Patents

Literature

70results about How to "Improve the uniformity of film formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

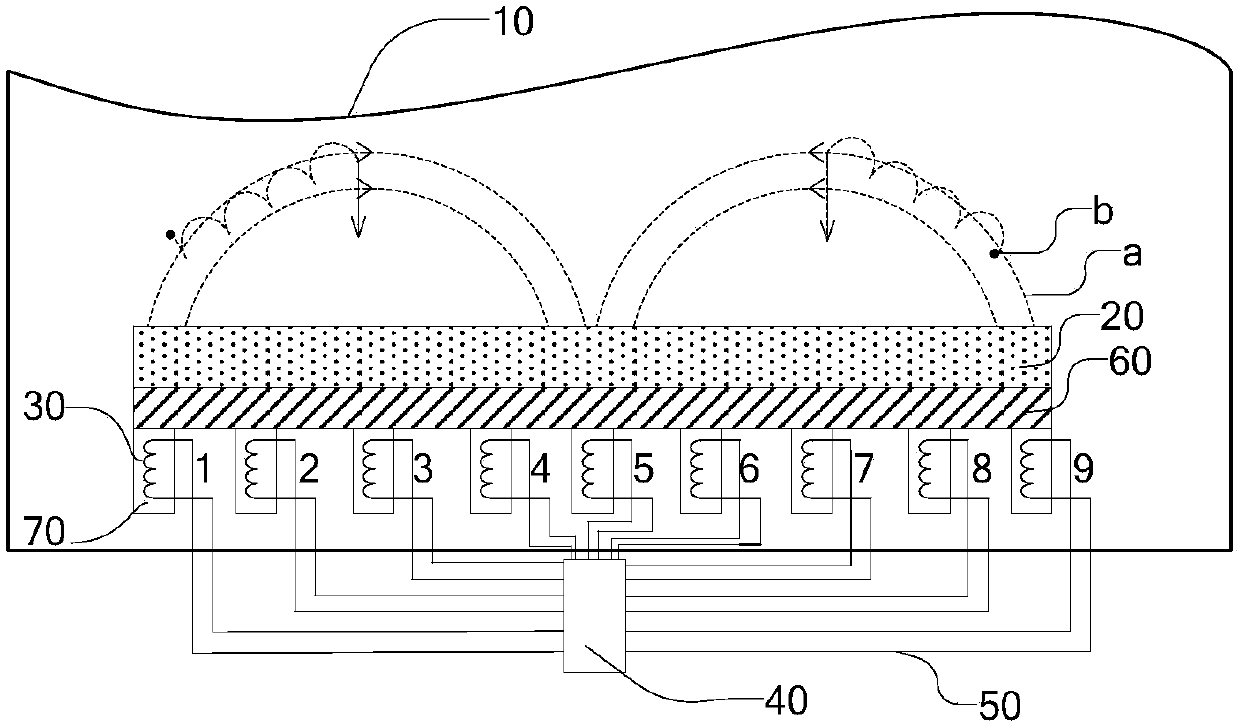

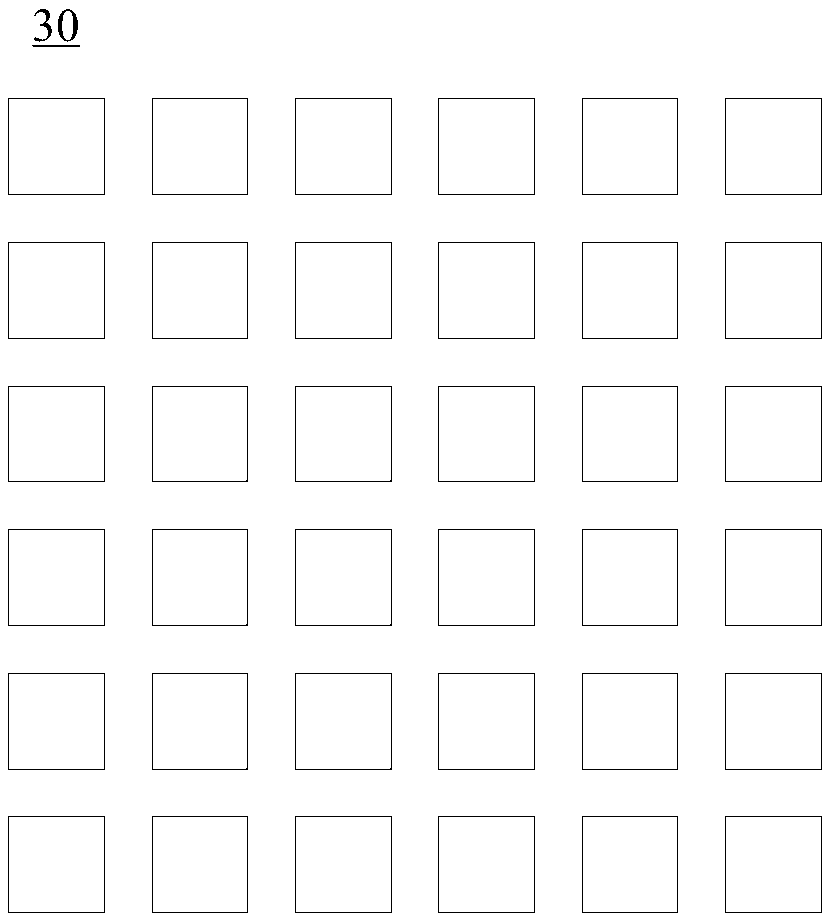

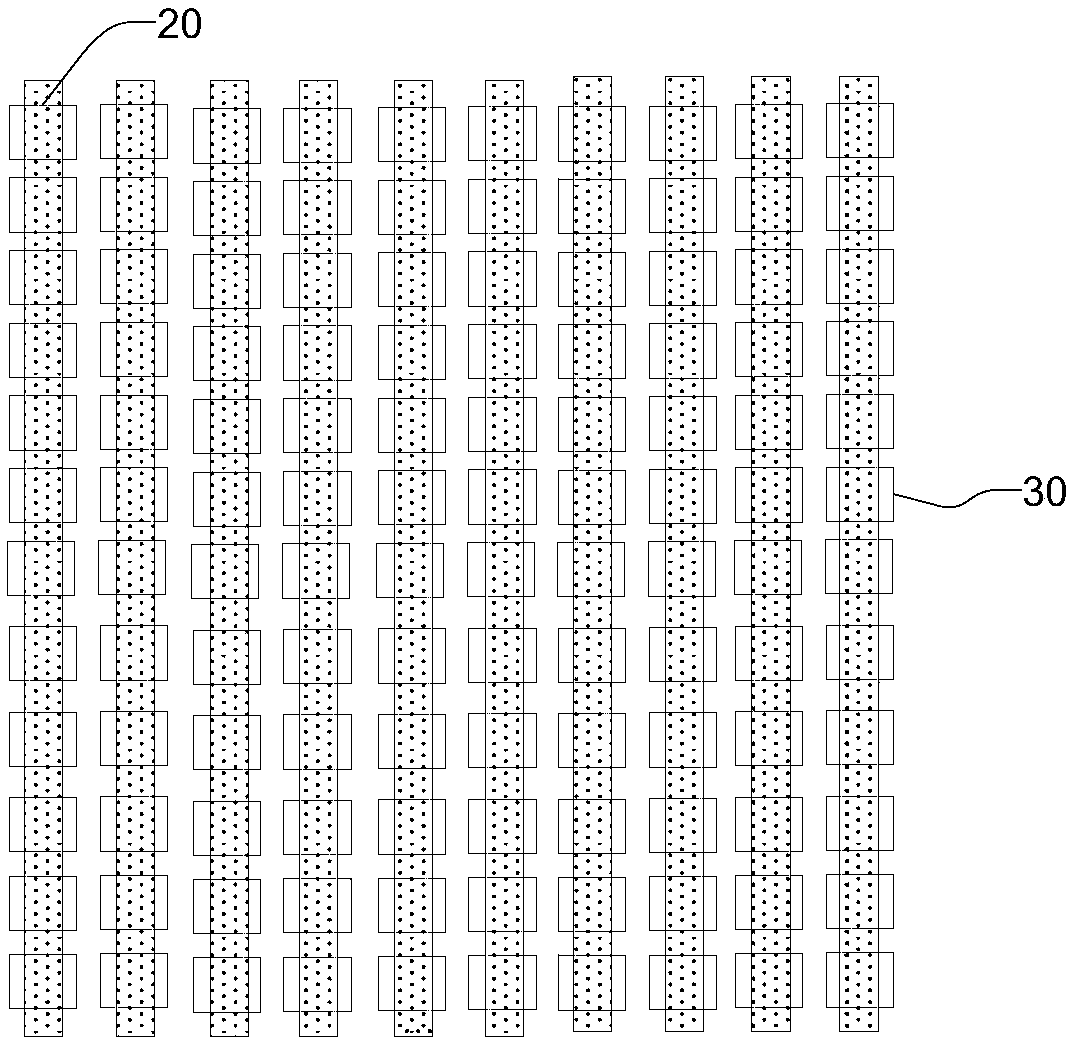

Organic light emitting display panel and manufacturing method thereof and display device

ActiveCN108281474AReduce evaporation rateImprove the uniformity of film formationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

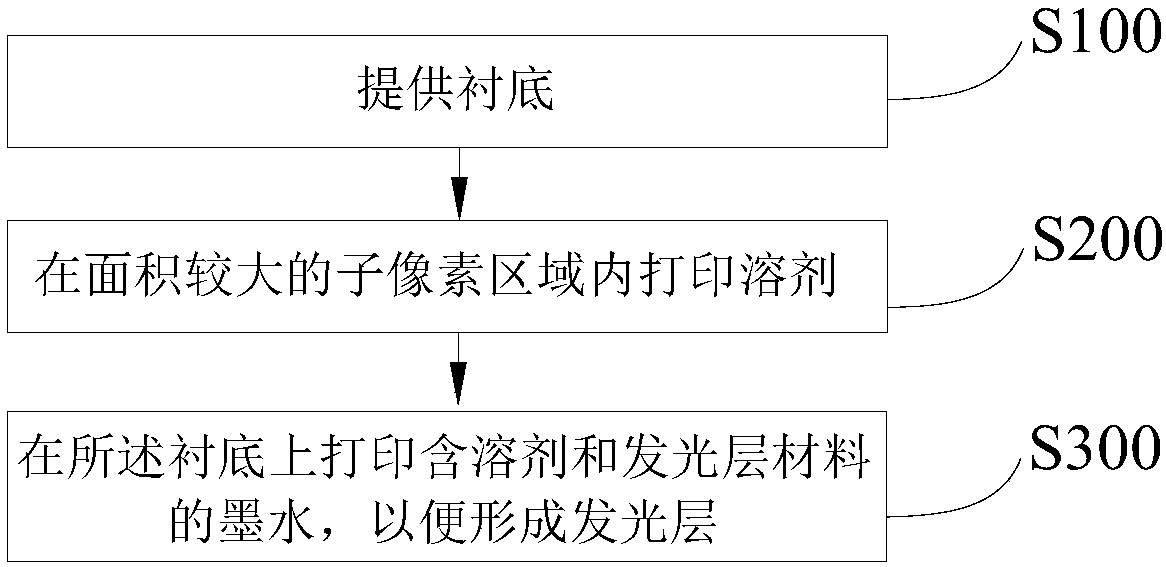

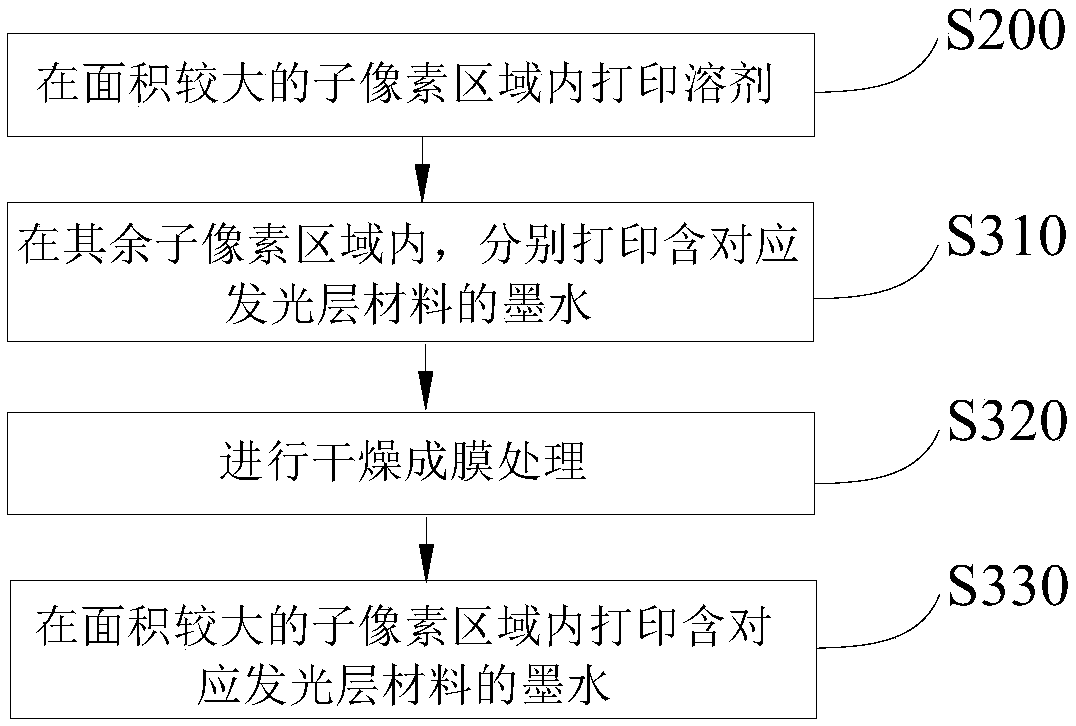

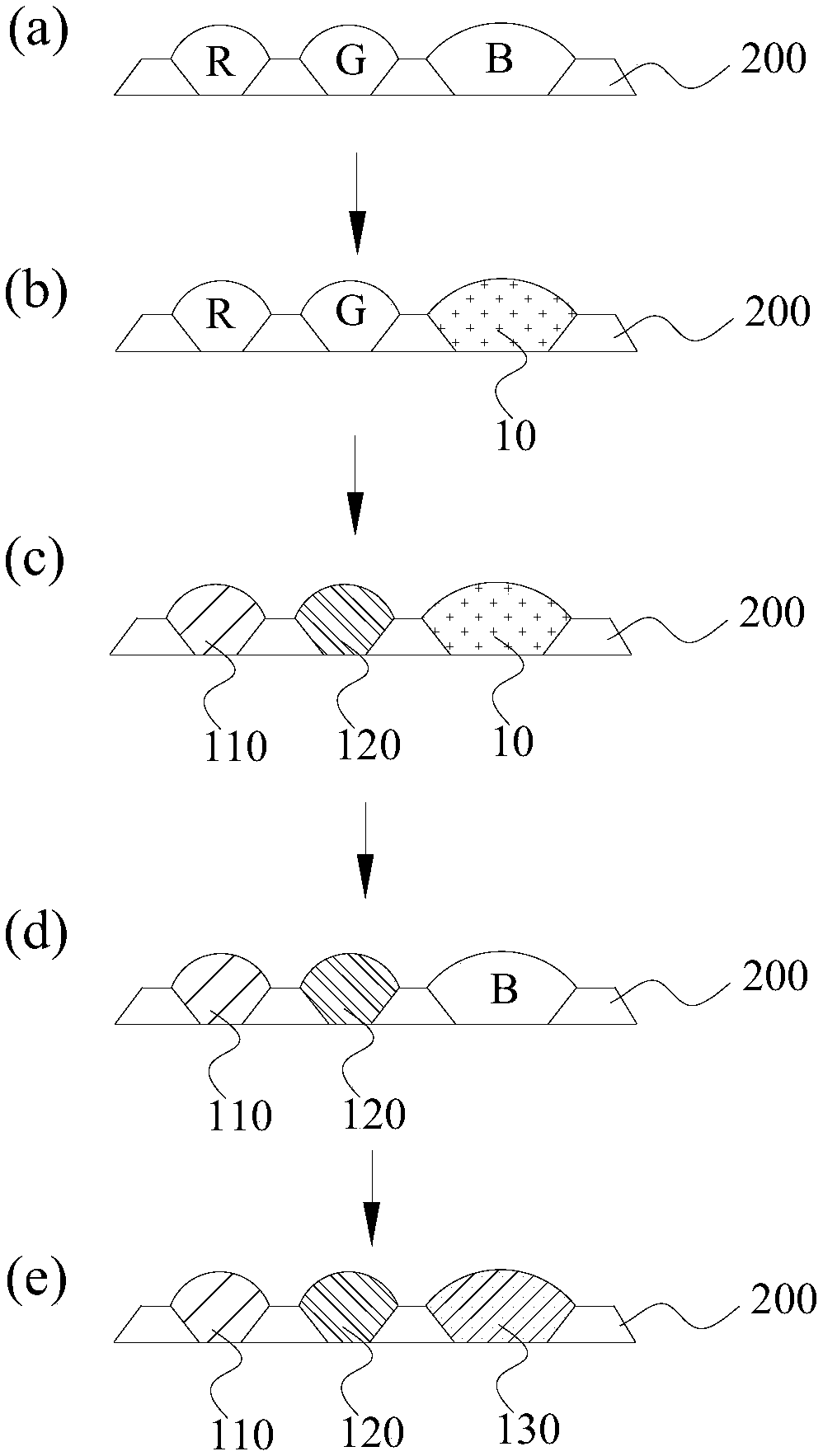

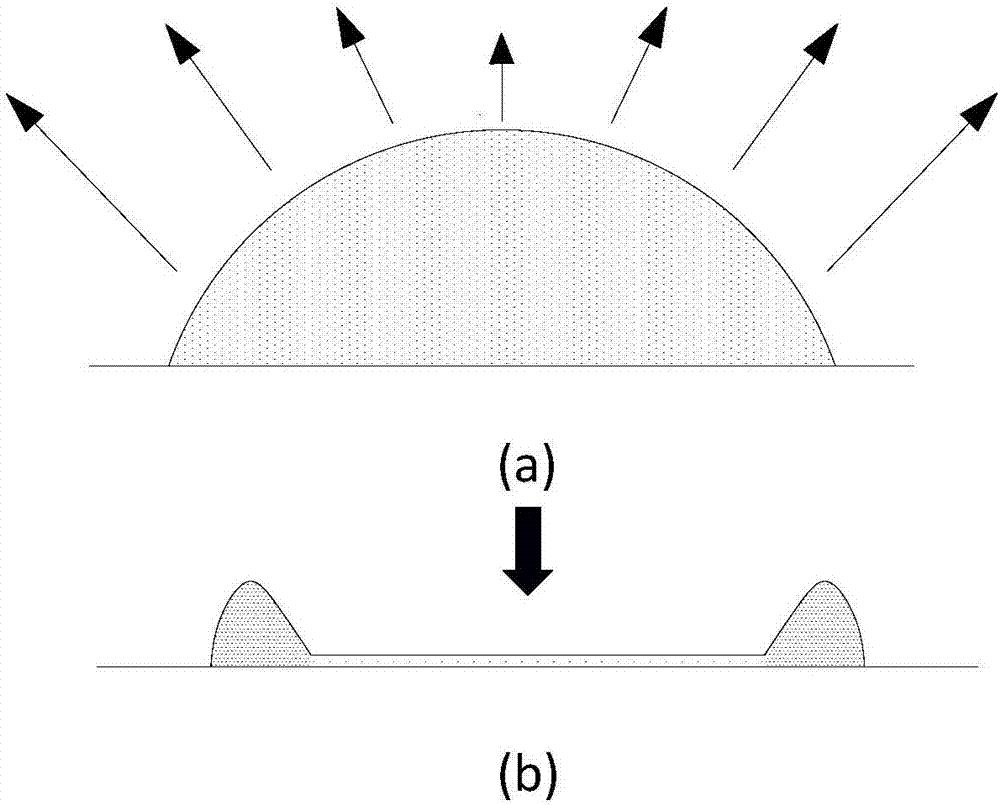

The invention discloses an organic light emitting display panel and a manufacturing method thereof, and a display device, and particularly provides a method for manufacturing the organic light emitting display panel. The method includes the steps of providing a substrate having a pixel defining layer which defines multiple sub pixel areas different in area and then printing with ink containing solvent and luminous layer materials on the substrate to form a luminous layer on the basis of the pixel defining layer, wherein the solvent is printed in large-area sub pixel area in advance before inkprinting. Ink volatilizing speed in ink printing in other small-area sub pixel areas can be reduced, film forming uniformity of the small-area sub pixel areas is improved, and further OLED display quality is improved.

Owner:BOE TECH GRP CO LTD

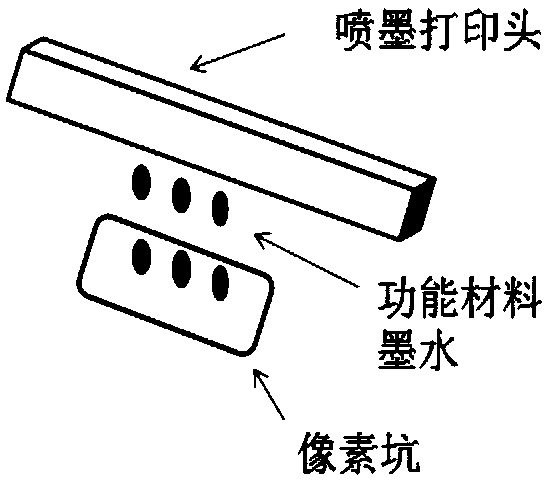

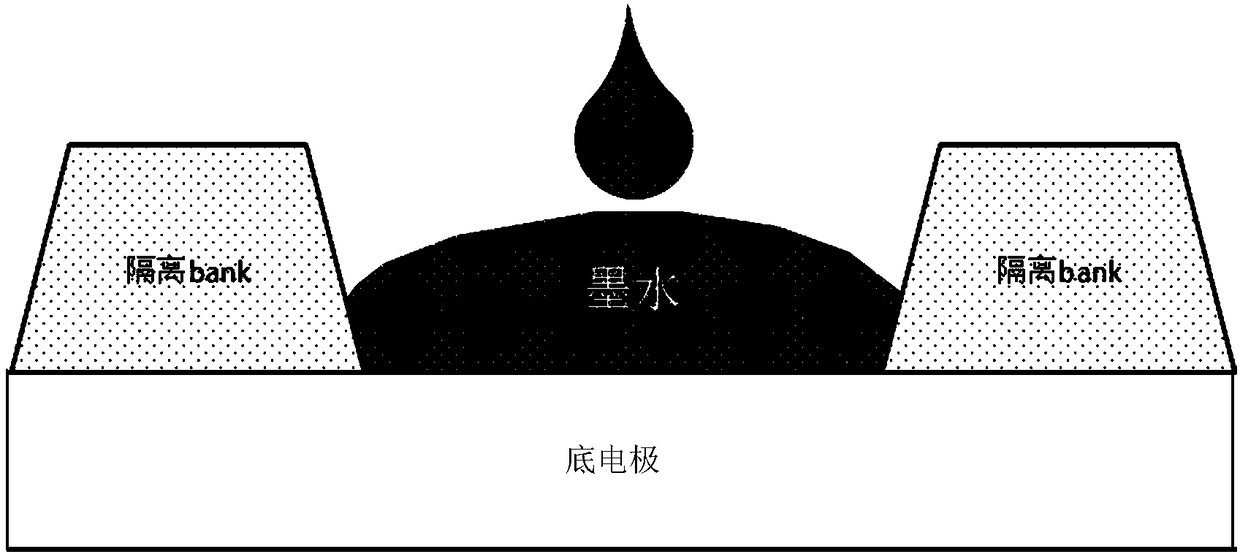

Preparation method of printed display device

ActiveCN107403824AImprove performanceReduce surface tensionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRoom temperature

The invention relates to a preparation method of a printed display device. The preparation method comprises the following steps of S1, depositing a first electrode layer on a substrate; S2, preparing a pixel definition layer on the first electrode layer and forming pixel pits; S3, performing ink-jet printing of functional layer ink in the pixel pints, and then putting into a saturated vapor atmosphere of a second solvent to perform vapor treatment, wherein the functional layer ink comprises a functional layer material and a first solvent; putting the device after vapor treatment into a room temperature condition, and naturally drying in air or nitrogen environment; and next, performing heat treatment to form a functional layer; and S4, depositing an electron transfer layer and a second electrode layer on the functional layer, and performing packaging to obtain the printed display device. By virtue of the preparation method of the printed display device, the wettability of ink and pixel Bank can be improved, so that the ink can be subjected to uniform film forming in the whole pixel region, and generation of electric leakage can be suppressed effectively.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

