Electric shaver

An electric shaver, active technology, applied in the direction of metal processing, etc., can solve the problems of increased noise, sealing ring leakage, increased load, etc., to achieve the effects of prolonged service life, good sealing performance, and excellent waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

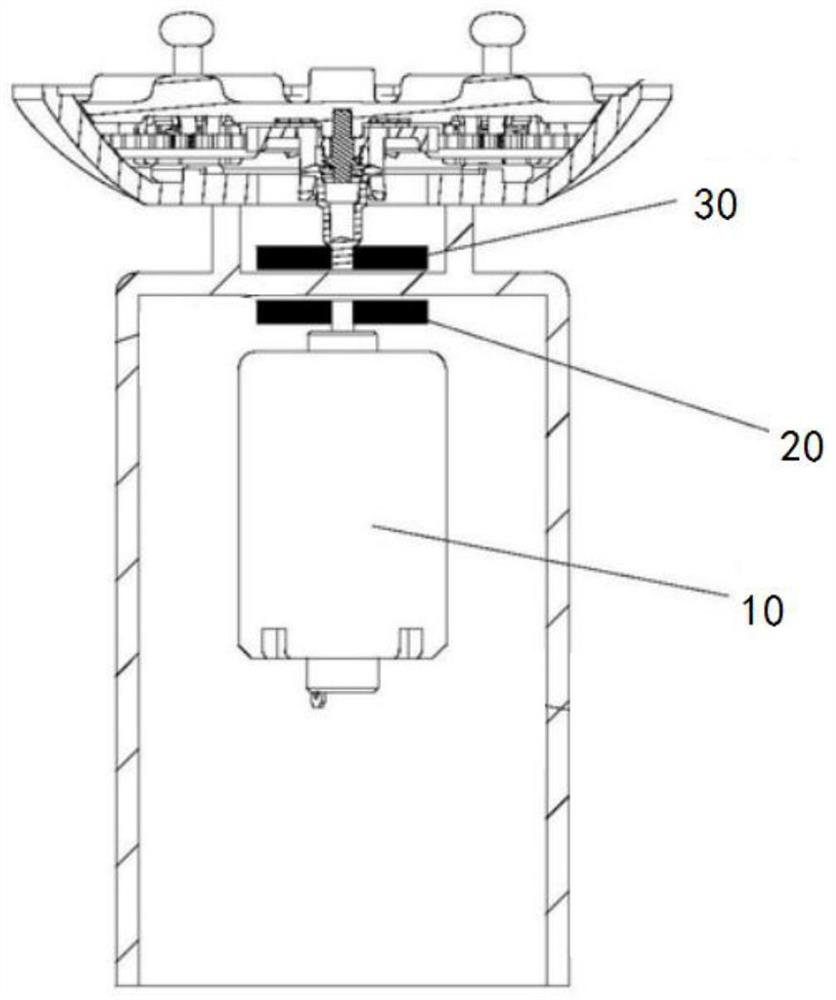

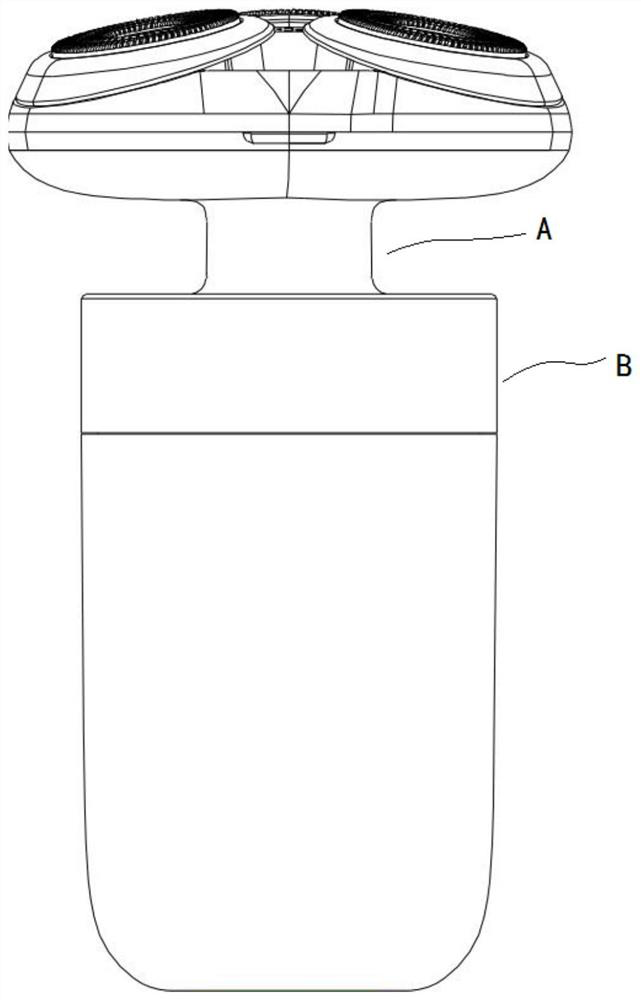

[0044] refer to Figure 2-Figure 4 As shown, an electric shaver includes a main body assembly and a head cover assembly. The head cover assembly is arranged on the main body assembly. unit, the head cover assembly includes a moving knife unit and an upper casing A for supporting the moving knife unit, the lower casing is embedded with an active magnetic assembly, and the upper casing is embedded with a driven magnetic assembly. The electric shaver When the knife is stationary and placed vertically, the magnetism corresponding to the longitudinal direction of the active magnetic assembly and the driven magnetic assembly is in a state of opposite sex attraction. Driven to rotate under the action of the assembly and the driven magnetic assembly; the central axis of the active magnetic assembly and the driven magnetic assembly coincides with the central axis of the electric shaver, and the central axis of the motor deviates from the electric shaver The central axis of 4-8cm (refe...

Embodiment 2

[0053] As shown in Embodiment 1, the assembly of the eccentric motor and the gear assembly is used to realize the magnetic attraction.

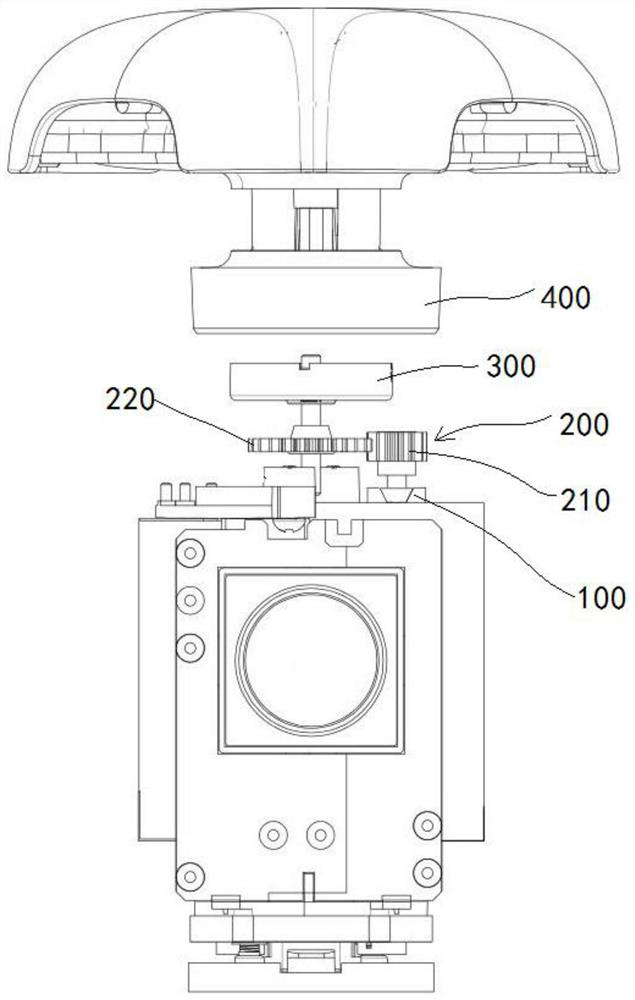

