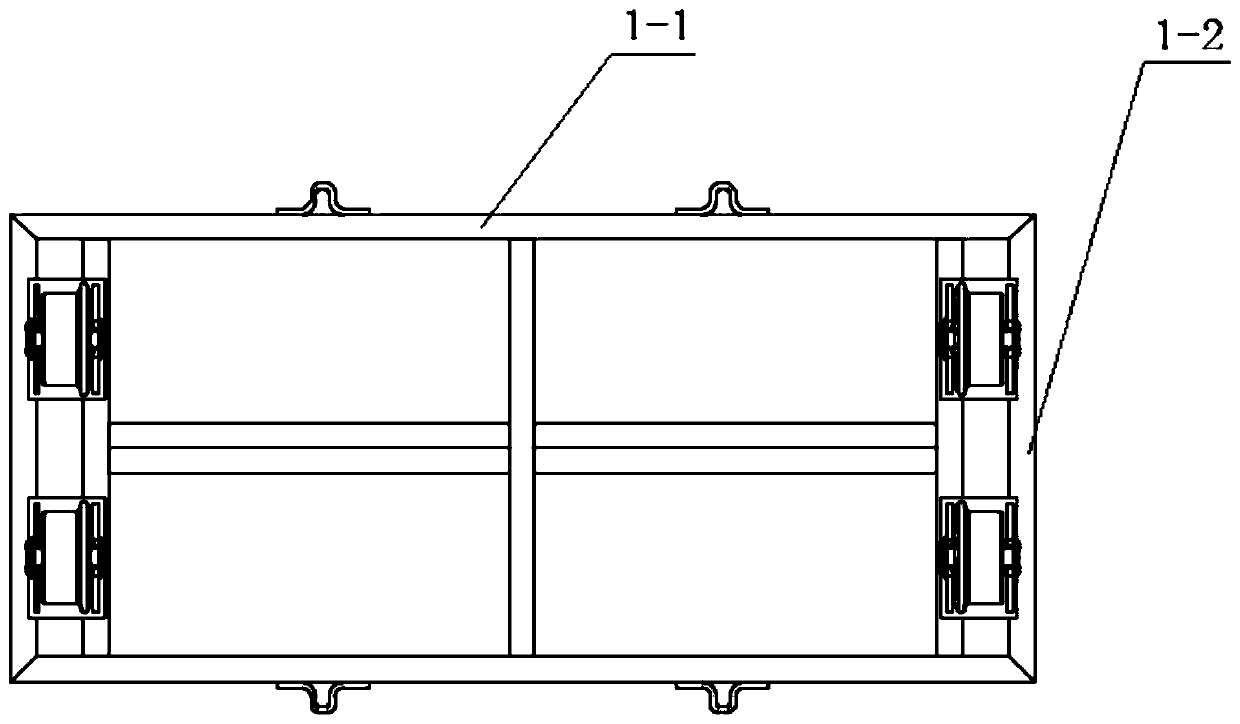

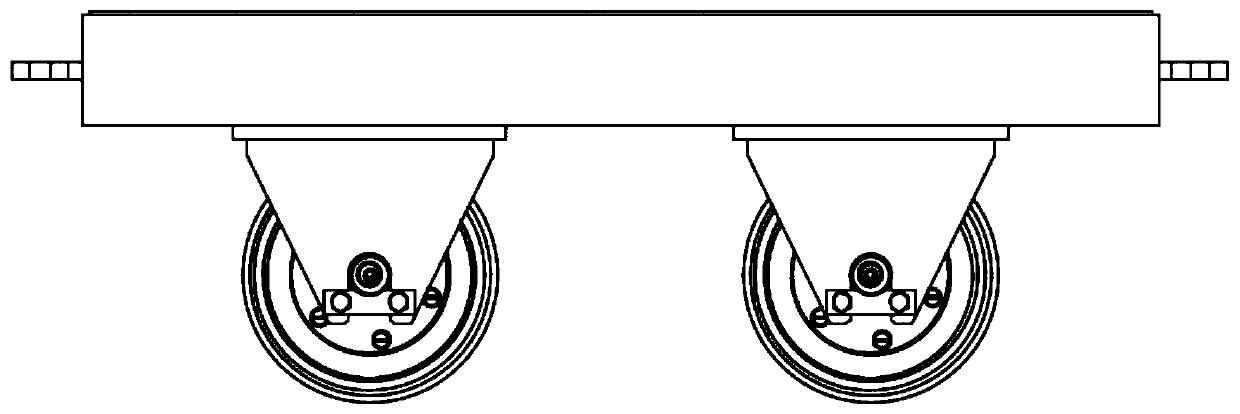

Embodiment 1

[0046] In this embodiment, the frame body size is 2000mm×300mm, and it is welded by three 8# channel steels (80×45×5mm) with a length of 2000mm and a width of 300mm, and three 8# channel steels with a length of 2000mm The steel is arranged in parallel along the front and back directions, and 5 8# channel steels with a width of 300mm are arranged in parallel along the left and right directions to form a rectangular frame body, which can not only ensure the overall strength, but also facilitate manufacturing. The vehicle frame body can be obtained by welding, and can be applied to the gap between two sleepers under the pre-assembled turnout rail, which solves the problem that the existing equipment cannot be applied to this scene. The wheel mounting plate is processed by 4 iron plates with a thickness of 10mm into a trapezoidal shape with an upper width of 80mm, a lower width of 60m, and a height of 140mm. A slot with a width of 30mm and a height of 50mm is cut in the middle of t...

Embodiment 2

[0050] combine Figure 13-Figure 16 , the present embodiment provides a construction method for applying the four-wheeled small flatbed vehicle to the transformation of the cross-over line turnout after the station of the subway operation line, and the construction method is as follows:

[0051] Set up a pre-assembled platform on both sides of the operating line, pre-assemble in blocks according to the composition of the cross-crossing turnout, set the four-wheeled flatbed under the pre-assembled turnout, and slide to the design position through the temporary guide rail and the existing line rail. Install 6 pairs of hydraulic high-leg track lifters on the pre-assembled turnout. During the sliding process, the direction is changed. Ascending, withdrawing from the temporary guide rail, and descending at the same time to carry out the work of starting and shifting the cross-crossing line. Reasonably arrange the connection of various disciplines, quickly complete the coordination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com