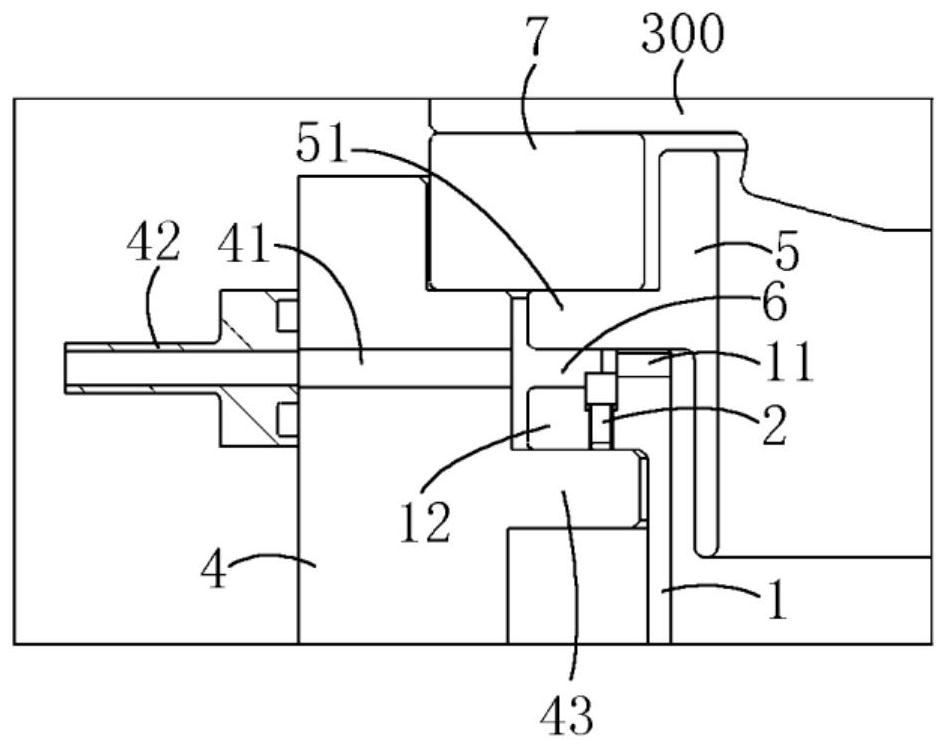

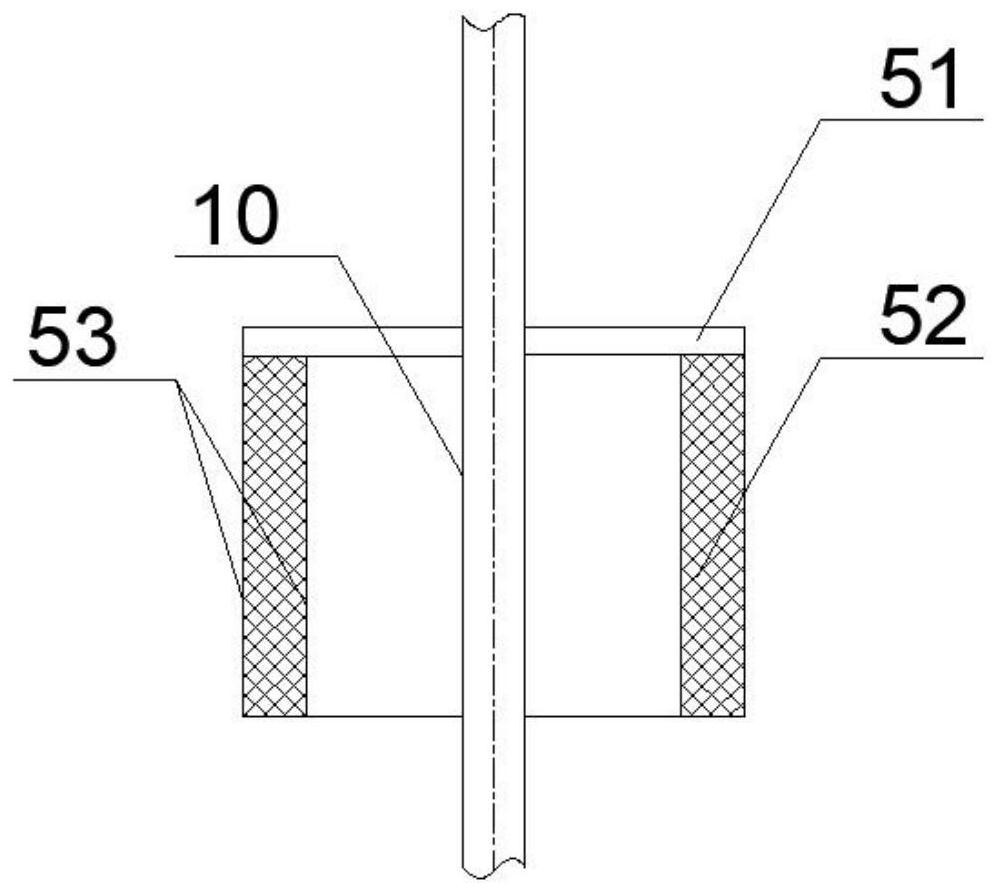

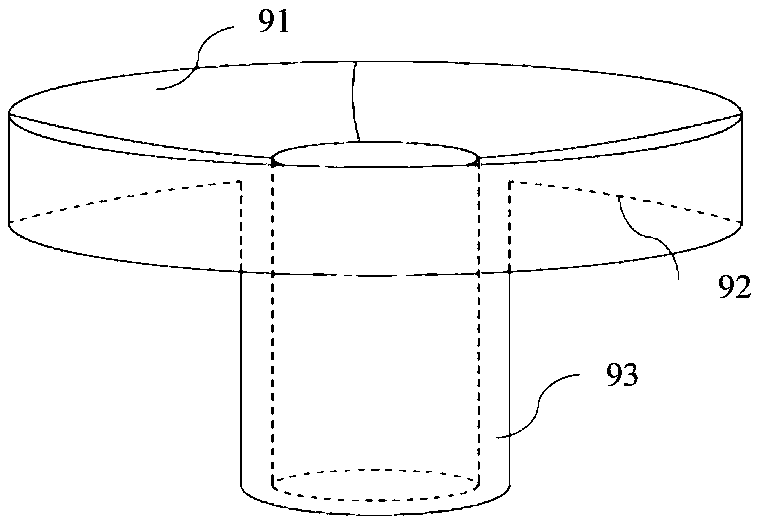

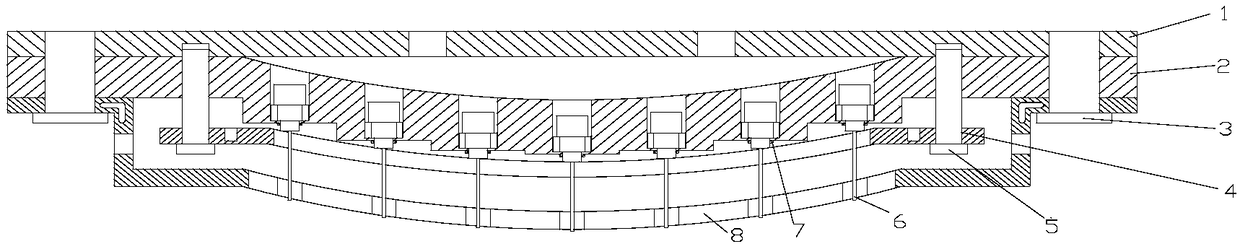

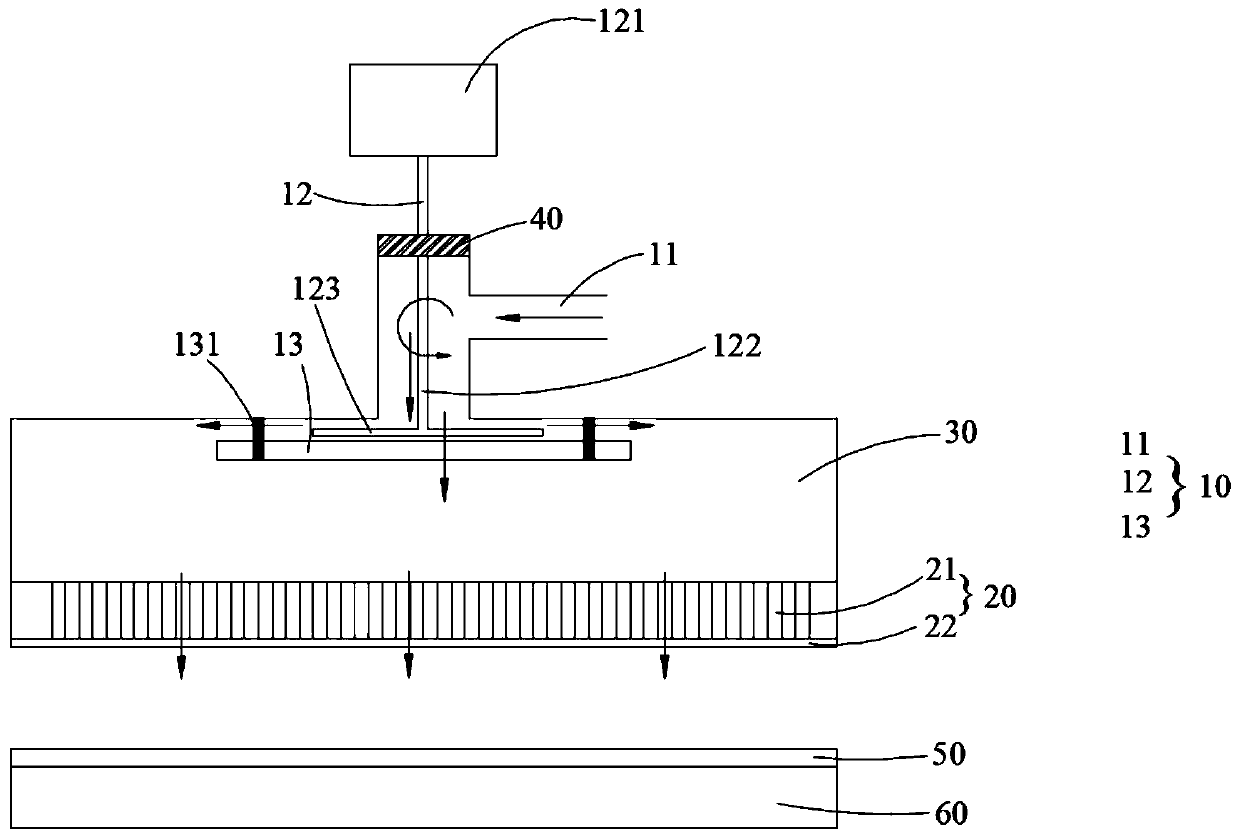

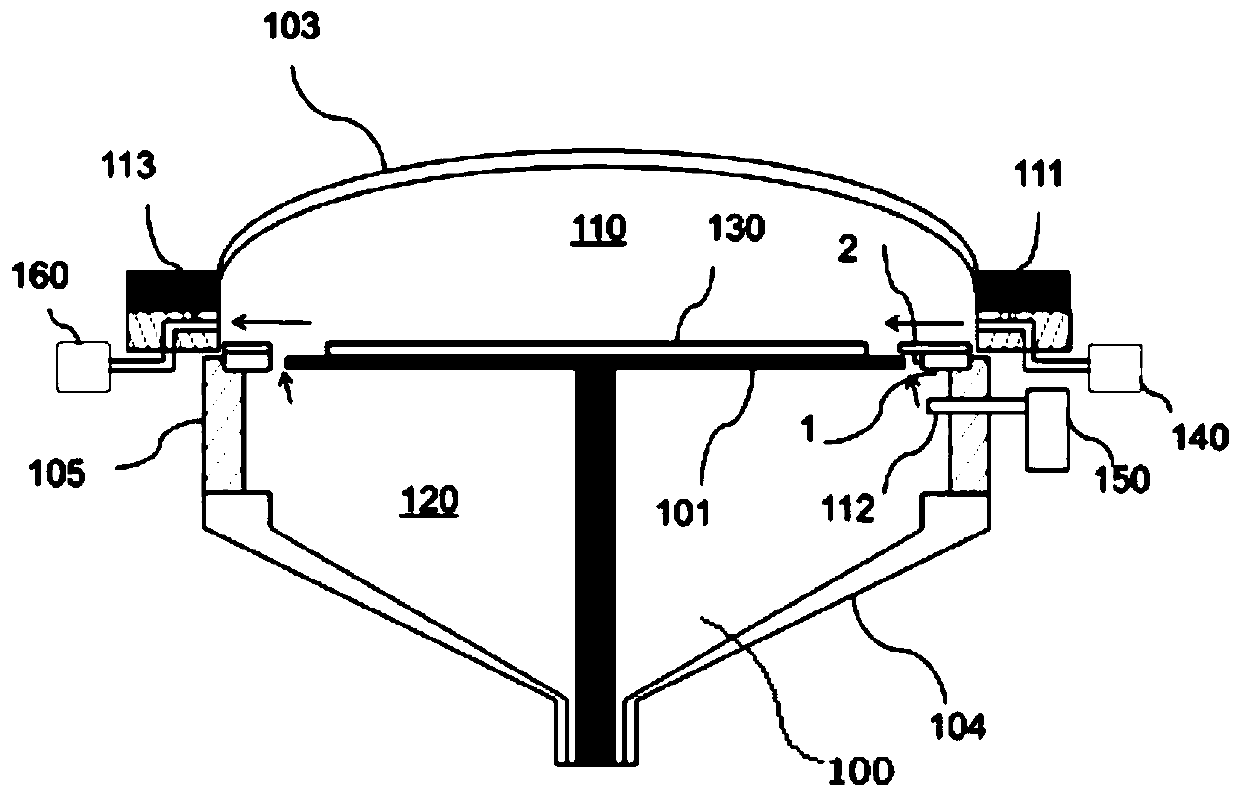

Semiconductor process equipment and air inlet mechanism thereof

PendingCN112863990AEvenly distributedImprove the uniformity of film formationElectric discharge tubesProcess equipmentInlet channel

The embodiment of the invention provides semiconductor process equipment and an air inlet mechanism thereof. The air inlet mechanism comprises an air inlet supporting piece, a flow uniformizing cover and a plurality of adjusting pieces. The air inlet supporting piece is used for being arranged at the top of a process chamber, the flow uniformizing cover is arranged in the air inlet supporting piece, an annular flow uniformizing cavity is formed between the air inlet supporting piece and the flow uniformizing cover, the air inlet supporting piece is provided with an air inlet channel communicated with the flow uniformizing cavity, and the air inlet channel is used for guiding in air; a plurality of air inlet holes distributed at intervals in the circumferential direction are formed in the flow uniformizing cover, and the flow uniformizing cavity is communicated with a process cavity of the process chamber through the air inlet holes; a flange extending in the circumferential direction is arranged on the outer circumferential wall of the flow uniformizing cover and located at the bottoms of the multiple air inlet holes. The multiple adjusting pieces are movably arranged on the flange and correspond to the multiple air inlet holes respectively, and the adjusting pieces are used for adjusting the flow of air entering the air inlet holes from the flow uniformizing cavity. According to the embodiment of the invention, uniform air inlet of the process chamber is realized, and the film forming uniformity and yield of wafers are greatly improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

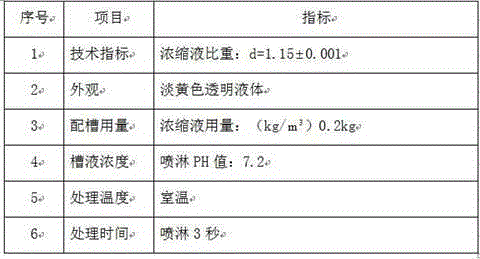

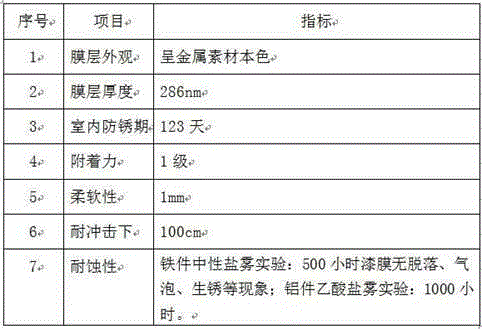

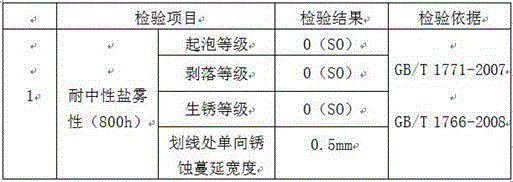

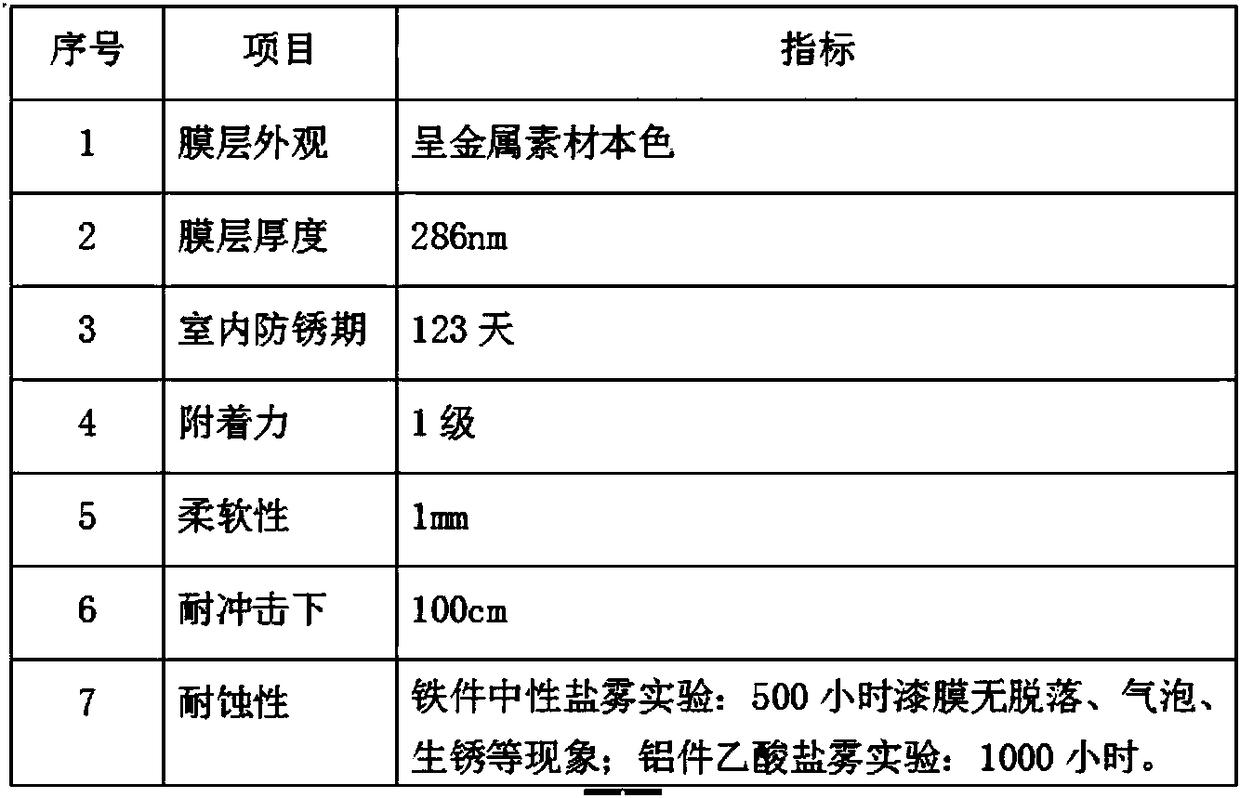

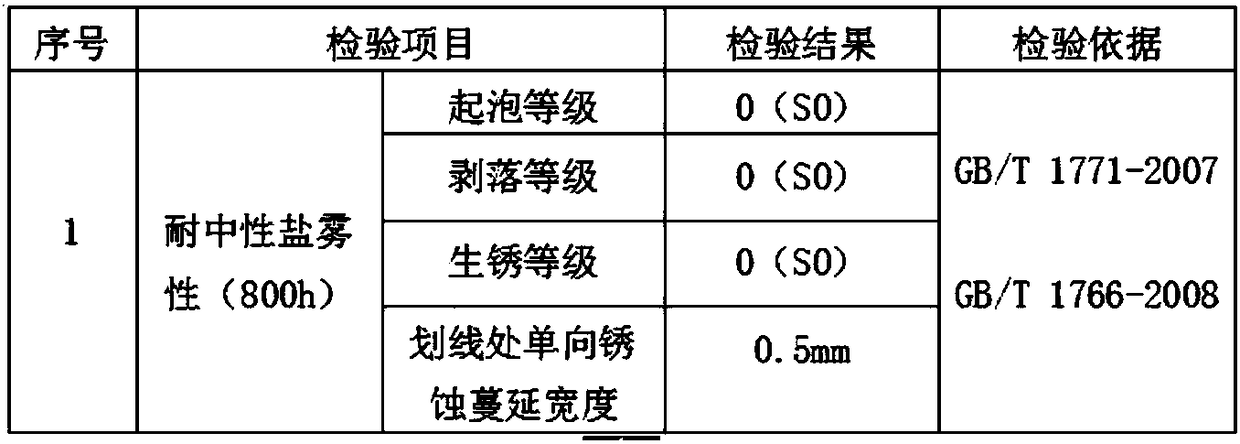

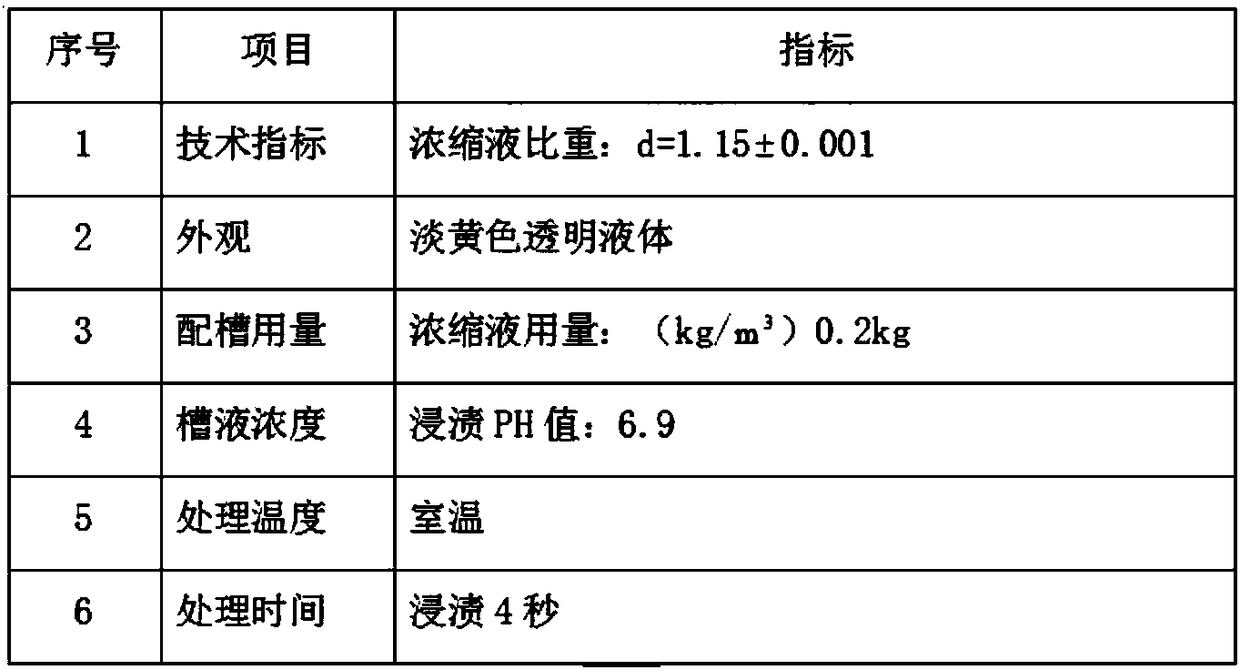

Silane treating agent for metal surfaces

ActiveCN105088217ASimple processLarge variable rangeMetallic material coating processesCorrosionMetal

The invention discloses a silane treating agent for metal surfaces. The silane treating agent is composed of, by weight, 20-30 parts of silane coupling agents, 20-30 parts of film-forming agents, 5-7 parts of complexing agents and 15-30 parts of purified water. According to the silane treating agent, the film-forming agents are thickening agents, and the complexing agents are sodium citrate, so that the silane treating agent has superior environment-friendly properties such as high ageing, hyper concentration, low carbon, energy conservation and no residue, phosphorus, zinc, chromium, fluorine or zirconium; a silane film has good effects of corrosion resistance property and adhesion property.

