Electrostatic spinning spray nozzle capable of achieving quick multi-needle-tip positioning

An electrospinning, multi-needle tip technology, applied in the field of electrospinning, can solve the problems of cumbersome installation and disassembly, difficult to quickly locate the needle tip, complex nozzle structure, etc. The effect of falling off and weakening the electric field interference suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

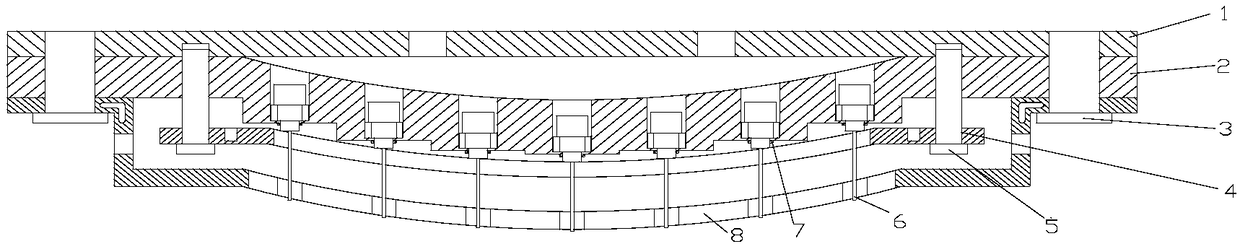

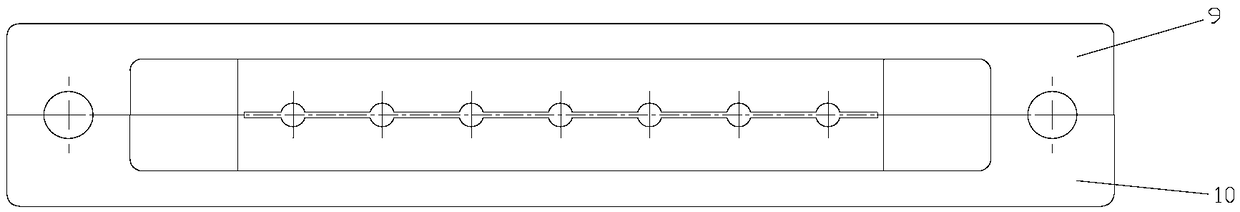

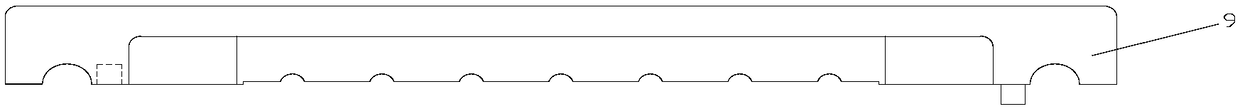

[0027] like figure 1 Shown is a specific embodiment of the present invention, which is provided with an upper cover plate 1, a needle mounting plate 2, an outer locking screw 3, a conductive plate 4, an inner locking screw 5, a needle array 6, a sealing ring 7 and a gas shield 8, Among them, the gas cover 8 is composed of a first gas cover module 9 and a second gas cover module 10, and the first gas cover module 9 and the second gas cover module 10 are quickly installed through the interference fit of the L-shaped groove and the L-shaped boss . The conductive plate 4 is composed of a first electrode plate 11 and a second electrode plate 12, and the first electrode plate 11 and the second electrode plate 12 are quickly installed through the interference fit between the groove and the boss. The upper cover 1 and the needle mounting plate 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com