Plasma enhanced chemical vapor deposition device

A chemical vapor deposition and plasma technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of limited uniformity improvement effect, increase machine cost, etc., and improve the uniformity of film formation , the effect of increased machine cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

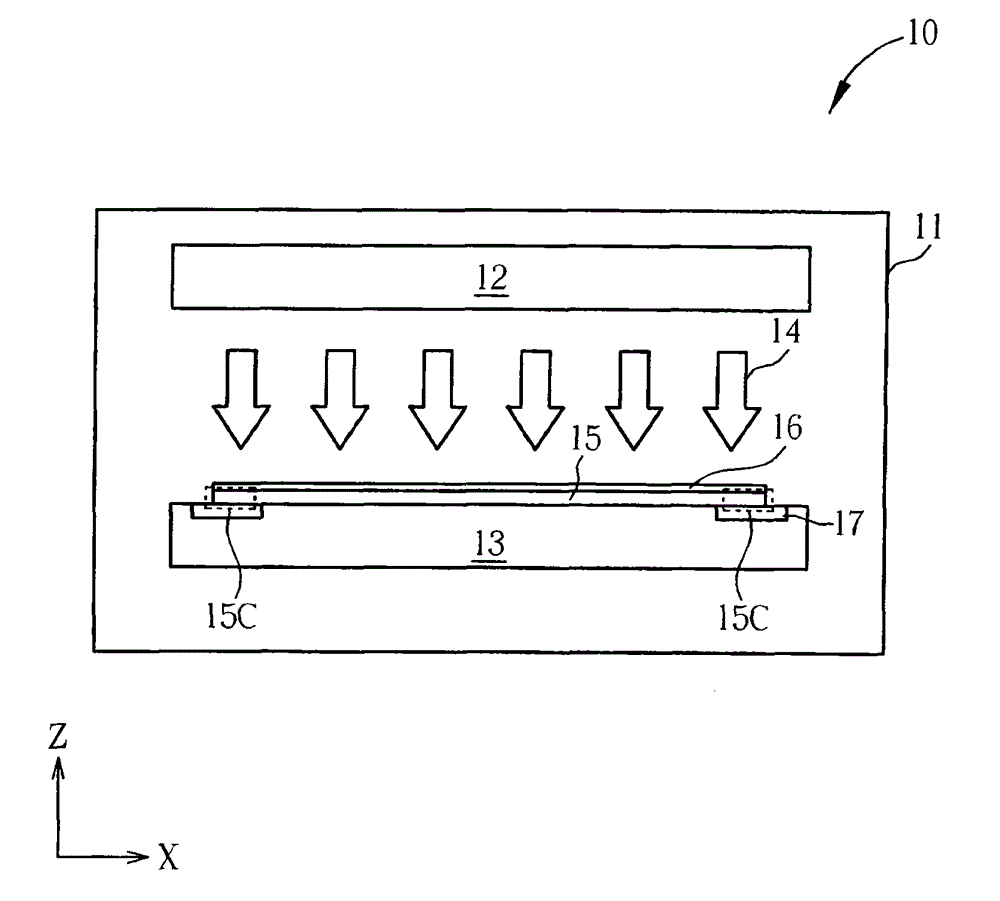

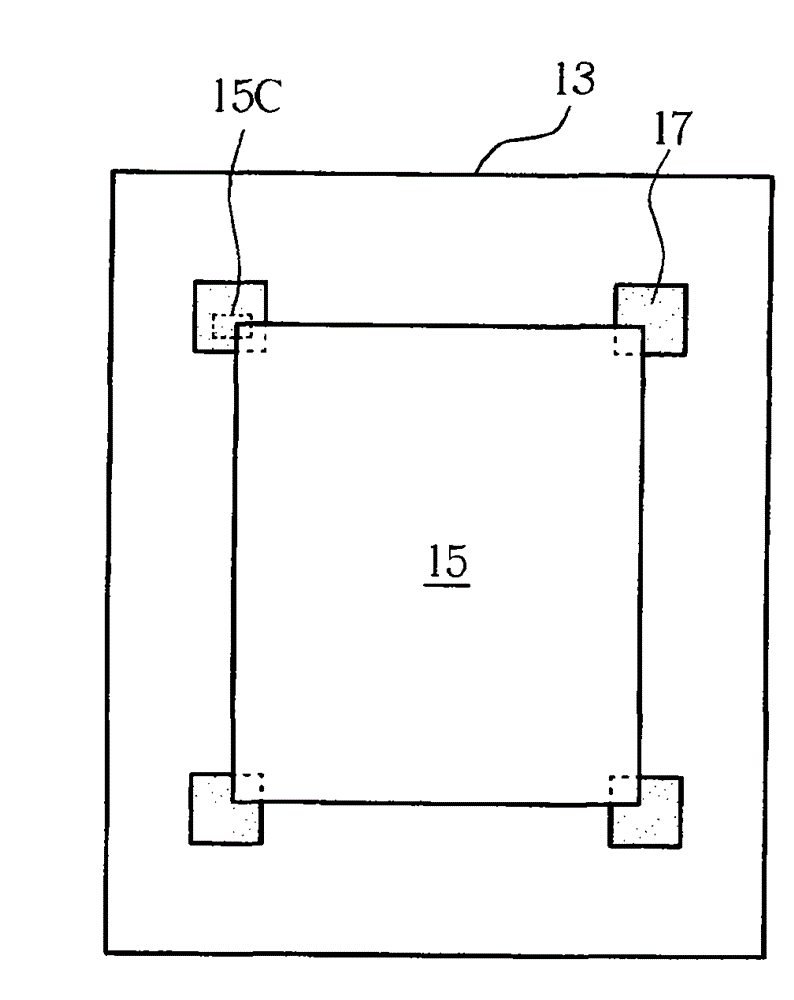

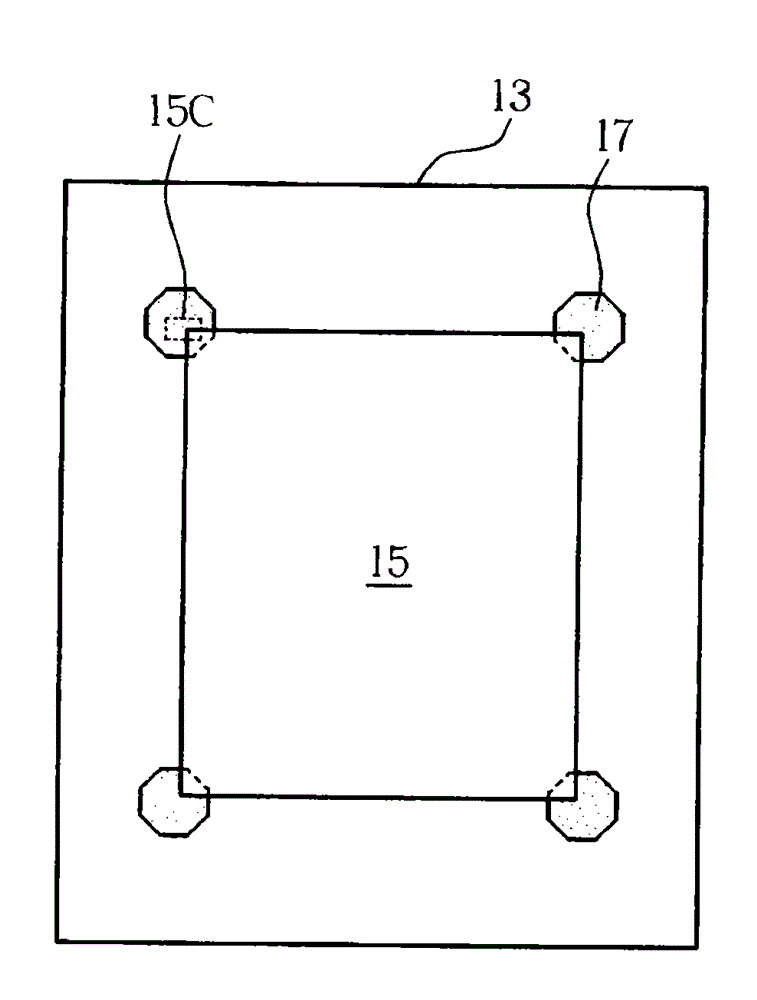

[0032] A preferred embodiment of the present invention provides a plasma-assisted chemical vapor deposition device. The plasma-assisted chemical vapor deposition device includes a preparation chamber, an upper electrode, a lower electrode and at least one patterned dielectric material device. The upper electrode and the lower electrode are disposed opposite to each other in the preparation chamber for generating a plasma-assisted chemical vapor deposition reaction to deposit a thin film material on a substrate disposed on the lower electrode. The patterned dielectric material device is disposed on the lower electrode and adjacent to at least one corner of the substrate.

[0033] A preferred embodiment of the present invention provides a plasma-assisted chemical vapor deposition device. The plasma-assisted chemical vapor deposition device includes a preparation chamber, an upper electrode, a lower electrode and at least one patterned dielectric material device. The upper elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com