Owner:杭州易博乐科技有限公司

Magnetron sputtering device and magnetic field distribution adjusting method thereof

ActiveCN107779836AImprove streaksIncrease profitVacuum evaporation coatingSputtering coatingSputteringClassical mechanics

The invention provides a magnetron sputtering device and a magnetic field distribution adjusting method thereof, and relates to the field of magnetron sputtering. Poor stripes of a planar target material can be effectively improved, and the utilization rate of a target material and the film formation homogeneity can be improved. The magnetron sputtering device comprises a sputtering cavity, the planar target material, at least three sets of electromagnetic coils, a driving unit and connection wires, wherein the planar target material is arranged in the sputtering cavity; the at least three sets of electromagnetic coils are arranged on the part, away from one side being sputtered, of the planar target material, one end of each set of electromagnetic coil faces the planer target material, and the other end is away from the planar target material; the driving unit is configured to control on-off and magnetism direction of each set of electromagnetic coil; and the connection wires correspond to the three sets of electromagnetic coils one by one, and are configured to be electrically connected with the three sets of electromagnetic coils and the driving unit.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

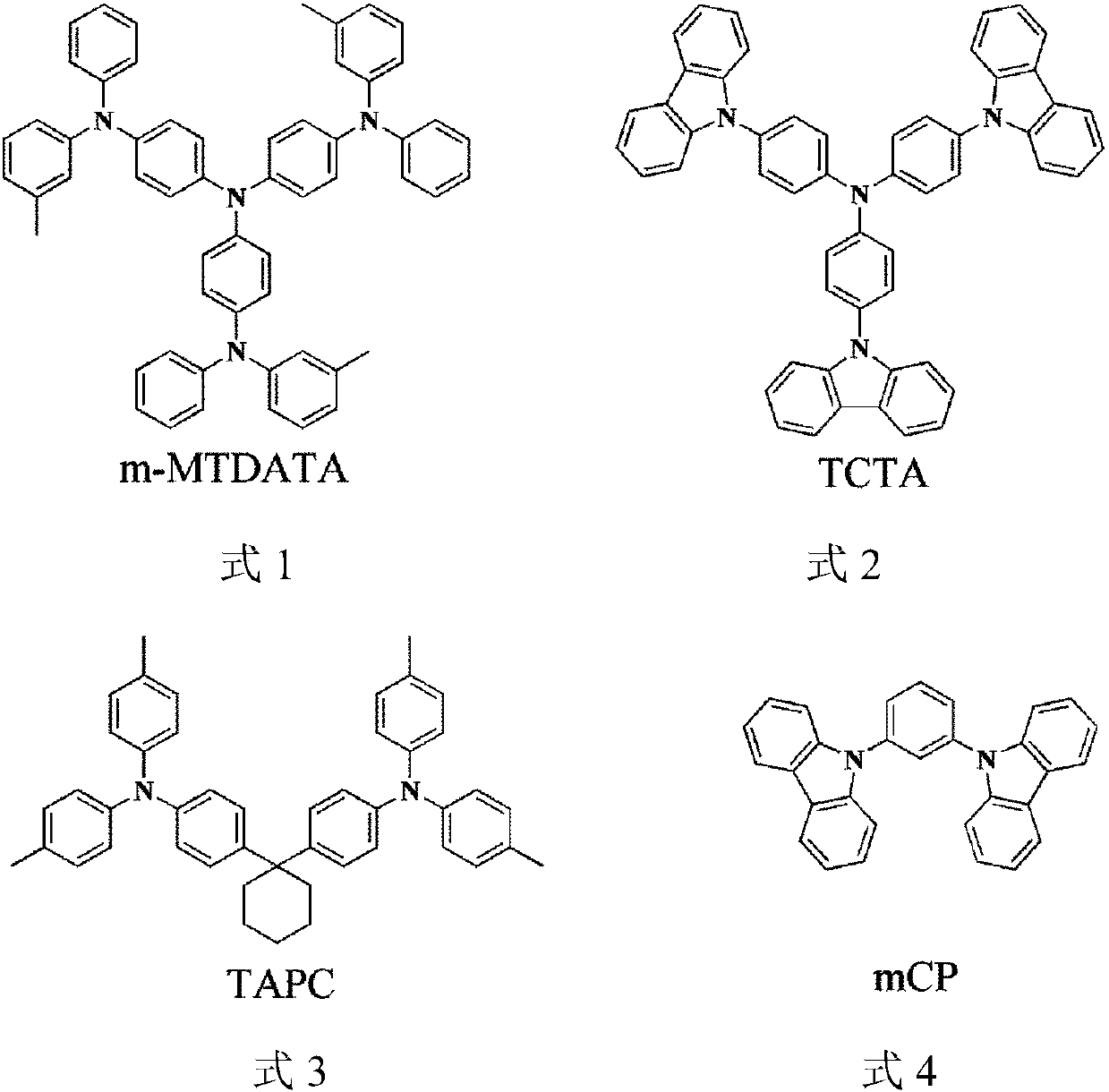

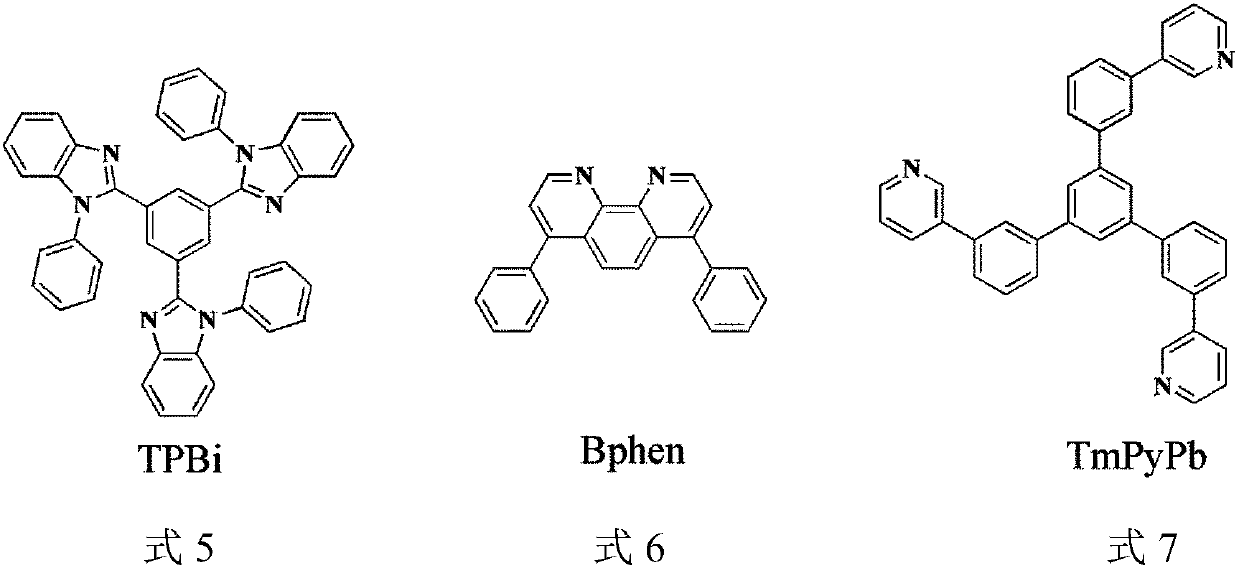

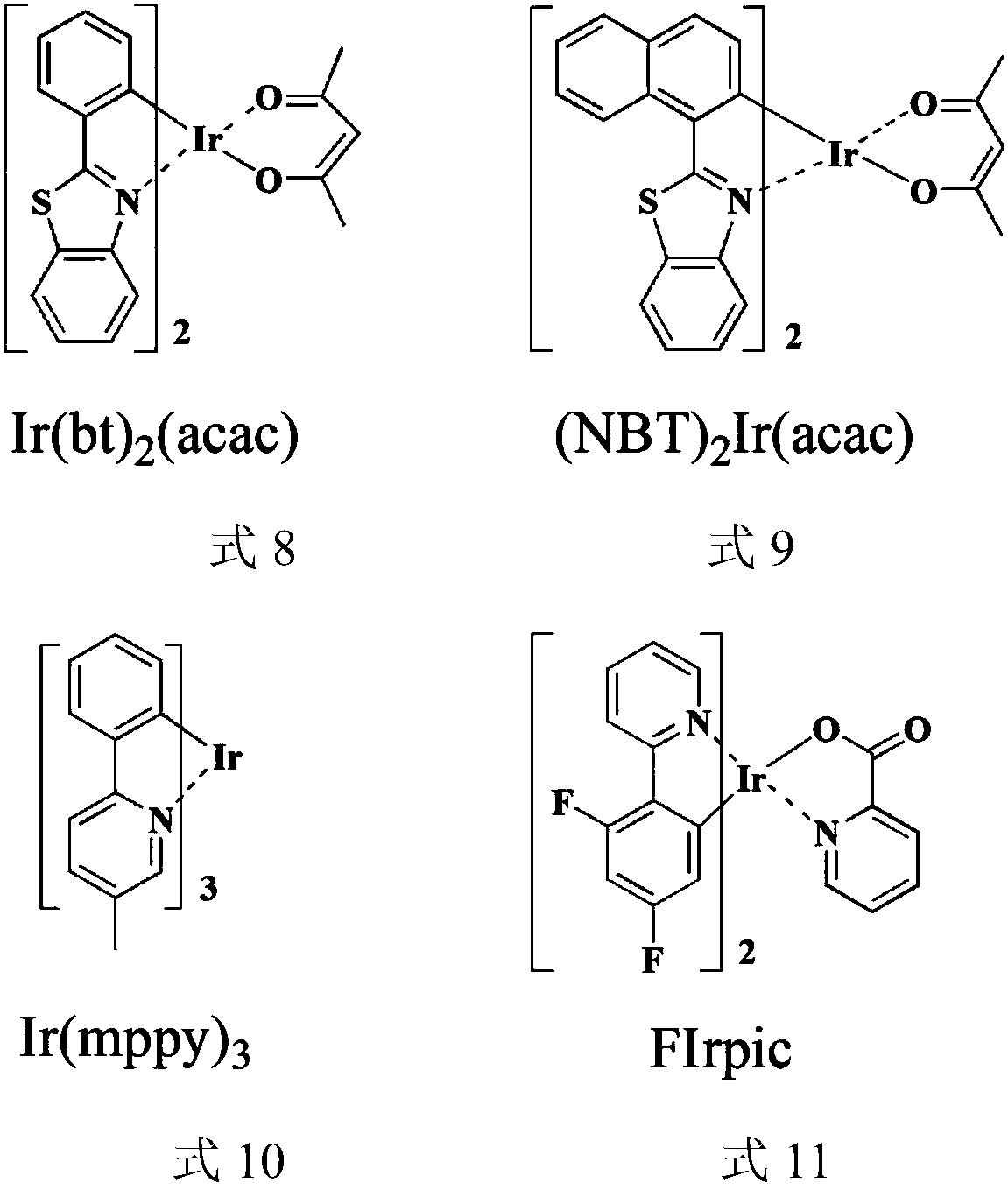

Ink for ink-jet printing of organic light-emitting layer, preparation method and applications thereof

InactiveCN110791151AThe state of ink output is stableWiden the formation areaInksElectron holeLight-emitting diode

The invention discloses ink for ink-jet printing of an organic light-emitting layer, wherein the ink is formed by uniformly mixing a mixed main body light-emitting material, a doped phosphorescent light-emitting material and a viscosity regulator, the mixed main body light-emitting material comprises a hole transport material and an electron transport material, the hole transport material and theelectron transport material are matched with carrier transport, and the triplet state energy levels of the hole transport material and the electron transport material are at least 0.1 eV higher than the triplet state energy level of the doped phosphorescent light-emitting material. The invention further discloses a preparation method of the ink and applications of the ink in manufacturing of organic light emitting diodes. According to the invention, the ink for ink-jet printing of an organic light-emitting layer is obtained through a simple process by mixing the hole transport material and theelectron transport material matched with carrier transport as the mixed main body light-emitting material, selecting the guest light-emitting material with the specific triplet state energy level performance and limiting the viscosity regulator and the organic solvent, so that the preparation method is simple, and the process requirement of ink-jet printing can be met.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

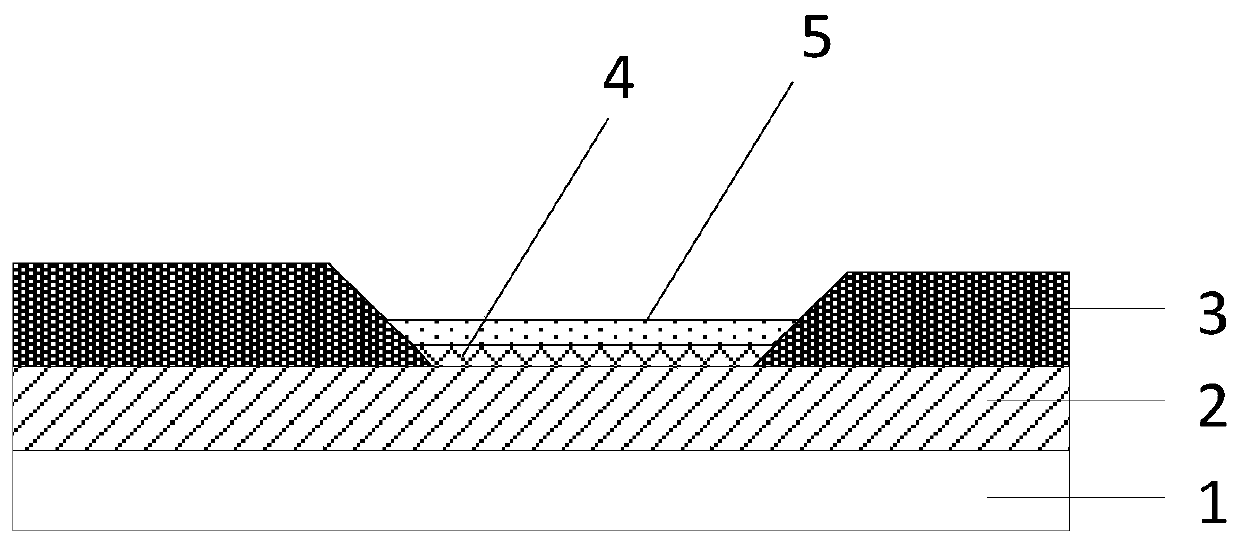

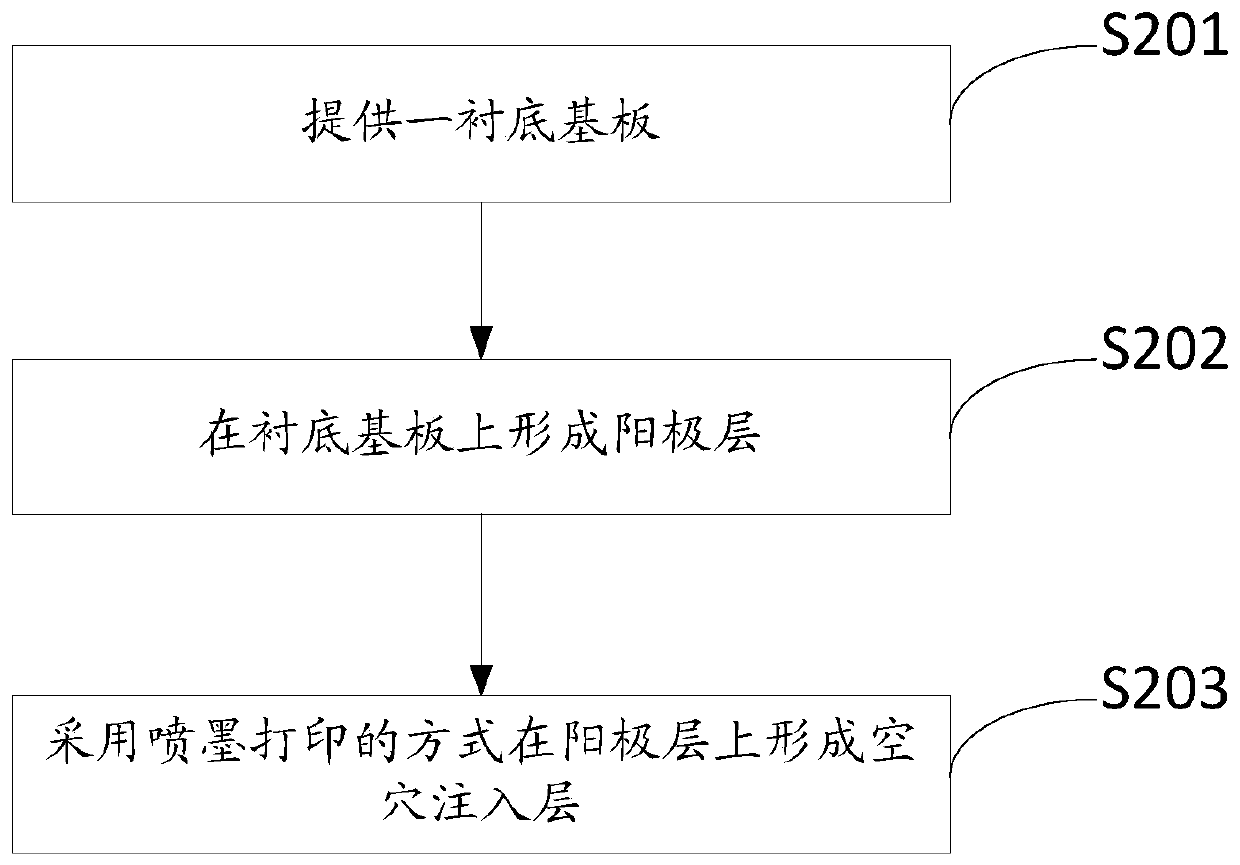

Hole injection layer ink, organic light-emitting device and manufacture method of hole injection layer ink

ActiveCN109735167AImprove the uniformity of film formationSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic light emitting device

The invention discloses hole injection layer ink, an organic light-emitting device and a preparation method of the hole injection layer ink. The hole injection layer ink comprises a solvent material,a hole transmission macromolecule material and a hole transmission nano-sphere, the hole transmission macromolecule material and the hole transmission nano-sphere are dissolved in the solvent material, the hole transmission macromolecule material and the hole transmission nano-sphere are materials with hole transmission characteristics for organic electrons, the hole transmission macromolecule material is provided with a preset contact angle, the hole transmission nano-sphere is arranged in the solvent material, so that the hole injection layer ink can be provided with a preset contact angle,the hole injection layer ink can achieve lyophobicity, and the film forming uniformity of a film layer adjacent to a hole injection layer can be improved.