[0054] refer to Figure 5 As shown, the electric shaver includes a motor bracket 500, the motor 100 is fixed on the lower housing B through the motor bracket 500, the motor bracket 500 covers the upper end of the motor, and the drive shaft 110 of the motor 100 runs through The motor bracket 500 is then connected to the gear assembly 200 .

[0055] Because the motor will vibrate to a certain extent during the rotation process, in order to reduce the vibration, a fixed motor bracket is used, and the motor bracket only fixes the upper end of the motor. Since the output force of the drive shaft is output from the drive shaft, the upper end of the motor is firmly If it is firmly fixed, the expected effect can be achieved, that is, the technical effect of reducing vibration to the greatest extent is achieved by using few materials.

[0056] Furth...

Embodiment 3

[0066] In addition to the electric shaver as described in Embodiment 1-Example 2, it also includes an auxiliary magnetic assembly, wherein the auxiliary magnetic assembly is only used to magnetically fix the upper shell and the lower shell, and the working state does not rotate .

[0067] refer to Figure 7 As shown, in this solution, the auxiliary magnetic attraction assembly includes a lower auxiliary magnet 310 and an upper auxiliary magnet 410 , and the magnetism corresponding to the longitudinal direction of the lower auxiliary magnet and the upper auxiliary magnet is in a state of opposite sex attraction.

[0068]Compared with the active magnet and the driven magnet, the auxiliary magnetic assembly can rotate, and it is in a static state, that is, the corresponding lower auxiliary magnet and upper auxiliary magnet are firmly fixed on the installation position, and the auxiliary magnetic assembly only serves as a pure suction. The combined action to connect the lower she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com