Buckle connection structure of injection package stator and PCBA board

A technology of shooting the stator and buckle connection, which is applied to the printed circuits and electrical components that are connected to the control/drive circuit and connected to non-printed electrical components, and can solve problems such as falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

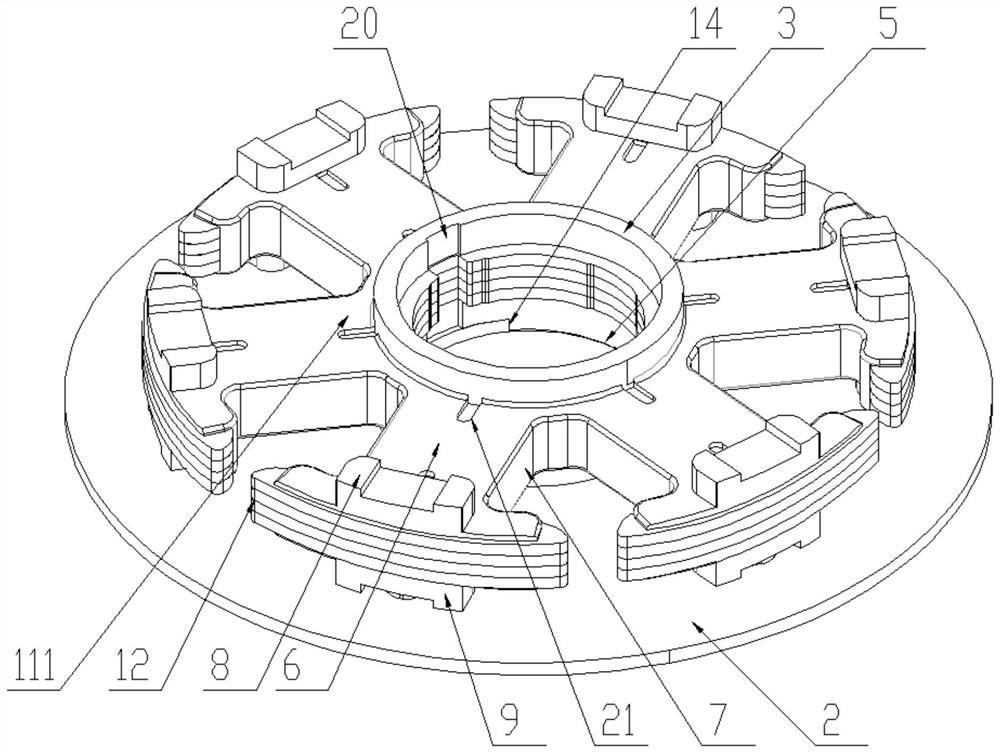

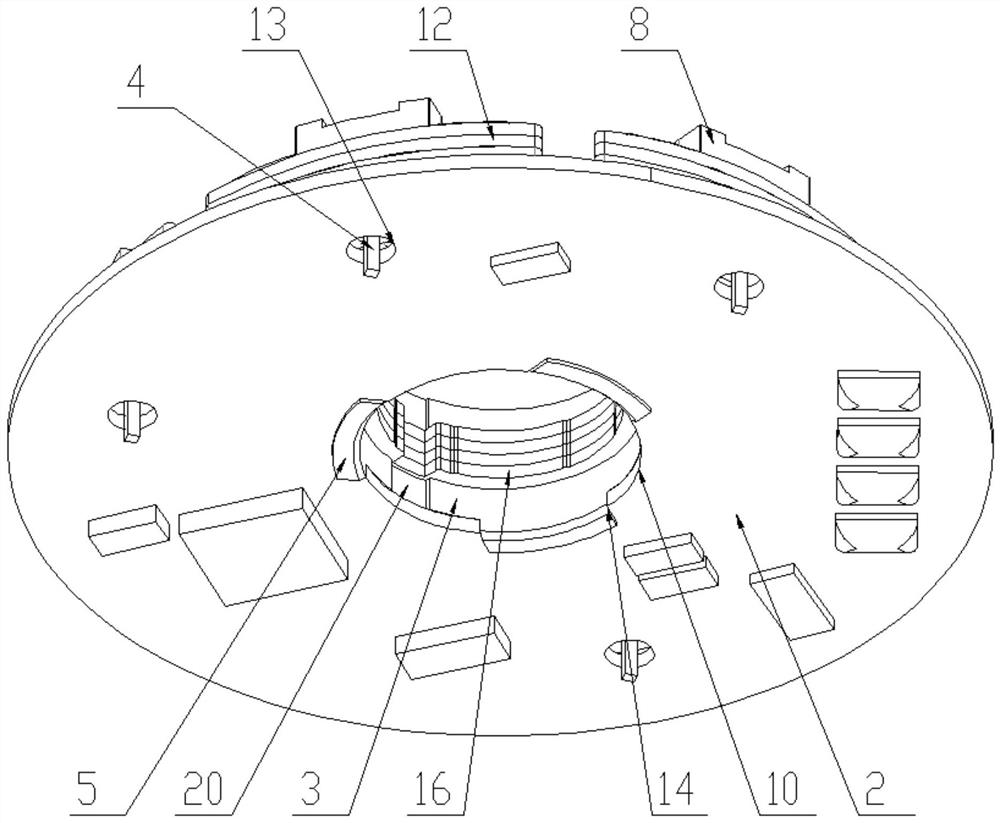

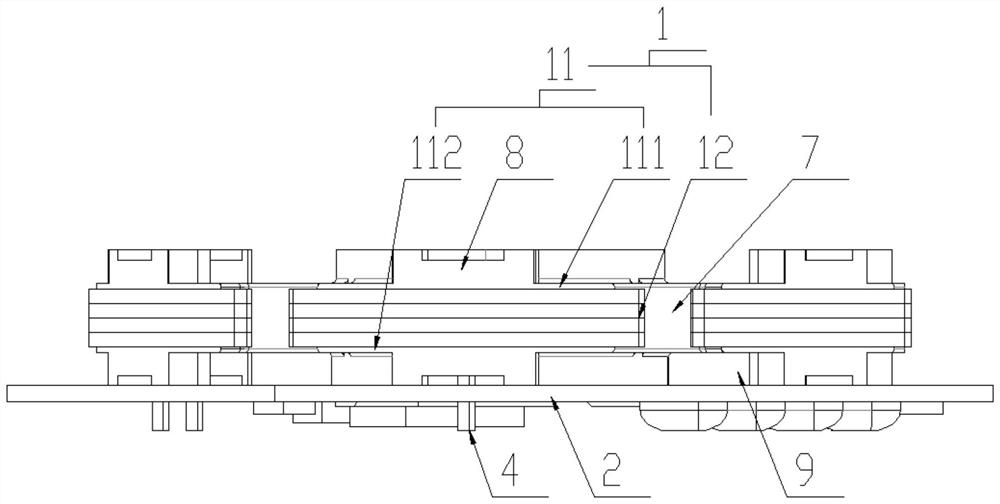

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] A buckle connection structure between a packaged stator and a PCBA board, comprising a packaged stator 1, a PCBA board 2 located at the bottom of the packaged stator 1, the packaged stator 1 includes an insulating center frame 11, several Silicon steel sheet 12, wherein, the insulating center frame 11 is provided with a center sleeve 3 with an integrated structure, and welding columns 4 arranged at intervals outside the center sleeve 3, and the bottom of the center sleeve 3 is provided with a number of coils around the center sleeve 3. buckles 5 arranged at intervals of one week and protruding toward the bottom of the center sleeve 3;

[0026] The insulating center frame 11 includes an upper plate 111 and a lower plate 112 connected to the outer wall of the center sleeve 3. The upper plate 111 and the lower plate 112 each have a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com