Owner:BOE TECH GRP CO LTD

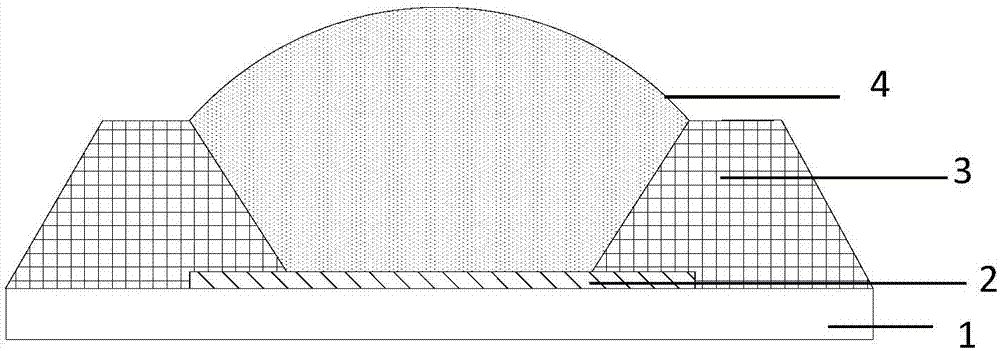

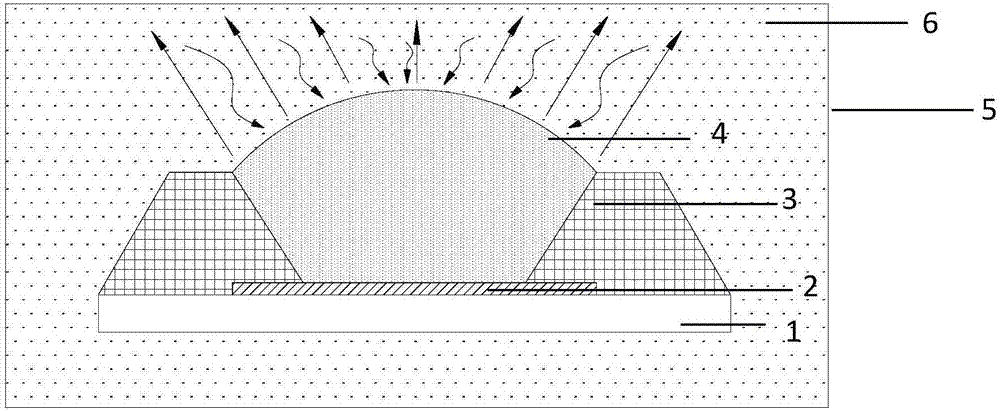

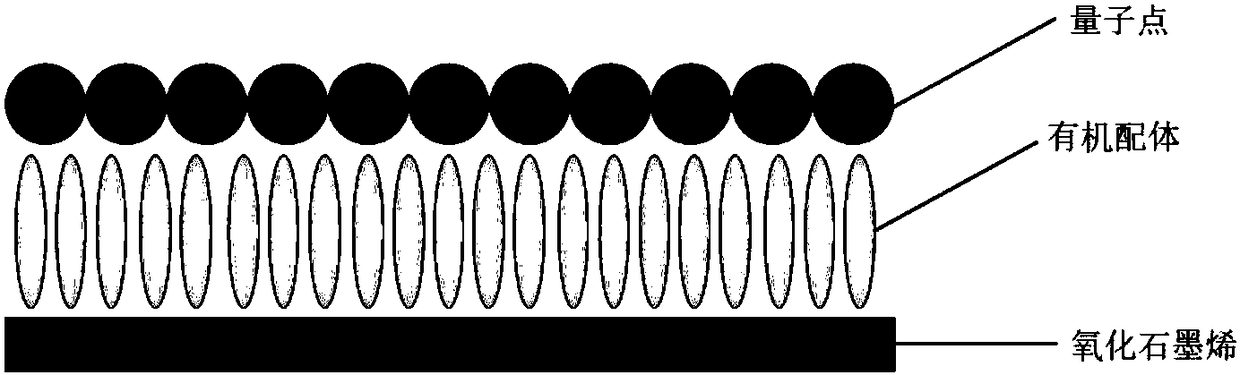

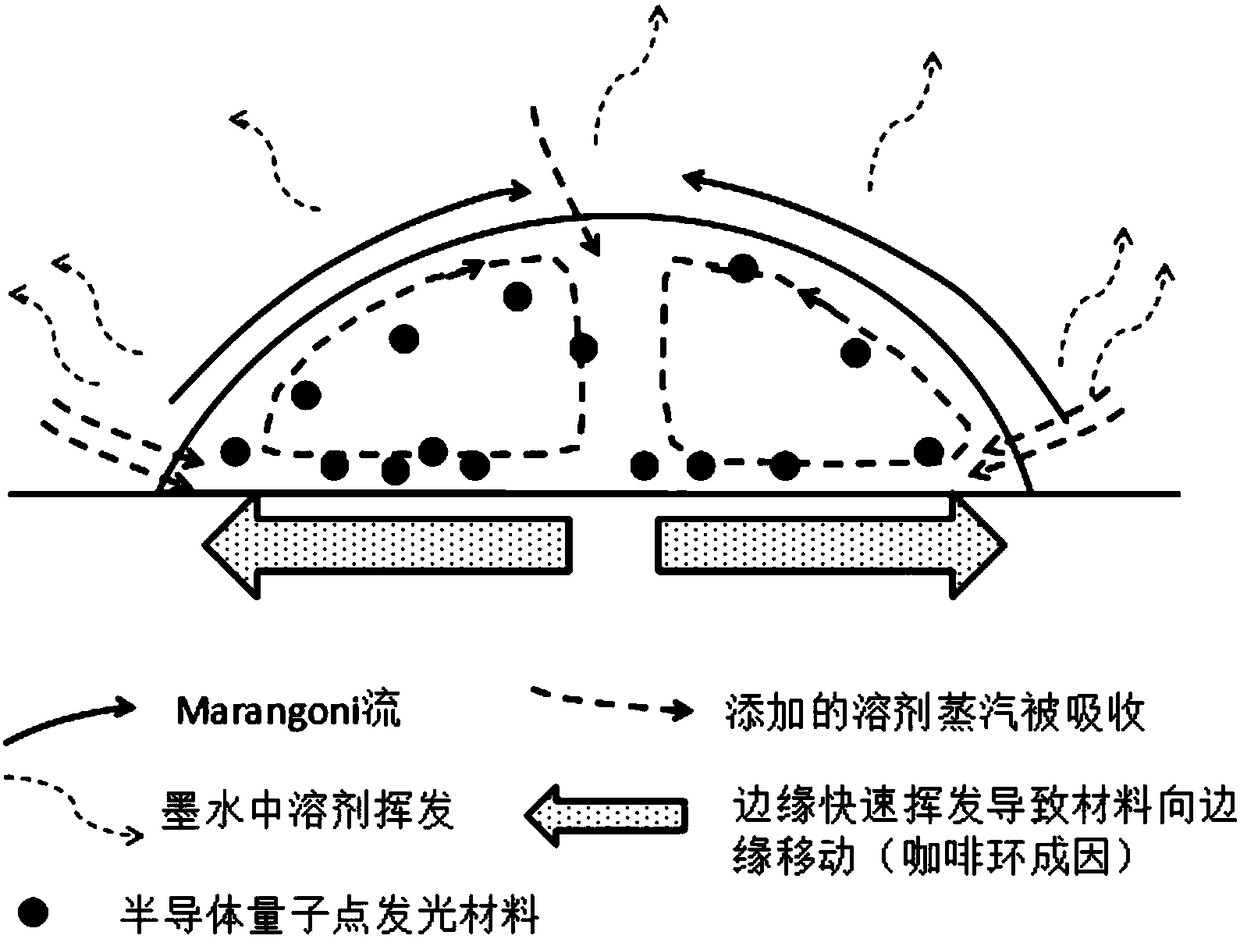

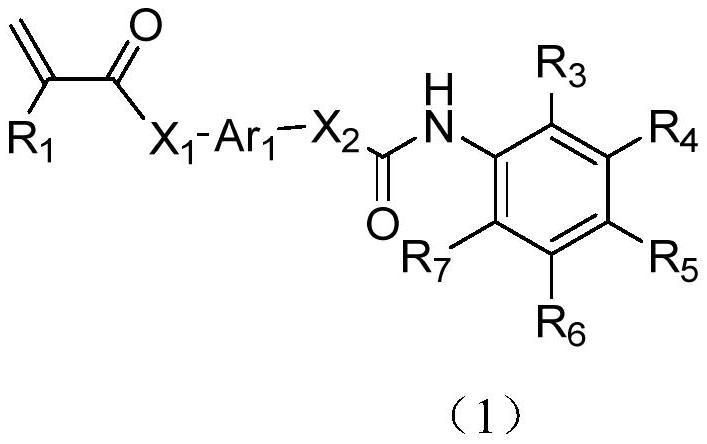

Composite luminescent layer, QLED device and preparation method thereof

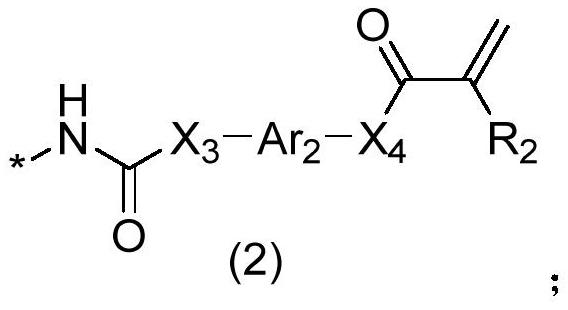

ActiveCN109216567AImprove the uniformity of film formationImprove uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotOxide

The invention provides a composite light-emitting layer, comprising an auxiliary functional layer formed by a graphene oxide and an organic amine ligand, and a quantum dot layer bonded on the auxiliary functional layer, wherein the surface of the graphene oxide contains electron-rich functional groups, and the structural formula of the organic amine ligand is Y- R-R1N + (R2) R3, wherein R is one of a hydrocarbyl group, an aryl group and derivatives thereof; R1, R2, R3 are independently selected from one of H and hydrocarbon groups; In the composite light-emitting layer, the organic amine ligand-R1N + (R2) R3 is connected to an electron-rich functional group on the graphene oxide surface, and Y of the organic amine ligand is bound to a quantum dot in the quantum dot layer.

Owner:TCL CORPORATION

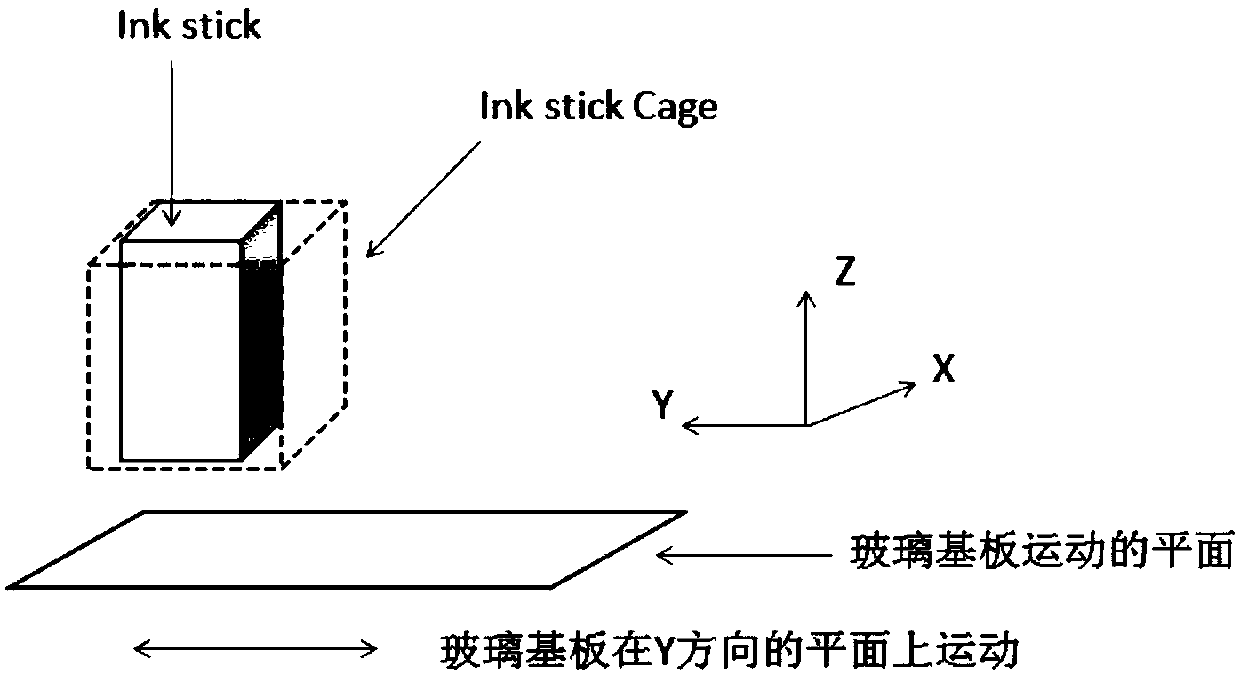

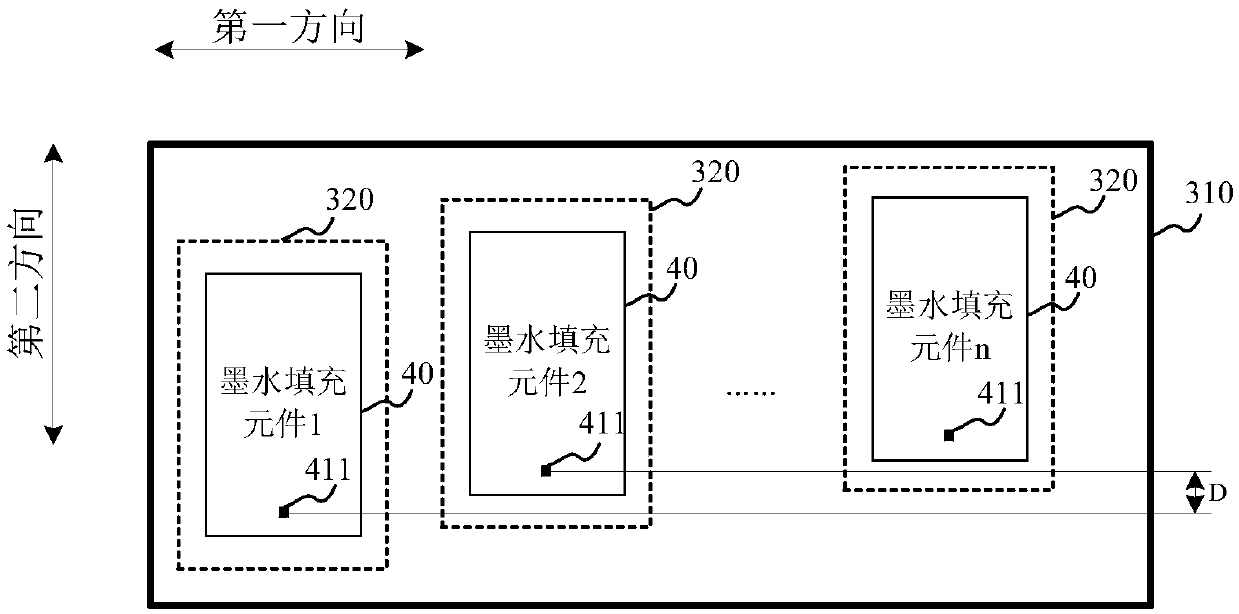

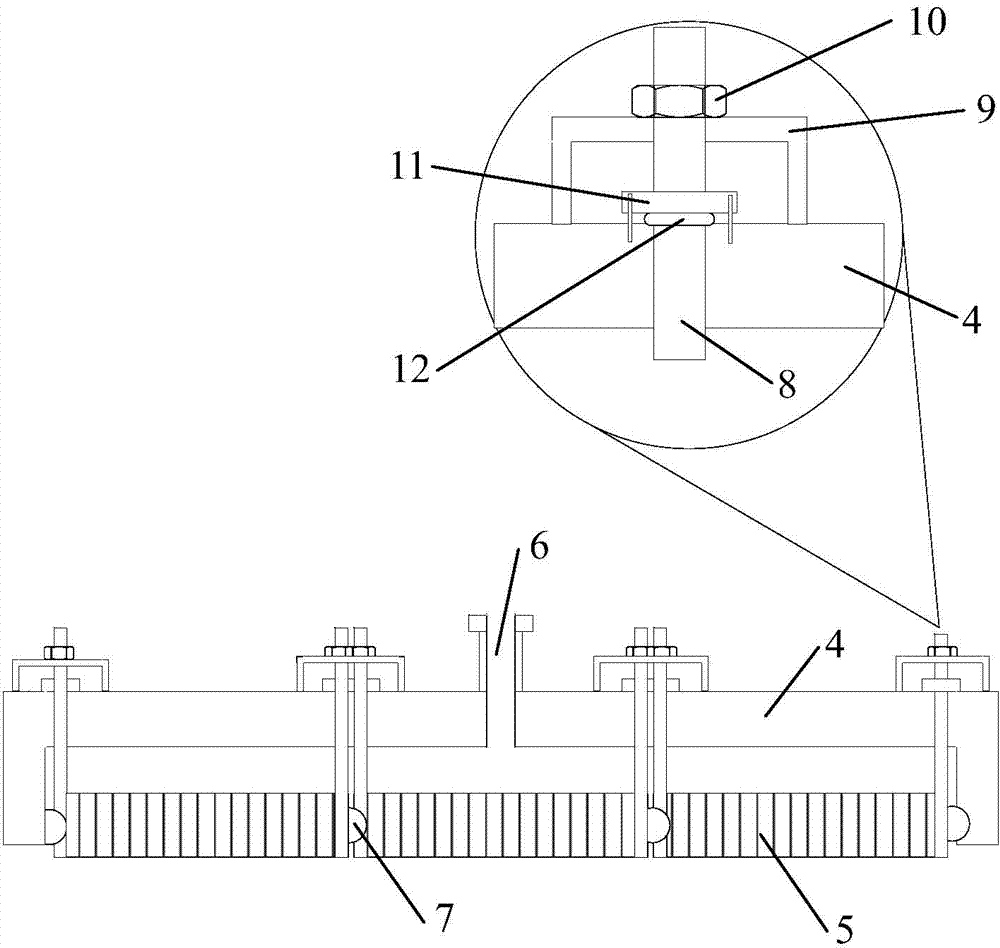

Ink filling element carrier, control method and device of ink filling element carrier, and computer equipment

The invention relates to an ink filling element carrier, a control method and device of the ink filling element carrier, and computer equipment, wherein the carrier comprises a carrier body and a plurality of groups of fixing pieces arranged on the carrier body, and each fixing piece is used for loading one ink filling element; each fixing piece is arranged in a first direction, wherein the firstdirection is a relative moving direction of the corresponding ink filling element and a printed substrate in a printing process; and when the ink filling elements are loaded on the fixing pieces, eachfixing piece can drive the corresponding ink filling element to move in a second direction, wherein the second direction is a direction perpendicular to the first direction in a plane parallel to theprinted substrate. According to the ink filling element carrier, the number of nozzles dripping ink to the same pixel pit can be flexibly regulated and controlled according to the sizes of pixel pitson the printed substrate; and when the sizes of the pixel pits on the substrate are small and the number of the pixel pits is increased, the number of nozzles dripping ink to the same pixel pit is increased, so that the printing process time is shortened, and the film forming uniformity of the substrate is improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Formation process of lithium ion battery

ActiveCN111934039AShorten the soaking timeEfficient dischargeFinal product manufactureSecondary cells charging/dischargingVacuum pumpingPhysical chemistry

The invention discloses a formation process of a lithium ion battery, which comprises the steps of A, standing a lithium ion battery cell subjected to liquid injection and pre-sealing in an environment of 35-85 DEG C for 4-72 hours; B, clamping the battery cell subjected to standing by adopting a high-temperature clamp, and performing charging and discharging under the conditions that the environment temperature is 35-85 DEG C and the clamp pressure is 0.1-1MPa; C, allowing the charged and discharged battery cell to stand in an environment of 35-85 DEG C for 4-72 hours; and D, carrying out vacuum pumping and sealing on the battery cell. According to the formation process, the consistency of the prepared lithium ion battery cell can be improved, the cycle performance of the battery cell canbe improved, the molding composition rate of the battery cell can be greatly improved, and the manufacturing cost of the battery cell can be reduced.

Owner:华鼎国联动力电池有限公司

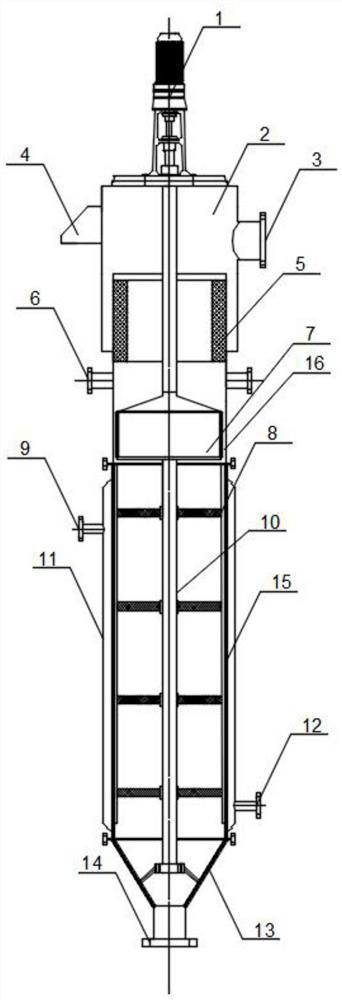

Efficient scraper film evaporation device

InactiveCN111701262AImprove the uniformity of film formationImprove evaporation heat transfer coefficientEvaporator accessoriesVapor–liquid separatorEvaporation heat transfer

The invention relates to an efficient scraper film evaporation device. The device is characterized in that a gear motor is arranged at the upper end of a separation chamber; the lower end of the separation chamber is connected with a gas-liquid separator; the bottom end of the gas-liquid separator is connected to an evaporator barrel; a rotating shaft is coaxially arranged in the evaporator barrel; the rotating shaft penetrates through the gas-liquid separator and the separation chamber and is connected to the end part of the motor shaft of the gear motor; a liquid distributor and a scraper are sequentially arranged on the rotating shaft in the evaporator barrel, a conical end socket is arranged at the bottom end of the evaporator barrel, a concentrated material outlet is formed in the bottom end of the conical end socket, a feeding port is formed in the evaporator barrel and located at the upper end of the liquid distributor, and an air outlet is formed in the upper end of the gas-liquid separator. The efficient scraper film evaporation device is scientific and reasonable in structural design, reasonable in liquid distribution and uniform in film formation, evaporation heat transfer can be improved, secondary steam entrainment is avoided, and the evaporation efficiency is improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

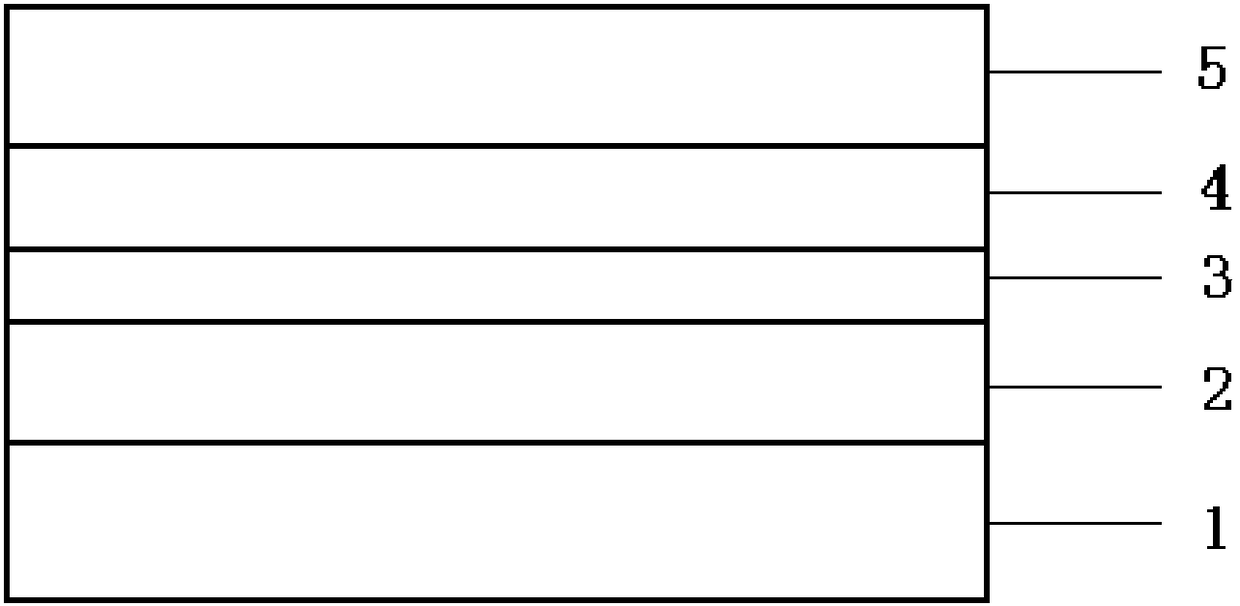

Preparation method of functional layer of QLED device

ActiveCN108735900AImprove performance and stabilityPromote refluxSolid-state devicesSemiconductor/solid-state device manufacturingSolvent vaporHole injection layer

The invention provides a preparation method of a functional layer of a QLED device. The method comprises the following steps of providing a pre-patterned pixel channel; providing inkjet printing equipment provided with two nozzles for containing functional layer ink and solvent vapor separately; and firstly spraying and dripping functional layer ink droplets on a substrate layer of the pixel channel through one spray head, then spraying the solvent vapor on the surfaces of the functional layer ink droplets through the other spray head and carrying out drying and film forming to prepare a functional layer, wherein the functional layer comprises a hole injection layer, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer and an electron injection layer; thefunctional layer ink comprises a functional layer material and an ink solvent; the flow of the solvent vapor meets the condition that local bias pressure is greater than vapor pressure at corresponding temperature; a solvent used for the solvent vapor meets the condition that the liquid phase surface tension of the solvent is smaller than that of the ink solvent; the solvent vapor and the ink solvent are mutually dissolved; and the functional layer material can be dissolved.

