Hot melting framework for retaining ring of fan

A buckle and hot-melt technology, applied in the magnetic circuit shape/style/structure, electromechanical devices, electrical components, etc., can solve the problems affecting the stability of the buckle 21, the floating of the positioning ring 22, etc., so as to avoid the loosening of the shaft. risk, improve reliability and stability, and ensure the effect of rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

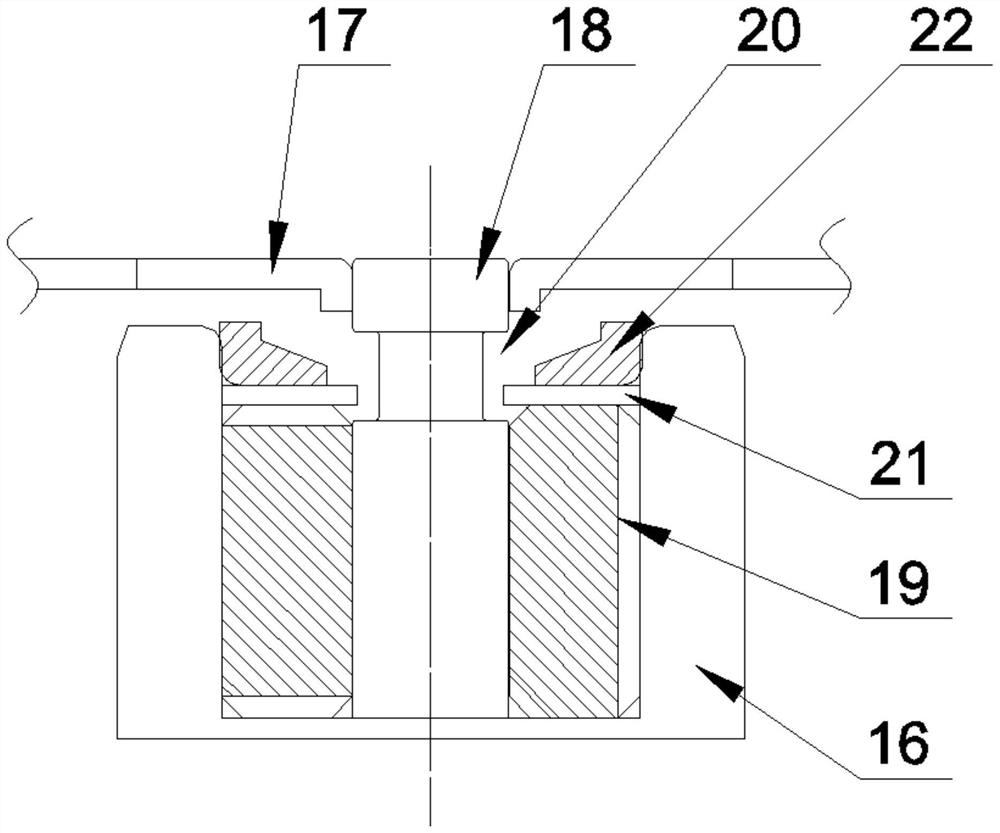

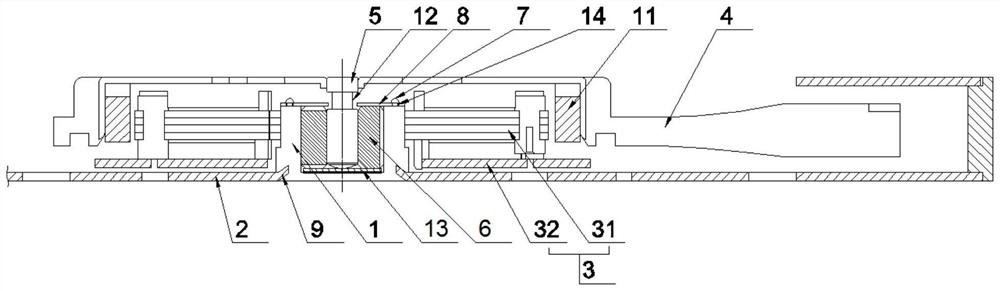

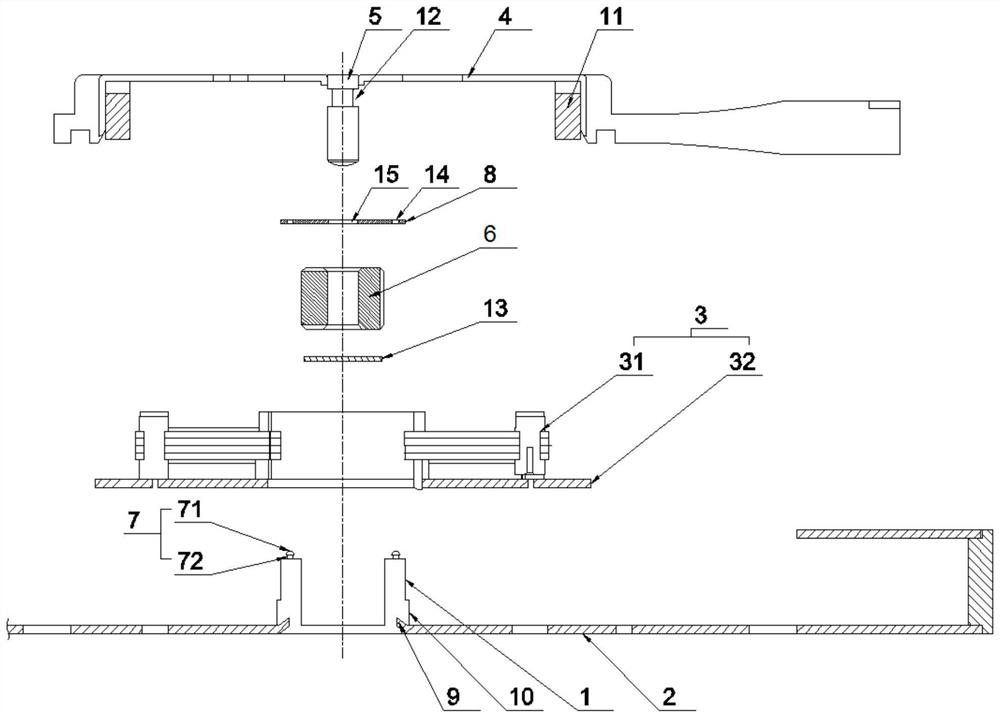

[0020] A fan clasp 8 hot-melt structure, including an outer frame 2 with a plastic inner tube 1, a motor assembly 3, and a fan blade assembly 4. The center of the fan blade assembly 4 is provided with an axis 5, and the axis 5 There is an oil-impregnated bearing 6 with clearance fit between the outer wall and the inner wall of the plastic middle tube 1, wherein the motor assembly 3 is fixed on the outside of the plastic middle tube 1, and the motor assembly 3 includes an injection package stator 31 fixed on the injection The PCBA board 32 at the bottom of the package stator 31, the inner wall of the injection package stator 31 is in interference fit with the outer wall of the plastic middle tube 1, and the outer frame 2 is provided with an oblique setting with the bottom of the outer frame 2 and is integrated with the plastic middle tube 1 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com