Owner:TCL CORPORATION

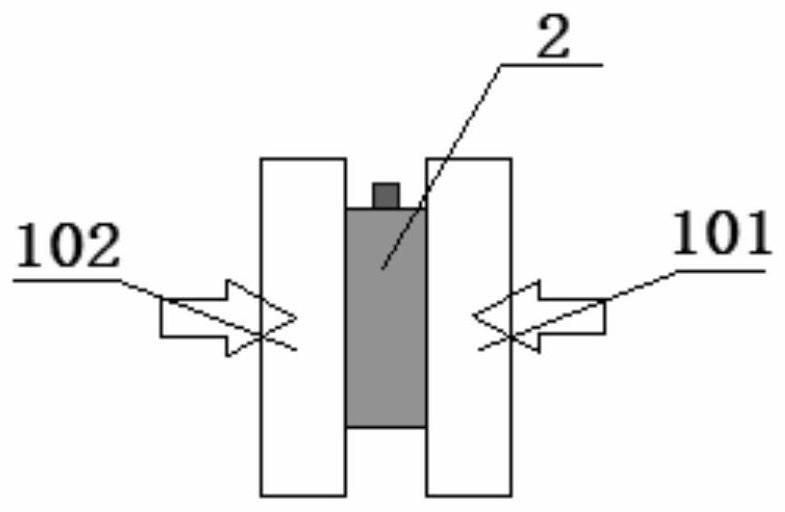

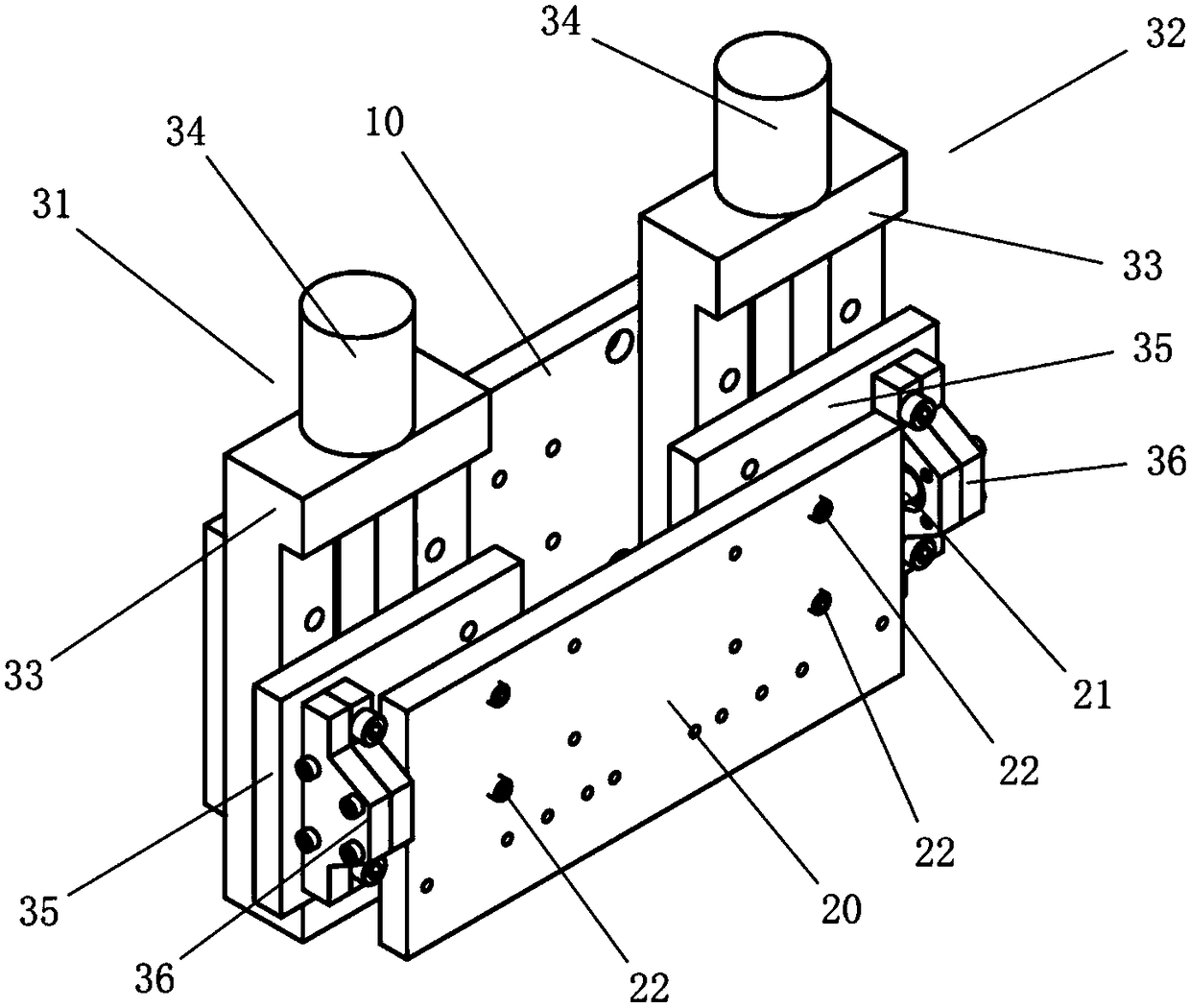

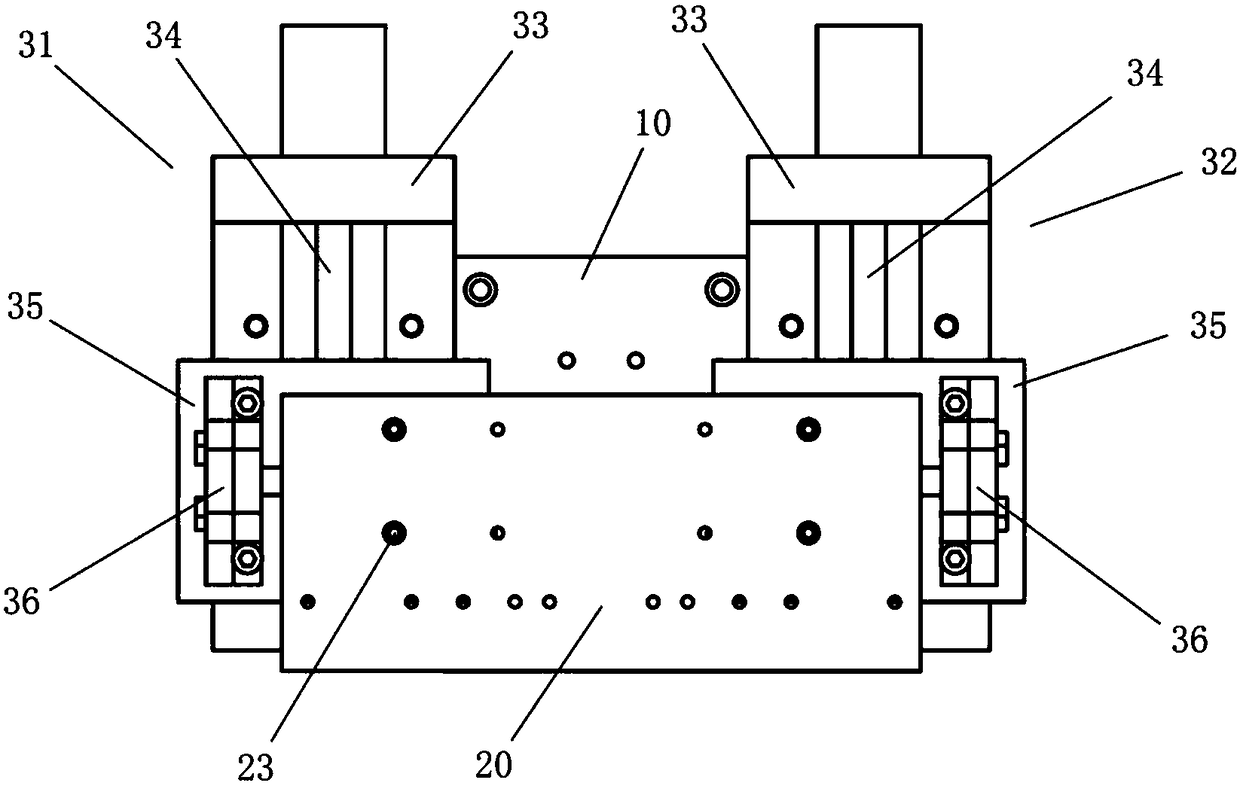

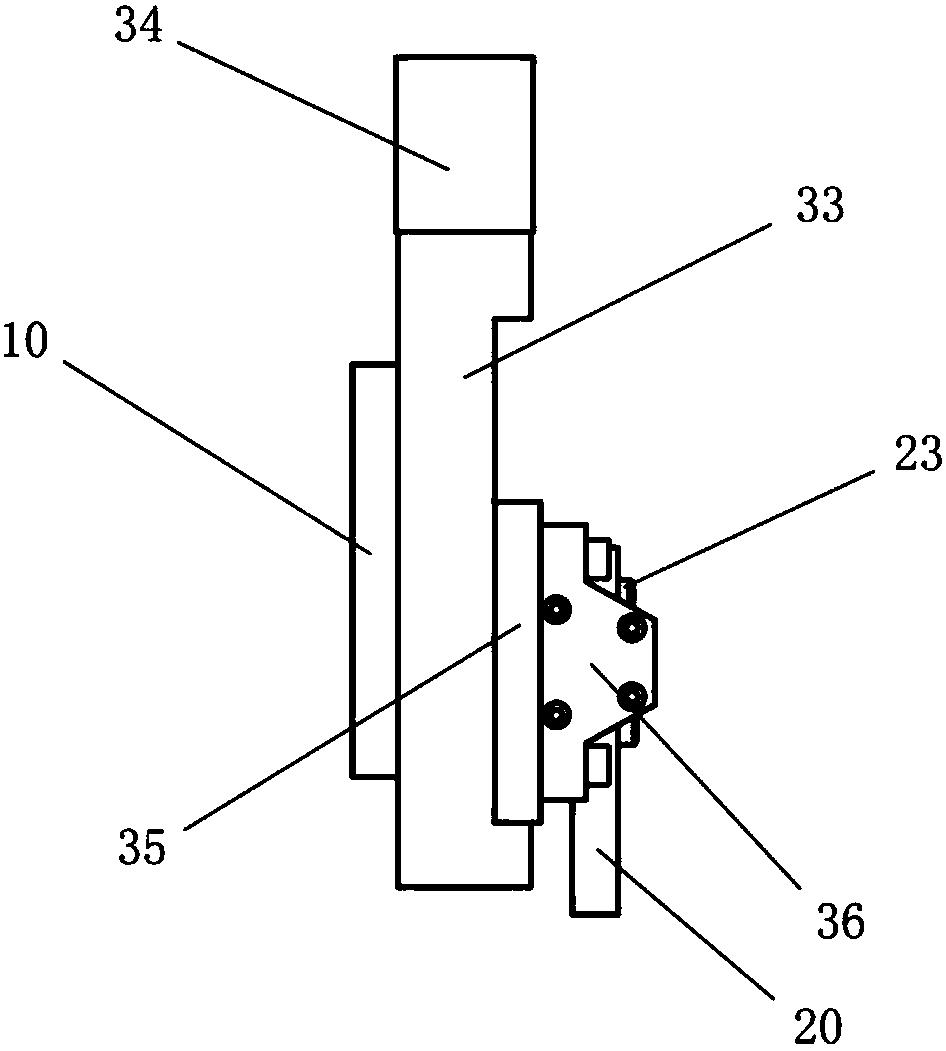

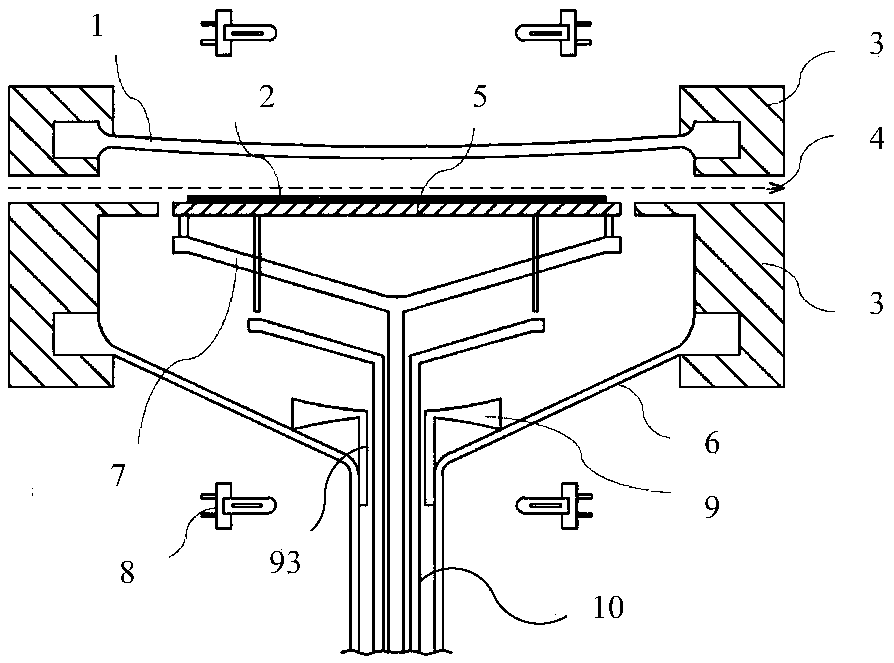

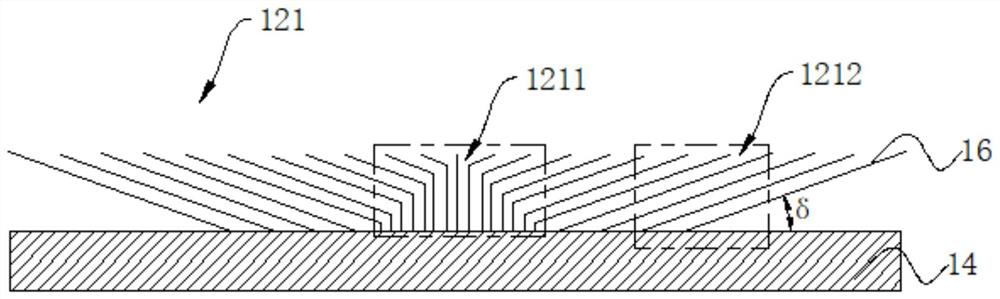

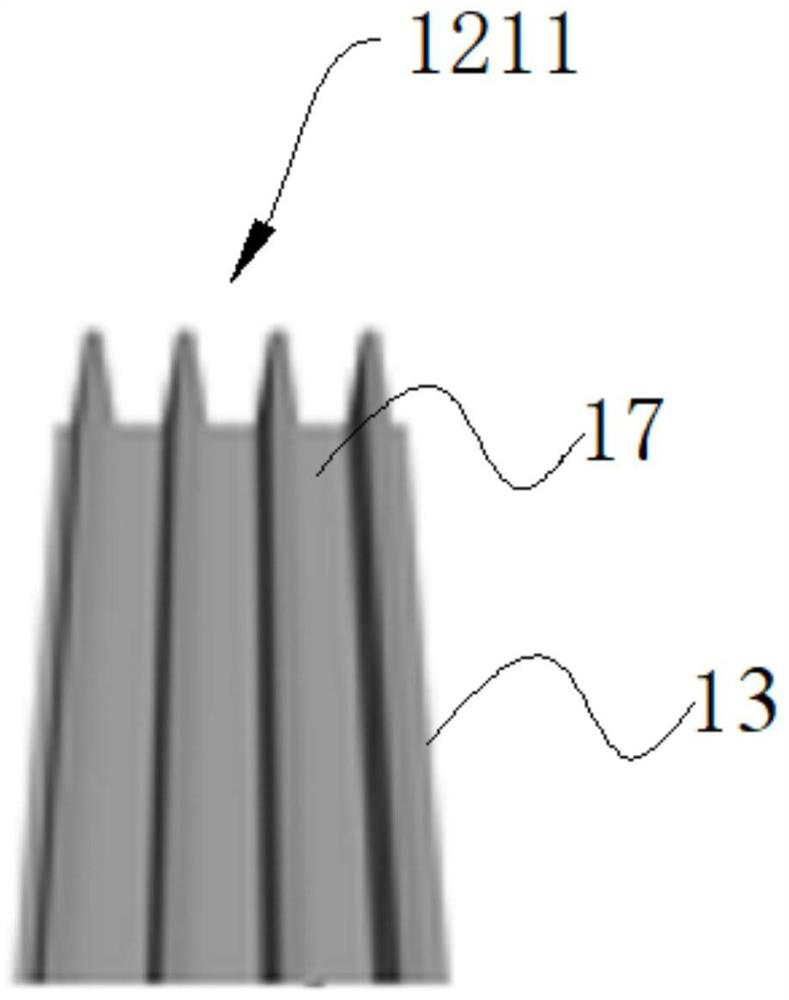

Angle adjustment device for coating head

PendingCN108405275AImproved film formation uniformity and formabilityAchieve independent regulationLiquid surface applicatorsCoatingsAgricultural engineeringFormability

The invention discloses an angle adjustment device for a coating head. The angle adjustment device comprises an adjustment device fixing plate (10), a coating head fixing plate (20) and a height adjustment device, wherein the adjustment device fixing plate (10) is used for fixing the angle adjustment device on a coating machine; the coating head fixing plate (20) is used for mounting the coating head; the height adjustment device comprises a first height adjustment mechanism (31) and a second height adjustment mechanism (32) mounted on the adjustment device fixing plate (10); the left and right ends of the coating head fixing plate (20) are movably mounted on the first height adjustment mechanism (31) and the second height adjustment mechanism (32) respectively; the first height adjustmentmechanism (31) and the second height adjustment mechanism (32) are used for adjusting the height of the left and right ends of the coating head fixing plate (20) respectively. The angle adjustment device realizes independent adjustment of the left and right single sides of the coating head, facilitates coating in a relatively matching state between the coating head and a coating platform, and further improves the film forming uniformity and formability of a product.

Owner:湖南纳昇电子科技有限公司

Polyurethane organic-inorganic composite material as well as preparation method and application thereof

PendingCN114231163AHigh refractive indexGood compatibilitySolid-state devicesSemiconductor/solid-state device manufacturingInorganic particleDisplay device

The invention discloses a polyurethane organic-inorganic composite material which comprises the following components in parts by weight: 1-3 parts of polyurethane resin, 1-3 parts of inorganic particles, 1 part of a photoinitiator and 4-6 parts of a diluent, the preparation method comprises the following steps: respectively heating the polyurethane resin and the photoinitiator to 50-80 DEG C, putting into the diluent, fully stirring, adding the inorganic particles, and continuously stirring at normal temperature for 1-2 hours to obtain the polyurethane organic-inorganic composite material, the polyurethane organic-inorganic composite material is applied to a display device as an optical functional layer; the display device at least comprises a substrate, an organic light-emitting layer and a cover plate, and the optical function layer is independently formed by the polyurethane organic-inorganic composite material or jointly formed by the polyurethane organic-inorganic composite material and a low-refractive-index material with the refractive index smaller than 1.5.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

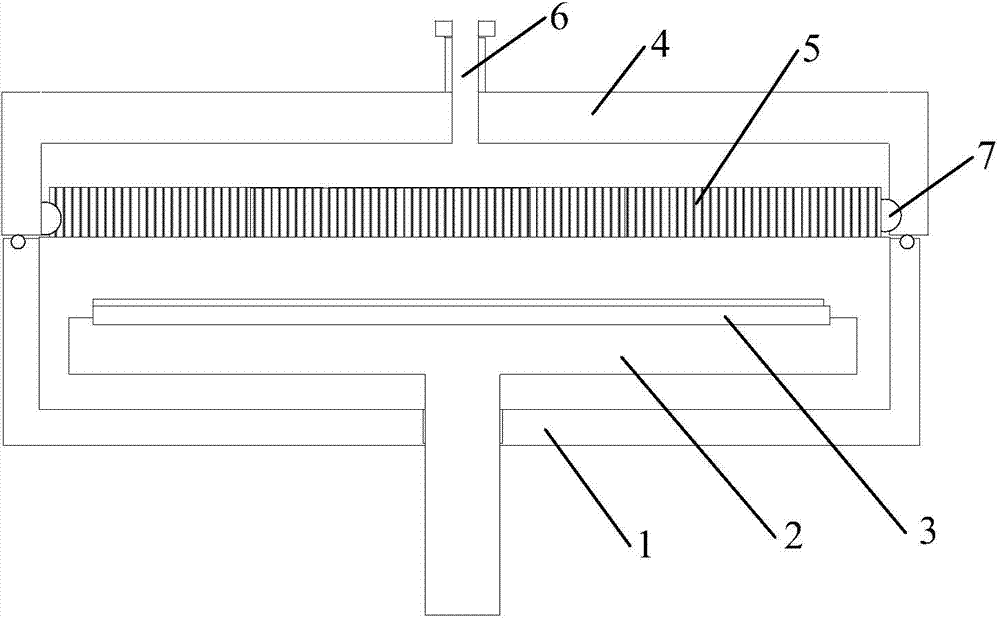

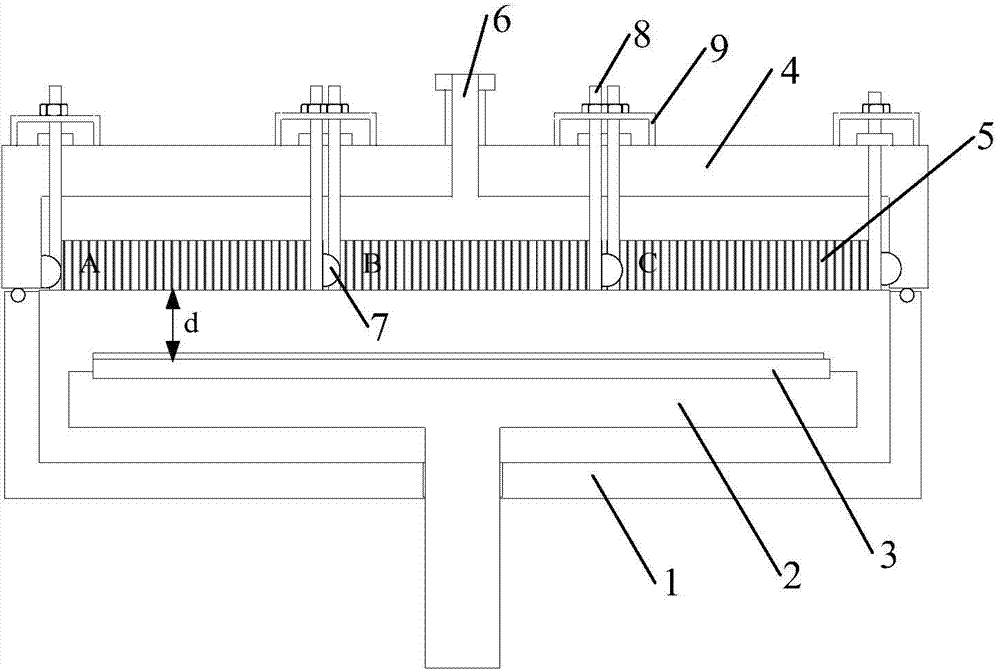

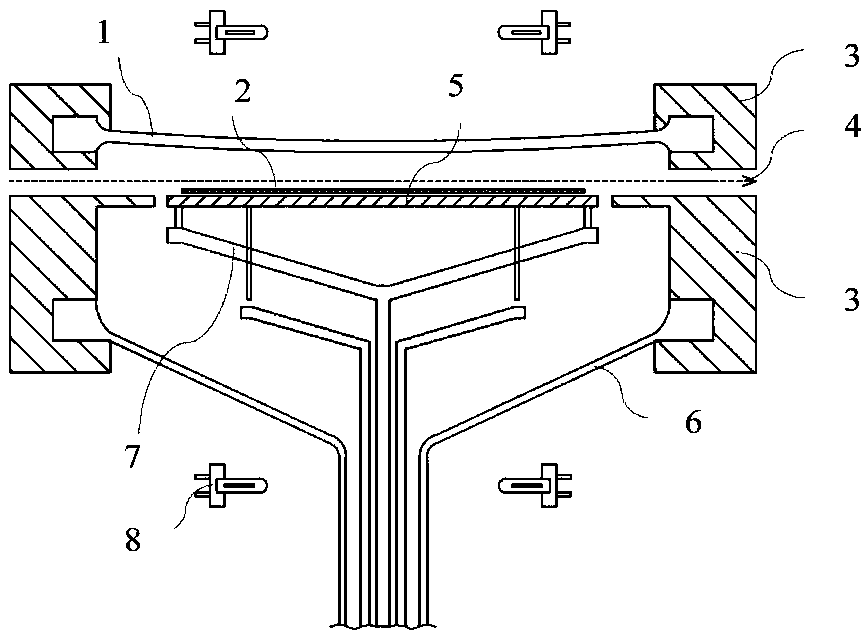

Chemical vapor deposition equipment

InactiveCN103924217AImprove the uniformity of film formationImprove yieldChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses chemical vapor deposition equipment which comprises a base and a cover plate, wherein the base and the cover plate are groove-shaped and form a vacuum reaction chamber after being fastened together; the base is internally provided with a platform deck on which a to-be-coated substrate is placed; the cover plate is internally provided with a gas diffuser; a top cover of the cover plate is provided with a gas inlet pipe; the gas diffuser is of a split structure and comprises multiple independent split diffusers; the multiple split diffusers are positioned in the same horizontal plane; each split diffuser is provided with an ascending-descending regulating mechanism used for driving the corresponding split diffuser to ascend and descend along the vertical direction. The chemical vapor deposition equipment is capable of ensuring that reactants sprayed by the whole gas diffuser are uniformly deposited on the substrate below, improving the film formation uniformity of the substrate, overcoming the local semiconductor film defect and poorness problem caused by equipment aging, improving the TFT (Thin-Film Transistor) product yield and prolonging the service lives of equipment spare parts.

Owner:BOE TECH GRP CO LTD +1

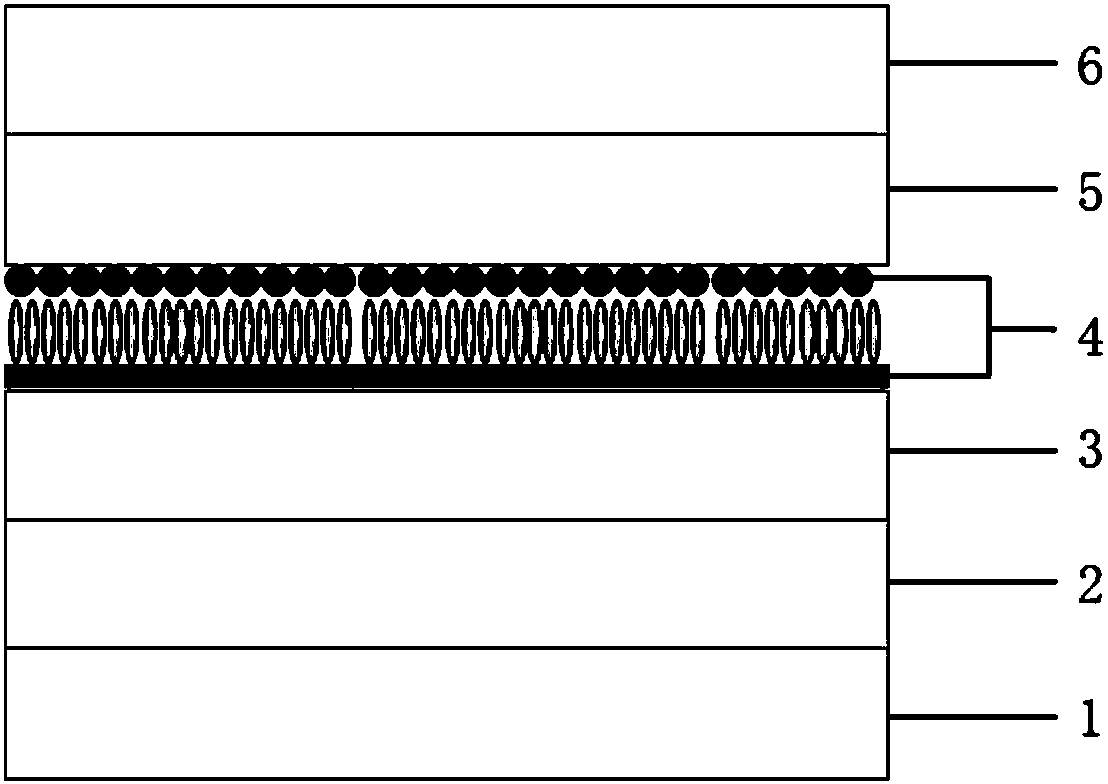

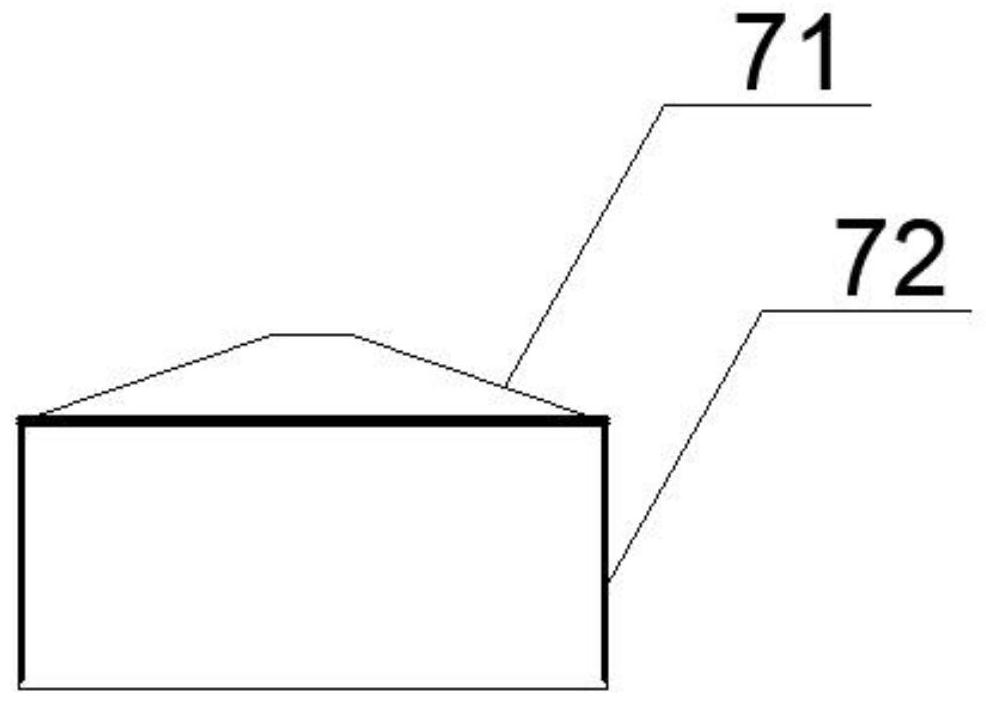

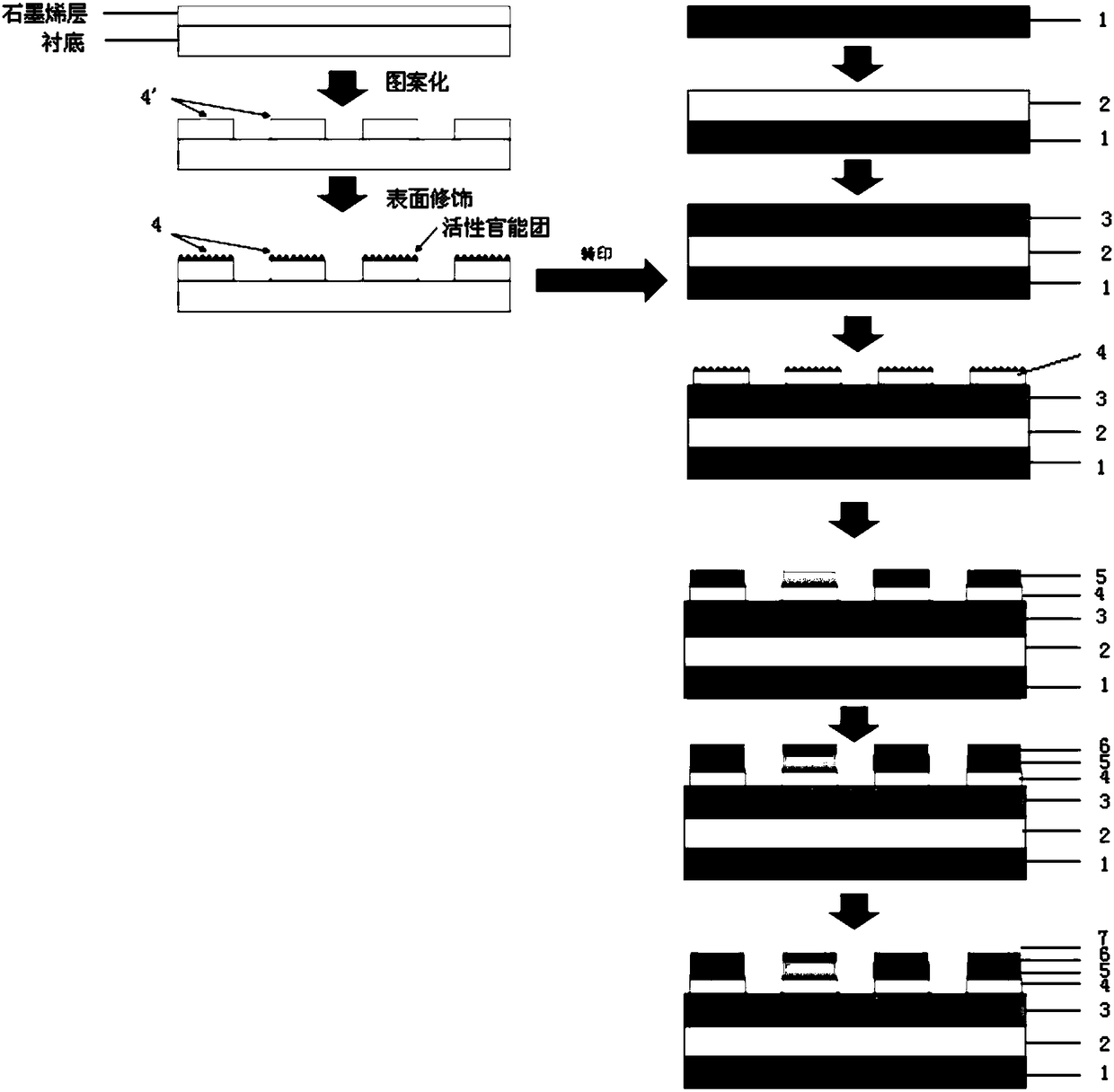

QLED device and preparation method thereof

ActiveCN109244252ASimple manufacturing processImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotHole transport layer

A QLED device comprises sequentially laminated bottom electrodes, first functional layer, a functionalized graphene pixel array disposed on the first functional layer, A light emit layer of a quantumdot arrange on that functionalized graphene pixel array, and a second functional layer and a top electrode sequentially bonded to the quantum dot light emitting layer, wherein the functionalized graphene pixel array comprises a graphene pixel array and an active functional group modified on the surface of the graphene pixel array, and the active functional group is modified on the surface of the graphene pixel array facing away from the hole transport layer, and the quantum dot light emitting layer is bonded with the functionalized graphene pixel array through the active functional group.

Owner:TCL CORPORATION

Epitaxial growth device and manufacturing method thereof

InactiveCN111304740ASolve uneven heatingImprove the uniformity of film formationSemiconductor/solid-state device manufacturingFrom chemically reactive gasesCrystallographyBell jar

The invention provides an epitaxial growth device and a manufacturing method thereof, and belongs to the technical field of semiconductors. The epitaxial growth device comprises a first quartz bell jar and a funnel-shaped second quartz bell jar, wherein the first quartz bell jar and the second quartz bell jar form a reaction chamber, a base for placing a silicon wafer and a base support frame forsupporting the base are arranged in the reaction chamber, heating bulbs for providing reaction energy are arranged outside the reaction chamber, and comprise a first heating bulb located on the side,close to the first quartz bell jar, of the base and a second heating bulb located on the side, close to the second quartz bell jar, of the base, the epitaxial growth device further comprises a light path control structure located in the reaction chamber and arranged between the second heating bulb and the base, and the light path control structure can refract part of light emitted by the second heating bulb and entering the reaction chamber through the funnel surface of the second quartz bell jar to an area far away from the center of the silicon wafer. According to the invention, the film forming uniformity of an epitaxial film can be improved.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

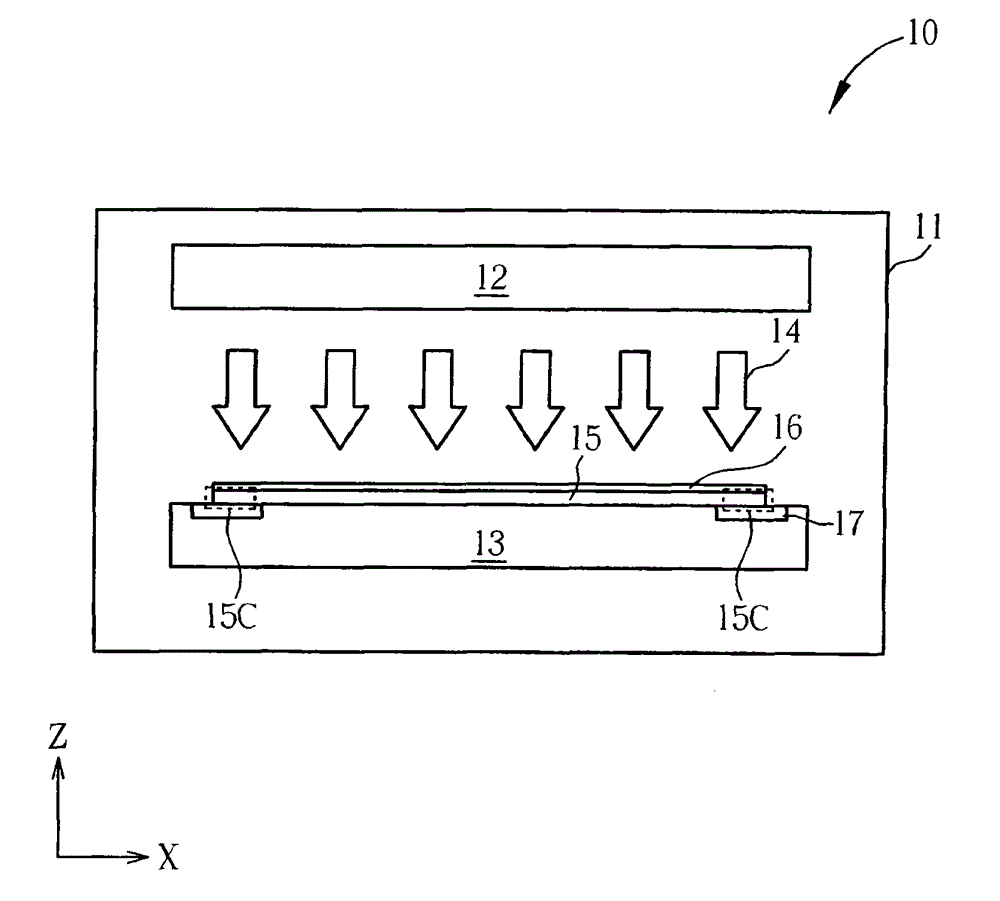

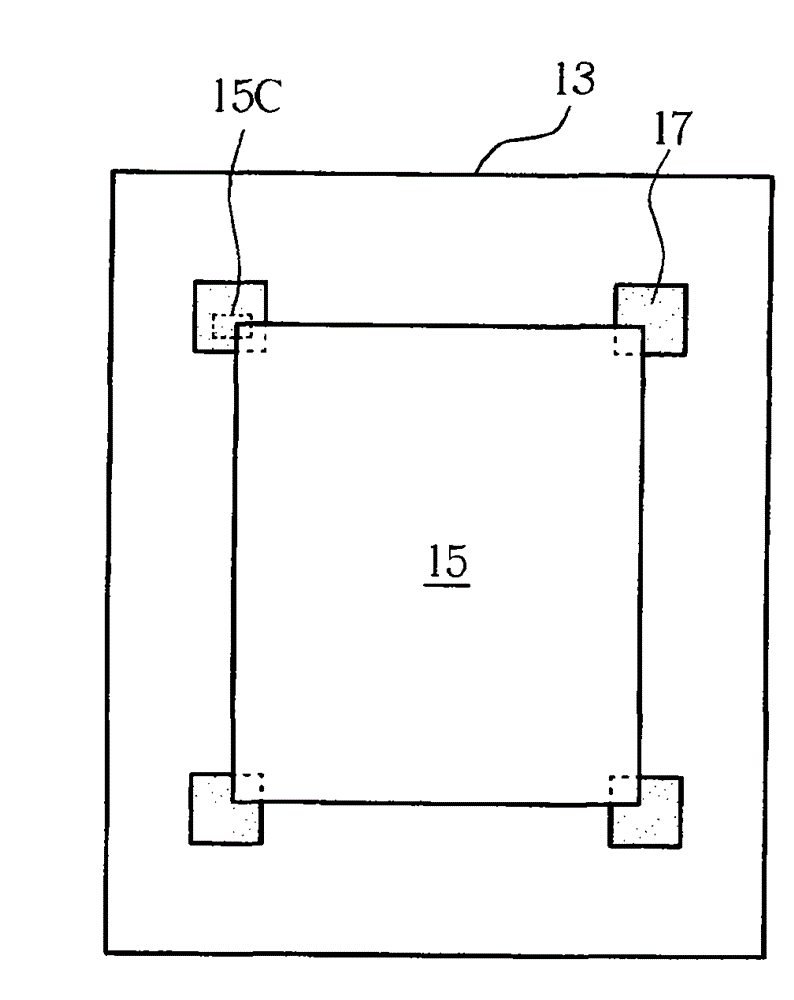

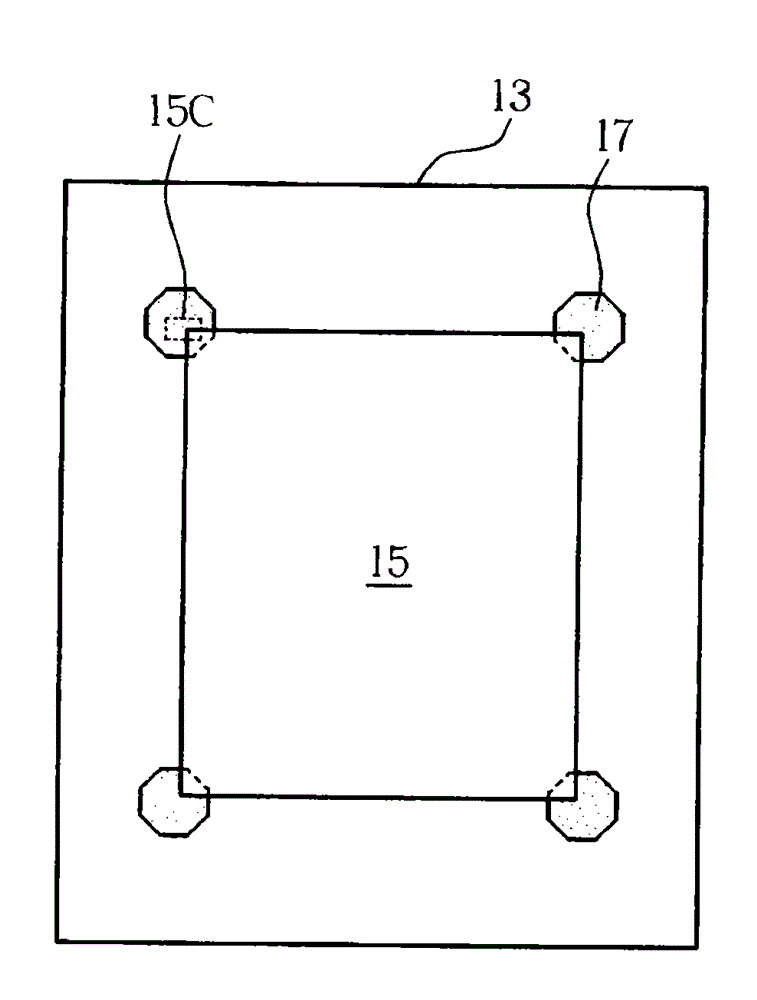

Plasma enhanced chemical vapor deposition device

ActiveCN102747340AImprove the uniformity of film formationChemical vapor deposition coatingGas phasePatterned media

The invention discloses a plasma enhanced chemical vapor deposition device, comprising a preparation chamber, an upper electrode, a lower electrode, and at least a patterning medium material unit, wherein the upper electrode and the lower electrode are oppositely arranged in the preparation chamber for conducting a plasma enhanced chemical vapor deposition to depositing a thin-film material on a substrate arranged on the lower electrode; and the patterning medium material unit is arranged on the lower electrode and adjacent to at least one corner of the substrate.

Owner:ARCHERS

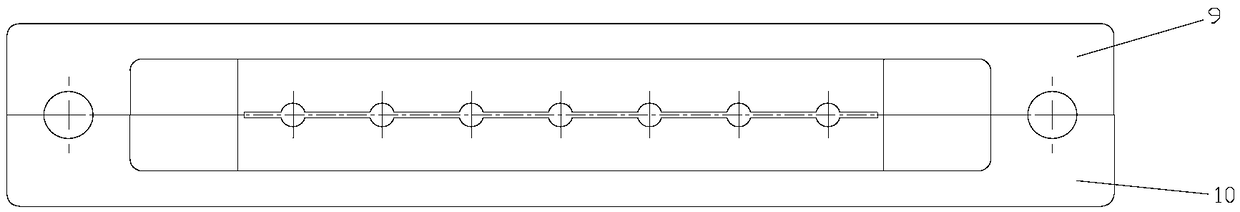

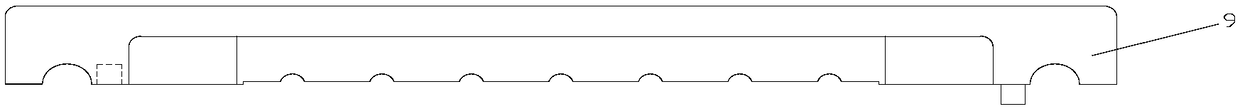

Electrostatic spinning spray nozzle capable of achieving quick multi-needle-tip positioning

ActiveCN109267159AOvercome conductivityOvercoming Microporous Problems on Gas MasksArtificial thread manufacturing machinesFilament/thread formingFiberTip position

The invention relates to an electrostatic spinning spray nozzle capable of achieving quick multi-needle-tip positioning and relates to electrostatic spinning. The spray nozzle comprises an upper coverplate, a needle tip mounting plate, an electric conduction plate, a needle tip array and an air cover; the upper cover plate is provided with a liquid inlet and connected with a liquid supply devicethrough a hose; the needle tip mounting plate is of a step structure, the step height difference is identical to the height difference of needle tips at the corresponding positions, and the needle tipmounting plate is provided with a needle tip positioning hole; the electric conduction plate is connected with a positive electrode of a high-voltage supply source and is of a separated structure; the needle tip array is provided with the needle tips distributed in an arc array, the needle tip at the middle position of the needle tip array is located at the lowest point, and the needle tips of the two sides of the needle tip array are symmetrically distributed; the air cover is provided with two air inlets and connected with an air supply device through an air guide pipe, and a pressure adjustment valve is used for controlling flow of air and magnitude of pressure intensity. Sheath air constraint is introduced, spinning jet injection is accelerated, the fiber spraying efficiency is improved, the jet flow is thinned, the diameter of a nano fiber is reduced, and the film formation uniformity and quality of an electrostatic spinning fiber are improved.

Owner:厦门定慧力教育科技有限公司

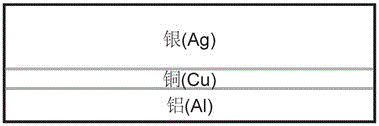

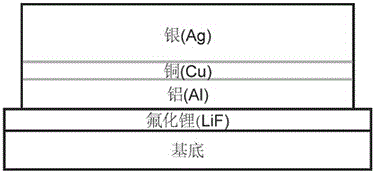

Transparent metal electrodes and their organic electroluminescent top-emitting devices

InactiveCN104022231BImprove transmittanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic electroluminescence

A transparent metal electrode and an organic electroluminescent top-emitting device based on the electrode, the transparent metal electrode is provided with three metal layers, the second metal layer Cu is stacked between the first metal layer Al and the second metal layer between. The thickness of the first metal layer Al is set to 2nm, the thickness of the second metal layer Cu is set to 1nm, and the thickness of the third metal layer Ag is set to 20-7nm. The transparent metal electrode of the invention has the advantages of high transmittance, high conductivity and high uniformity of film formation. The organic electroluminescent top-emitting device based on the transparent metal electrode of the present invention has high efficiency.

Owner:YUNNAN UNIV

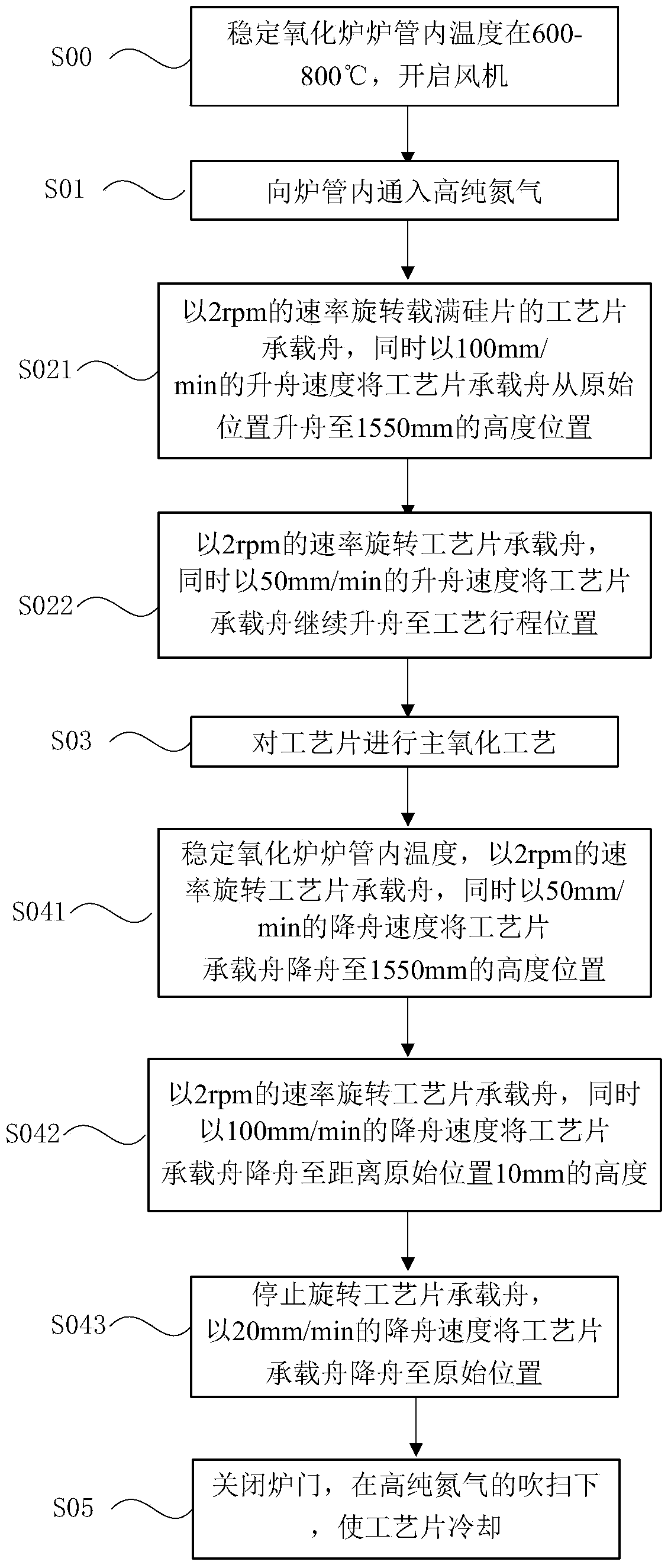

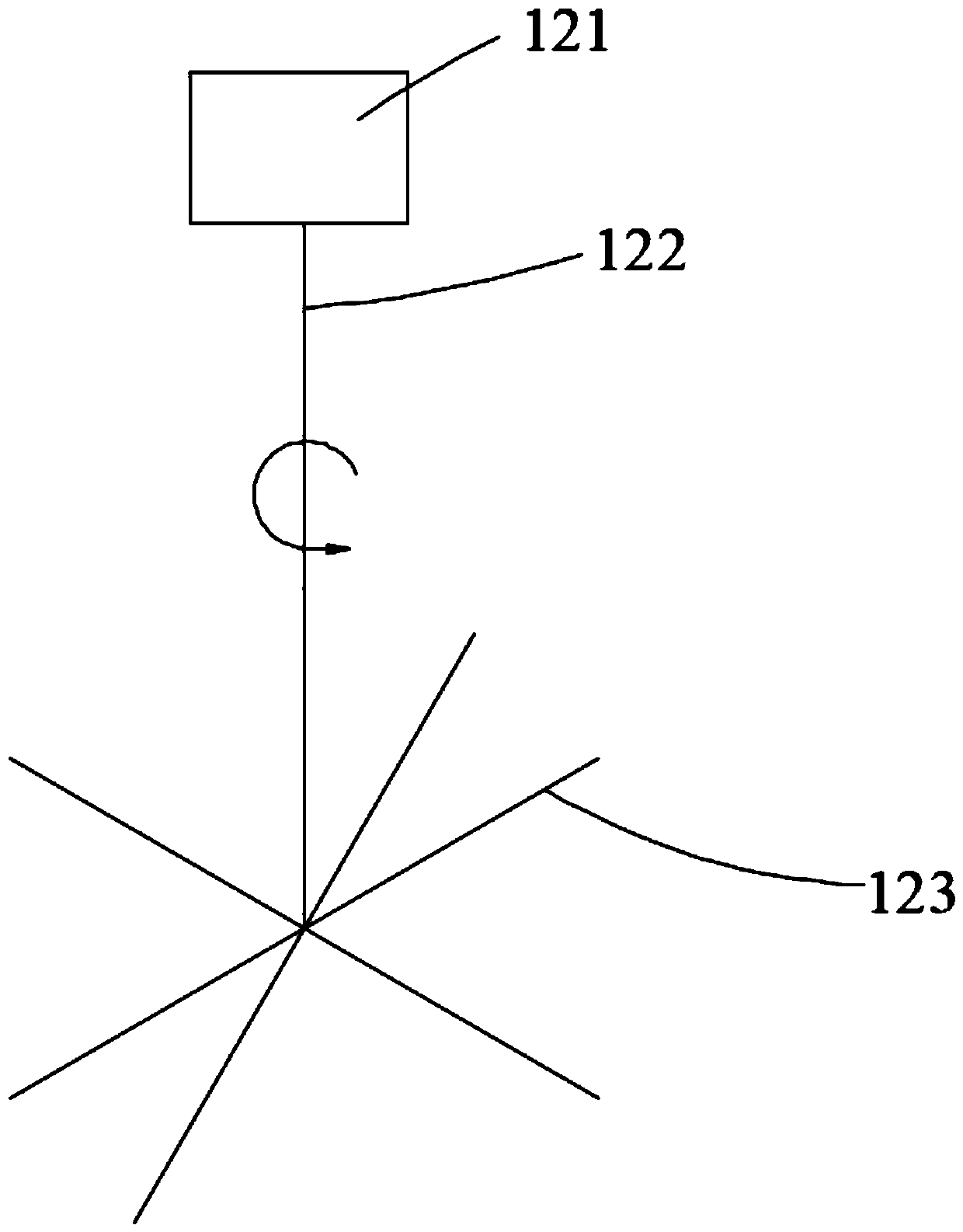

Method for improving film formation uniformity of wafer

ActiveCN103928317AImprove the uniformity of film formationGood film uniformitySemiconductor/solid-state device manufacturingNitrogen gasSemiconductor

The invention discloses a method for improving the film formation uniformity of a wafer. The method comprises the steps that nitrogen gas is fed into a hot oxidizing furnace tube; a wafer holder is rotated; the wafer holder is lifted to a first position from the original position; the wafer holder keeps rotating, and a main oxidation process is conducted on the wafer; after the main oxidation process is completed, the wafer holder keeps rotating, and the wafer holder drops to the original position from a process stroke position. According to the method for improving the film formation uniformity of the wafer, the wafer holder keeps rotating at a low speed in the boat lifting process, the boat dropping process and the main oxidation process, as a result, the influence of nonuniform distribution of a temperature field and a gas flow field on the film formation uniformity of the wafer can be reduced, the film formation uniformity of the wafer in a semiconductor vertical furnace device is optimized, and the production cost is reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Gas spray device and chemical vapor deposition method

ActiveCN110923669AImprove mixing uniformityImprove the uniformity of film formationChemical vapor deposition coatingThermodynamicsEngineering

The invention provides a gas spray device. The gas spray device comprises a ventilation system and a spray system which are arranged in an up-down corresponding mode; the spray system and the ventilation system are connected through a cylinder body of the gas spray device; the ventilation system comprises a side ventilation channel, a rotating mechanism and a gas wind shield; and the spray systemcomprises a spray head. According to the gas spray device provided by the invention, the gas flow speed of gas is increased according to the shape or the rotation speed of fan blades, and the mixing uniformity of the gas is enhanced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

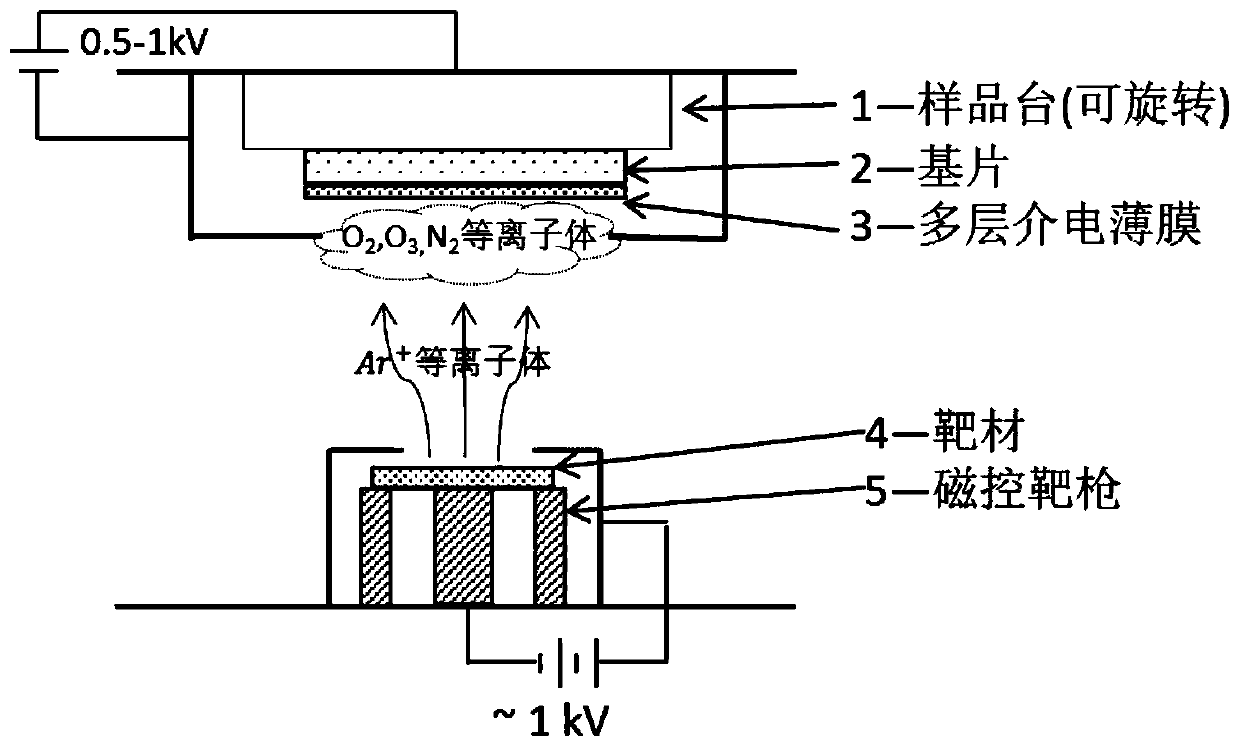

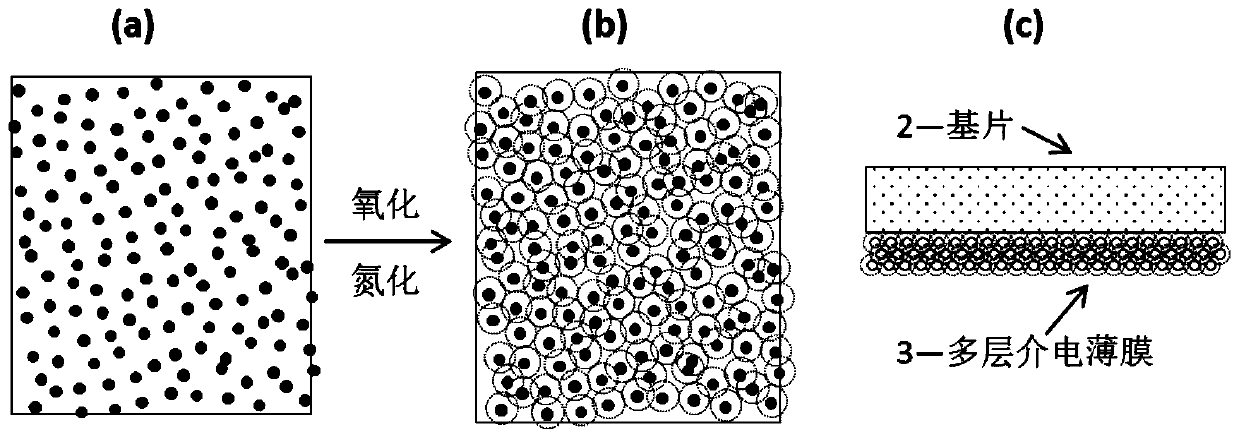

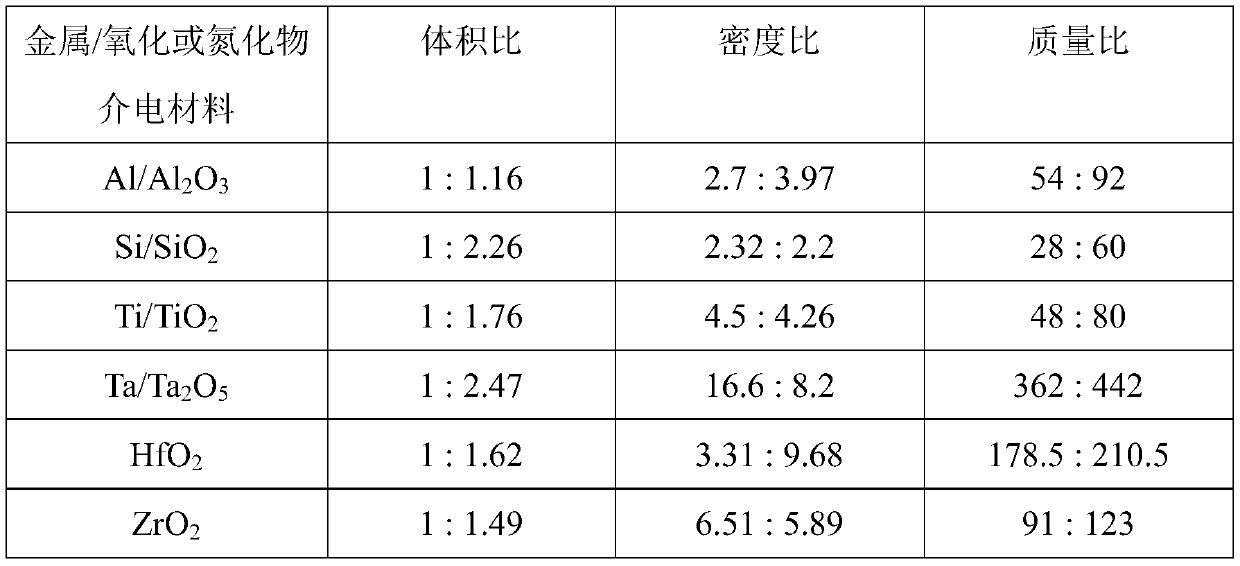

Method for preparing ultrathin pinhole-free dielectric films

InactiveCN109763101ASolving the problem of pinhole defectsPinhole defect noVacuum evaporation coatingSputtering coatingRedoxGas plasma

The invention discloses a method for preparing ultrathin pinhole-free dielectric films. The method comprises the steps that (1), 0.5-1nm ultrathin films are obtained by deposition through a physical vapor deposition method; (2), the 0.5-1nm ultrathin metal films or ultrathin nonmetal films obtained in the step (2) are subjected to a redox reaction through gas plasma with oxidation characteristics;and (3), the step (1) and the step (2) are repeatedly carried out according to the target thickness of the to-be-prepared ultrathin pinhole-free dielectric films, and the ultrathin pinhole-free dielectric films with the target thickness are obtained. The method for preparing the ultrathin pinhole-free dielectric films has no chemical corrosion, can be in situ in the same cavity, and is high in film forming speed; and the ultrathin pinhole-free dielectric films prepared by the method has high adhesivity, high compactness and no pinhole defect, and the thickness and the uniformity can be controlled in a large area.

Owner:NANJING UNIV

Preparation method of composite blue-light emitting materials displayed by OLED, and application of the composite blue-light emitting materials

ActiveCN106876611AImprove voltage stabilityImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPolypyrrolePolyfluorene

The invention belongs to the field of blue-light emitting materials, and specifically relates to a preparation method of composite blue-light emitting materials displayed by OLED, and an application of the composite blue-light emitting materials. The preparation method of composite blue-light emitting materials displayed by OLED is characterized by taking blue-light emitting materials as the base, refrigeration-rubbing poly-phenylene vinylene organic matter and polyfluorene organic matter together with the blue-light emitting materials, and dispersing the refrigeration-rubbing poly-phenylene vinylene organic matter, the polyfluorene organic matter and the blue-light emitting materials in liquid-state polypyrrole, thus greatly improving the voltage stability, the heat stability, the luminous efficiency and the service life of the composite blue-light emitting materials obtained through refrigeration-rubbing composition. The application method of the composite blue-light emitting materials prepared through the above method is characterized by roller coating, rotation coating and printing the liquid-state composite blue-light emitting materials on a substrate to form a coating layer, and utilizing instantaneous heat rapid polymerization of microwave to form a stable luminous thin film layer on the substrate, thus greatly improving film forming uniformity, high effectiveness, ultrathin property and compactness of the luminous thin film layer, and greatly improving the service life of the device.

Owner:中山市海家菱家居饰品有限公司

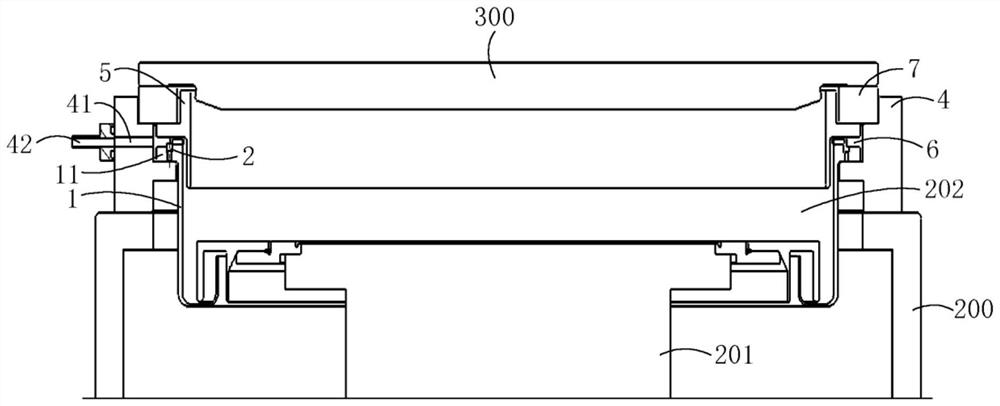

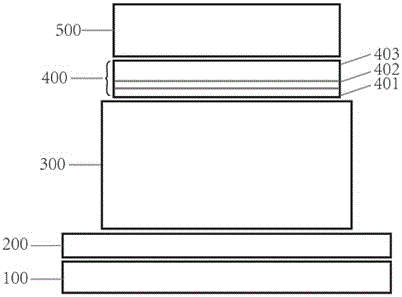

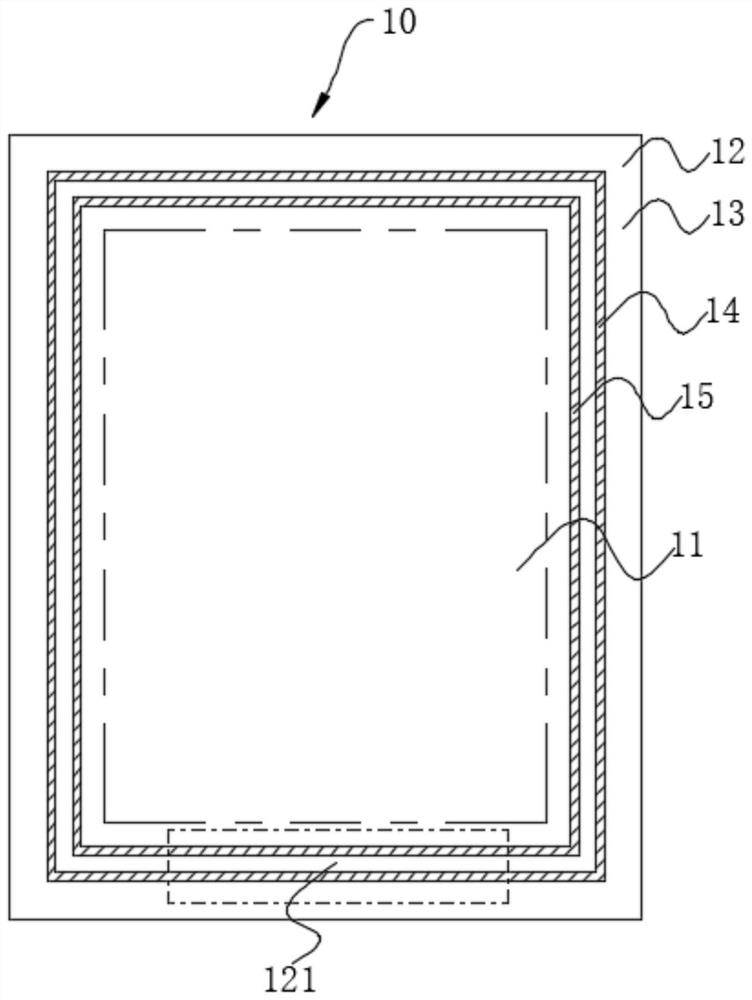

Display substrate, preparation method thereof, display panel and display device

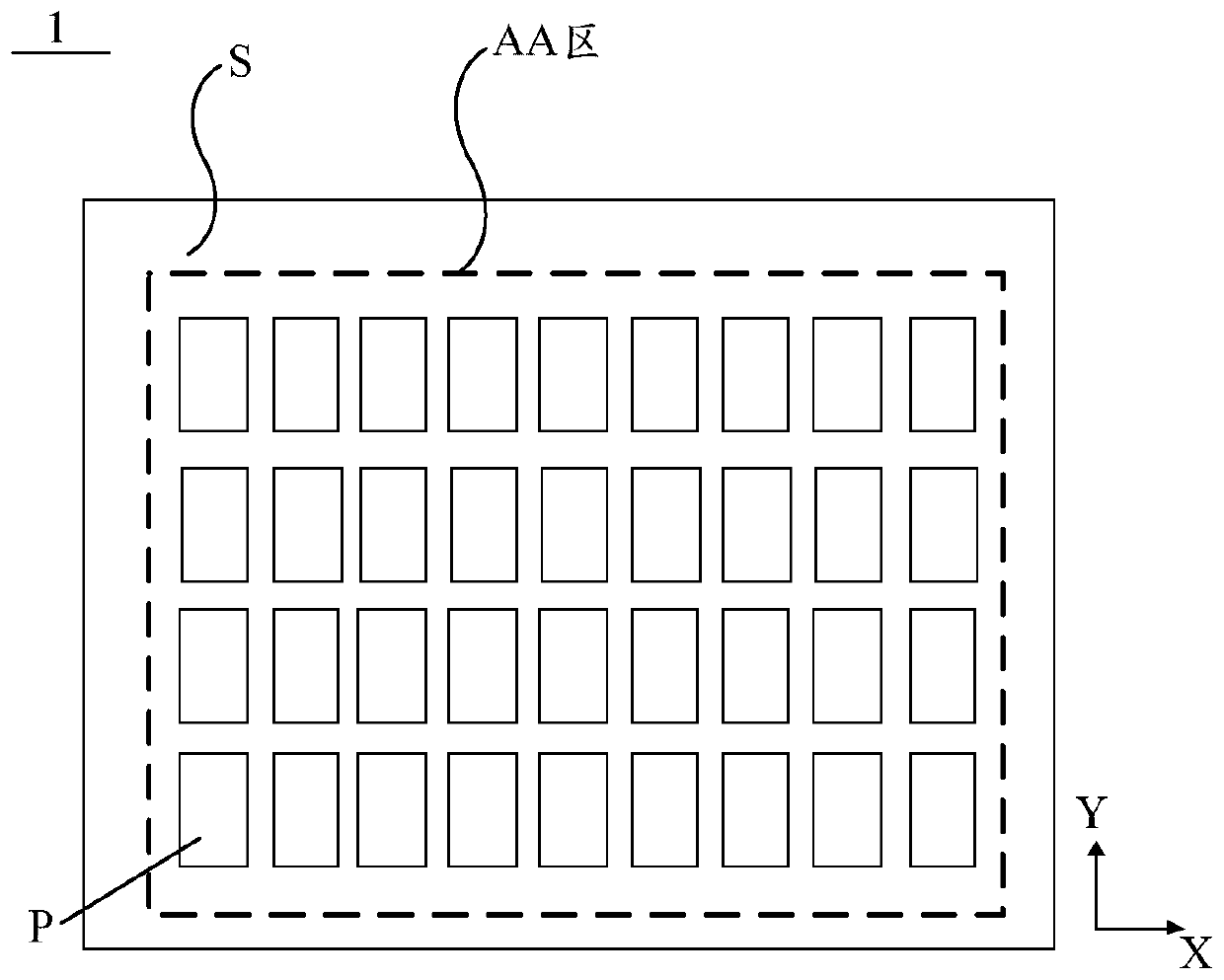

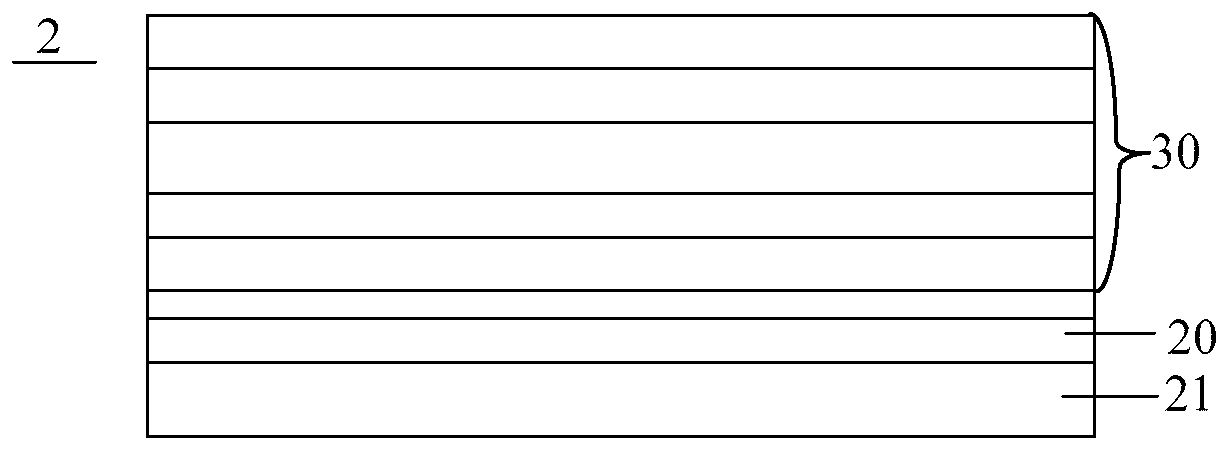

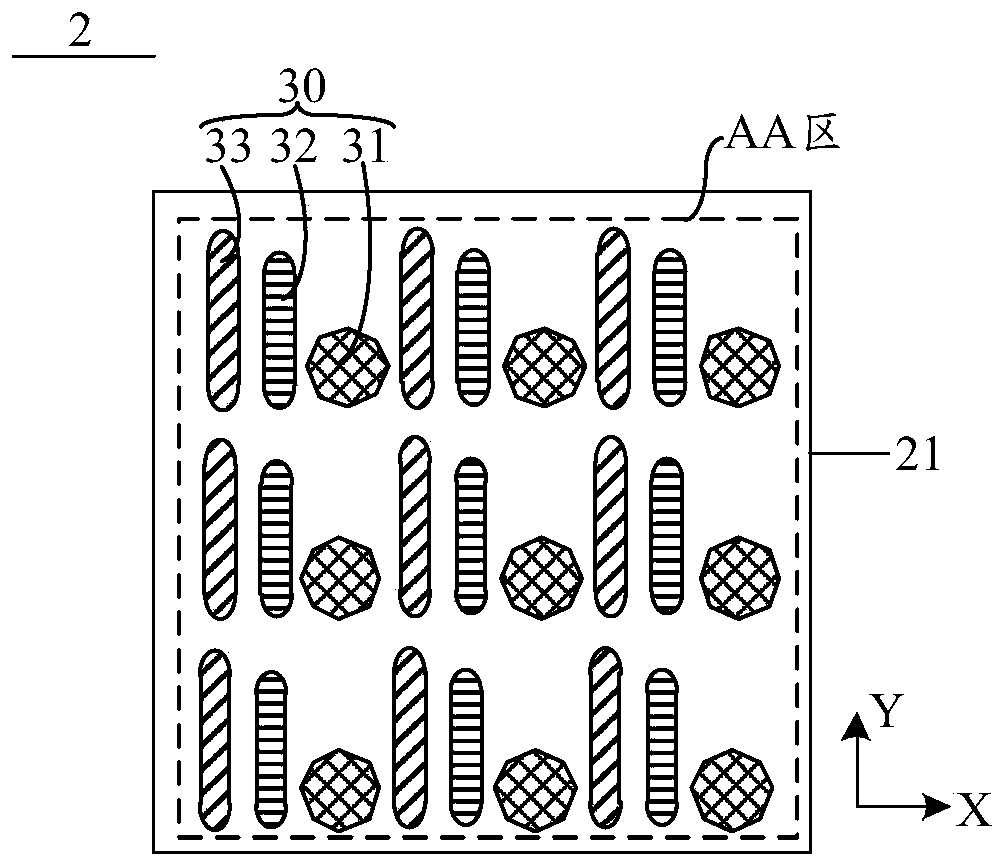

ActiveCN110600521AImprove the uniformity of film formationReduce the speed difference of movementSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention provides a display substrate, a preparation method thereof, a display panel and a display device, which relate to the technical field of display and aim to solve the problem of relatively low film forming uniformity. The display substrate comprises a substrate and a plurality of light-emitting units arranged in a display area on the substrate. The light-emitting layer in at least one light-emitting unit is manufactured by adopting an ink-jet printing process, and the distances from all points on the edge of the cross section, perpendicular to the thickness direction of the substrate, of the light-emitting layer to the center of the cross section are approximately equal.

Owner:BOE TECH GRP CO LTD

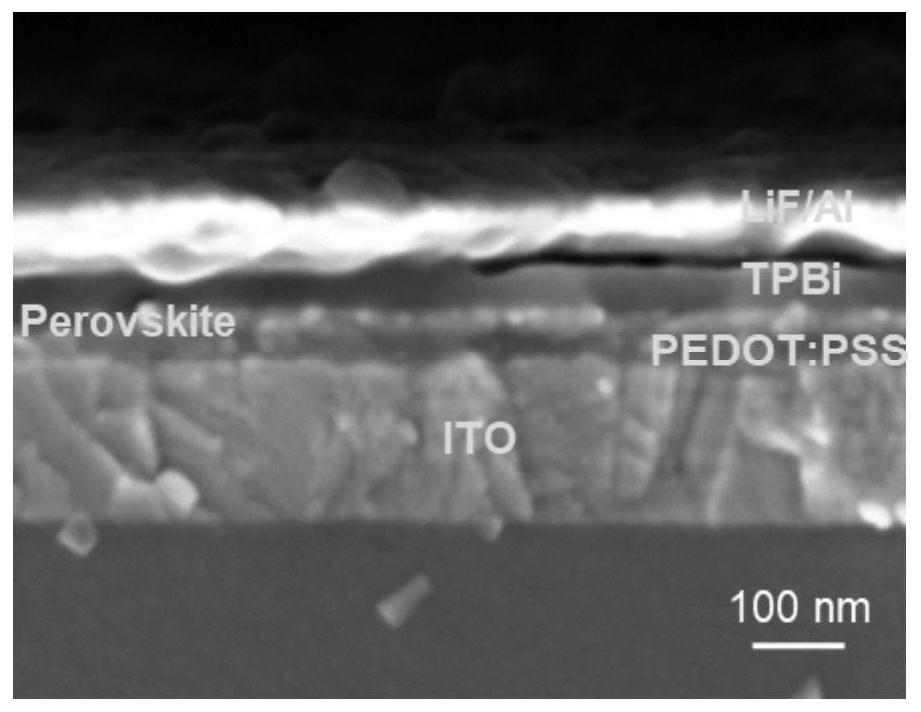

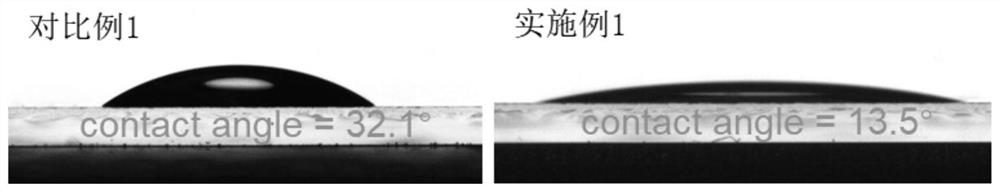

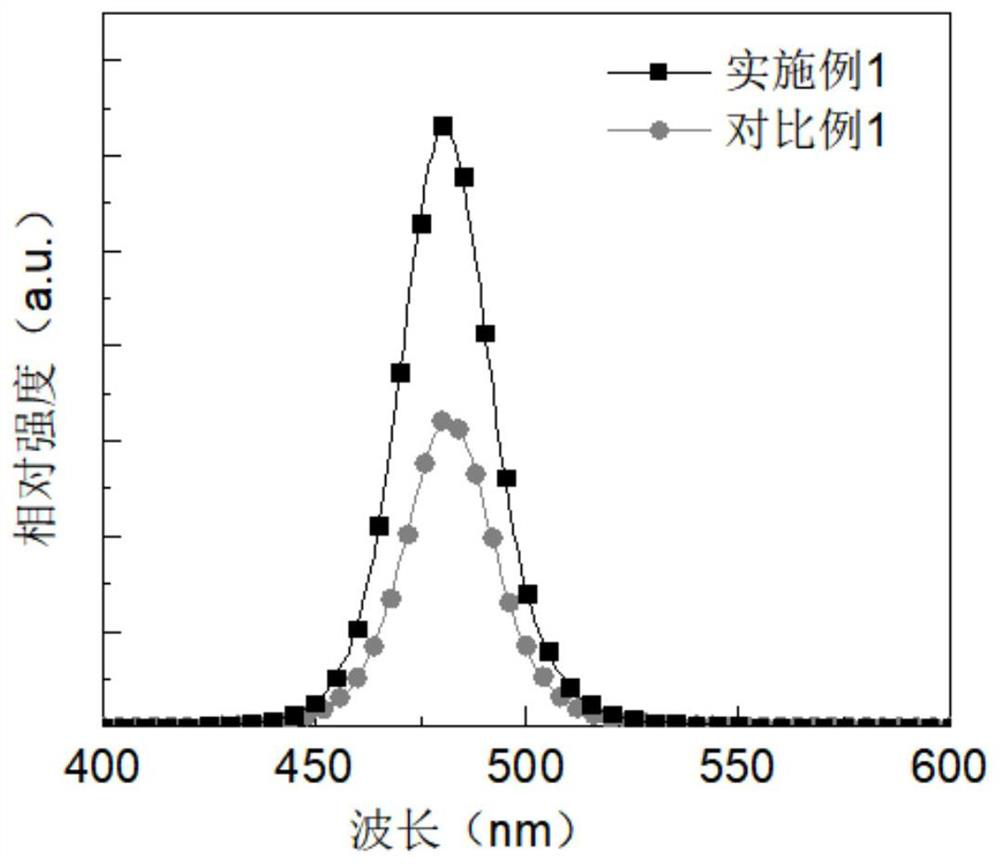

Blue-light perovskite light-emitting diode based on modified hole transport layer and production method thereof

PendingCN113594383ALow costEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingPhotoluminescencePropanolamine

The invention relates to a blue-light perovskite light-emitting diode based on a modified hole transport layer and a production method thereof. The device comprises an anode substrate, the modified hole transport layer, a perovskite light-emitting layer, an electron transport layer and a cathode. According to the invention, the propanolamine molecular additive is creatively introduced so that the crystal growth of the blue light perovskite luminescent layer can be effectively regulated and controlled, a high-quality luminescent film with high uniformity, high crystallinity and low defect density is formed, and the photoluminescence characteristic and the spectral stability of the film are enhanced; and the brightness and the external quantum efficiency of the produced blue light perovskite light-emitting diode are obviously improved, and the service life of the produced blue light perovskite light-emitting diode is obviously prolonged. The modification method disclosed by the invention is low in cost, simple to operate, remarkable in effect and suitable for various existing preparation processes such as spin coating, blade coating, printing, ink-jet printing and the like.

Owner:SUZHOU UNIV

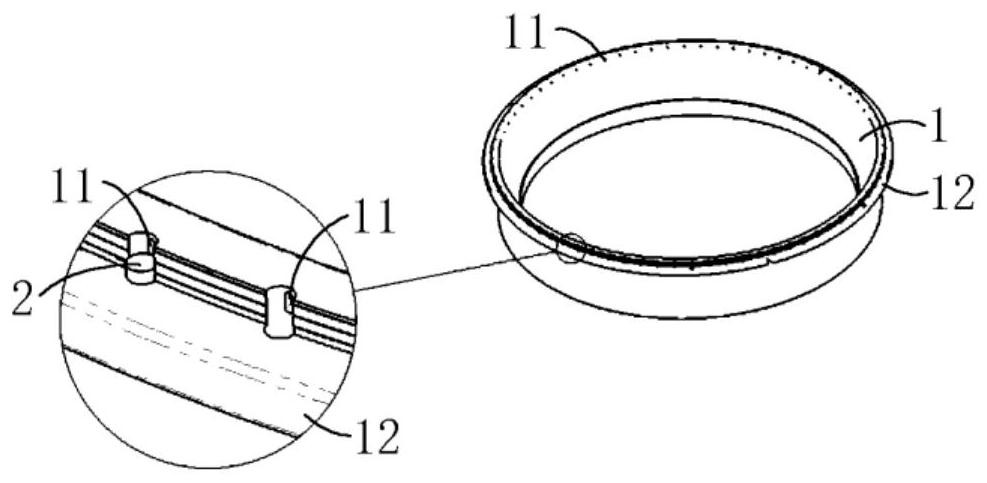

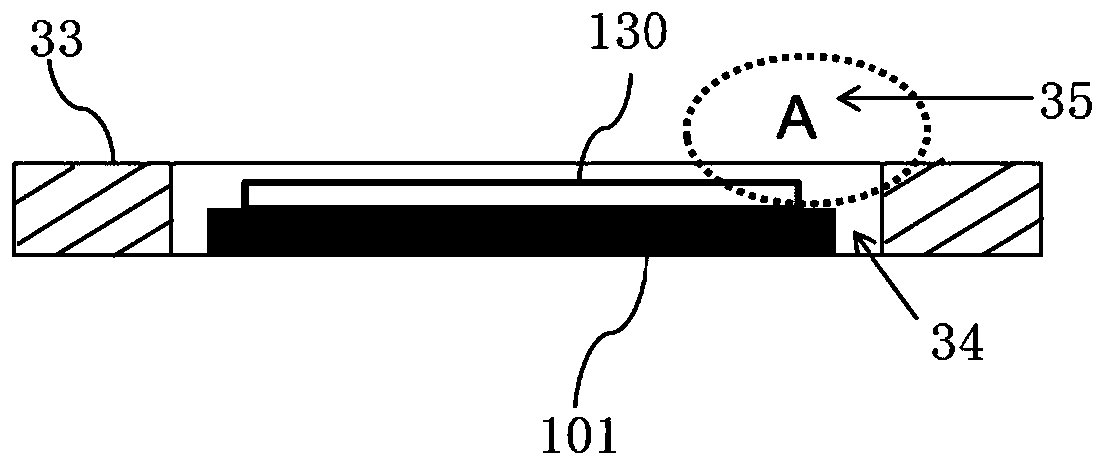

Preheating ring for epitaxial growth equipment, and epitaxial growth equipment

PendingCN111599716AAvoid flowImprove the uniformity of film formationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas passingEngineering

The invention discloses a preheating ring for epitaxial growth equipment, and the epitaxial growth equipment. The preheating ring comprises an upper ring part and a lower ring part, wherein the upperring part and the lower ring part are coaxially superposed from top to bottom, the outer diameter of the upper ring part is equal to that of the lower ring part, the inner diameter of the upper ring part is smaller than that of the lower ring part, an exhaust channel is arranged on one side of the upper ring part so as to rapidly discharge purified gas and treated gas, and the inner diameter of the upper ring part is smaller than that of the lower ring part, so that the upper ring part shields the inner circumferential surface of the lower ring part, the purified gas is prevented from flowingupwards through a gap between a substrate supporting piece and the lower ring part, turbulent flow and extra flow resistance are prevented from being formed near the edge of a substrate, the deposition efficiency of the edge of the substrate is improved, and the film forming uniformity of the substrate is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Silane treatment agent for metal surface

ActiveCN105088217BLarge variable rangeSimple processMetallic material coating processesSilanesMaterials science

The invention discloses a metal surface silane treatment agent, which includes 20 to 30 parts by weight of silane coupling agent, 20 to 30 parts of film-forming agent, 5 to 7 parts of complexing agent, and 15 to 30 parts of pure water. The film-forming agent is a thickening agent, and the complexing agent is sodium citrate, which makes the present invention have high aging effect, super concentration, low carbon and energy saving, no residue, no phosphorus, no zinc, no chromium, no fluorine, Zirconium-free and superior environmental performance, the silane film has anti-corrosion properties and excellent adhesion properties.

Owner:浙江易渤乐控股集团有限公司

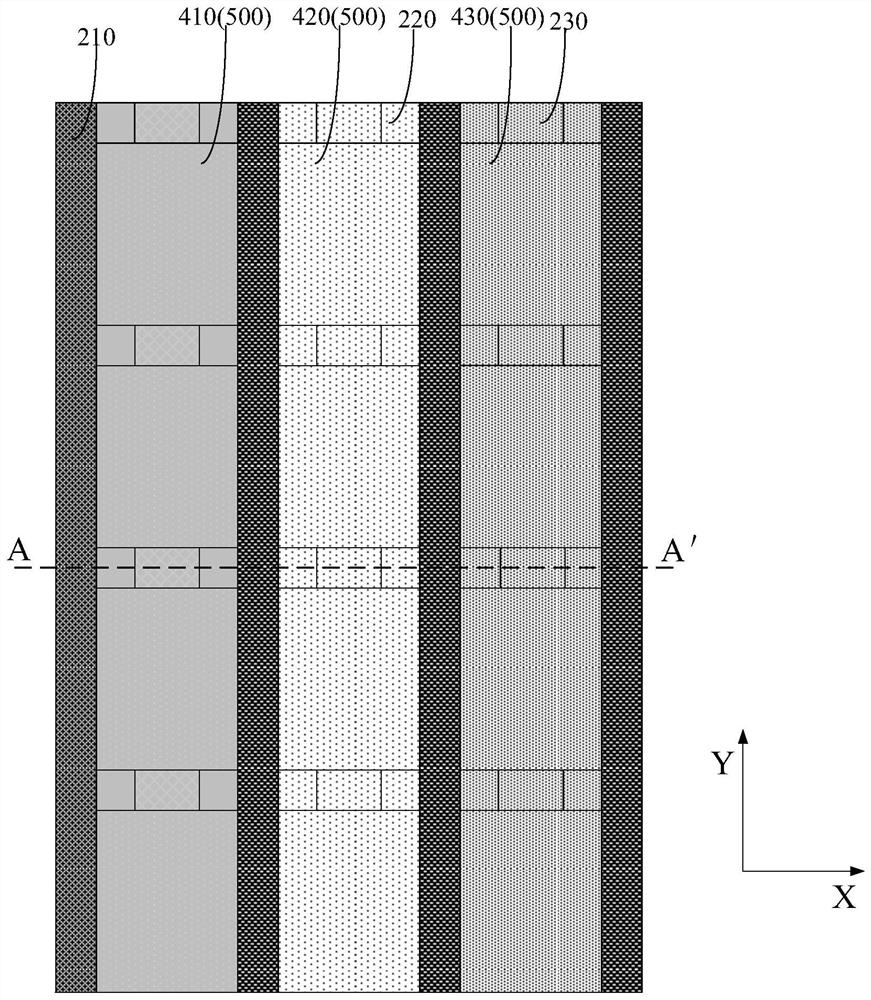

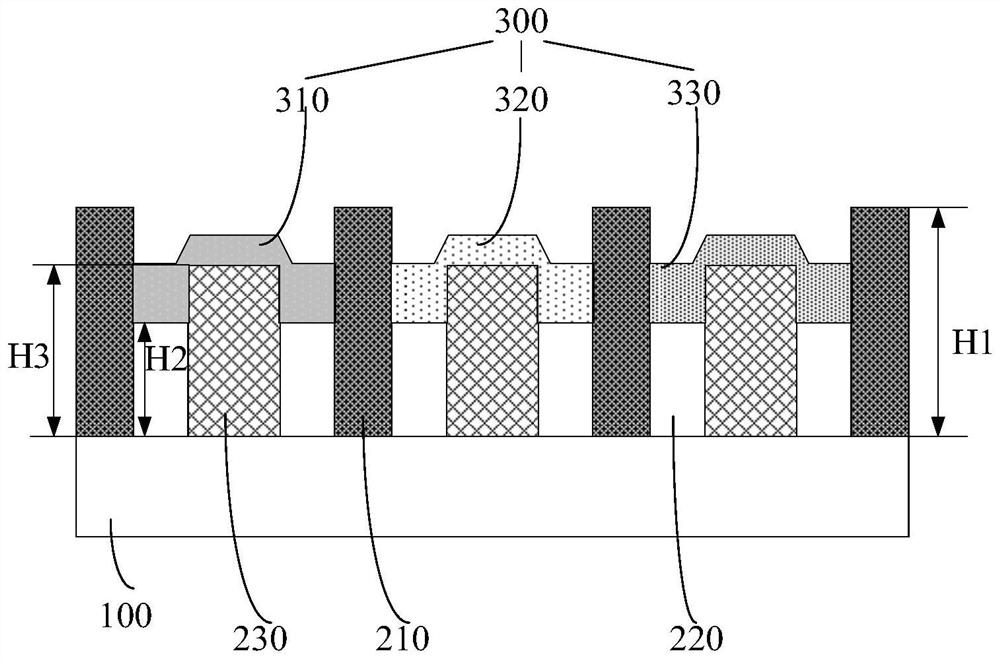

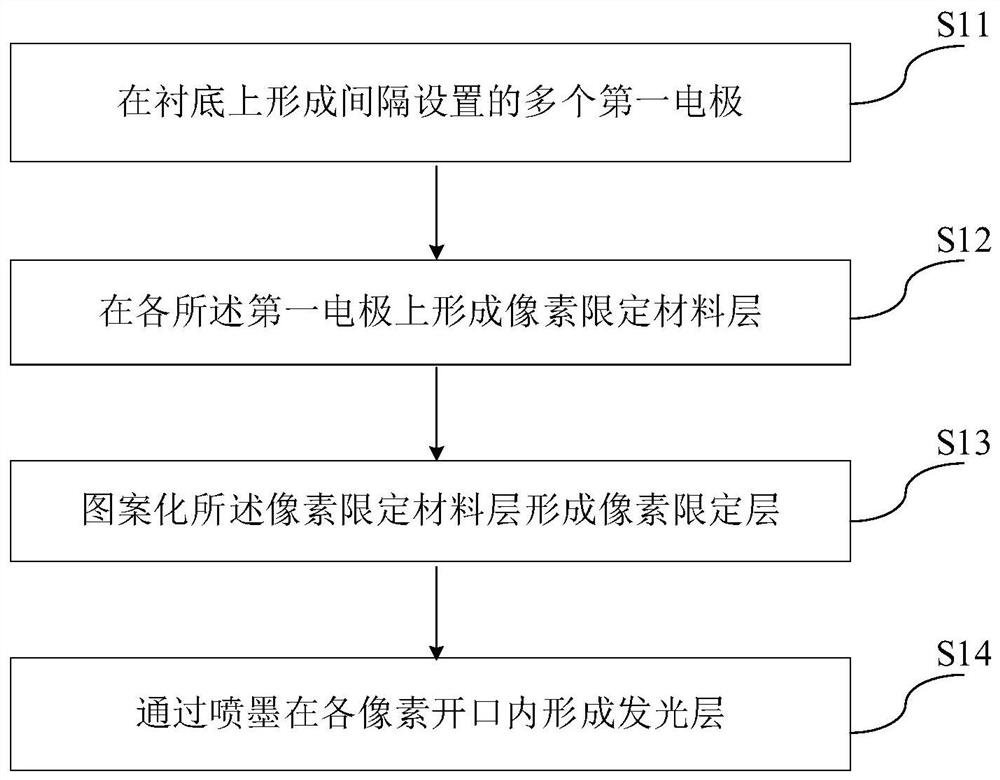

Array substrate and manufacturing method thereof, display panel and display device

ActiveCN112234085AImprove liquidityImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an array substrate and a manufacturing method thereof, a display panel and a display device. The array substrate comprises a plurality of first electrodes arranged on a substrate at intervals, a pixel defining layer disposed on the first electrodes and a light emitting layer, wherein the pixel defining layer defines a plurality of pixel openings; the light emitting layer isdisposed within the pixel openings; the pixel defining layer includes a first sub-portion, a second sub-portion and a third sub-portion; the first sub-portion is disposed between two adjacent pixel openings of the light emitting layer of different colors, and the first sub-portion has a first height; and the second sub-portion and the third sub-portion are arranged between the two adjacent pixelopenings of the light-emitting layer with the same color, the second sub-portion is located between the first sub-portion and the third sub-portion, the second sub-portion has a second height, the third sub-portion has a third height, and the third height is smaller than the first height and larger than the second height. According to the invention, the second sub-portion with the third height isarranged between the third sub-portion with the second height and the first sub-portion with the first height so that the fluidity of ink in pixels with the same color is improved, and the film forming uniformity is increased.

Owner:BOE TECH GRP CO LTD

oled display panel

ActiveCN110993817BExtended service lifeImprove liquiditySolid-state devicesSemiconductor/solid-state device manufacturingAcute angleThin membrane

The present application discloses an OLED display panel, which includes a display area and a non-display area, and also includes an array substrate, a first barrier wall, a second barrier wall, multiple metal traces, multiple first grooves, and a thin film encapsulation layer; Wherein, the metal wiring layer is located in the fan-out wiring area of the array substrate close to the lower frame, part of the metal wiring is arranged along a direction perpendicular to the first retaining wall, and the other part of the metal wiring is The included angle with the first retaining wall is an acute angle; a plurality of the first grooves are arranged in the fan-out wiring area, and the first grooves are arranged along the direction of the metal wiring; the The part of the array substrate corresponding to the second region is further provided with a plurality of second grooves, and the second grooves are arranged along a direction perpendicular to the first barrier wall.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com